The Differences Between Wires and Cables? An Engineer’s Perspective

What is the difference between wire and cable? As a cable technology engineer, I often encounter confusion regarding "wire" and "cable". While the two terms are often used interchangeably in the electrical and communications engineering fields, they refer to different entities with specific characteristics and applications. Understanding these differences is critical to proper system design, installation, and maintenance.

In the intricate world of electrical and data transmission, precision in terminology is not merely academic; it’s fundamental to safety, performance, and reliability. The terms “wire” and “cable” are foundational, yet their precise meanings are often blurred in common parlance. From my vantage point as a cable technology engineer, I’ll dissect these terms, explore their construction, and highlight their distinct roles.

What are the Wires? Unveiling the Single Conductor

Let’s begin with the elemental component: the wire.

Defining the Essence of a Wire

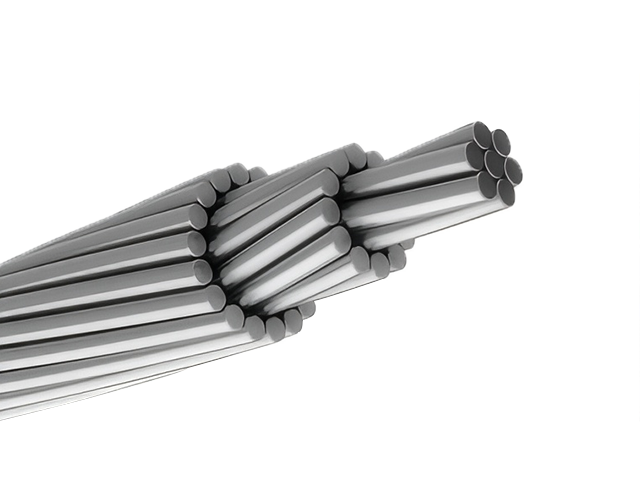

Technically, a wire is a single electrical conductor. This single conductor is typically made of a metallic material like copper or aluminum, chosen for its excellent conductivity. The primary function of a wire is to carry an electrical current or telecommunication signals from one point to another.

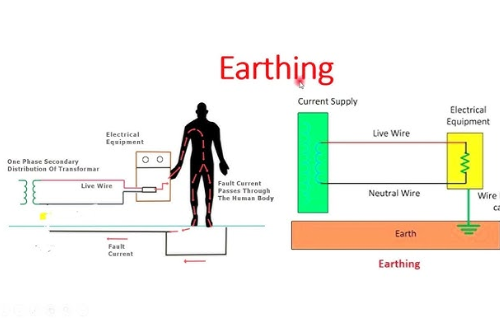

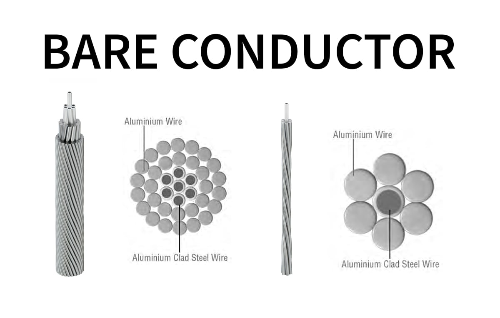

Wires can be bare (uninsulated) or covered with an insulating layer. Bare wires are commonly used in applications such as overhead power lines, where air serves as an insulator, or for grounding purposes. Insulated wires feature a non-conductive coating, typically made of plastic (like PVC or polyethylene) or sometimes rubber, to prevent short circuits, electrical shock, and protect the conductor from environmental factors.

Solid Wire vs. Stranded Wires – A Core Distinction

Within the category of single conductor wires, two primary forms exist:

- Solid Wire: A solid wire consists of a single, solid metallic core.

- Advantages: Solid wires are generally less expensive to manufacture, offer lower resistance for a given cross-sectional area (due to the absence of air gaps between strands), and are more rigid. This rigidity makes them ideal for permanent installations where they are not subject to frequent movement, such as in building wiring within conduits or for breadboarding applications.

- Disadvantages: Their rigidity also makes them more susceptible to breaking if repeatedly flexed or bent.

- Stranded Wires: Stranded wires are composed of multiple thin single strands of metal twisted or braided together to form a larger, more flexible conductor.

- Advantages: The primary benefit of stranded wires is their significantly higher flexibility and resistance to metal fatigue from vibration or bending. This makes them suitable for applications requiring movement, such as in appliance power cords, headphone cables, and within robotic arms.

- Disadvantages: Stranded wires are typically more expensive than solid wires of the same current-carrying capacity due to the more complex manufacturing process. They also have a slightly larger overall diameter for the same ampacity because of the air gaps between strands.

The choice between solid and stranded wire construction depends heavily on the specific application’s requirements for flexibility, durability, and cost.

What are the Cables? Beyond the Individual Wires

Now, let’s elevate our discussion to cables.

Defining the Assembly of a Cable

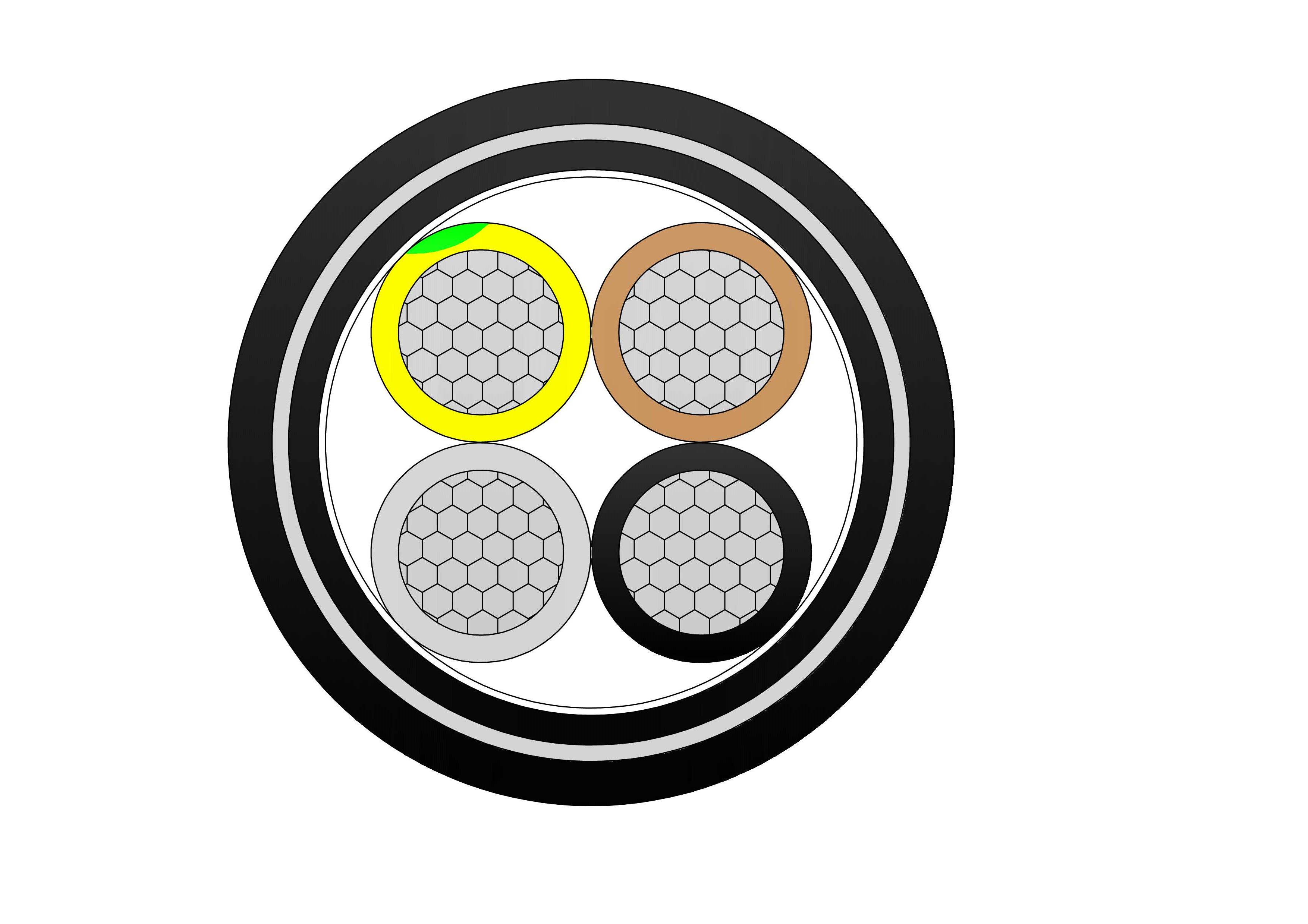

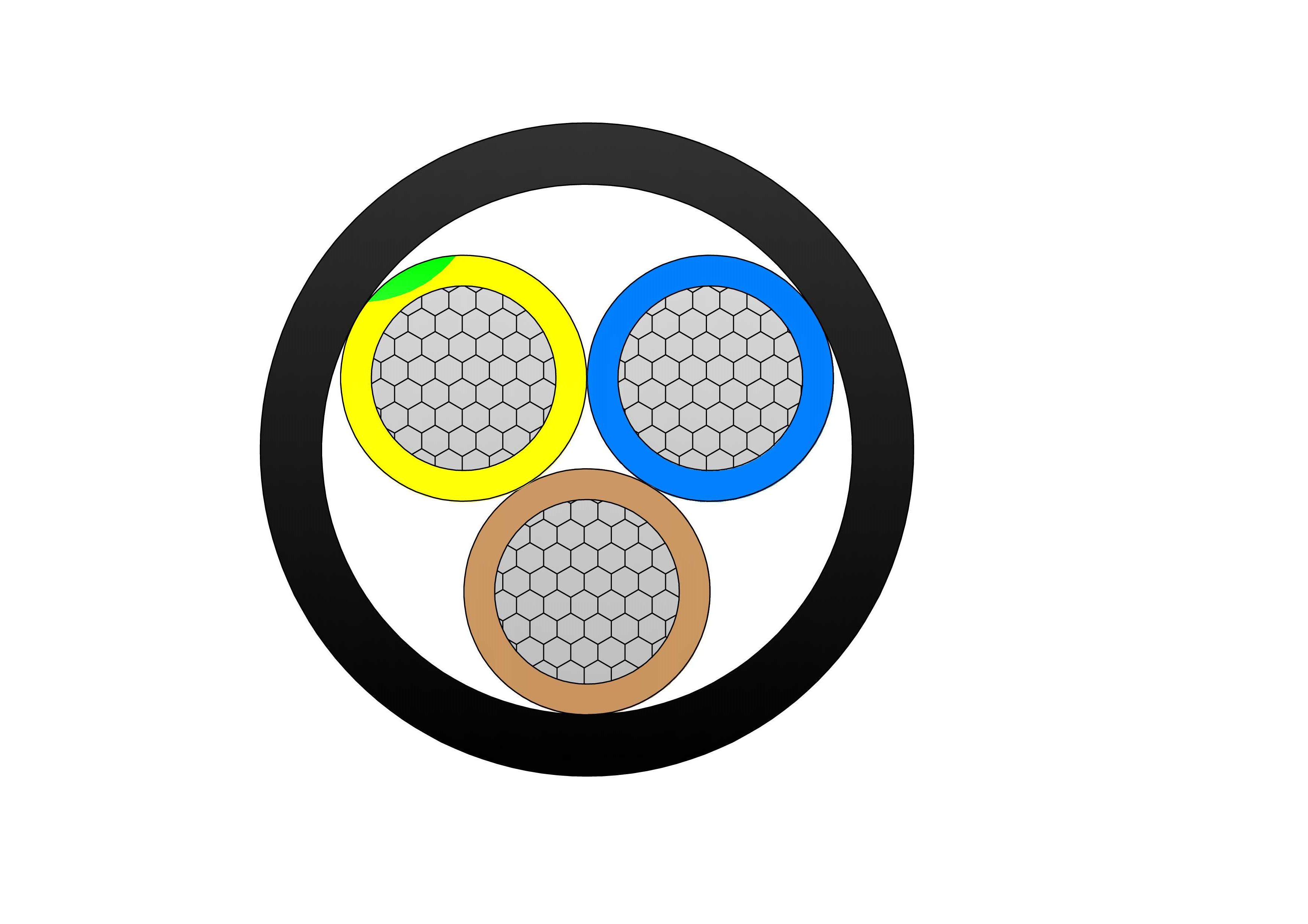

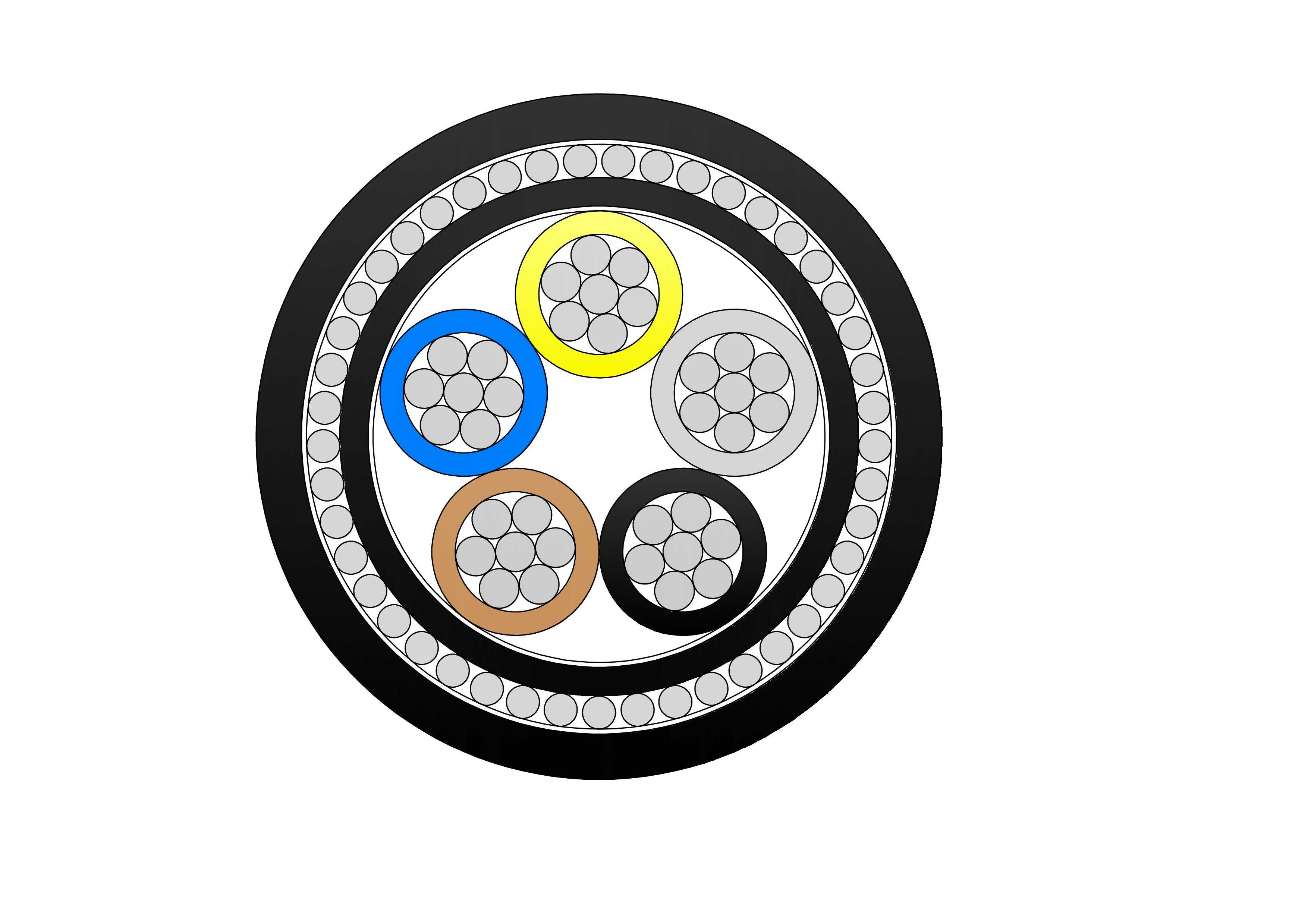

A cable is a more complex structure, typically consisting of two or more individual wires (which can be solid or stranded) bound, twisted, or braided together. These constituent wires are often individually insulated. The entire assembly is then usually encased in an outer protective sheath or jacket. The purpose of a cable is not just to conduct electricity or signals, but also to organize, protect, and sometimes shield these conductors.

Therefore, while a wire is a component, a cable is an assembly. Think of it this way: wires and cables are related, but a cable is a more comprehensive system. Many electrical wires are, in fact, components within a larger cable structure.

Key Components and Purpose of Cables: Including Electrical Wires

Cables are designed to manage multiple conductors efficiently and protect them from:

- Physical Damage: Abrasion, crushing, kinking.

- Environmental Factors: Moisture, chemicals, temperature extremes, UV radiation.

- Electromagnetic Interference (EMI): Shielding is often incorporated into cables to prevent external noise from corrupting signals or to prevent the cable itself from radiating noise.

A typical type of cable might include:

- Conductors: The individual wires carrying the current or signal.

- Insulation: Dielectric material surrounding each conductor.

- Fillers: Non-conductive materials used to maintain the cable’s shape and protect conductors.

- Shielding: A metallic layer (braid or foil) to reduce EMI.

- Jacket: The outermost protective layer.

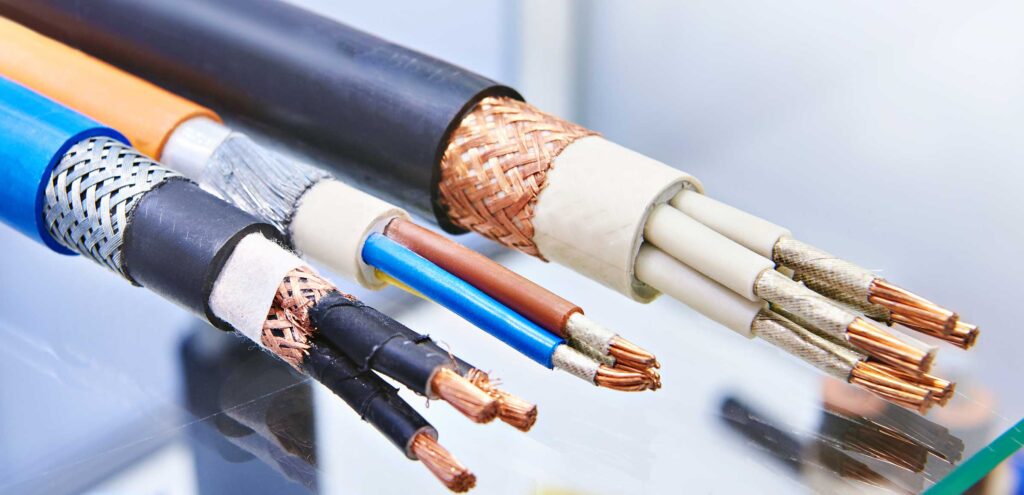

Exploring Different Types of Cable and Their Applications

The world of cables is vast, with designs tailored to specific applications. Here are a few prominent examples:

- Coaxial Cable: Consists of a central solid wire conductor, surrounded by an insulating layer, then a conductive shield (braid or foil), and finally an outer insulating jacket. Used extensively for radio frequency signals, cable television, and broadband internet.

- Twisted Pair Cable: As the name suggests, this type of cable comprises two insulated copper wires twisted together. The twisting helps to reduce crosstalk and electromagnetic interference.

- Unshielded Twisted Pair (UTP): Common in telephone wiring and Ethernet networks (e.g., Cat 5e, Cat 6).

- Shielded Twisted Pair (STP): Includes an additional shielding layer for enhanced noise immunity, used in environments with high EMI.

- Multi-Conductor Power Cables: These electrical wires (often multiple insulated stranded wires or solid wire conductors) are bundled together within a common jacket for distributing electrical power. They are fundamental to any electrical installation, from residential wiring to industrial machinery.

- Ribbon Cable: Consists of multiple insulated wires laid parallel to each other, forming a flat, wide cable. Often used for internal interconnections in computers and electronic devices due to their space-saving design.

- Fiber Optic Cable: A significant departure from traditional electrical wires, a fiber optic cable transmits information as pulses of light through thin strands of glass or plastic (optical fibers).

- Construction: Typically includes one or more optical fibers, strength members, and an outer protective jacket.

- Advantages: Offers extremely high bandwidth, immunity to EMI, low signal attenuation over long distances, and enhanced security. It’s not a single conductor in the electrical sense, nor does it carry electrical current.

- Relevance: While not carrying electricity, fiber optic cables are crucial in modern telecommunications and data networking, replacing copper wires and cables in many backbone and high-speed applications.

Wires and Cables: A Comparative Analysis from an Engineering Standpoint

To crystallize the distinctions:

|

Feature |

Wire |

Cable |

|

Definition |

A single conductor (can be solid wire or stranded wires ). |

Two or more individual wires (or optical fibers) assembled within a common protective covering. |

|

Complexity |

Simpler construction. |

More complex, multi-component assembly. |

|

Conductor Count |

Typically, one (though a stranded wire technically has multiple single strands forming one conductor). |

Two or more distinct, often individually insulated, conductors. |

|

Protection |

May be bare or have a single layer of insulation. |

Features individual conductor insulation, fillers, often shielding, and a robust outer jacket for overall protection. |

|

Application |

Component level, internal wiring, breadboarding, specific tasks like grounding. |

System-level connections, power distribution, data transmission, signal routing in various environments. |

|

Visibility |

Often visible as individual strands or insulated units (e.g., jumper wires). |

Usually seen as the complete sheathed assembly (e.g., power cord, Ethernet cable). |

|

Durability |

Generally less durable, especially if uninsulated or unjacketed. |

Designed for higher durability against mechanical stress and environmental factors. |

The choice between using individual wires and cables or a pre-assembled type of cable depends entirely on the engineering requirements of the electrical installation or communication system. Factors such as current carrying capacity, voltage rating, signal integrity, environmental conditions, flexibility (solid and stranded considerations), and EMI susceptibility all play a crucial role.

The Significance of Solid and Stranded Conductors in Wires and Cables

The solid and stranded nature of the conductors within wires and cables significantly impacts their performance and suitability.

- For electrical wires in fixed installations, such as residential wiring run through conduits, solid wire conductors are often preferred for their cost-effectiveness and ease of termination in screw terminals or punch-down blocks.

- Conversely, in applications requiring flexibility, such as appliance cords, patch cables, or internal wiring in devices subject to vibration, stranded wires are indispensable. The individual single strands allow the conductor to bend repeatedly without fatiguing and breaking. This principle extends to the individual wires used within larger, flexible type of cable assemblies.

Engineering Precision in Terminology

As a cable technology engineer, it is crucial to correctly distinguish between wires (single conductors) and cables (combinations of multiple conductors, or fiber optic components). Although these terms may be used more broadly in daily life, accuracy is essential in engineering design, manufacturing, and electrical installation because it is related to the quality of engineering and the safety of life.

It is crucial to understand whether the application requires solid wire or stranded wire, the necessity of shielding, the appropriate jacket material, and the overall configuration of the wires in a certain cable. Often, this directly affects the safety, reliability, performance, and service life of electrical and communication systems. From simple wires to complex fiber optic assemblies, each component is designed for a specific purpose, and recognizing the subtle differences between wires and cables is the first step to achieving efficient system design.