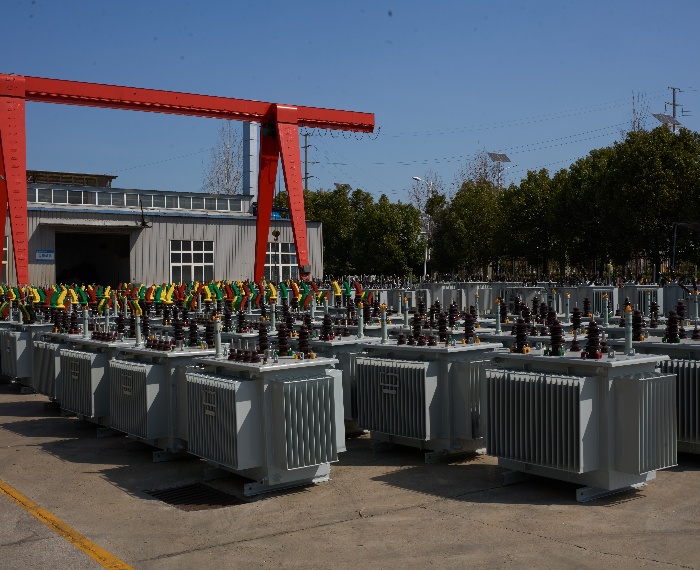

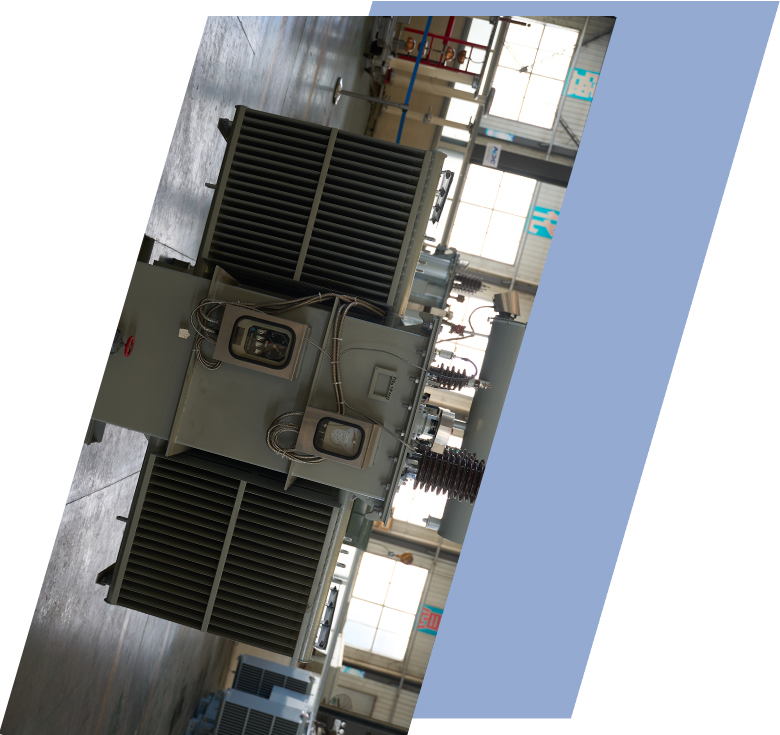

31500kVA 35kV Oil-Immersed Copper Transformer For Substation

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 33 or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Oil immersed transformer

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA, IEC, CE

- Application Power Substations, Industrial Power Supply

- Power Rating 31500kVA

- Certificate UL, CESI, IEEE

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 31500 kVA | |

| Rating Primary Voltage | 2.4 - 34.5kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| Insulating Oil Weight | 9500 kg | |

| Total Weight | 37600 kg | |

| Outline Dimensions(L×W×H)in. | 5200 × 3840 × 4400(mm) | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

Packing and Shipping

For further protection, the 31500kVA transformer is wrapped with multi-layer protective materials, including shock-absorbing padding, waterproof covers, and high-strength binding straps. Sensitive components such as OLTCs, temperature gauges, and monitoring devices are either removed and boxed separately or reinforced with protective shields. Accessories, spare parts, and documentation—including test reports, manuals, and quality certificates—are packed in individual crates and clearly labelled for easy identification upon arrival at the site.

Shipping options are arranged according to customer requirements, destination, and project timeline. For domestic transport, the transformer is typically moved by a heavy-duty truck equipped with specialised suspension systems that minimise vibration. For international shipping, the unit is loaded onto flat racks or open-top containers using cranes with certified lifting points to avoid structural stress. All lifting, loading, and securing operations are performed by trained professionals following international standards such as IEC, ISO, and maritime regulations. During transit, GPS tracking and shock monitoring devices may be installed to observe the transformer's status in real time.

Upon reaching the destination, unloading procedures are coordinated with the site team to ensure safe handling. The packaging is removed only after a final inspection is completed, confirming the 31500kVA 35kV oil-immersed copper transformer has arrived without damage. This comprehensive packing and shipping process guarantees that every unit is delivered safely, efficiently, and in optimal condition for immediate deployment.

Manufacturer Test

Progress Test

During the manufacturing of the 31500kVA 35kV Oil-Immersed Copper Transformer, rigorous Progress Tests are conducted at key stages to ensure premium quality and compliance with IEC 60076 standards.

After core-coil assembly, tests include winding DC resistance at all taps, insulation resistance between copper windings and core (PI ≥ 2.5), core grounding current (<100 mA), and preliminary no-load loss measurement. Before tanking, the voltage ratio at principal and extreme taps (deviation ≤ ±0.5%) and vector group (typically Yd11 or Dyn11) are verified.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Conducted per IEC 60076 with client/third-party witness:

- Winding resistance at all taps

- Ratio & vector group verification (deviation ≤±0.5%)

- No-load loss & current at 90%-110% voltage

- Load loss & impedance at rated current

- Separate-source & induced withstand voltage with PD (<10 pC at 1.5Um/√3)

- Full-wave lightning impulse 170 kV peak (HV)

- Insulation resistance, PI (≥2.5), tanδ, oil BDV

- Temperature rise test (when specified)

- OLTC 10-cycle operation at max current

- Final accessory & painting inspection

Official protocol signed upon acceptance, ensuring the 31500kVA 35kV Oil-Immersed Copper Transformer is fully qualified for reliable high-voltage service.

Routine Test - Lightning Impulse

Check all terminals and connections to ensure they are secure and free of contamination.

Perform the test under suitable environmental conditions: relative humidity less than 75%, temperature between 20-30°C, no rain.

Current waveform Impedance

Reaction voltage waveform

Ambient temperature and humidity during testing

The voltage waveform meets the standard requirements, and the equipment does not have abnormal discharge or local breakdown: good

Obvious damage or non-standard waveform during the test: Further inspection or corrective measures are required

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.