5kVA Conventional Type Single Phase Pole Mounted Transformer

- Primary Voltage Ratings 2.4-34.5kV

- Secondary Voltage Ratings 480-240/240-120 or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Conventional Type

- BIL 30-150kV

- Standards IEEE, IEC, ISO, CE

- Application Home, commercial or small industry

- Power Rating 5kVA

- Certificate UL ,IEC, ISO, CE

- Cooling Method ONAN, KNAN

- Oil Mineral Oil or FR3

- Opeartion Step Down

Technical Specifications

| Rated Power | 5 kVA |

| Rating Primary Voltage | 12.4-34.5kV |

| Secondary Voltage | 480-240V 240-120V 277V Customized |

| Frequency | 50/60Hz |

| Vector Group | Ii0,Ii6 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 2% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 15 kg |

| Total Weight | 92 kg |

| Outline Dimensions(W×D×H) | 465×485×855 (mm) |

| Lifting Lug |

| Tap Changer |

| Pressure Relief Valve |

| Tank Cover and clamp |

| L.V Bushing |

| HV Bushing |

| Ground Strap |

| Nameplate |

| Non-PCB decal |

| High Voltage Warning Signs |

| Suport lug |

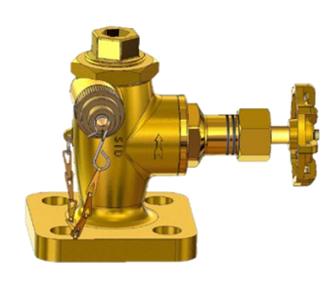

| Oil fill valve |

Customization Optional

Users can choose different insulation levels according to the environmental conditions of the region (such as temperature and humidity). Common insulation levels include Class A (105°C), Class B (130°C) and Class F (155°C). Providing a higher insulation level can improve the heat resistance of the transformer, thereby adapting to higher temperatures or more severe working environments.

Some transformers can provide load regulation function, allowing users to adjust the output voltage as needed to adapt to grid load fluctuations or ensure stable power supply. And to prevent the transformer from being damaged due to overload or overheating, you can choose to install an automatic temperature control protector, which can automatically disconnect the power supply when the temperature is too high to protect the transformer from damage.

These optional specifications provide additional flexibility for the 5kVA conventional single-phase pole-mount transformer, enabling it to be customized according to different environmental conditions, working needs and safety requirements. These configurations help improve the performance, reliability and adaptability of the transformer to meet the needs of specific industries, regions or customers.

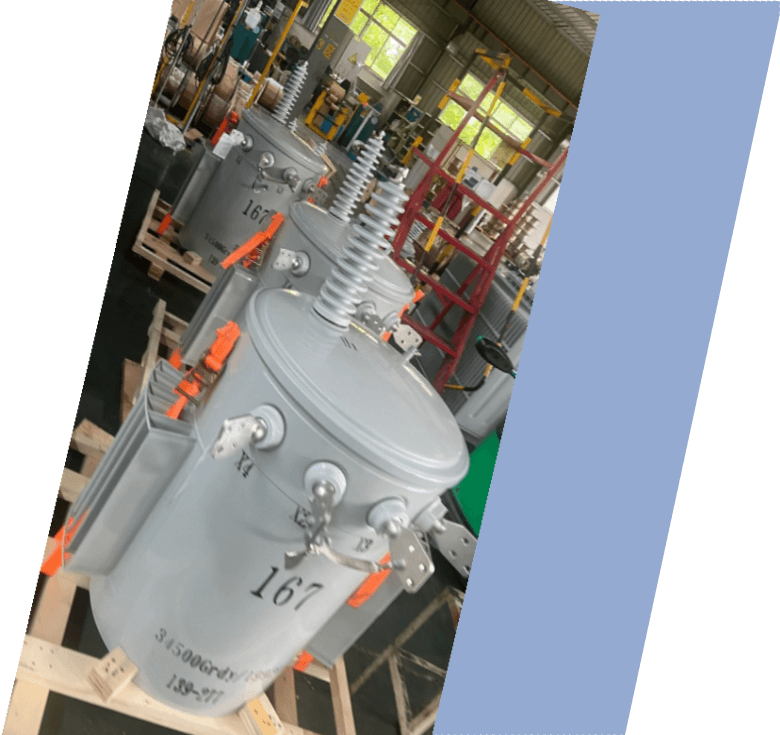

Packing and Shipping

The transformers are first wrapped with moisture-proof and dust-proof materials to protect the equipment from the external environment. Commonly used packaging materials include plastic film, foam padding, and anti-rust paper. The transformers are usually placed in sturdy wooden boxes or steel frames to provide additional physical protection from collisions or vibrations during transportation.

According to the weight and size of the transformer, choose the appropriate transportation tools (such as trucks, containers, etc.) for loading. According to customer requirements and destinations, transformers can be transported by land, sea or air. For international transportation, customs declaration and export procedures may be required.

The transformers are firmly fixed in the transport vehicle or container to prevent displacement or vibration during transportation. Tie straps, wooden pallets, and other fixings are usually used to ensure the stability of the equipment.

In the container, the transformer is usually placed on a dedicated bracket to reduce pressure and friction on the equipment.

Through careful packaging and shipping arrangements, the 5kVA conventional single-phase pole-mount transformer can remain safe and intact during transportation, ensuring that customers receive quality equipment to meet their power needs.

Sustainability shapes packing, utilizing recyclable materials and optimized loading to reduce emissions. Impact recorders on crates log transit conditions for arrival verification. Accessories like arresters or fuses ship separately with checklists for on-site completeness. Specialized carriers handle electrical gear logistics, securing permits and following safety protocols across routes.

Upon receipt, unpacking guides detail safe handling, oil refilling, and connection specs. Site coordination supports pole mounting in remote areas. This complete process ensures the transformer arrives pristine, ready for quick installation, and reliable service in low-demand overhead networks.

Manufacturer Test

Progress Test

The process testing of a 5kVA Conventional Type Single Phase pole Mounted transformer is an important step to ensure that the product meets the standards at every stage of the production process. Before the production starts, all raw materials are strictly checked, especially in terms of the windings and insulation materials of the transformer. The windings of the transformer are electrically tested to check parameters such as the resistance of the windings and the insulation resistance. After the transformer is assembled, a load test is performed. By fully verifying the various performances of the transformer (such as output voltage, load capacity, efficiency, etc.), it is ensured that it meets all technical requirements and user needs. Oil quality sampling ensures a dielectric over 30kV and low contaminants. Tank weld inspections employ penetrant and ultrasonic for leak-proof seams, while pole mounting brackets undergo load and alignment verification. All data logs enable quality oversight and adjustments.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On Load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Factory acceptance testing for the 5kVA conventional single phase pole mounted transformer starts with visual/dimensional audits per drawings, verifying tank finish, bushing placement, and mounting features. Winding DC resistance uses Kelvin bridges, corrected to reference temperature within 1%. Turns ratio/polarity across taps validate with TTR to 0.4% error. Dissipation factor at 10kV limits tan delta below 0.5%. No-load loss/current at rated voltage confirm efficiency, excitation controlled. Load loss/impedance from short-circuit method yield accurate metrics. Power frequency withstand applies kV without breakdown. Induced voltage stresses insulation. Oil tests verify breakdown over 35kV and low gases. Continuing FAT for the 5kVA conventional single phase pole mounted transformer, impulse testing at 60-95kV BIL proves withstand with waveforms. Noise levels meet limits in acoustics. Temperature rise under load caps at 65°C. Accessory tests check pressure relief, gauges, taps. Frequency response analysis confirms mechanical integrity. All results per IEEE C57.12.20/ANSI with traceability, witnessing, and resolutions for approval before shipment.

Routine Test - Impulse Tests

Voltage divider (used to measure impulse voltage waveform, resistor divider or capacitor divider)

Oscilloscope (used to record impulse waveform, common brands such as Tektronix, Keysight)

Calibrate and check the impulse voltage generator, measurement system, and control system to ensure that the instruments and equipment are in good condition and meet the test standards.

Connect the impulse voltage generator correctly to each winding terminal (high voltage terminal, ground terminal) of the device under test, and ensure that all test instruments are well grounded.

Apply Test Voltage:

Select the appropriate impulse voltage waveform and amplitude according to the rated voltage of the equipment

Front Time

Time to Half-Value

Peak Voltage

Distortion

Ambient temperature and humidity (especially when the test environment needs to be corrected)

If the waveform deviation is too large, adjust the impulse generator parameters and reapply the test.

In special cases, inter-winding impact, voltage-to-ground impact or coil corner impact are performed (according to the test plan).

Waveforms are stable and meet standard specifications.

Waveform variations between repeated tests are minimal (usually good waveform overlap with no noticeable abnormal excursions).

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.