75kVA Three Phase Pad Mounted Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 208GrdY/120; 416GrdY/240 or Customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards CSA C227.4 , CSA C802.1

- Application EV charging, Utility, BESSPower

- Power Rating 75kVA

- Certificate UL/cUL, CSA, CESI, and other certificates.

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 75 kVA |

| Rating Primary Voltage | 11950Delta or Customized |

| Secondary Voltage | 480GrdY/277 208GrdY/120 400GrdY/230 Customized(208Y/120 V to 4,160 V) |

| Frequency | 50/60Hz |

| Vector Group | Dyn1/Yyn0/Dyn11/Dyn5 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 3.5% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 205 kg |

| Total Weight | 650 kg |

| Outline Dimensions(L×W×H)in. | 900×710×1100 (mm) |

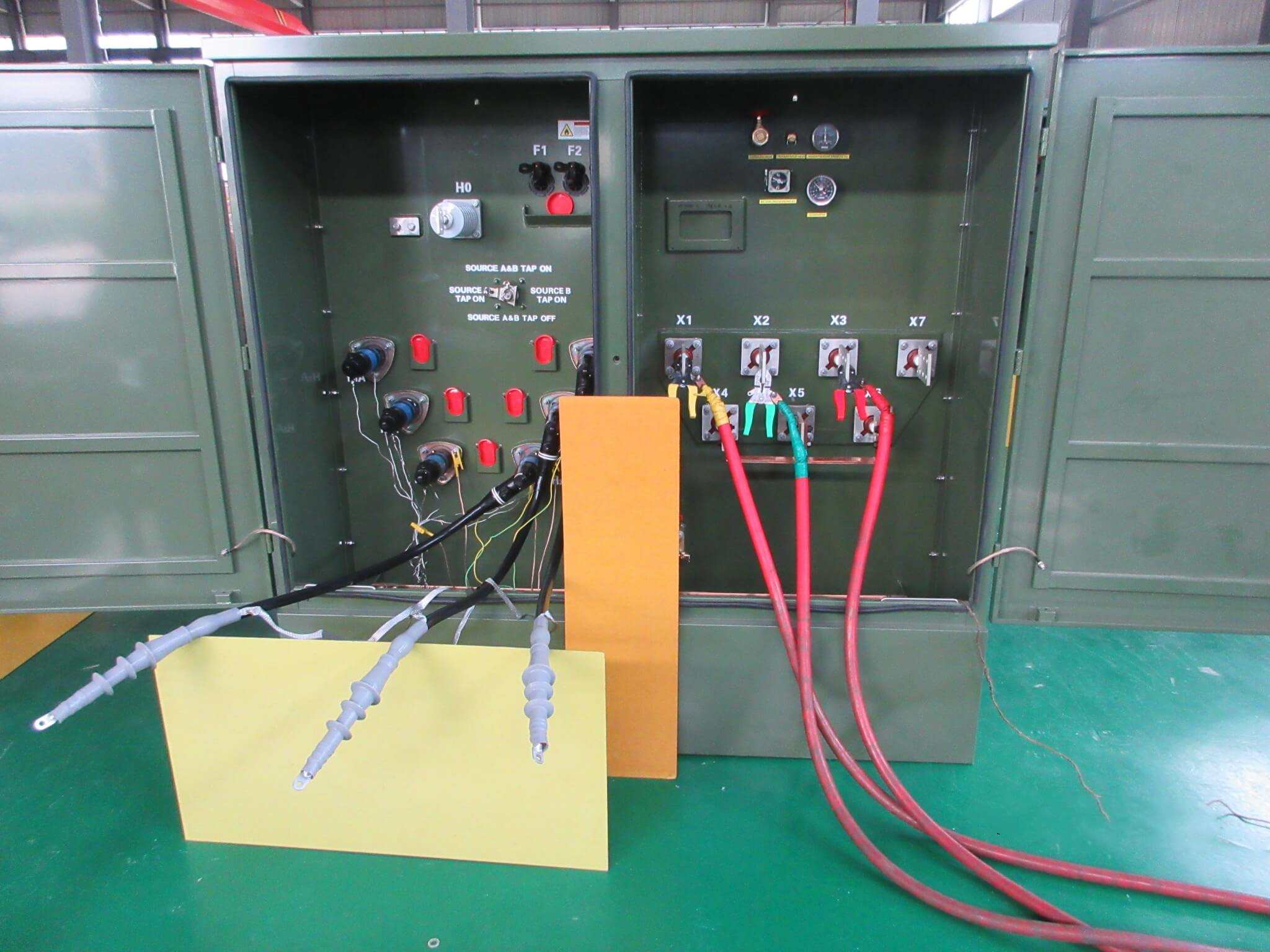

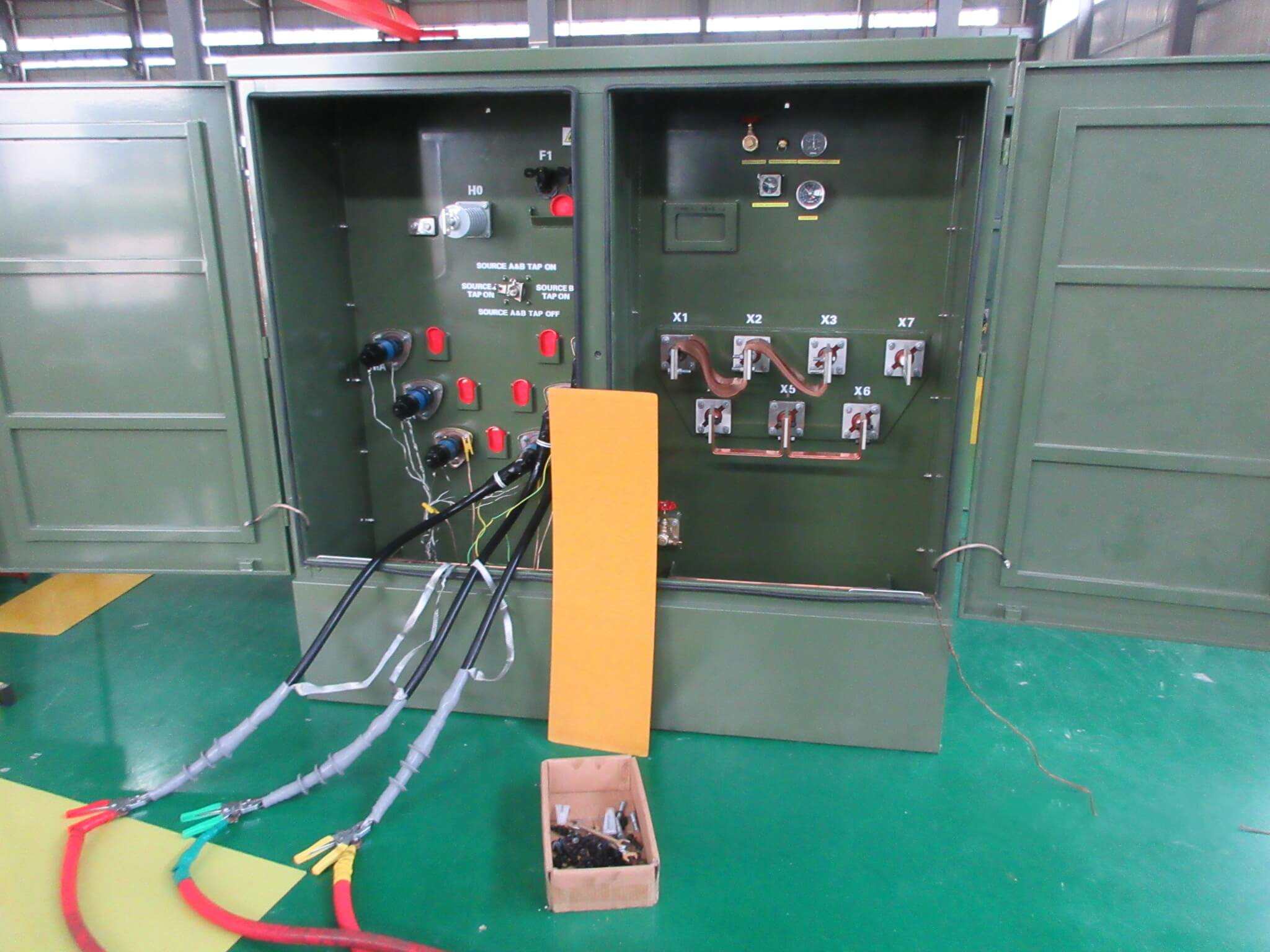

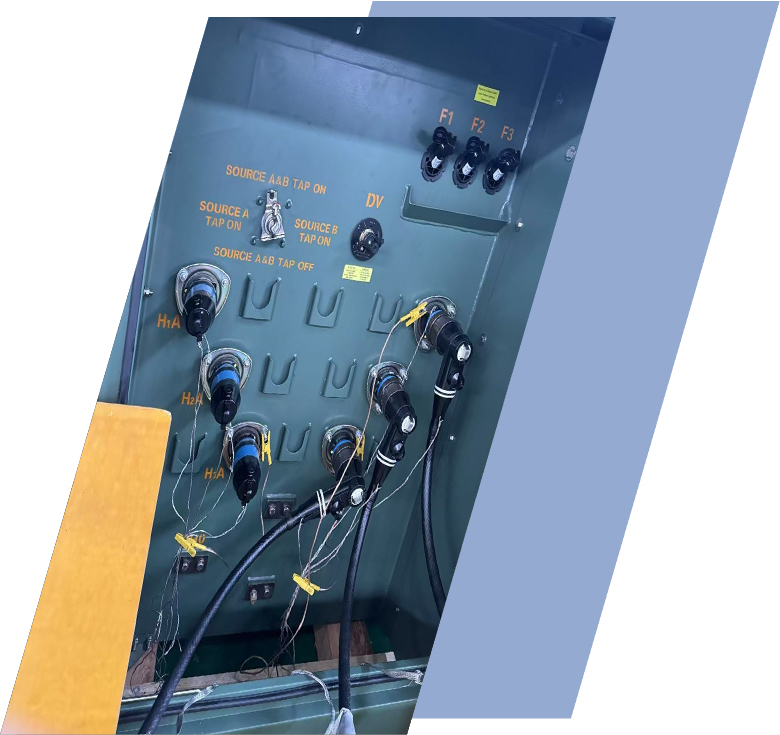

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | Terminal Box |

| Non-PCB decal | High Voltage Warning Signs |

Customization Optional

Packing and Shipping

Shipping is usually done via flatbed trucks or containers, depending on the destination and transport logistics. The packaging is designed to protect the transformer from mechanical damage, such as impacts or vibrations, while maintaining its integrity. All relevant shipping labels, including the weight, dimensions, and handling instructions, are clearly marked on the packaging to ensure smooth handling upon arrival. If shipping internationally, customs documentation and export packaging requirements will also be addressed to facilitate hassle-free clearance.

Sustainability guides packing selections, favoring responsibly sourced, recyclable wood and consolidated loading to lower carbon emissions. Attached impact and tilt recorders log transit conditions, supporting arrival verifications and efficient claim resolution. Optional accessories such as arresters, fuses, or gauges are crated separately with detailed inventories for onsite reconciliation. Proven carriers specializing in pad-mounted gear obtain required permits and follow rigorous safety measures across land and sea routes.

Post-delivery assistance includes pad foundation recommendations, detailed unpacking protocols, fluid refill guidelines, and connection torque specifications. Coordination with local teams facilitates safe installation and rapid energization. This thorough logistics process safeguards transformer quality, accelerates commissioning, and enables seamless deployment in underground three-phase commercial power infrastructures.

Manufacturer Test

Progress test

NPC Electric manufacture pad mounted transformer have the strict quality control from the raw material stage, Each 75 kVA transformer undergoes a series of routine tests before it leaves the factory, in strict adherence to the ANSI/IEEE C57.12.90 standard. These tests are critical to ensuring the transformer's performance and safety. The routine tests consist of the following:

Ratio tests on each connection.

(b) Polarity verification.

(c) Assessment of no-load losses at 105% rated voltage, corrected to 85°C.

(d) Evaluation of exciting current at 105% rated voltage.

(e) Measurement of load losses and impedance at rated current, conducted on the rated voltage connection, and corrected to 85°C. It's important to note that this test is performed on the high-voltage connection that exhibits the highest measured loss value.

(f) Applied voltage tests.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Advancing through FAT for the 75kVA three phase pad mounted transformer, lightning impulse withstand at 60-150kV BIL (voltage-dependent) applies full and chopped waves to affirm insulation robustness. Sound level testing in acoustic isolation meets regulatory thresholds. Temperature rise under equivalent load simulation restricts top-oil and winding increases to 65°C. Accessory functionality checks pressure relief operation, gauges, tap changer mechanics, and parking stands. Sweep frequency response analysis verifies core and winding mechanical condition. Comprehensive test compilation follows IEEE C57.12.90, ANSI C57.12.34, and DOE protocols with calibration traceability, client witnessing, and prompt discrepancy resolution prior to final acceptance and shipment readiness. Load loss and impedance derive accurately from short-circuit testing for performance validation. Power frequency withstand imposes specified kV for one minute without disruption. Induced voltage assessment stresses turn insulation. Fluid evaluation confirms breakdown voltage above 40kV and minimal gas content.

Routine Test - Applied Voltage

Voltage source: usually 1 kV, 5 kV, 10 kV, or customized according to customer needs

Temperature and humidity meter: used to record environmental conditions

Check the connection terminals and wiring to ensure that they are not loose or contaminated.

Test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20-30°C).

Properly connect the test equipment to the bushings or terminals of the device under test and ensure that all connection points are properly grounded.

Selecting the test voltage:

Select the appropriate applied voltage based on the rated voltage of the equipment.

Measuring leakage current

Applied voltage

Current stability

Any possible voltage fluctuations

The current value exceeded the allowable range and the equipment needs to be inspected or maintained (pending repair)

There was a serious fault or instability and the equipment could not continue to operate (unqualified)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.