Copper and Aluminum Conductors: Key Differences in Electrical Cables

In modern electrical systems, the choice of conductor material has become a core engineering decision affecting system safety, energy efficiency, lifecycle cost, and long-term reliability. As the most widely used electrical conductors, copper and aluminum dominate the global wire and cable market, especially in power distribution, commercial buildings, and industrial infrastructure. According to International Electrotechnical Commission (IEC) and National Electrical Code (NEC) standards, the application of these two materials covers a wide range of scenarios, from high-voltage power transmission to low-voltage residential wiring.

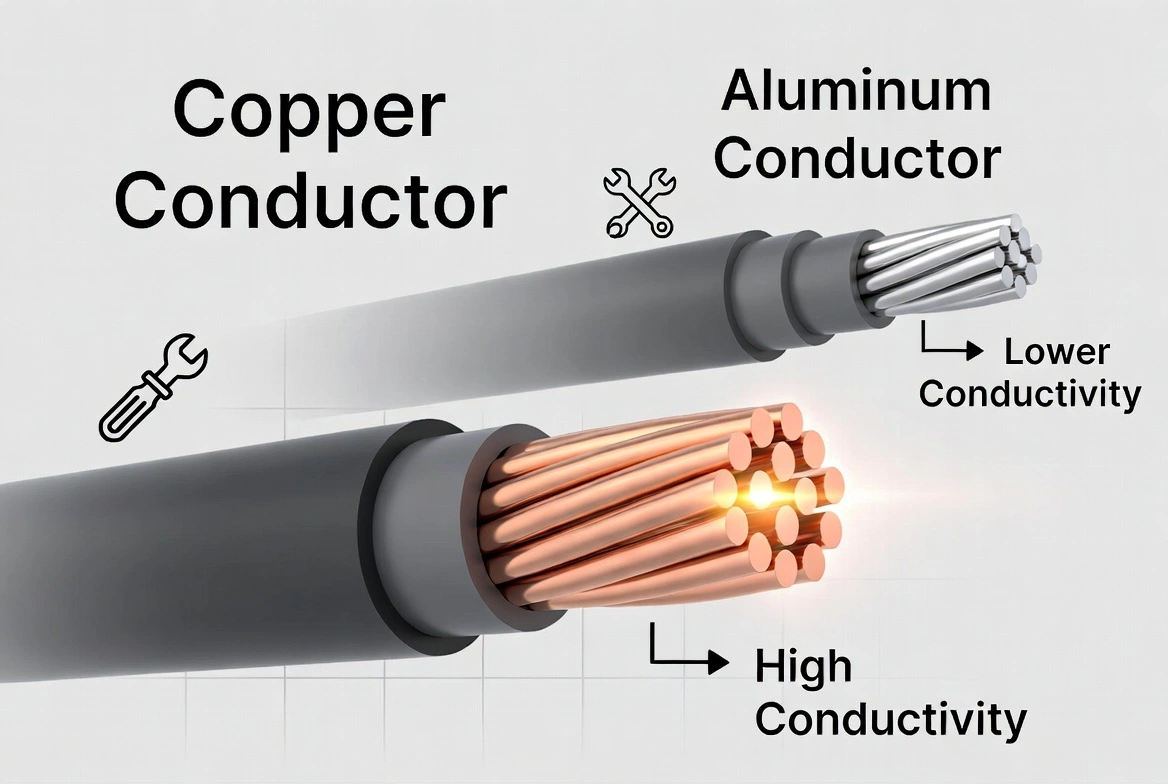

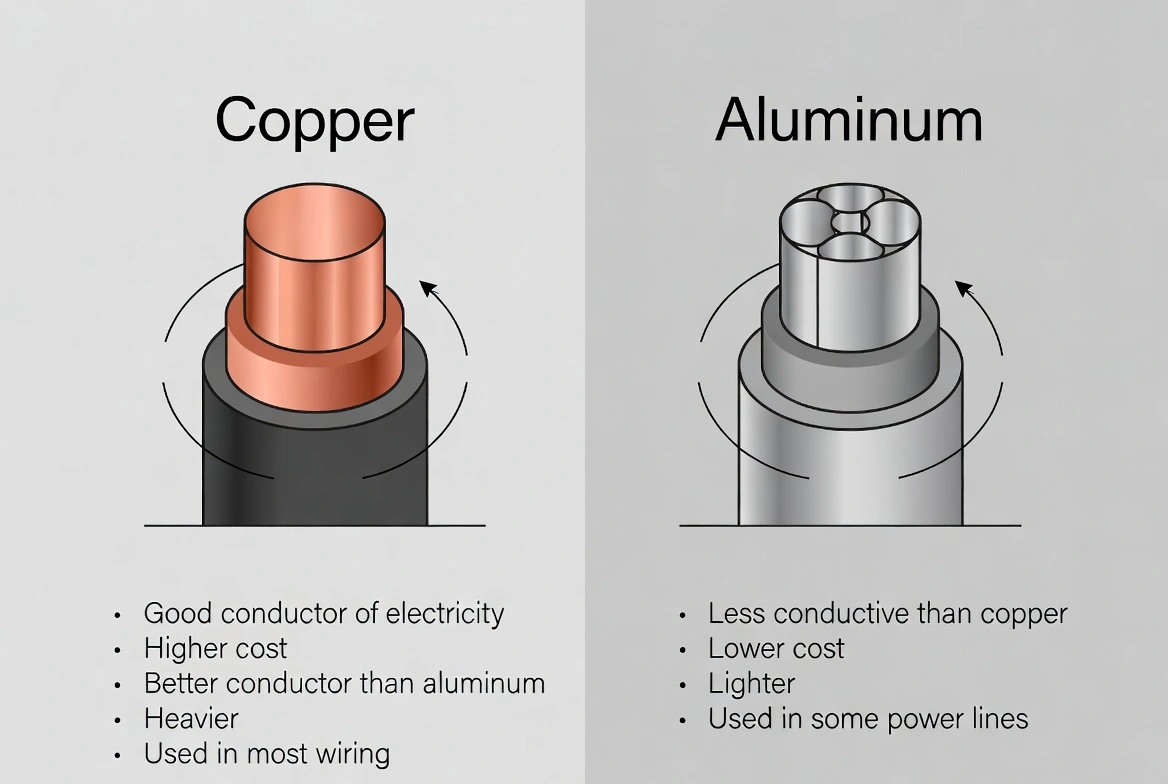

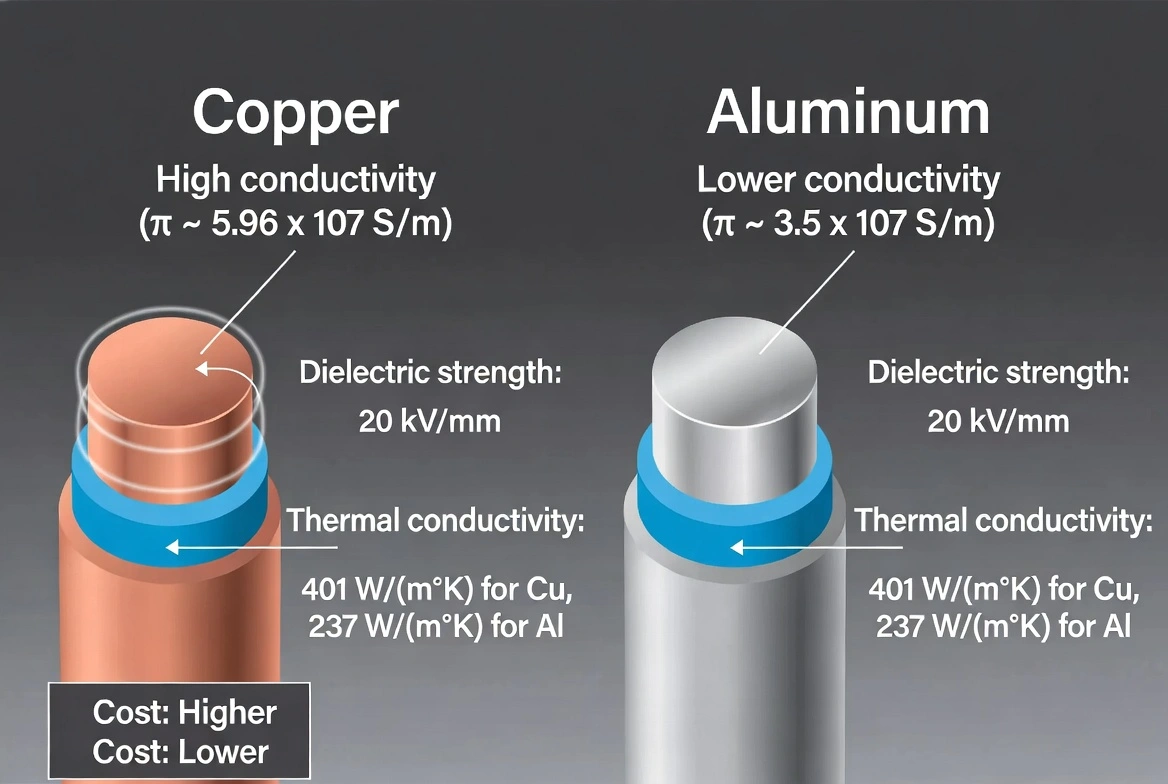

From an engineering perspective, choosing between copper and aluminum cables involves much more than just an initial cost comparison. Copper is renowned for its superior conductivity (resistivity of only 1.68 × 10⁻⁸ Ω·m), effectively reducing energy loss and heat buildup, ensuring efficient transmission. Simultaneously, copper's high mechanical strength and strong corrosion resistance make it suitable for high-load and harsh environment applications, such as data centers or offshore platforms. However, aluminum, with only one-third the density of copper, is lighter and cheaper (typically saving 20-50%), making it excellent for long-distance transmission lines such as overhead lines. However, its lower conductivity (resistivity 2.82 × 10⁻⁸ Ω·m) necessitates larger cross-sections to compensate, and its susceptibility to oxidation can lead to connection point failures.

During installation, copper cables are more flexible, facilitating bending and termination, while aluminum cables require specialized tools and alloy connectors to prevent loosening due to thermal expansion differences. Regulatory requirements are also crucial; for example, the EU RoHS Directive restricts the use of hazardous substances, driving the development of environmentally friendly aluminum alloys. Overall, engineers must weigh the trade-offs based on project requirements: copper is suitable for high-reliability applications, while aluminum optimizes cost-effectiveness. A comprehensive evaluation can enable sustainable electrical system design, reducing maintenance costs and improving overall performance.

Electrical Conductivity and Performance

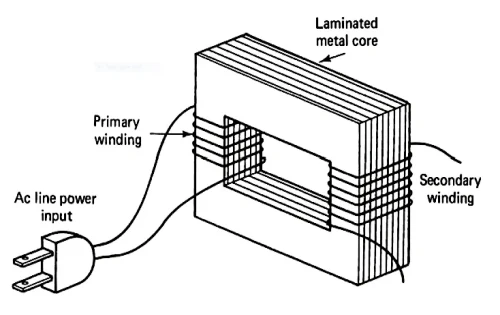

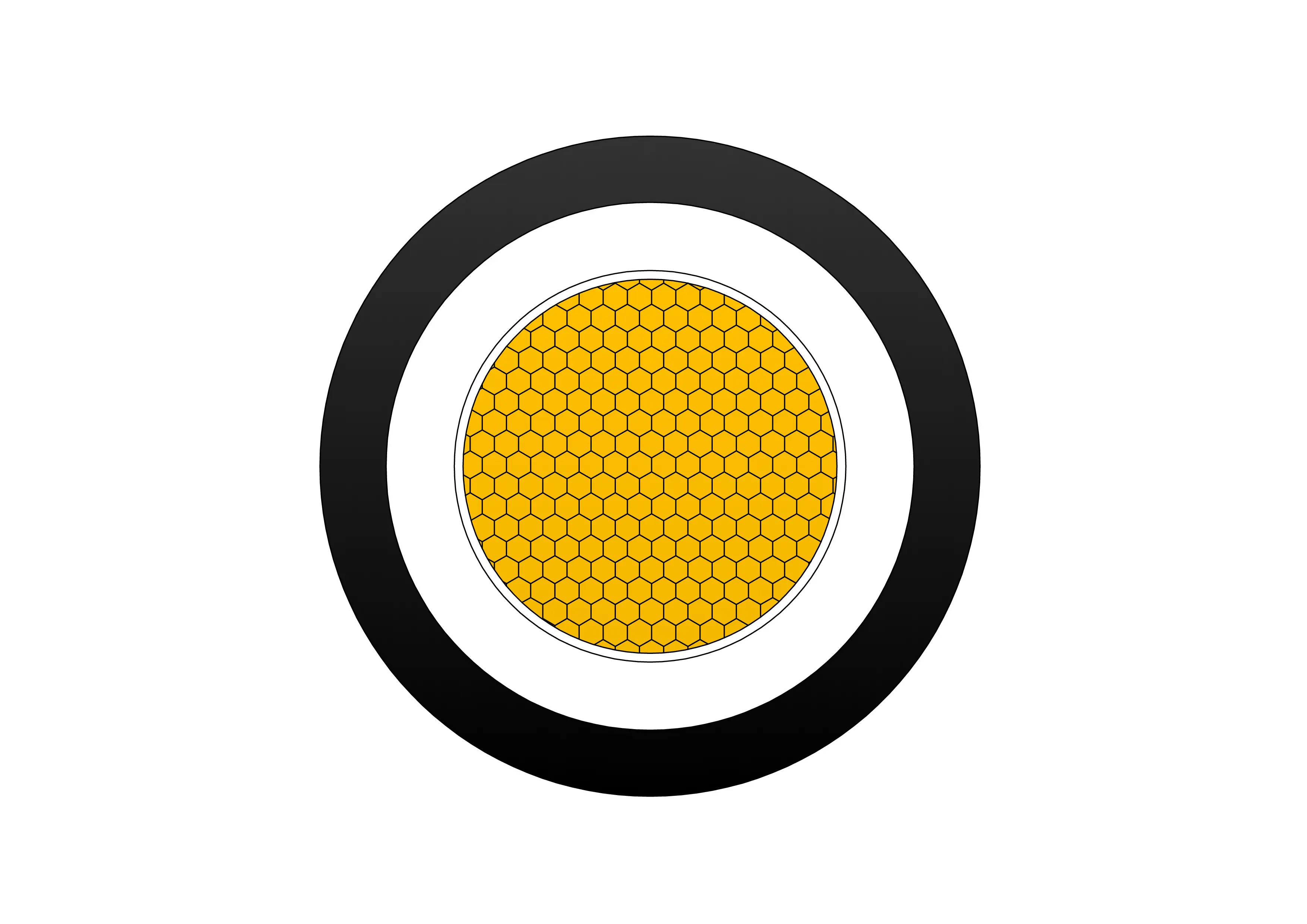

Electrical conductivity is one of the primary performance indicators of any electrical wire. Copper has long been regarded as the benchmark material due to its superior ability to carry current with minimal energy loss.

Copper conductors offer approximately 60% higher conductivity than aluminum conductors of the same cross-sectional area. This means that a copper wire can carry the same current as an aluminum wire with a smaller diameter, resulting in more compact cable designs and reduced voltage drop.

However, aluminum conductors compensate for lower conductivity by using a larger cross-sectional area. In practice, aluminum cables are engineered to meet the same current-carrying requirements as copper by increasing conductor size.

Mechanical Strength and Durability

From a mechanical perspective, strength copper is significantly higher than aluminum. Copper conductors demonstrate better resistance to fatigue, vibration, and mechanical stress, making them ideal for environments where cables are frequently bent, terminated, or subjected to movement.

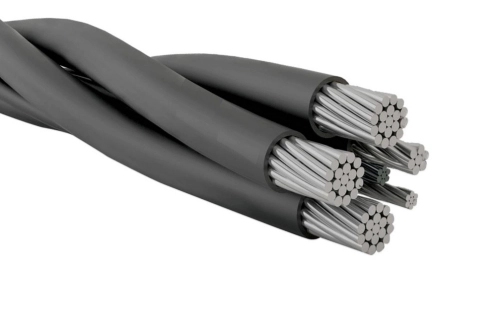

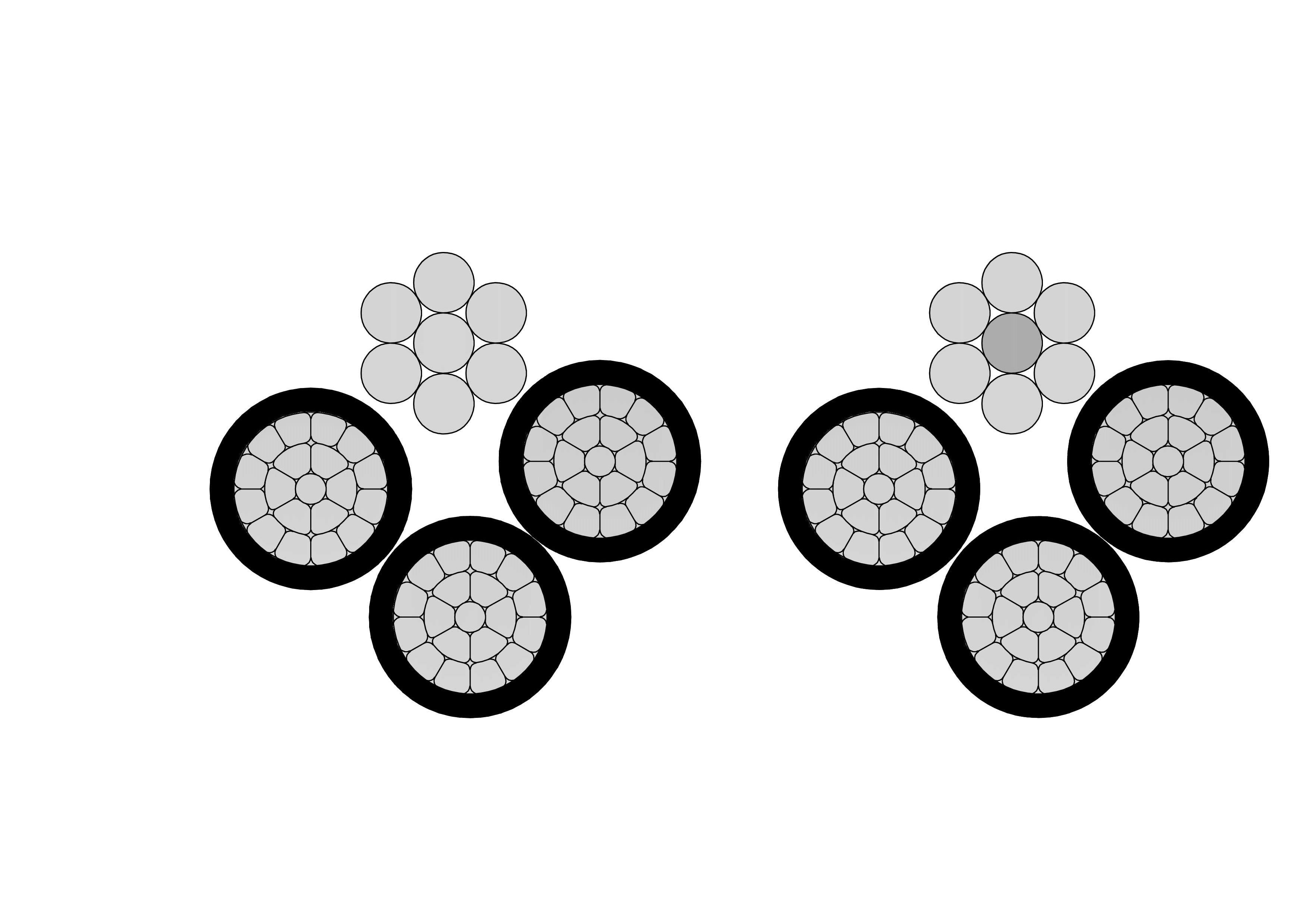

Aluminum wire, while lighter, has lower tensile strength and is more susceptible to mechanical deformation. This is why aluminum conductors are often used with reinforced designs, such as aluminium armoured cable, especially in underground or outdoor installations.

In demanding environments—such as industrial plants or areas with high mechanical stress—copper conductors often provide longer service life with fewer maintenance issues.

Weight, Handling, and Installation

One of aluminum’s major advantages is weight. Aluminum conductors are approximately 50% lighter than copper, which significantly reduces handling effort during installation. For large-scale power distribution projects, this weight reduction lowers labor costs and structural loading, especially in overhead systems.

In high-capacity installations such as feeders using 2/0 copper cable or 3/0 copper cable, aluminum alternatives can be easier to transport and install over long distances. This advantage becomes particularly important in utility-scale projects and high-rise commercial buildings.

Thermal Expansion and Connections

A key practical consideration in real-world installations is thermal expansion. Aluminum expands and contracts more than copper when temperatures change. If not properly addressed, this can lead to loose connections, increased resistance, and overheating.

Modern aluminum cable installations mitigate these risks through:

- Proper torque-controlled terminations

- Anti-oxidation compounds

- Certified aluminum-rated connectors

Copper conductors, by contrast, are more stable under temperature fluctuations and generally require less specialized termination practices.

Safety and Fire Performance

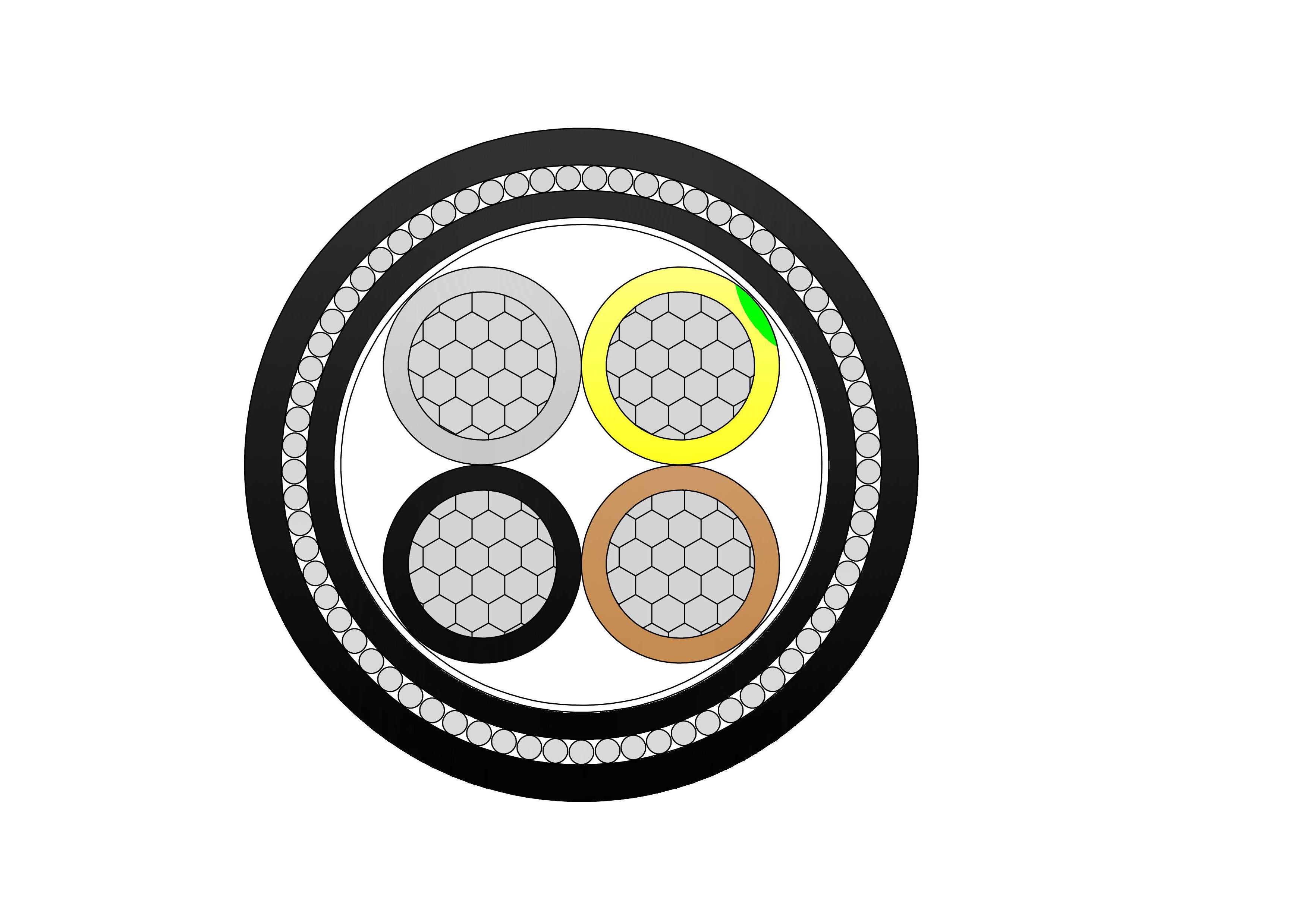

Copper cables offer excellent performance under high-temperature conditions and maintain conductivity even during fire exposure. Specialized solutions such as mineral insulated copper cable are widely used in critical systems where fire resistance and circuit integrity are mandatory.

Aluminum conductors require careful insulation selection and proper protection to achieve equivalent safety levels. In many installations, aluminum is paired with advanced insulation systems and armored designs to ensure compliance with safety codes.

Cost and Economic Considerations

From a procurement perspective, aluminum cable is typically 30–50% less expensive than copper cable. For large-scale electrical systems, this cost difference can significantly impact project budgets.

However, engineers must consider total lifecycle cost, including:

- Installation labor

- Termination requirements

- Maintenance frequency

- Service life

In smaller systems or environments requiring compact routing, copper often proves more cost-effective over time despite higher initial material cost.

Typical Applications in Electrical Systems

|

Application Area |

Preferred Conductor |

Reason |

|

Commercial buildings |

Copper conductors |

Compact size, high reliability |

|

Power distribution feeders |

Aluminum conductors |

Cost efficiency, lightweight |

|

Fire-resistant circuits |

Copper cable |

Superior heat resistance |

|

Underground installations |

Aluminium armoured cable |

Mechanical protection |

|

Industrial machinery |

Copper wire |

High strength and flexibility |

Compliance with Electrical Codes

Both copper and aluminum conductors are widely accepted under international electrical standards when properly designed and installed. Modern electrical systems rely on strict adherence to conductor sizing, termination practices, and insulation requirements regardless of material choice.

Field experience consistently shows that most failures are caused not by conductor material itself, but by improper installation, undersized cables, or incorrect terminations.

Practical Selection Guidance

From an engineering and construction standpoint:

- Choose copper conductors where space is limited, reliability is critical, or frequent terminations are required.

- Choose aluminum conductors for long-distance power transmission, large feeders, and cost-sensitive projects with proper installation controls.

The most effective electrical designs consider both materials as complementary solutions rather than competitors.

Both copper and aluminum conductors play essential roles in modern wires and cables infrastructure. Copper delivers superior conductivity, mechanical strength, and long-term stability, while aluminum offers economic and logistical advantages for large-scale power distribution.

By understanding the real-world performance characteristics of each material, engineers, contractors, and project managers can make informed decisions that optimize safety, efficiency, and total project value in today’s evolving electrical landscape.