The Future of Factory Production with Automation Technology: From AI Robots to Smart Manufacturing

In modern manufacturing, automation technology plays a crucial role in reshaping factory production. From traditional assembly lines to smart factories powered by AI-powered robotics and information technology automation, companies are exploring ways to optimize processes, improve efficiency, and reduce the physical burden on workers. So, what is automation technology, and why is it so crucial to modern production lines?

Automation technology refers to the application of control systems, robotics, and computer software to perform tasks with minimal human intervention. In a factory context, it covers everything from automated conveyor belts to advanced industrial automation technology that integrates artificial intelligence, sensors, and real-time monitoring. The goal is not to replace workers but to help them focus on higher-value tasks while routine, repetitive, or hazardous activities are handled by machines.

What is Automation Technology?

At its core, automation technology is the use of machines and digital systems to complete tasks automatically. This includes:

- Mechanical Automation – Machines that replace manual work, such as robotic arms for welding or packaging.

- Information Technology Automation – Software that manages production schedules, inventory tracking, and predictive maintenance.

- AI Robots – Intelligent machines capable of learning, adapting, and performing complex tasks in dynamic environments.

This combination ensures both physical tasks and decision-making processes are automated, creating a seamless flow in production lines.

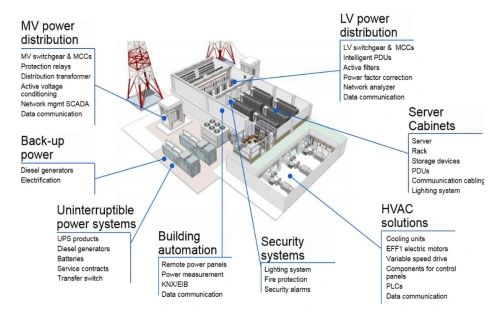

Industrial Automation Technology in Factories

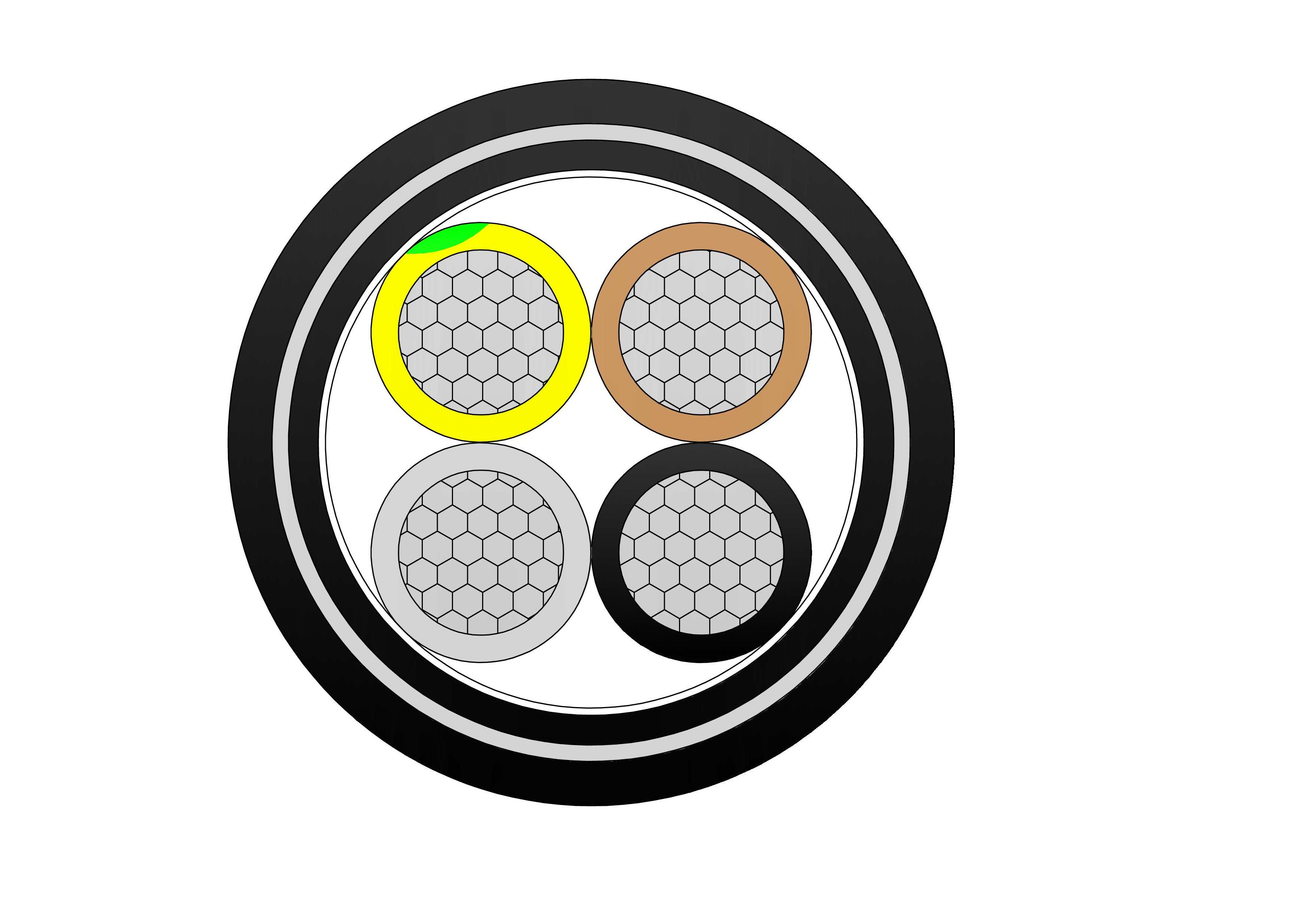

Industrial automation technology has advanced rapidly with the rise of Industry 4.0. Factories today integrate:

- Sensors and IoT Devices – For monitoring temperature, vibration, or machine performance in real time.

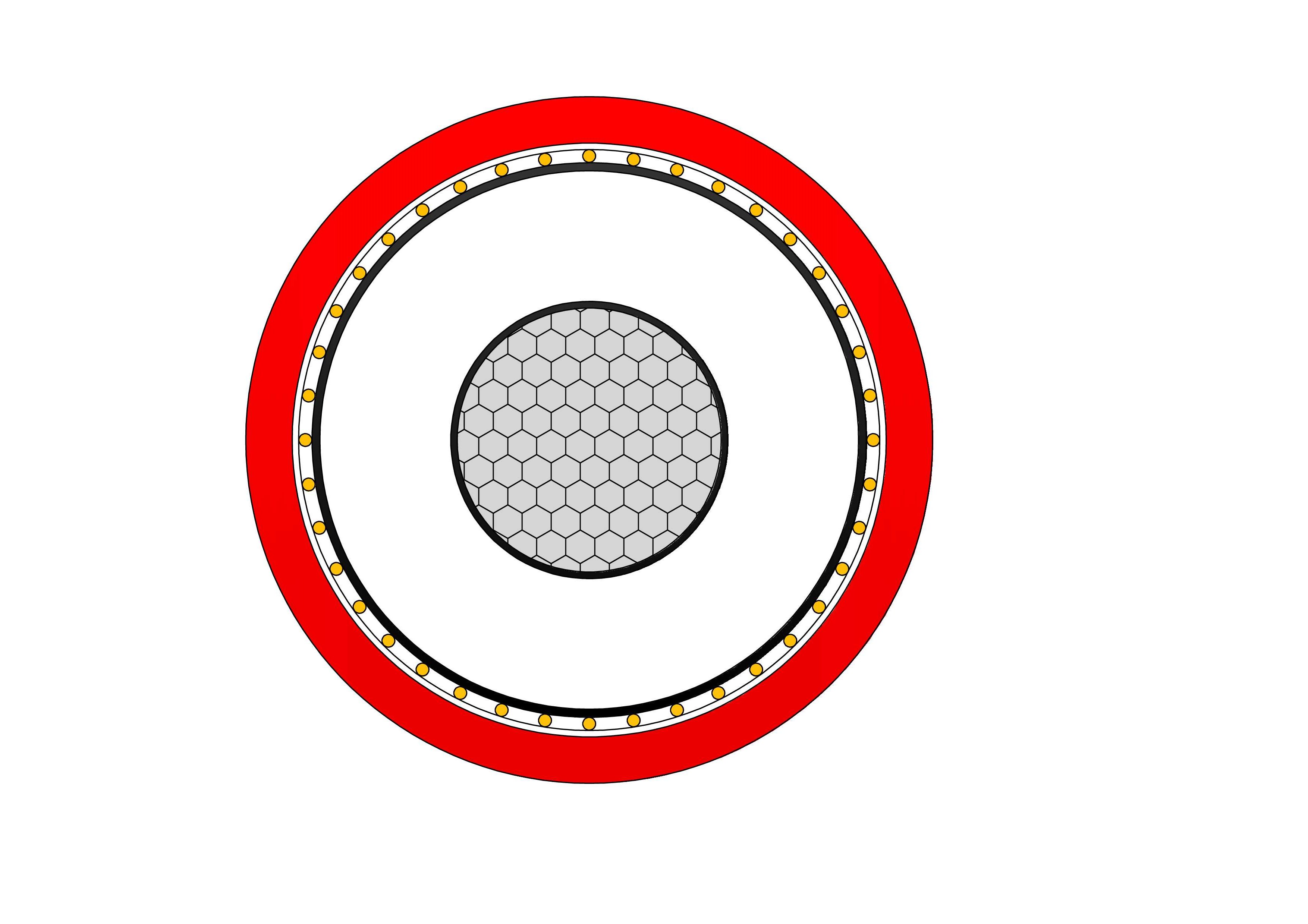

- Robotics – High-precision robotic arms that can perform repetitive tasks such as assembly, welding, or painting.

- AI and Machine Learning – Used in quality control systems to detect defects faster than human inspectors.

- Automated Business Technologies – Enterprise-level systems that connect production, supply chain, and marketing into a unified platform.

This ecosystem transforms factories into smart production environments, where efficiency is maximized, downtime is reduced, and worker safety is enhanced.

Benefits of Automation for Workers and Factories

Automation technology is often misunderstood as a threat to human labor. In reality, its purpose in factory production is to reduce physical strain, minimize risks, and create new opportunities. Key benefits include:

- Reducing Heavy Manual Labor

Workers no longer need to handle dangerous or physically exhausting tasks. For example, automated forklifts transport heavy materials safely, while AI robots manage repetitive assembly. - Improving Productivity

Machines can operate continuously without fatigue, ensuring faster production rates. Combined with information technology automation, production schedules are optimized with minimal delays. - Enhancing Worker Safety

Dangerous environments, such as high-temperature furnaces or chemical plants, can now be managed by automated systems, reducing the risk of accidents. - Creating Higher-Skilled Jobs

While repetitive labor decreases, new roles in robot programming, data analysis, and system maintenance emerge, giving workers career development opportunities.

Information Technology Automation in Production

Information technology automation plays a hidden but critical role in factory operations. It includes:

- Predictive Maintenance – Using AI to analyze machine data and predict when equipment might fail, preventing costly downtime.

- Supply Chain Management – Automated tracking systems ensure raw materials arrive just in time for production.

- Data Integration – Connecting machines, departments, and even external suppliers into one transparent ecosystem.

This ensures that production runs smoothly, workers receive real-time alerts, and managers can make faster, data-driven decisions.

The Role of AI Robots

AI robots represent the most advanced level of automation in factories. Unlike traditional robots, they learn from data, adapt to new tasks, and collaborate with humans. For example:

- Collaborative Robots (Cobots): Designed to work side by side with humans, assisting in assembly or inspection.

- Autonomous Mobile Robots (AMRs): Capable of navigating factory floors independently, delivering parts where needed.

- AI-Powered Quality Control: Robots equipped with vision systems can detect product flaws that are invisible to the human eye.

By taking over monotonous or hazardous tasks, AI robots allow workers to focus on problem-solving and innovation.

Marketing Automation Technology Updates in Manufacturing

Although often associated with sales, marketing automation technology updates are increasingly relevant in factory production. Manufacturers now use similar systems to:

- Automate communication between production and suppliers.

- Provide real-time order updates to customers.

- Use customer demand data to adjust production schedules automatically.

This creates a customer-driven production model, where factories respond quickly to market changes without overburdening workers.

Challenges and Future Trends

Despite its benefits, automation in factories comes with challenges:

- High Initial Costs – Installing robots and IT systems requires significant investment.

- Skill Gap – Workers need training to manage and maintain automated systems.

- Integration Issues – Legacy machines may not easily connect with modern automated technologies.

Looking ahead, industrial automation technology will become more affordable and user-friendly. AI robots will continue evolving, making factories more flexible, adaptive, and worker-friendly. The focus will be on human-robot collaboration, where machines handle routine tasks while humans bring creativity and problem-solving skills.

Automation technology in factory production is not about replacing workers but empowering them. From information technology automation to AI robots, factories are becoming smarter, safer, and more efficient. By reducing physical strain, enhancing safety, and streamlining operations, automation enables workers to focus on higher-value activities while companies boost productivity and competitiveness.

As automated business technologies and industrial automation technology continue to evolve, the future of factory production lies in collaboration between humans and machines—a future where workers are relieved from burdensome tasks and empowered to thrive in an advanced industrial ecosystem.