Electricity Science and Safety: 300 Questions on Substations (Part 3)

Substations are essential nodes and key transportation hubs within the power system. They perform crucial functions such as energy collection, voltage transformation (step-up and step-down), and power distribution. As a foundational element of the power grid, substations ensure the reliable supply of electricity to various sectors of society. Their safe and stable operation is vital for the uninterrupted transmission of electric power, supporting the continuity of industrial production and daily life, enhancing economic and social value for enterprises, and ensuring the safety of lives and property.

Frequently Asked Questions (FAQ)

101. What regulations should be followed when inspecting equipment?

Answer: ( 1 ) Other workstations are not allowed, and barriers must not be moved or crossed. ( 2 ) When inspecting outdoor equipment during thunderstorms, insulated boots must be worn, and lightning rods and arresters must not be approached. ( 3 ) When high-voltage equipment is grounded, no one should approach within 4 meters of the fault point indoors, and no one should approach within 8 meters of the fault point outdoors. Personnel entering the above range must wear insulated boots and insulated gloves when touching the equipment casing or frame. ( 4 ) After inspecting the high-voltage room, the door must be locked. ( 5 ) Special inspections will be conducted in special weather conditions.

102. What are the inspection items for transformer gas relays?

Answer: ( 1 ) The valve on the gas relay connecting pipe should be in the open position. ( 2 ) The transformer's breather should be in normal working condition. ( 3 ) The gas protection connecting piece should be correctly inserted. ( 4 ) Check that the oil level in the oil pillow is at the appropriate position, and the relay should be full of oil. ( 5 ) The gas relay waterproof cover should be secure.

103. What items should be inspected normally for voltage transformers?

Answer: ( 1 ) Check if the porcelain parts have any cracks, damage, or abnormal sound or discharge. ( 2 ) Check if the oil level is normal or if there is any oil leakage. ( 3 ) Check if the wiring terminals are loose. ( 4 ) Check if the connectors have changed color due to overheating. ( 5 ) Check if the absorbent has changed color. ( 6 ) Check if the voltage indication is normal.

104. What are the inspection items for lightning arresters?

Answer: ( 1 ) Check the porcelain part for damage, cracks, and discharge. ( 2 ) Check whether the discharge recorder is working. ( 3 ) Check whether the lead connector is firm. ( 4 ) Check whether there is any abnormal sound inside the lightning arrester.

105. What are the inspection items for sows?

Answer: ( 1 ) Check whether all contact parts are in good contact and whether the temperature test wax sheet has melted. ( 2 ) Check whether the soft busbar has broken fat or loose strands. ( 3 ) After each ground fault, check whether the supporting insulator has discharge marks. ( 4 ) Check the busbar for snow accumulation and melting on snowy days. ( 5 ) After a thunderstorm, check whether the insulator has damage, cracks, and discharge marks. ( 6 ) Remove debris before strong winds.

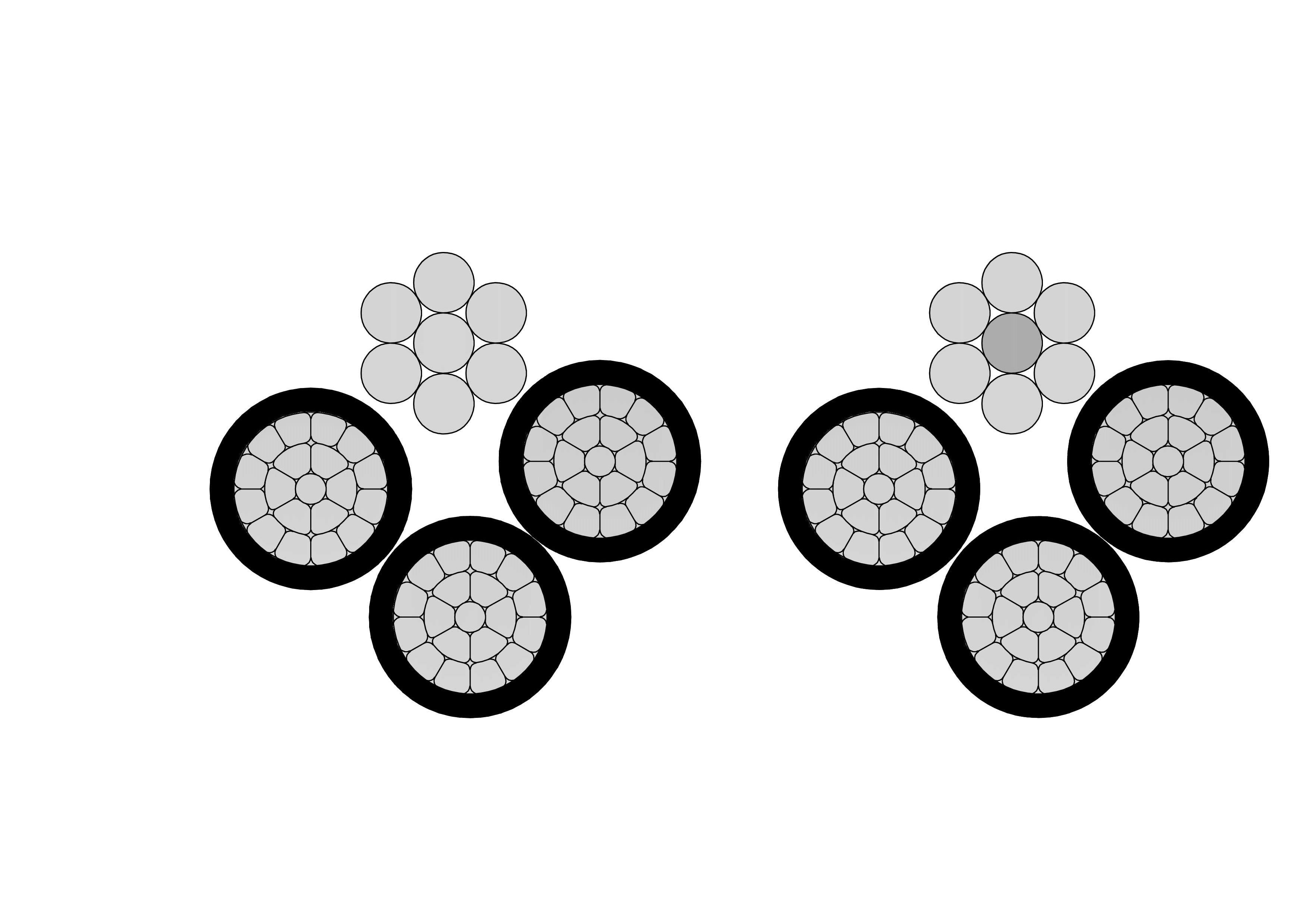

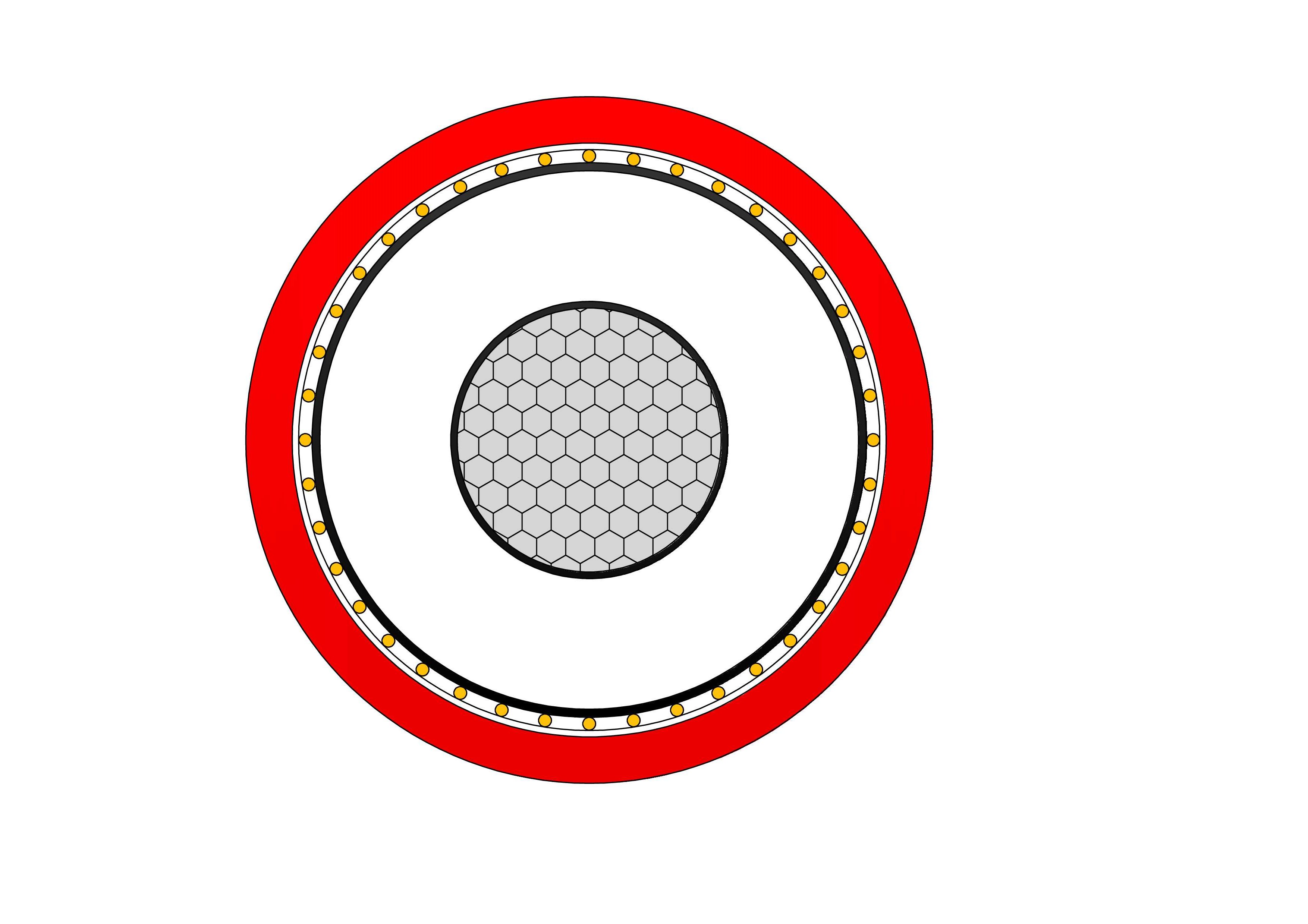

106. What are the inspection items for power cables?

Answer: ( 1 ) Check the cable and terminal box for oil leakage and whether the insulating glue has softened and overflowed. ( 2 ) Check whether the insulator is clean and intact, whether there are cracks and flashover marks, and whether the lead connector is intact and not hot. ( 3 ) Check whether the outer sheath of the exposed cable is intact and the support is firm. ( 4 ) Check whether the outer sheath is well grounded.

107. What are the items for normal inspection of equipment in the main control room, relay protection room and 10 ( 6 ) KV distribution room?

Answer: ( 1 ) No abnormal sound or burning smell. ( 2 ) All instrument signal indicator windows should be consistent with the operating conditions and indicate correctly. ( 3 ) The protective connecting piece is in the correct position (should be consistent with the actual situation). ( 4 ) The three-phase voltage of the system is balanced (approximately) and within the specified range. ( 5 ) The three-phase ammeters of the power supply line and the transformer main switch are approximately balanced.

108. What harm does lack of oil in a transformer do to its operation?

Answer: If the oil level of the transformer is too low, the light gas will be activated; when there is a serious lack of oil, the iron core and windings are exposed to the air and are easily affected by moisture, which may cause insulation breakdown.

109. Why is the oil pump not allowed to continue running after the forced oil circulation transformer stops?

A: The reason is that the transformer housing is flat and its cooling area is very small, which cannot even dissipate the heat generated by the transformer's no-load losses. Therefore, it is dangerous to force the oil circulation transformer to completely stop the cooling system.

110. What safety precautions should be taken when taking gas from a running transformer?

Answer: ( 1 ) Gas extraction must be performed by two persons, one to operate and one to monitor. ( 2 ) When climbing the transformer to extract gas, maintain a safe distance to prevent falls. ( 3 ) Avoid accidentally touching the probe.

111. What causes the transformer to make abnormal sounds?

Answer: ( 1 ) Overload. ( 2 ) Poor internal contact, sparking. ( 3 ) Loose parts. ( 4 ) Grounding or short circuit in the system. ( 5 ) Large load changes caused by starting a large motor.

112. Why is it not allowed for the secondary circuit to be short-circuited during the operation of the voltage transformer?

Answer: During normal operation of the voltage transformer, the secondary load impedance is very large. The voltage transformer is a constant voltage source with very small internal impedance and capacity. The primary winding wire is very thin. When a short circuit occurs in the secondary of the transformer, the primary current is very large. If the secondary fuse is not selected properly and the fuse cannot blow, the voltage transformer is very likely to burn out.

113. Under what circumstances should the capacitor be shut down immediately?

Answer: ( 1 ) Flashover or severe discharge of the bushing. ( 2 ) Overheating or melting of the joint. ( 3 ) Expansion and deformation of the casing. ( 4 ) Discharge sound inside or abnormality of the discharge equipment.

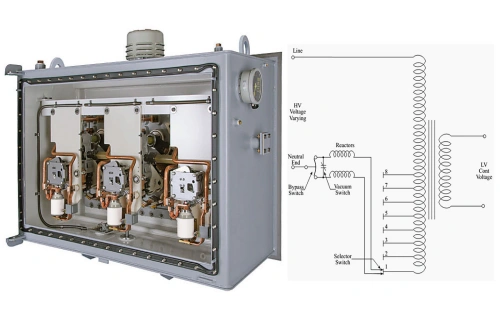

114. What are the regulations for the operation of arc suppression coil tap switching?

Answer: ( 1 ) The arc suppression coil tap should be switched according to the tap position assigned by the on-duty dispatcher. ( 2 ) Before switching the tap, make sure there is no ground fault in the system. Then disconnect the arc suppression coil with the isolating switch and install the grounding wire before switching the tap and measuring the DC resistance. The arc suppression coil can be put into operation only after the DC resistance is measured and qualified.

115. What phenomena occur when single-phase grounding occurs in a low-current grounding system?

Answer: ( 1 ) The alarm sounds, the grounding light window is emitted, and the grounding signal relay is tripped. ( 2 ) If the fault point is high-resistance grounding, the grounded phase voltage decreases, and the voltages of the other two phases to ground are higher than the phase voltages. If the fault point is metallic grounding, the grounded phase voltage drops to zero, and the voltages of the other two phases to ground rise to the line voltage. ( 3 ) The pointer of the three-phase voltmeter keeps swinging, which is intermittent grounding.

116. What abnormalities may occur during the operation of the isolating switch?

Answer: ( 1 ) Overheating of the contact part. ( 2 ) Cracks or breakage of the insulator, cracks in the conductor clamp. ( 3 ) Poor quality of the glued part of the post insulator and natural aging, causing the insulator cover to fall off. ( 4 ) Flashover, discharge, and grounding breakdown due to severe contamination or overvoltage.

117. What are the reasons for false tripping of oil circuit breakers?

Answer: ( 1 ) Protection malfunction. ( 2 ) Incorrect operation of the circuit breaker mechanism. ( 3 ) Secondary circuit insulation problem. ( 4 ) Parasitic tripping circuit.

118. What impact will it have on operation if the traffic light indicating the position of the circuit breaker is not on?

Answer: ( 1 ) It cannot accurately reflect the tripping and closing positions of the circuit breaker, which can easily lead to misjudgment in the event of a fault. ( 2 ) If the tripping circuit is faulty, the circuit breaker cannot trip in time when an accident occurs, which will aggravate the accident. ( 3 ) If the closing circuit is faulty, the circuit breaker cannot automatically reclose after tripping or fails to reclose automatically. ( 4 ) Normal operation cannot be performed in the event of a tripping and closing circuit fault.

119. What should you pay attention to when replacing the red light bulb of a circuit breaker?

Answer: ( 1 ) Two people must be present to replace the bulb. ( 2 ) The bulb should be replaced with one with the same voltage and wattage as the original bulb. ( 3 ) If the bulb socket needs to be removed, use insulating tools to prevent short-circuiting or grounding the DC.

120. What equipment is included in the protection scope of mother differential protection?

Answer: The protection range of bus differential protection is the primary electrical part between the current transformers used for bus differential protection of all outgoing circuit breakers in each section of the bus, that is, the entire bus and all electrical equipment connected to the bus.

121. What are the characteristics of zero-sequence current protection?

A: The most significant feature of zero-sequence current protection is that it only responds to single-phase ground faults. Because other non-grounded short-circuit faults in the system do not generate zero-sequence current, zero-sequence current protection is not affected by any other faults.

122. What functions does the CSL-216 microcomputer line protection have?

Answer: It has three-stage overcurrent protection and three-phase primary reclosing. In addition, it also has measurement, telesignaling, remote control, and grounding line selection functions.

123. What are the requirements for inspecting the power distribution equipment entering and exiting the high-voltage room?

Answer: When inspecting the power distribution equipment and entering or exiting the high-voltage room, you must lock the door.

124. What are the requirements for inspecting outdoor high-voltage equipment during thunderstorms?

Answer: ( 1 ) Wear insulating boots. ( 2 ) Do not get close to lightning arresters and lightning rods.

125. What are the daily maintenance items for batteries?

Answer: ( 1 ) Sweep away dust and keep the room clean. ( 2 ) Repair unqualified and aged batteries promptly. ( 3 ) Eliminate leaked electrolyte. ( 4 ) Apply vaseline to the connection terminals regularly. ( 5 ) Charge and discharge the battery regularly. ( 6 ) Fill the electrolyte, paying attention to the specific gravity level and temperature. ( 7 ) Record the operating status of the battery.

126. What are the hazards of a DC system operating with positive or negative grounding?

A: A positive ground fault in a DC system can cause malfunctioning of protection devices. This is because the tripping coil of the electromagnetic operating mechanism is typically connected to the negative power supply. If these circuits are grounded or if the insulation is poor, malfunctioning of the protection devices can occur. If the negative pole of a DC system is grounded, any additional ground fault in the circuit can short-circuit the tripping or closing circuit, causing the protection device or circuit breaker to fail to operate, burn out relays, or blow fuses.

127. What is the reason for the light gas action?

Answer: ( 1 ) Air enters the transformer due to poor oil filtration, refueling, or a cooling system. ( 2 ) The oil level drops below the light gas float of the gas relay due to a temperature drop or oil leakage. ( 3 ) A transformer fault produces a small amount of gas. ( 4 ) A through short circuit occurs. ( 5 ) The gas relay or secondary circuit is faulty.

128. How to select fuses for AC circuit, DC circuit control and signal circuit?

Answer: ( 1 ) The AC circuit fuse should be selected according to 1.2 times the rated current of the protection equipment. ( 2 ) The DC control signal circuit fuse is generally selected to be 5_10A.

129. What may be the cause of false oil level in a transformer?

Answer: ( 1 ) The oil level gauge is clogged. ( 2 ) The respirator is clogged. ( 3 ) The safety airway vent is clogged. ( 4 ) The membrane-protected oil pillow does not exhaust all the air during refueling.

130. What are the causes of transformer winding insulation damage?

Answer: ( 1 ) Line short circuit fault. ( 2 ) Long-term overload operation, severe insulation aging. ( 3 ) Winding insulation damp. ( 4 ) Poor contact between winding joints or tap changer joints. ( 5 ) Lightning wave intrusion, causing winding overvoltage.

131. What are the inspection items for capacitors?

Answer: ( 1 ) Check whether the capacitor has expansion, oil spraying, or oil leakage. ( 2 ) Check whether the porcelain part is clean and whether there are any discharge marks. ( 3 ) Check whether the grounding wire is firm. ( 4 ) Check whether the series reactor of the discharge transformer is intact. ( 5 ) Check the temperature in the capacitor room. The minimum allowable temperature in winter and the maximum allowable temperature in summer should comply with the manufacturer's regulations. ( 6 ) Check whether the external fuse of the capacitor is broken.

132. What are the normal inspection items for reactors?

Answer: ( 1 ) The joints should have good contact and no heat. ( 2 ) The supporting insulators should be clean and free of debris. ( 3 ) The surrounding area should be clean and free of debris. ( 4 ) The vertically arranged reactor should not be tilted. ( 5 ) Doors and windows should be tight.

133. What are the normal inspection items for isolating switches?

Answer: ( 1 ) The porcelain part should be intact and free of cracks. ( 2 ) All joints should not be loose or hot. ( 3 ) The blade should be fully engaged and in good contact, and the temperature test wax sheet should not melt. ( 4 ) The transmission mechanism should be intact and the pins should not fall off. ( 5 ) The interlocking device should be intact. ( 6 ) The hydraulic device of the hydraulic mechanism isolating switch should not leak oil, and the mechanism housing should be well grounded.

134. What should be paid attention to during normal inspection of coupling capacitors?

Answer: ( 1 ) Check whether the capacitor porcelain sleeve is damaged or has discharge marks. ( 2 ) Check whether the upper and lower leads are secure, whether the grounding wire is in good condition, and whether the grounding switch is in the correct position. ( 3 ) Check whether there is any discharge sound from the leads and other parts. ( 4 ) Check whether there is any oil leakage. ( 5 ) Check whether the discharge neon lamp of the secondary voltage extraction device is not discharging (it should not be lit). ( 6 ) Check whether the combined filter is complete and tight without leaks.

135. After a single-phase grounding occurs in a 10KV system with single busbar connection, the grounding phenomenon still persists after power outages are carried out on each line. What is the reason?

Answer: ( 1 ) Both lines are grounded at the same time. ( 2 ) The busbar equipment in the station is grounded.

136. What is the setting principle of time-limited overcurrent protection?

Answer: The setting principle of the time-limited overcurrent protection operating current is: the operating current must be greater than the load current, and the protection device will not operate at the maximum load current. When an external short circuit occurs in the next-level line, if the current relay at this level has been started, then after the lower-level protection cuts off the fault current, this 6 protection should be able to return reliably.

137. Why are 10KV distribution lines only equipped with overcurrent protection but not quick-break protection?

Answer: The power supply distance of the 10KV distribution line is short, and the short-circuit current values at the beginning and end of the line are not much different. The quick-break protection is adjusted according to avoid the short-circuit current at the end of the line, and the protection range is too small. In addition, the overcurrent protection action time is short. When these two conditions are met, there is no need to install current quick-break protection.

138. Why should the current coil be connected in series with the contacts of the output intermediate relay?

A: The purpose of connecting the current coil in series with the contacts is to prevent contact jitter, vibration, or even a brief closure that prevents the switch from tripping. Therefore, protective outputs typically use a self-holding connection with the current coil in series. When a fault condition occurs, the contacts close, energizing the series current coil and creating a self-holding mechanism to ensure reliable tripping of the switch.

139. On what principle is the differential protection of the transformer installed?

A: Transformer differential protection is based on the circulating current principle. Two current transformers of the same model are installed on either side of the transformer, with their secondary terminals connected using the circulating current method. During normal operation and external fault conditions, no current flows through the differential relay. However, if a phase-to-phase short circuit occurs within the transformer, a significant current flows through the differential relay.

140. Under what circumstances is the zero-sequence protection of the transformer put into operation?

Answer: The transformer zero-sequence protection should be installed on the side where the neutral point of the transformer is directly grounded. It is used to protect the internal winding and lead-out wires on that side from ground short circuits. It can also serve as backup protection when the corresponding busbar and line are short-circuited to ground. Therefore, when the neutral point grounding switch of the transformer is closed, the zero-sequence protection can be put into operation.

141. Which lines are equipped with cross-differential directional protection? What faults does the cross-differential protection respond to?

A: Cross-linked differential directional protection can be installed on two parallel lines with the same impedance. Cross-linked differential directional protection responds to internal faults in the parallel lines, but not to external faults.

142. Under what circumstances will the synchronous reclosing device not operate?

A: It will not operate in the following cases: ( 1 ) If a permanent fault occurs in the line, the circuit breaker equipped with a no-pressure reclosing switch will open immediately after reclosing, and the synchronous reclosing switch will not operate. ( 2 ) If the no-pressure reclosing switch refuses to operate, the synchronous reclosing switch will not operate either. ( 3 ) If the synchronous reclosing switch refuses to operate.

143. Under what circumstances will the circuit breaker's reclosing function be taken out of operation?

Answer: The reclosing switch will be deactivated in the following cases: ( 1 ) When the interrupting capacity of the circuit breaker is less than the busbar short-circuit capacity, the reclosing switch will be deactivated. ( 2 ) If the number of fault trips of the circuit breaker exceeds the specified value, or if the number of trips does not exceed the specified value but the circuit breaker is seriously spraying oil or emitting smoke, the reclosing switch should be deactivated with the approval of the dispatcher. ( 3 ) If there is live work on the line, the reclosing switch should be deactivated when ordered by the on-duty dispatcher. ( 4 ) If the reclosing device fails, the reclosing switch should be deactivated with the approval of the dispatcher.

144. Under what circumstances will the backup power supply automatic transfer device operate?

Answer: If the circuit breaker on the power supply side of the working bus is disconnected for some reason, causing the working bus to lose power, the automatic transfer device will operate and the backup power supply will be put into operation.

145. What inspections should be done on relay protection devices before they are put into operation after being newly put into operation or after being shut down?

Answer: The following checks should be done: ( 1 ) Check the relay protection records to ensure that they are qualified before commissioning, and understand the precautions. ( 2 ) Check that the secondary callback and relay are intact. ( 3 ) The markings are clear and correct.

146. What reclosing modes can be achieved by CL166 microcomputer line protection?

Answer: Four reclosing modes are available: asynchronous, no-voltage check, synchronous check, and temporary line current check.

147. What are the main functions of the DFP-500 transformer's main protection?

Answer: It has differential protection and non-electrical quantity protection. The differential protection includes compound ratio differential and differential quick-break protection. The non-electrical quantity protection mainly includes mthe ain transformer body gas protection and the on-load tap-changing gas protection.

148. What information does the WXB-11 microcomputer protection fault report include?

Answer: The fault report can print out the fault time (year, month, day, hour, minute, second), fault type, distance from the fault point to the protection installation, various protection action conditions and time sequence, and the sampling values of each phase voltage and current 20 seconds before the fault and 40 seconds after the fault.

149. After the DFP-500 protection fault trips, what information is included in the fault report displayed on the LCD?

Answer: The fault report includes the report number, the time when the fault occurred, the operating element, and the operating time of each element. For current-operated elements, the fault type and the fault current of the maximum phase are also recorded.

150. What could be the possible fault if only the inspection interruption alarm is given but no information is printed? How to handle it?

A: This is due to an abnormality in the human-machine dialogue plug-in. The plug-in should be replaced. This phenomenon may also occur when the human-machine dialogue plug-in is in the debugging position.

-AL-medium-voltage-power-cable-2.jpg)

2Y-high-voltage-power-cable-2.webp)

2Y-high-voltage-power-cable-2.webp)