Dry-Type Transformer Installation Guide: Step-by-Step Instructions for Safe and Efficient Setup

Dry-type transformers play an indispensable role in modern power distribution systems. Unlike traditional oil-immersed transformers, dry-type transformers are cooled and insulated by air or solid insulating materials (such as cast resin), eliminating the use of oil. This gives them significant advantages in fire safety and environmental friendliness. Because they do not require oil as a cooling medium, the fire risk of dry-type transformers is greatly reduced, making them particularly suitable for applications with high safety requirements, such as high-rise buildings, factories, and urban power systems.

Furthermore, dry-type transformers typically have lower maintenance costs because they do not require the regular inspection and oil replacement required for oil-immersed transformers. Proper installation of dry-type transformers is crucial for ensuring their efficient operation. Careful selection of a suitable location is essential, ensuring adequate ventilation and heat dissipation, and avoiding excessive vibration and external contaminants. Correct electrical connections and grounding measures are also critical to prevent accidents caused by electrical faults. Whether in industrial, commercial, or residential applications, ensuring that the installation of dry-type transformers complies with relevant regulations can significantly improve the reliability and long-term operational stability of the power system.

What Is a Dry-Type Transformer?

A dry-type transformer is an electrical transformer that uses air or solid insulation for cooling, rather than oil. Cast resin insulation is often used in these transformers because it is fire-resistant, durable, and provides excellent electrical insulation properties. These transformers are commonly used in urban areas, industrial settings, and renewable energy projects due to their compact design and enhanced safety features.

Advantages of Dry-Type Transformers

Before diving into the installation process, it’s important to understand why dry-type transformers are favored in many applications:

-

Fire Safety: Since they don't use oil, dry-type transformers reduce the risk of fires caused by electrical faults or leakage.

-

Low Maintenance: Dry-type transformers require less maintenance than oil-filled versions, making them a cost-effective solution in the long run.

-

Environmentally Friendly: The absence of oil makes them more environmentally friendly, as there’s no risk of oil spills or leaks.

-

Compact Design: These transformers are smaller and lighter than oil-filled transformers, making them ideal for installations in confined spaces.

Step-by-Step Dry-Type Transformer Installation

The proper installation of dry-type transformers ensures they perform efficiently and safely. Below are the key steps to follow during the installation process:

1. Choosing the Right Location

Before installing the dry-type transformer, the first step is to choose the correct location. The location should meet the following criteria:

-

Ventilation: Dry-type transformers rely on air cooling, so the area must have adequate airflow. Choose a location with enough ventilation to prevent overheating.

-

Dry and Clean Environment: The environment should be dry and free from dust and moisture, as excessive humidity can affect the performance of the transformer.

-

Accessibility: Ensure the installation site is easily accessible for future maintenance, inspections, and repairs.

-

Compliance with Standards: Check local electrical codes and safety regulations to ensure the transformer’s location complies with installation requirements.

2. Preparing the Installation Site

Once the location is chosen, prepare the site for installation:

-

Mounting Surface: Dry-type transformers are typically installed on a flat and sturdy base. Use concrete pads or steel frames for mounting. The mounting surface must support the weight of the transformer and provide stability.

-

Space for Clearance: Allow adequate space around the transformer for proper ventilation and to comply with safety clearance requirements. Typically, a minimum of 1-2 feet of clearance around the transformer is recommended.

3. Mounting the Transformer

Dry-type transformers are often mounted on concrete or steel bases to ensure they are stable during operation. Follow these steps to mount the transformer:

-

Position the Transformer: Carefully place the transformer on the prepared base, ensuring it is level and properly aligned.

-

Secure the Transformer: Use mounting brackets or bolts to secure the transformer to the base. Make sure the mounting is firm to avoid any vibrations or shifting during operation.

-

Check Alignment: Verify that the transformer is correctly aligned with the intended direction of electrical flow.

4. Electrical Connections

Once the transformer is mounted, the next step is to make the electrical connections:

-

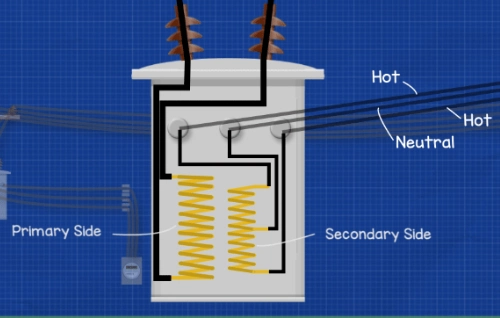

Connect Primary and Secondary Windings: The primary windings should be connected to the incoming power supply, while the secondary windings should be connected to the load side of the electrical system.

-

Neutral and Grounding: Proper grounding is crucial to ensure safety. Connect the neutral conductor and ground the transformer according to local electrical codes.

-

Check Tightness: Ensure that all connections are tight and secure to avoid electrical faults or overheating.

5. Insulation and Cooling Considerations

The dry-type transformer insulation (often cast resin) is designed to prevent electrical faults. The insulation prevents short circuits and ensures the transformer operates safely under load. It is also critical for efficient heat dissipation.

-

Ensure Proper Insulation Integrity: Check that the cast resin insulation is intact and free from damage during the installation. Any damage can compromise the transformer’s performance.

-

Monitor Cooling Ventilation: Ensure that the cooling system is not obstructed. Natural air convection is essential for maintaining safe operating temperatures in dry-type transformers.

6. Final Testing and Commissioning

After completing the installation, the next step is to test the transformer’s operation:

-

Initial Power-up: Power up the transformer and check for any unusual sounds, odors, or temperature increases. These could indicate potential issues such as wiring problems or overheating.

-

Voltage Testing: Verify that the output voltage levels are consistent with the specified ratings. Use a multimeter to check the secondary voltages and confirm the transformer is performing as expected.

-

Load Test: Apply the transformer to a light load to test its response. Monitor the temperature to ensure the transformer operates within safe temperature limits.

7. Maintenance Considerations

While dry-type transformers require less maintenance than oil-filled transformers, routine checks are still necessary:

-

Regular Inspections: Schedule regular inspections to check for signs of wear, damage, or overheating. Pay attention to the cooling system and ensure that ventilation slots are clear.

-

Cleanliness: Keep the transformer clean and free from dust or debris, which can obstruct airflow and impact performance.

-

Periodic Testing: Conduct periodic tests to check the electrical resistance and ensure that insulation is intact.

The installation of dry-type transformers is a critical process that ensures safe, efficient, and reliable power distribution. By following the proper installation steps, including choosing the right location, securing the transformer, and ensuring the correct electrical connections, you can maximize the transformer's lifespan and performance. With their cast resin insulation, low-maintenance requirements, and fire-resistant properties, dry-type transformers are a perfect choice for environments that prioritize safety and reliability.

Whether you are installing a dry-type triplex transformer for industrial applications or a small dry-type transformer in a commercial building, following these guidelines will ensure a successful installation and long-term operational efficiency.

2Y-high-voltage-power-cable-2.webp)