33kV Oil Immersed Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

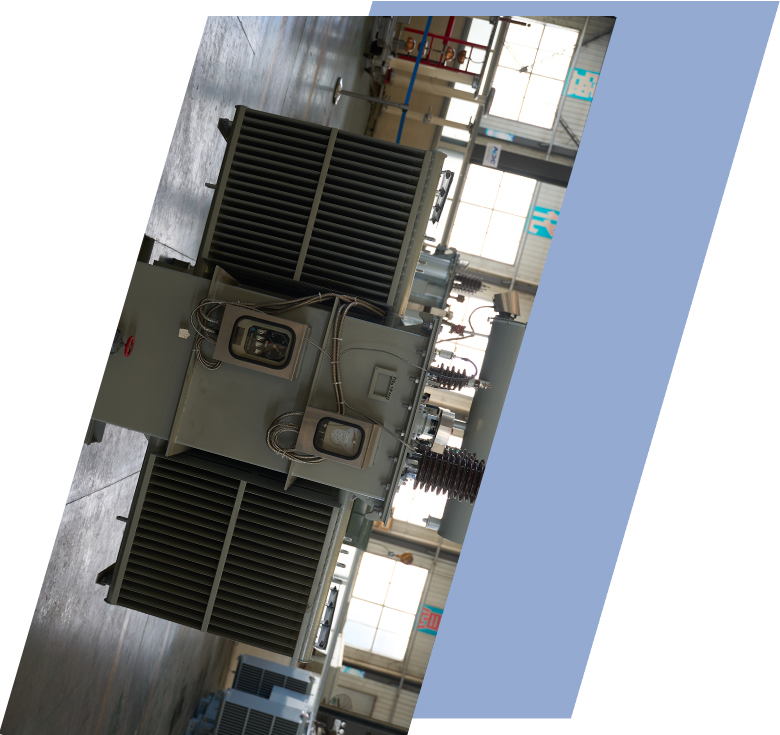

- Type Oil immersed distribution transformer

- BIL 33kV

- Standards IEEE, ANSI, NEMA, IEC, CE

- Application industrial heavy factories and mines

- Power Rating 30kVA - 5000kVA

- Certificate UL, CESI, IEEE

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 30kVA - 5000kVA | |

| Rating Primary Voltage | 2.4 - 34.5kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| Insulating Oil Weight | 850 kg | |

| Total Weight | 5000 kg | |

| Outline Dimensions(L×W×H)in. | 2650 × 1650 × 2450(mm) | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

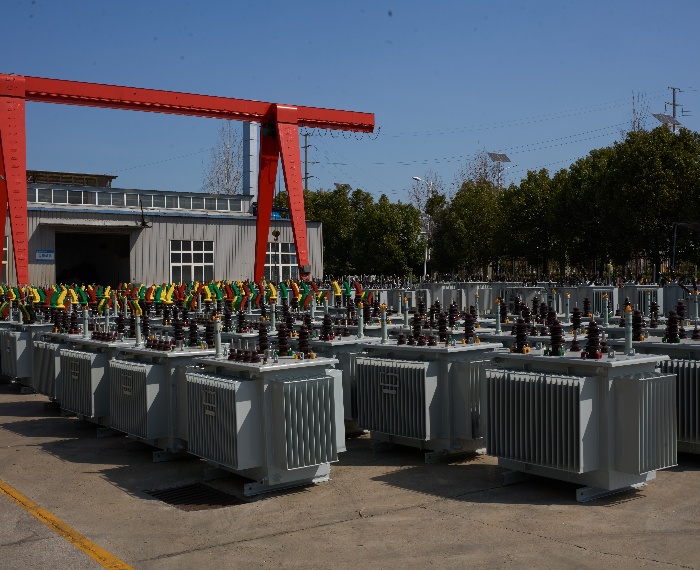

Packing and Shipping

Component-specific safeguards include radiators detached and crated with anti-vibration padding, high-voltage bushings (porcelain or RIP) individually shock-mounted in reinforced boxes, OLTC mechanisms locked and protected, and control cubicles sealed with desiccants. The main body mounts on heavy steel skids or ISPM-15 compliant wooden/steel frames with custom blocking, lateral braces, and energy-absorbing materials rated for 3-5g impacts. Packaging incorporates multi-layer weatherproof covers, VCI corrosion inhibitors, humidity/temperature indicators, and electronic shock/tilt recorders fortraceability.

Ocean freight—predominant for export—utilizes flat-rack, open-top, or break-bulk vessels with IMO-compliant lashing, salt-mist barriers, and protective sheeting; road/rail segments employ specialized low-loader trailers with weight-distributed cradles and marked lifting points. Full export documentation package comprises commercial invoices, packing lists, certificates of origin/conformity, detailed test reports (routine/type), dimensional/lifting drawings, oil SDS, handling/installation manuals, and HS code declarations (8504.23 for >650kVA).

We manage comprehensive logistics from factory to destination, including FOB/CIF terms, customs facilitation, insurance coordination, and value-added services like third-party inspections, on-site unloading supervision by certified riggers, oil filtration/degassing, erection oversight, and commissioning support. This integrated approach minimizes risks, upholds transformer integrity, complies with international regulations, and guarantees punctual, damage-free delivery for worldwide utility, industrial, and renewable projects.

Manufacturer Test

Progress Test

Insulating oil incoming progress test evaluates dielectric breakdown voltage moisture acidity tan-delta and gas content per IEC 60296 with multi-stage filtration/dehydration to achieve <10ppm water and zero contaminants. Core-coil vacuum drying progress tracks oven temperature cycles residual moisture extraction and dew point attainment below -50°C for Class A insulation integrity. Final tanking progress monitors vacuum oil impregnation hot oil circulation degassing nitrogen sealing and extended pressure hold/leak detection tests. Protection device progress verifies Buchholz relay operation gas accumulation tripping oil temperature/pressure gauge calibration relief valve setpoint and OLTC drive mechanism sequencing smoothness.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Load loss short-circuit impedance and temperature rise tests short secondary apply reduced voltage compute copper losses impedance (6-10%) efficiency at full load and simulate thermal performance (top-oil <60K windings <65K). Oil quality routine includes breakdown voltage (>60kV/2.5mm) water content (<20ppm) acidity DGA baseline zero acetylene. Functional verification covers pressure relief device activation Buchholz/gas relay tripping temperature indicator alarms OLTC full-range operation and sound power level (<60dB). Mechanical integrity confirms tank overpressure withstand leak-free seals bushing flashover margins and accessory wiring. Detailed FAT protocol yields traceable reports calibration certificates optional client/third-party witnessing ensuring IEC 60076 full compliance type/routine test certification prior to release.

Routine Test - Induced Voltage

AC voltage source, commonly 2 kV, 5 kV, 10 kV, or customized according to test requirements.

Environmental thermometer and hygrometer, used to record the temperature and humidity of the environment for appropriate test evaluation.

Check the connection wires and terminals to ensure they are secure and free of contamination.

Test under suitable environmental conditions: relative humidity below 75%, no rain (recommended temperature: 20-30°C).

Connect the test equipment to the appropriate terminals or bushings of the device under test, ensuring that the connections are secure and properly grounded.

Apply Test Voltage:

Select the appropriate induction voltage according to the rated voltage and standard of the equipment.

Induced Voltage

Applied Current

Voltage peak, stability and waveform (waveform analysis)

Any abnormal current or voltage changes during the measurement process.

1% < Inductive voltage ≤ 3% (Good): still within acceptable range.

Inductive voltage > 3% : faulty or not meet safety requirements and requires further analysis and repair.

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.