For the 25000kVA Oil-Immersed Copper Transformer, the Factory Acceptance Test is performed to verify that the completed unit meets all technical specifications and international standards before shipment. The FAT includes detailed visual inspections of the transformer tank, core, windings, and all accessories. Electrical tests such as ratio measurement, winding resistance, insulation resistance, induced voltage, and applied AC withstand tests are conducted to ensure stable performance. Temperature rise assessment, oil dielectric strength testing, and pressure tightness checks validate the reliability of the oil-immersed system. Functional tests on tap changers, cooling systems, bushings, and protection devices confirm operational accuracy. Through these comprehensive FAT procedures, the 25000kVA oil-immersed copper transformer is guaranteed to operate safely and efficiently in high-demand power distribution environments.

25000kVA Oil-Immersed Copper Transformer For Substation

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 33 or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Oil immersed transformer

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA, IEC, CE

- Application Power Substations, Industrial Power Supply

- Power Rating 25000kVA

- Certificate UL, CESI, IEEE

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 25000 kVA | |

| Rating Primary Voltage | 2.4 - 34.5kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| Insulating Oil Weight | 8530 kg | |

| Total Weight | 36510 kg | |

| Outline Dimensions(L×W×H)in. | 5100 × 3640 × 4220(mm) | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

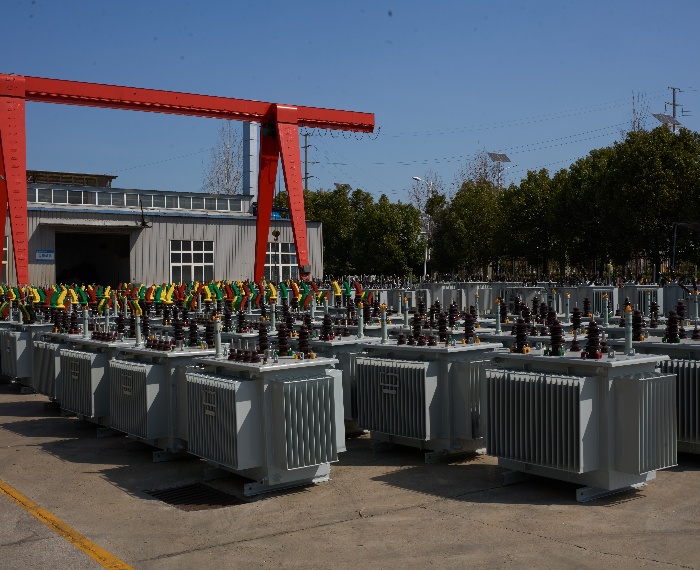

Packing and Shipping

Packing Process:

Each transformer undergoes a complete inspection before packing, ensuring that all components—including bushings, radiators, tap changers, and oil levels—fully meet factory standards. The transformer is then wrapped with moisture-proof and dust-proof protective film to shield it from humidity, corrosion, and contaminants that may affect performance during transport.

A custom-built heavy-duty steel-reinforced wooden crate is designed according to the transformer’s size and weight. Shock-absorbing padding, support blocks, and internal braces are added to prevent movement inside the crate. For large-capacity transformers like the 25,000kVA unit, the tank and accessories are often packed separately to reduce shipping risks and ensure safer handling. All crates are sealed, strapped with steel bands, and clearly labelled with handling marks, lifting points, and transformer specifications.

Shipping Process:

Because of the transformer’s large capacity and weight, ocean freight or heavy-load land transport is typically used. Our logistics team selects reliable carriers experienced in handling oversized electrical equipment. Detailed export documents are prepared, including packing lists, invoices, test reports, and customs paperwork to ensure smooth clearance for international shipping.

During transportation, the transformer is securely fixed using steel chains or heavy-duty straps to prevent movement on the trailer or vessel. Real-time shipment tracking is provided so customers can monitor the delivery progress. Upon arrival at the destination port or site, local logistics partners assist with unloading using cranes or custom lifting equipment suitable for a 25,000kVA transformer.

Once delivered, each component is inspected again to verify that no damage occurred during transit. Our team offers guidance for on-site oil filling, assembly, and commissioning if required. Through strict packing standards and professional shipping management, we ensure the 25,000kVA oil-immersed copper transformer reaches your project site safely, efficiently, and ready for installation.

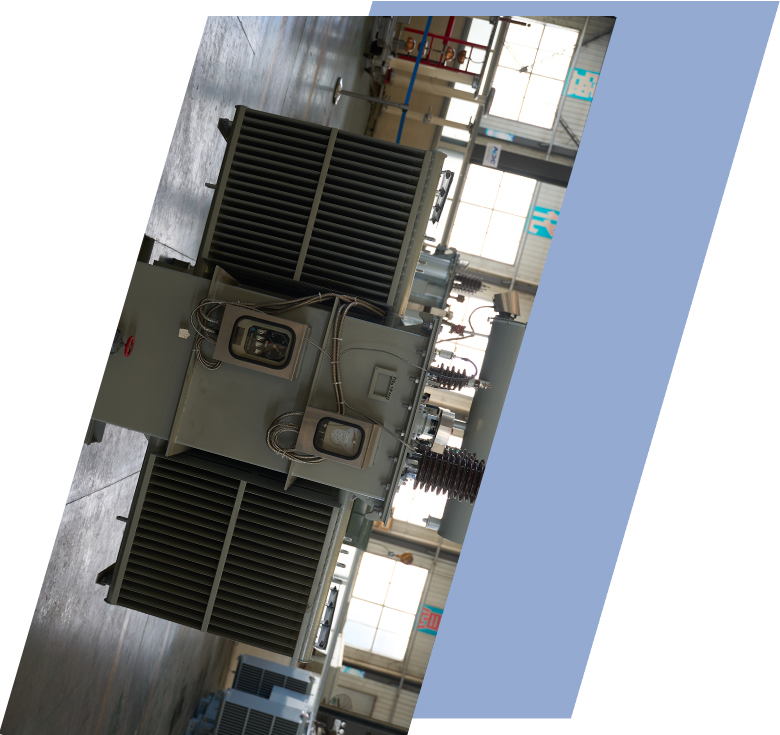

Manufacturer Test

Progress Test

During the manufacturing of the oil-immersed transformer, a strict Progress Test is conducted to ensure every production stage meets high-standard requirements. The inspection includes checking core lamination accuracy, coil winding tension, and inter-turn insulation quality. Welding integrity, fastening torque, and assembly tolerances are continuously monitored and recorded. All copper conductors and insulation materials undergo sampling tests for heat resistance, dielectric strength, and mechanical durability. After semi-assembly, preliminary tests such as DC resistance, insulation resistance, and turns ratio verification are performed to detect any early-stage defects. This Progress Test runs throughout the production process, ensuring the completed transformer delivers reliable performance, long service life, and stable operation under demanding conditions.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Routine Test - Insulation Resistance (Rated Voltage)

Apply Test Voltage: Select the appropriate test voltage according to the rated voltage of the equipment.

Insulation resistance value (MΩ or GΩ)

Test voltage (kV)

Test duration (usually 1 minute reading)

Ambient temperature and humidity

Insulation resistance value 1,000 MΩ ~ 10,000 MΩ (good)

Insulation resistance value < 1,000 MΩ

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.