What Is an Overhead Transformer? Ultimate Guide to Pole-Mounted Transformers Selection and Maintenance

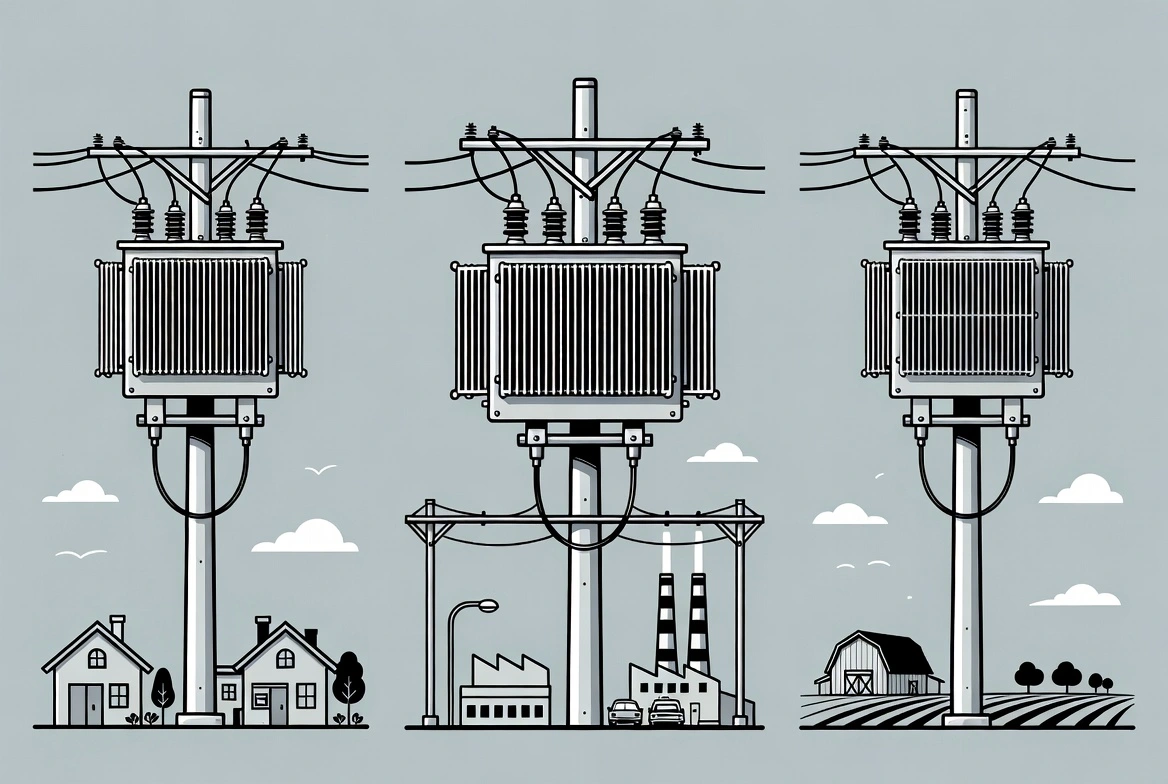

Overhead transformers, often called pole-mounted transformers or pole-type transformers, are key equipment in power distribution systems. Their core function is to step down the voltage of electricity from high-voltage transmission lines (such as 11kV or 33kV) to a low-voltage secondary voltage (such as 220V/400V) for safe use by residential, commercial, and industrial users. These transformers employ an oil-immersed design and are typically equipped with an ONAN (natural oil-natural air) cooling system to ensure efficient heat dissipation and long-term stable operation. Due to their cost-effectiveness, ease of installation, and relatively simple maintenance, they are widely used in urban streets, rural power grids, suburban transmission lines, and industrial parks, and are particularly suitable for overhead line systems, avoiding the complex layout of underground cables.

From an engineering perspective, the structural design of overhead transformers emphasizes durability and adaptability, capable of withstanding environmental challenges such as extreme weather conditions, including high and low temperatures, strong winds, and lightning strikes. Common types include single-phase transformers (capacity 5-167kVA, suitable for low-load residential areas) and three-phase transformers (capacity up to 1000kVA, suitable for commercial loads), as well as CSP (fully self-protected) models with built-in fuses and surge arresters for enhanced safety. Selection should consider load requirements, voltage level, environmental factors, and efficiency standards (such as compliance with IEEE, ANSI, or IEC standards) to minimize energy loss (typically controlled to 1-2%). Installation involves securing the transformer to a pole (at least 4.5 meters high), proper grounding, and connecting high-voltage/low-voltage cables, ensuring it is kept away from flammable materials and equipped with protective devices.

Maintenance is crucial for ensuring reliability, including regular visual inspections for oil leaks, corrosion, and insulation damage; annual oil sample testing (checking dielectric strength and contaminants); and electrical tests such as insulation resistance and winding ratio. Proactive maintenance can reduce failure rates by 50% and extend lifespan to 20-30 years. Furthermore, using environmentally friendly insulating oils (such as biodegradable ester oils) reduces fire risk and environmental impact. Overall, the proper application of overhead transformers not only improves power supply efficiency but also promotes sustainable energy distribution and drives grid modernization.

How an Overhead Transformer Works

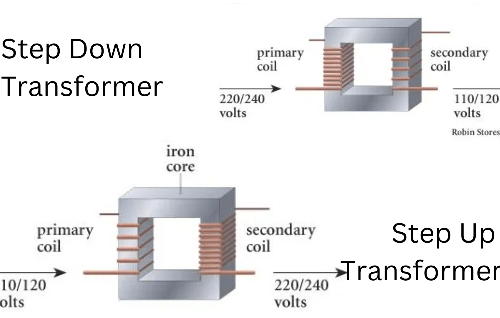

To understand how a transformer works, it is essential to look at its internal structure and operating principle.

An overhead transformer uses electromagnetic induction between a primary winding and a secondary winding. The primary side receives high-voltage electricity (typically 11kV, 13.8kV, or 33kV). This voltage induces a magnetic field in the transformer core, which then produces a lower, safer secondary voltage—commonly 400V, 230V, or 120V—suitable for residential, commercial, or small businesses' use.

Because overhead transformers are mounted above ground, they rely on natural air circulation and insulating oil to dissipate heat efficiently, minimizing energy loss during continuous operation.

Types of Pole-Mounted Transformers

Single Phase Overhead Transformer

A single-phase transformer is widely used in residential areas and rural distribution systems. It is cost-effective, compact, and suitable for low to moderate power demands.

3 Phase Overhead Transformer

A 3-phase overhead transformer is typically applied in industrial zones, commercial districts, and areas with higher load density. These units support balanced loads, improved voltage stability, and higher efficiency for motors and industrial equipment.

Compared with a pad-mounted transformer, overhead units offer easier visual inspection and lower civil construction costs, making them a preferred solution in many utility networks.

Typical Voltage Levels and Applications

Overhead transformers operate across standardized voltage levels depending on regional grid design and load requirements:

- Primary voltage: 6.6kV to 35kV

- Secondary voltage: 120V / 240V / 400V / 690V

They play a crucial role in voltage distribution, ensuring end users receive stable, regulated power with minimal fluctuation.

Key Components of an Overhead Transformer

Understanding transformer components helps engineers and technicians assess performance and maintenance needs:

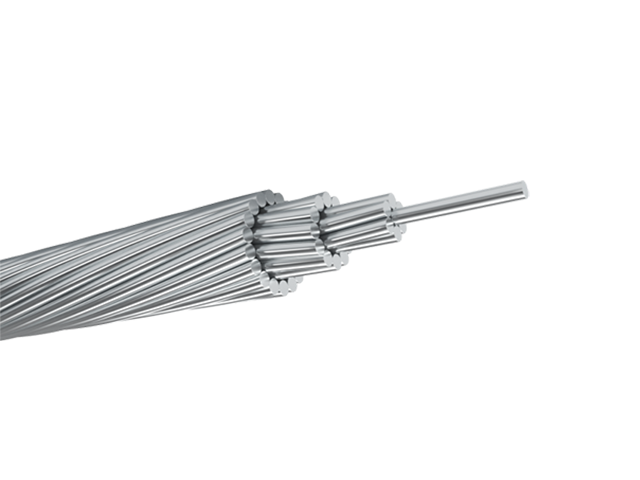

- Core: Laminated steel core for magnetic flux control

- Primary and secondary winding: Copper or aluminum conductors

- Insulating oil: Provides cooling and electrical insulation

- Oil level indicator: Critical for safe operation

- Bushings: Interface between internal windings and external conductors

- Tank and mounting brackets: Structural protection for pole installation

Maintaining proper oil level is especially important to prevent insulation degradation and overheating.

Overhead Transformer Installation Considerations

Proper transformer installation is essential for long-term performance and safety. In real-world projects, utilities and EPC contractors must consider:

- Pole strength and height

- Clearance from ground, buildings, and roadways

- Mechanical loading from cables and wind

- Earthing and lightning protection

- Accessibility for maintenance

Incorrect installation can result in accelerated insulation aging, increased energy loss, and safety hazards.

Table: Comparison of Overhead Transformer Configurations

|

Parameter |

Single Phase Transformer |

3 Phase Overhead Transformer |

|

Typical Application |

Residential, rural areas |

Industrial, commercial zones |

|

Power Capacity |

Low to medium |

Medium to high |

|

Voltage Stability |

Moderate |

High |

|

Installation Cost |

Lower |

Higher |

|

Efficiency |

High |

Very high |

|

Load Balance |

Not required |

Required |

Maintenance and Reliability in Harsh Environments

Overhead transformers are exposed to harsh environments, making preventive maintenance essential. Field experience shows that routine inspections significantly extend service life.

Key maintenance activities include:

- Checking oil level and oil quality

- Inspecting bushings for cracks or contamination

- Monitoring temperature and load conditions

- Verifying grounding integrity

- Inspecting secondary winding connections

High-quality transformers with proper sealing and corrosion protection perform reliably even in coastal, desert, or cold climates.

Efficiency, Energy Loss, and System Performance

Modern overhead transformers are designed for high efficiency, reducing no-load and load losses. Lower losses translate directly into reduced operating costs for utilities and improved sustainability.

By selecting the correct transformer capacity and maintaining proper loading, operators can significantly reduce energy loss while maintaining consistent voltage distribution.

Overhead Transformers vs Pad Mounted Transformers

While a pad-mounted transformer is commonly used in underground distribution systems, overhead transformers remain dominant in overhead networks due to:

- Lower total installation cost

- Faster fault identification

- Easier maintenance access

- Reduced civil engineering requirements

Both types play important roles, but overhead transformers continue to be a backbone solution in many regions.

The Role of Overhead Transformers in Modern Power Networks

An overhead transformer is far more than a simple piece of equipment—it is a critical link between high-voltage transmission lines and end-user power consumption. Whether serving residential communities, small businesses, or industrial customers, pole-mounted transformers enable safe, efficient, and reliable voltage transformation.

By understanding how a transformer works, selecting the right configuration, and implementing disciplined maintenance practices, utilities and engineers can ensure long service life, high efficiency, and dependable power delivery across the entire distribution system.