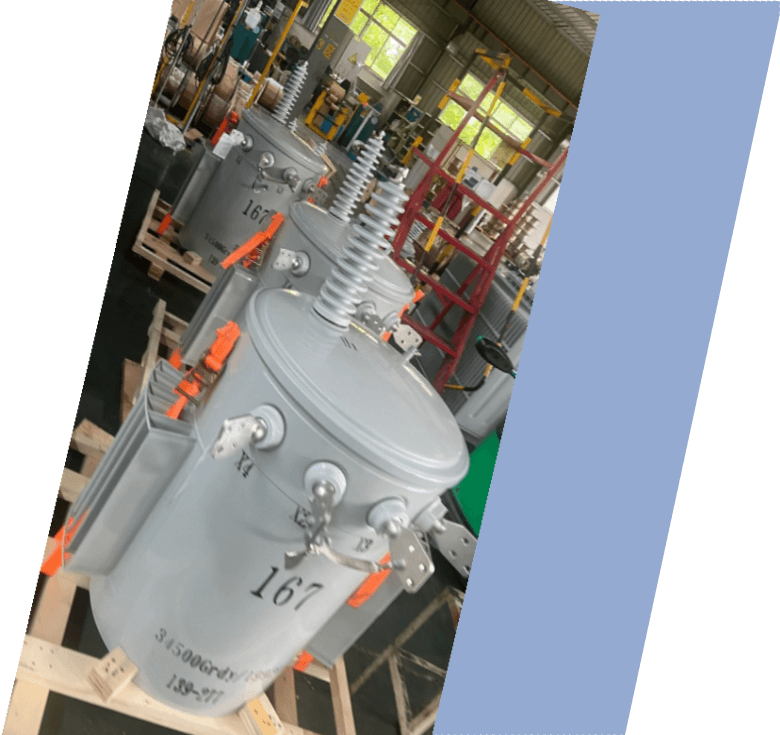

150kVA Single Phase Pole Mounted Transformer

- Primary Voltage Ratings 2.4kV, 11kV, 33kV, 34.5kV

- Secondary Voltage Ratings 480-240/240-120 or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Conventional Type

- BIL 30-150kV

- Standards IEEE, ANSI, NEMA, ASTM

- Application small businesses, warehouses, and streetlights

- Power Rating 150kVA

- Certificate CE, ISO

- Cooling Method ONAN, KNAN

- Oil Mineral Oil or FR3

- Opeartion Step Down

Technical Specifications

| Rated Power | 150kVA |

| Rating Primary Voltage | 12.4-34.5kV |

| Secondary Voltage | 480-240V 240-120V 277V Customized |

| Frequency | 50/60Hz |

| Vector Group | Ii0,Ii6 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 2% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 130 kg |

| Total Weight | 600 kg |

| Outline Dimensions(W×D×H) | 790×850×1305 (mm) |

| Lifting Lug |

| Tap Changer |

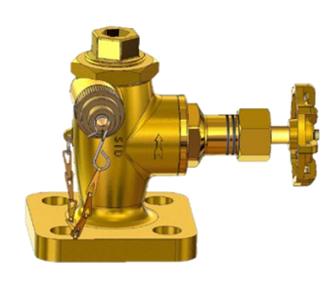

| Pressure Relief Valve |

| Tank Cover and clamp |

| L.V Bushing |

| HV Bushing |

| Ground Strap |

| Nameplate |

| Non-PCB decal |

| High Voltage Warning Signs |

| Suport lug |

| Oil fill valve |

Customization Optional

Packing and Shipping

For shipping, we coordinate multimodal logistics tailored to destination requirements. Domestic deliveries often use flatbed trucks with specialized trailers for oversized loads, securing the crate with chains and tarps to shield from weather. International shipments favor ocean freight via 20-foot or 40-foot containers, or roll-on/roll-off vessels for larger units, with corrosion inhibitors applied for saltwater exposure. Air freight is reserved for urgent needs, though rare due to size constraints. Real-time tracking via GPS ensures visibility, and insurance covers potential damages. Compliance with international standards like IEC and IEEE guarantees smooth customs clearance, reducing delays in global distribution of the 150kVA single phase pole mounted transformer.

Environmental considerations guide our packing process, incorporating recyclable materials where possible to align with sustainable practices. For high-value shipments, we include impact recorders to monitor transit forces, allowing post-delivery verification. Pre-shipment inspections confirm all accessories, such as bushings and taps, are securely packed separately if needed. This comprehensive strategy not only protects the equipment but also optimizes costs by selecting efficient routes and carriers experienced in handling electrical gear. Whether shipping to remote rural sites or urban hubs, our methods ensure the transformer is ready for immediate installation upon arrival.

Finally, upon receipt, we provide detailed unpacking guidelines to prevent mishandling. This includes torque specifications for reassembly and oil level checks post-transport. Our logistics partners specialize in heavy equipment, adhering to DOT regulations for road hauls and IMO standards for maritime. By prioritizing safety and efficiency, we deliver the 150kVA single phase pole mounted transformer worldwide, supporting seamless integration into power grids while minimizing downtime and operational disruptions.

Manufacturer Test

Progress Test

During the manufacturing of the 150kVA single phase pole mounted transformer, progress tests begin with core assembly verification, where high-quality silicon steel laminations are inspected for burr-free cuts and proper interleaving to ensure low no-load losses. Winding resistance is measured using a micro-ohmmeter on both primary and secondary coils at ambient temperature, confirming values align with design specs within 0.5% tolerance to detect any loose connections or material defects early. Insulation resistance testing follows, applying 2500V DC between windings and ground for one minute, aiming for readings exceeding 1000 megohms to verify dielectric strength and moisture absence. Turns ratio assessment employs a TTR tester across all tap positions, validating the exact voltage transformation ratio against nameplate data with accuracy better than 0.5%. Magnetic balance checks involve applying voltage to one winding phase and measuring induced voltages in others, ensuring symmetry within 5% deviation to confirm uniform flux distribution. No-load current excitation at rated voltage monitors magnetizing current below 1% of full load, indicating core integrity without excessive hysteresis losses. Partial discharge testing under high voltage detects any internal voids or impurities by limiting noise to under 100pC, safeguarding long-term reliability.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

The factory acceptance test for the 150kVA single phase pole mounted transformer commences with a thorough visual inspection of the unit, checking dimensions, paint finish, nameplate accuracy, and welding quality to ensure compliance with drawings and no transport-induced damage. DC winding resistance is measured on primary and secondary sides using the volt-amp method, with current limited to 15% of rated, verifying values match factory benchmarks within 1% after temperature correction to 75°C. Turns ratio testing across all taps uses a precision TTR instrument, confirming ratios align with specifications to 0.5% accuracy, while polarity is validated via additive/subtractive checks. Insulation resistance employs a 5000V megger for one minute between windings, core, and tank, requiring over 2000 megohms at 20°C. Power factor or tan delta testing on bushings and windings at 10kV measures dissipation below 0.5%, detecting moisture or contamination. No-load loss and excitation current are assessed at rated voltage and frequency, ensuring losses stay under guaranteed values per DOE standards. Load loss and impedance are determined by short-circuiting the secondary and applying reduced voltage to the primary, calculating efficiency above 98%. Applied voltage withstand tests ramp to 34kV on the primary for one minute without breakdown. Partial discharge monitoring during overvoltage holds levels below 50pC. Oil samples undergo dielectric strength testing above 40kV and DGA for gas content under 50ppm.

Routine Test - On load Loss Test

Voltage source and current source (usually rated voltage, or adjusted according to the test standard, such as 10 KV, 20 KV, 35 KV, etc.)

Temperature and humidity meter (used to record ambient temperature and humidity for correction of test data)

The test environment should be dry and rainless, with a relative humidity of less than 75% and a recommended temperature range of 20–30°C.

Connect the test equipment to the appropriate terminals of the device under test and ensure that all wiring is correct and the device is well grounded.

Apply Test Voltage:

Apply the specified test voltage at the rated frequency and adjust the low voltage side to maintain the rated current (or specified current).

On-Load Loss Power

Input Power and Output Power

Current

Voltage

Temperature (temperature rise or winding temperature)

Ambient temperature and humidity during the test

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.