Top Electrical Transformer Bushing Solutions for Power Transformers

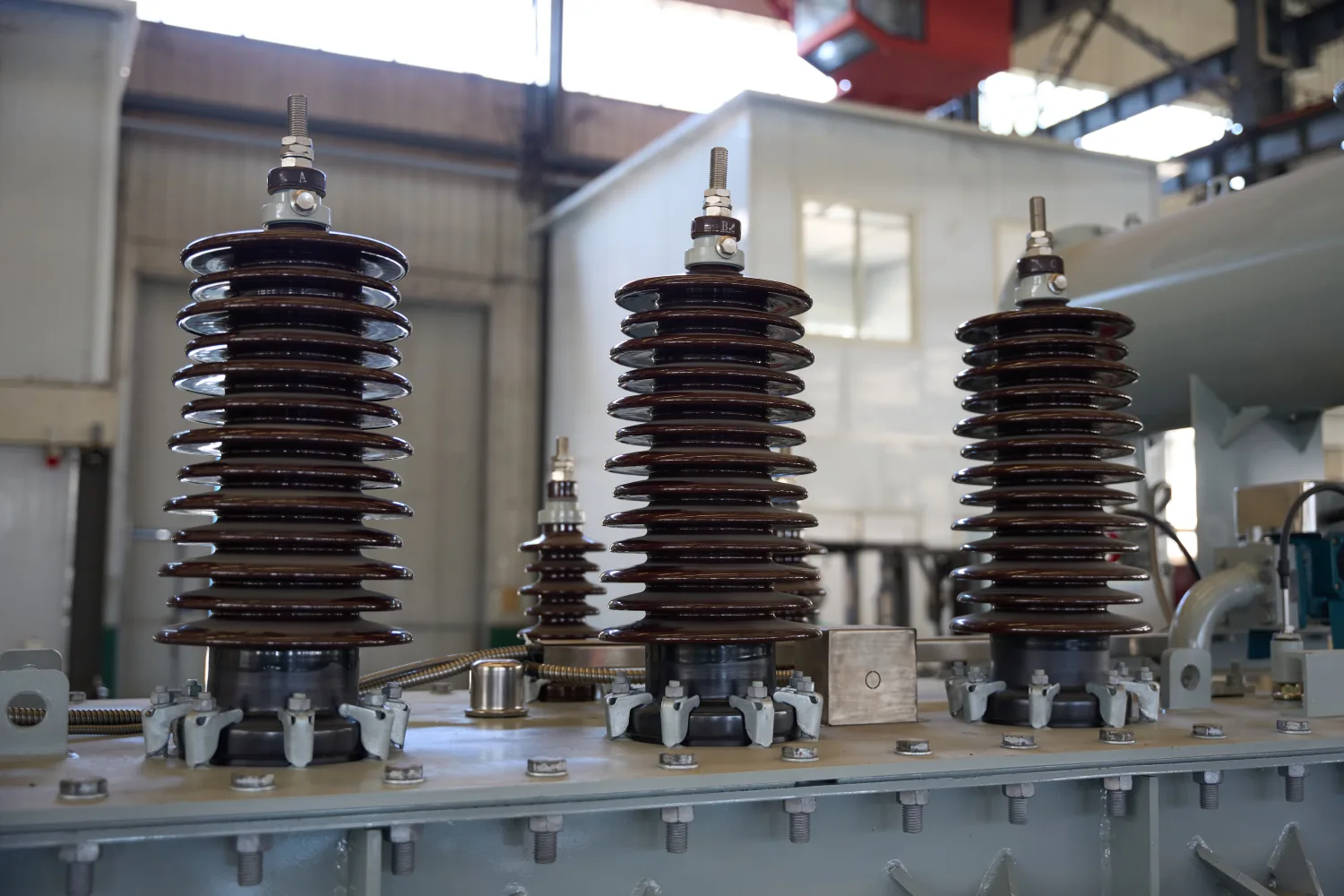

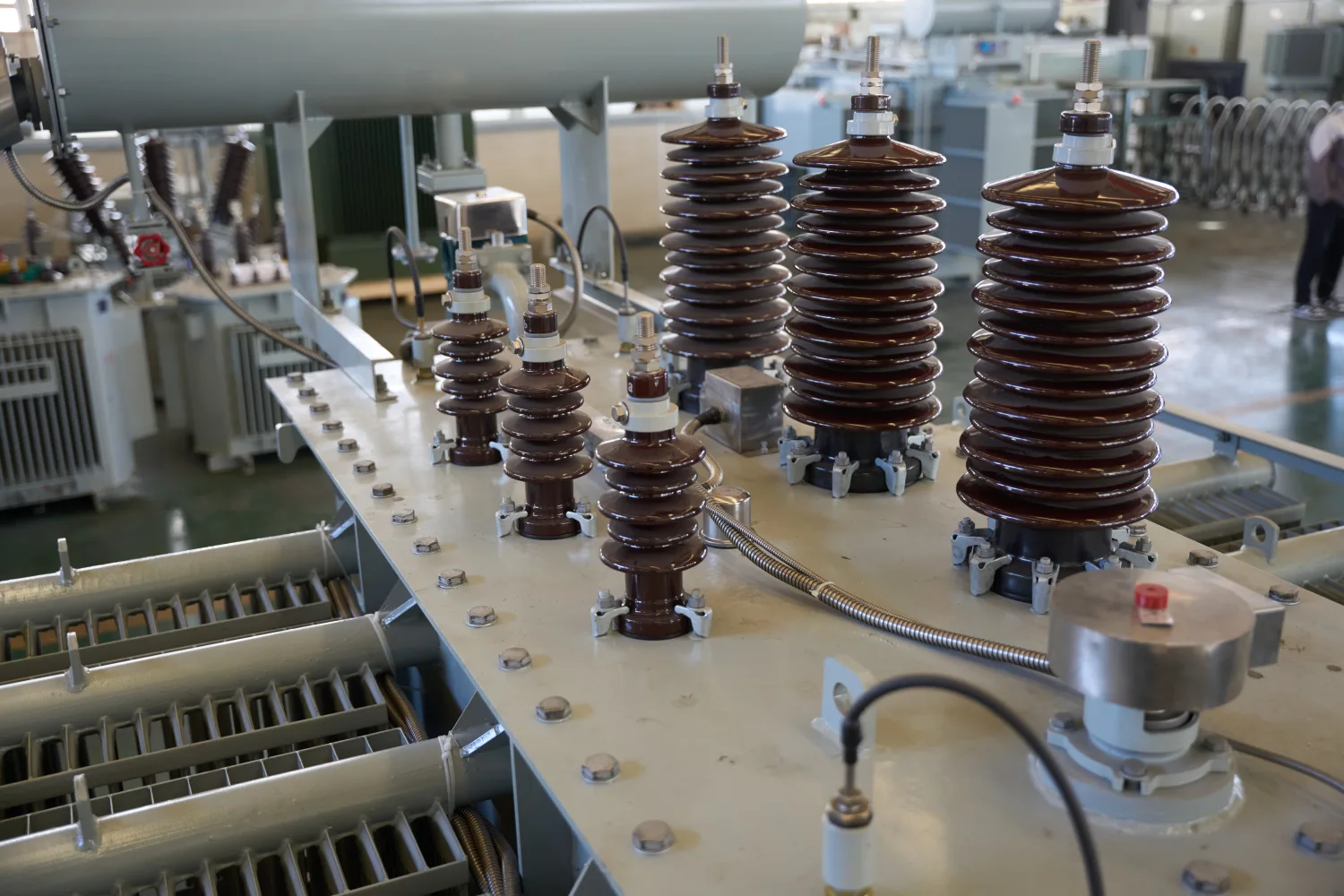

Transformer bushings play an indispensable and crucial role in power systems. They are not only vital channels for electrical connections between transformers and the outside world, but also core insulating components ensuring the safe transmission of high-voltage electricity. As a bridge carrying high voltage and high current, bushings must possess excellent insulation performance, the ability to withstand strong electric field stress, and maintain stability during long-term operation. In modern power systems, whether it's high-voltage transmission transformers, distribution transformers, or large power equipment in power plants and substations, transformer bushings undertake critical functions such as preventing electrical breakdown, reducing partial discharge, and ensuring the safe lead-out of conductors.

With the continuous increase in grid capacity and the sustained rise in system voltage levels, transformer bushings have also undergone continuous upgrades in structural design, material selection, and insulation technology. For example, the widespread application of new technologies such as capacitive graded bushings, composite material bushings, and dry-type capacitive bushings enables them to maintain high reliability even under high voltage, high load, and complex environments. A thorough understanding of the types, insulation principles, and operating requirements of transformer bushings is not only helpful in optimizing the design of power equipment but also of great significance for improving the safety and stability of the entire power system.

Understanding Transformer Bushings

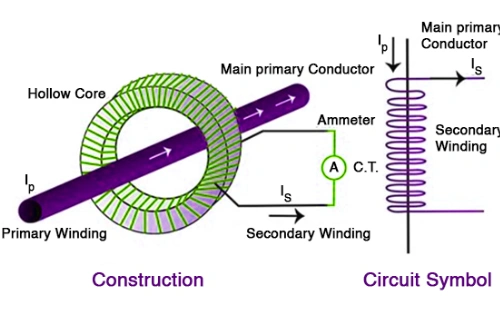

Transformer bushings are insulating components that allow the electrical current to pass through a transformer’s outer casing to the grid without causing a short circuit or breakdown of the insulating materials. Bushing current transformers play a vital role by measuring the current passing through the bushing, making them essential in monitoring and controlling power flow. The bushing in the transformer ensures that the internal electrical system remains properly insulated from the environment, maintaining operational safety and efficiency.

Types of Transformer Bushings

Voltage Bushings

Voltage bushings are essential in managing the high-voltage current passing from the transformer to the power grid. These bushings are specifically designed to handle the electrical stresses generated by higher voltage systems. In high-voltage transformers, bushing insulation must be able to withstand large amounts of electric field stress without breaking down.

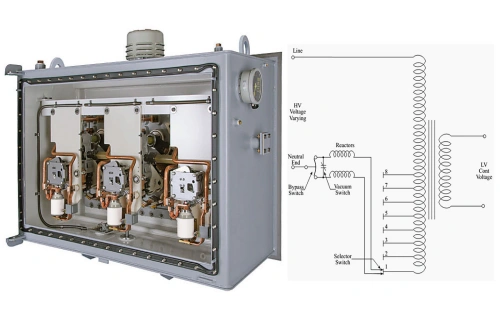

Capacitance Graded Bushings

Capacitance graded bushings are designed to distribute the electric field stress evenly across the transformer bushing. These bushings allow for better control of electrical stresses, preventing the creation of hotspots that could lead to failures. They use a graded insulation system to ensure that the electrical field is evenly distributed, enhancing transformer performance and longevity.

Condenser Type Bushings

Condenser-type bushings are often used in transformers operating at high voltages, providing better insulation and enhanced performance in demanding environments. These bushings consist of multiple layers of insulation that progressively decrease in capacitance as the voltage increases. This design helps reduce the electric field stress across the entire bushing, ensuring a more efficient and safe operation.

Porcelain vs. Composite Bushings

Traditionally, transformer bushings were made of porcelain, offering excellent mechanical strength and insulation properties. However, composite bushings have gained popularity due to their lightweight nature and enhanced resistance to environmental factors such as moisture, corrosion, and contamination. Both materials have their advantages, but composite bushings are often favored in applications requiring frequent handling or exposure to harsh weather conditions.

Technical Table

| Bushing Type | Key Feature | Typical Application | Advantages |

| Voltage Bushings | Designed to manage high voltage current and electrical stress | High voltage transformer applications | Superior insulation, reliable in high-stress environments |

| Capacitance Graded Bushings | Even distribution of electrical stresses through insulation | Suitable for high-voltage power transformers | Minimizes electric field stress, improves operational reliability |

| Condenser Type Bushings | Multi-layered insulation system with varying capacitance levels | High voltage and high power transformers | Excellent for high voltage, improves insulation performance |

| Porcelain Bushings | Traditional bushing material is known for its strength | General power transformers and distribution systems | Durable and strong, widely used for industrial and utility applications |

| Composite Bushings | Lightweight, resistant to environmental contamination | Areas with high environmental exposure, renewable energy systems | Corrosion-resistant, suitable for harsh conditions and frequent handling |

Transformer Bushing Design and Insulation

When selecting transformer bushings, the bushing design and bushing insulation are the most important factors to consider. Insulation materials must be chosen based on the transformer’s voltage rating, environmental conditions, and the specific operating requirements. The insulation system should be designed to handle electric field stress and to prevent breakdowns under operational conditions.

Capacitance graded bushings and condensed type bushings are commonly used in high-voltage transformers to minimize electrical stresses. The overall bushing design must ensure that the conductor passes safely through the insulating material, allowing the electrical current to flow without causing damage to the transformer or the power system.

Factors Affecting Transformer Bushing Performance

Several abiotic factors can affect the performance and lifespan of transformer bushings. These include temperature fluctuations, moisture, dirt, and environmental contamination. Over time, these factors can degrade the bushing insulation, increasing the risk of failure. Regular inspection and maintenance are critical to ensure the bushings continue to operate optimally.

Additionally, understanding how the conductor passes safely through the bushing is essential for ensuring the transformer operates at peak efficiency. If the conductor is not properly sized or the bushing is not correctly installed, the transformer’s performance could be compromised.

Selecting the Right Transformer Bushing for Power Transformers

When selecting a transformer bushing, it’s important to consider factors such as:

-

Voltage rating: Higher voltage bushings must withstand greater electrical stresses.

-

Insulation type: Choose between condensers or capacitance graded insulation based on your application.

-

Environmental conditions: Consider abiotic factors like temperature, humidity, and exposure to chemicals.

-

Safety requirements: Ensure the bushing meets all safety standards, particularly for high-voltage applications.

By carefully evaluating these factors, you can choose the right bushing that ensures long-term reliability and minimizes the risk of transformer failure.

Maintenance and Best Practices

Maintaining transformer bushings is essential for prolonging their service life and ensuring safe transformer operation. Key practices include:

-

Regular inspections: Check for signs of damage, wear, or contamination.

-

Cleaning: Keep bushings clean and free from debris to prevent insulation breakdown.

-

Testing: Conduct periodic tests to assess bushing performance and electrical integrity.

Transformer bushings are essential components in ensuring the safe and reliable operation of power transformers. Whether you’re dealing with high voltage, capacitance graded bushings, or condensers, selecting the right transformer bushing and ensuring proper installation and maintenance will enhance system performance, reduce downtime, and improve safety. By understanding the design, types, and best practices for bushing insulation and electrical stresses, power engineers can optimize the performance of their electrical systems and avoid costly failures.

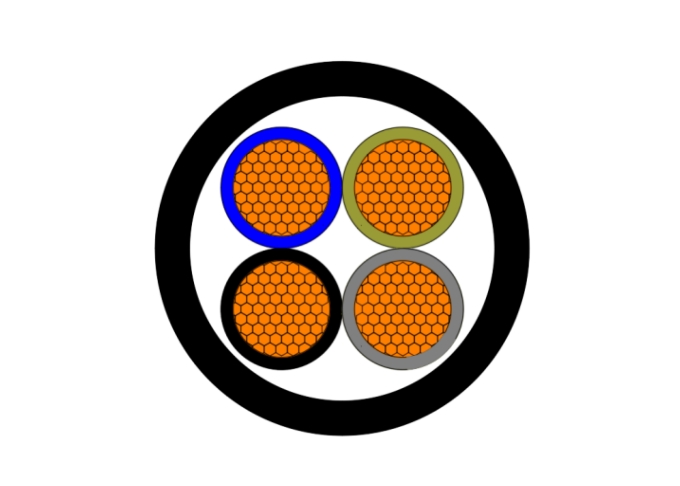

2Y-high-voltage-power-cable-2.webp)

2Y-high-voltage-power-cable-2.webp)