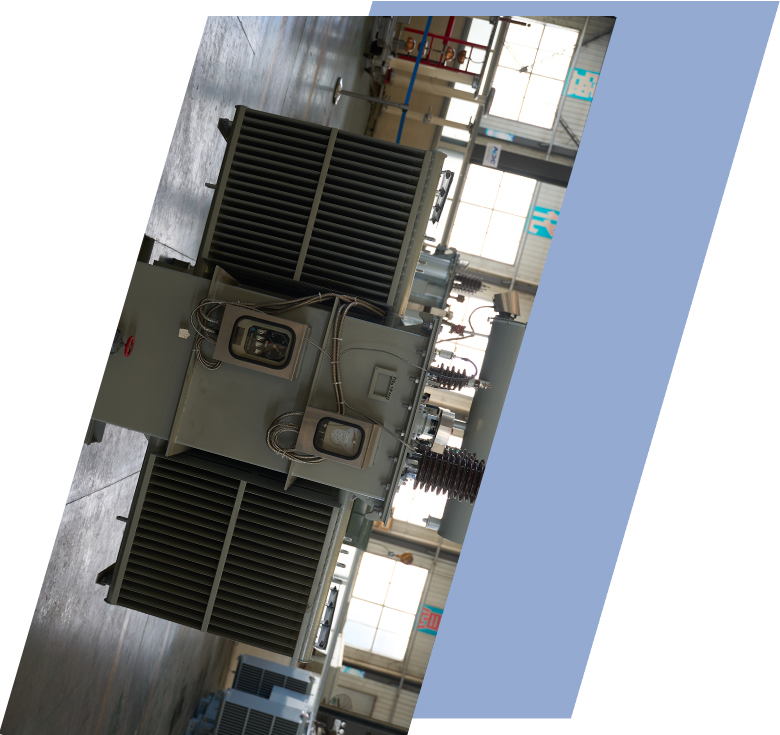

20kV Three-Phase Oil-Immersed Power Transformer 50-2500kVA Copper

- Primary Voltage Ratings 35kV, 34.5kV, 33kV, 46kV or others

- Secondary Voltage Ratings 13.8kV 6kV 10kV or others

- H.V. Tap Range ±8×1.25% or others

- Type Oil-immersed power transformer

- BIL 20kV

- Standards IEEE, ANSI, NEMA, IEC, CE

- Application industrial distribution networks, large factories

- Power Rating 50-2500kVA

- Certificate UL, CESI, IEEE

- Cooling Method ONAN/ONAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 50-2500kVA | |

| Rating Primary Voltage | 20 kV | |

| Secondary Voltage |

6.6kV 10kV 13.8kV Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

Packing and Shipping

All bushings, oil level gauge, temperature gauges, and tap changer handle are dismantled and packed in separate IPPC-fumigated wooden crates with shock-proof foam and desiccant. The main body is fixed on a reinforced steel skid, wrapped with waterproof film, and placed in a fully sealed plywood crate reinforced with a 50×50 mm steel frame. Clear bilingual markings “20kV Three-Phase Oil-Immersed Power Transformer 50-2500kVA Copper”, lifting points, centre-of-gravity, and “Keep Dry” are applied. Four shock recorders monitor the entire journey.

Land transport uses standard low-bed trailers (height <4.3 m). Sea freight is loaded in 40ft OT/FR containers or break-bulk, secured with certified lashing belts. Complete documentation includes a packing list, fumigation certificate, nitrogen pressure report, and 110% marine insurance.

These professional measures ensure every unit arrives in perfect condition, ready for immediate installation and commissioning worldwide.

Manufacturer Test

Progress Test

During production, the 20kV Three-Phase Oil-Immersed Power Transformer undergoes strict staged Progress Tests:

- Core-coil: winding DC resistance at all taps, insulation resistance (PI ≥ 2.0), core grounding current <50 mA.

- Pre-tanking: ratio at all taps (deviation ≤ ±0.5%), vector group Dyn11/Yyn0 verification.

- After vapor-phase drying & vacuum oil-filling: final insulation resistance, tanδ ≤ 0.004, PD <5 pC at 1.5Um/√3, oil BDV >60 kV.

- Tank sealing: 24 h leakage test + 0.3 bar pressure/vacuum test. All records are submitted for client approval before FAT.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

The Factory Acceptance Test is performed strictly in accordance with IEC 60076-1/3/5/11, GB/T 1094, and customer technical specifications, fully witnessed by the client or third-party inspection agency (SGS, BV, TÜV, etc.).

- Winding resistance measurement at all tap positions (ambient temperature, corrected to 75 °C)

- Voltage ratio and polarity test at rated tap and all off-circuit/on-load tap positions (tolerance ≤ ±0.5 %)

- Vector group and magnetic balance verification (typically Dyn11 or Yyn0)

- No-load loss and no-load current at 90 %, 100 %, and 110 % rated voltage on principal tap

All raw data, oscillograms, and calibration certificates are recorded in the official FAT protocol. The transformer is released for shipment only after client signature, ensuring every 20kV Three-Phase Oil-Immersed Power Transformer 50-2500kVA Copper is 100 % qualified for immediate energization and long-term reliable service.

Routine Test - Applied Voltage

Voltage source: usually 1 kV, 5 kV, 10 kV, or customized according to customer needs

Temperature and humidity meter: used to record environmental conditions

Check the connection terminals and wiring to ensure that they are not loose or contaminated.

Test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20-30°C).

Properly connect the test equipment to the bushings or terminals of the device under test and ensure that all connection points are properly grounded.

Selecting the test voltage:

Select the appropriate applied voltage based on the rated voltage of the equipment.

Measuring leakage current

Applied voltage

Current stability

Any possible voltage fluctuations

The current value exceeded the allowable range and the equipment needs to be inspected or maintained (pending repair)

There was a serious fault or instability and the equipment could not continue to operate (unqualified)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.