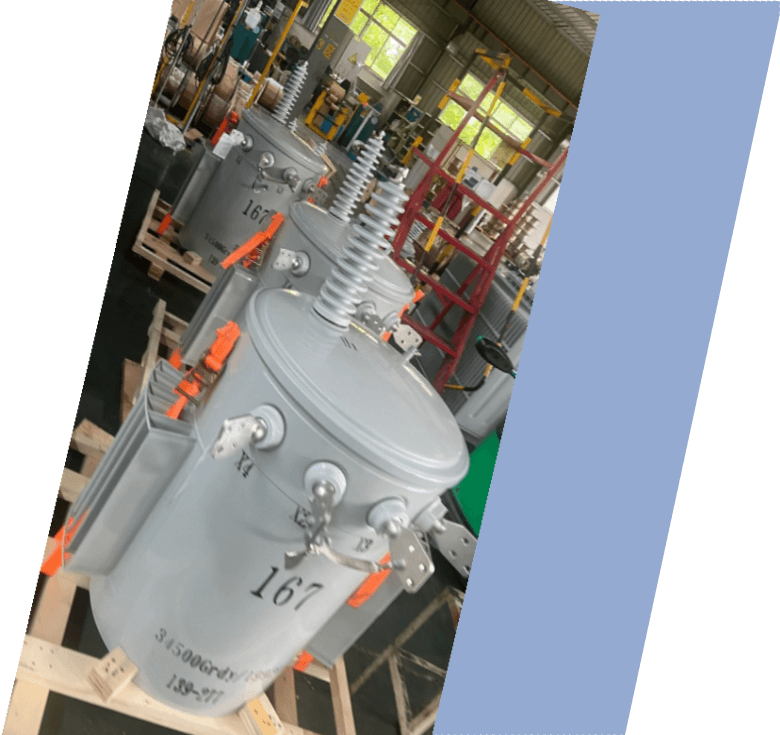

11kV Single Phase Pole Mounted Transformer

- Primary Voltage Ratings 10.5kV-11.5kV or others

- Secondary Voltage Ratings 230V、240V、220/440V 或 415V

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Conventional Type

- BIL 11 kV

- Standards IEEE, ANSI, NEMA, ASTM

- Application Residential, commercial, agricultural and light industrial

- Power Rating 5kVA - 333kVA

- Certificate CE, ISO

- Cooling Method ONAN, KNAN

- Oil Mineral Oil or FR3

- Opeartion Step Down

Technical Specifications

| Rated Power | 5kVA - 333kVA |

| Rating Primary Voltage | 10.5kV-11.5kV |

| Secondary Voltage | 480-240V 240-120V 277V Customized |

| Frequency | 50/60Hz |

| Vector Group | Ii0,Ii6 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 2% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Lifting Lug |

| Tap Changer |

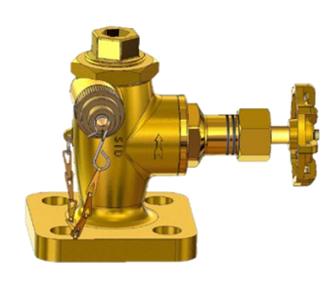

| Pressure Relief Valve |

| Tank Cover and clamp |

| L.V Bushing |

| HV Bushing |

| Ground Strap |

| Nameplate |

| Non-PCB decal |

| High Voltage Warning Signs |

| Suport lug |

| Oil fill valve |

Customization Optional

Packing and Shipping

Shipping is tailored for efficiency, with domestic routes using flatbed trucks or specialized trailers equipped with secure tie-downs and weather covers to protect against elements. International transport favors 20/40-foot containers or flat-racks for ocean freight, with anti-corrosion measures for marine exposure and lashing compliant to IMO standards. Urgent needs may use air cargo, though size typically favors sea or road. Real-time GPS tracking and comprehensive insurance cover the journey, while adherence to IEC, customs, and export regulations speeds clearance and minimizes delays for global delivery of the 11kV single phase pole mounted transformer.

Sustainability informs our approach, utilizing recyclable materials and route optimization to reduce emissions. Impact detectors on crates record transit conditions for post-delivery checks. Accessories like arresters or fuses ship separately with checklists for verification. Experienced carriers in heavy electrical goods manage oversized loads, securing permits and following safety protocols across terrains.

Upon arrival, unpacking guides detail safe handling, oil refilling, and torque specs for connections. We coordinate site delivery, including route planning for remote poles. This complete process guarantees the 11kV single phase pole mounted transformer reaches installation sites intact, ready for swift commissioning and reliable service in overhead power systems.

Manufacturer Test

Progress Test

Midway in assembly for the 11kV single phase pole mounted transformer, short-circuit impedance testing injects low voltage to target 4-4.5% with minimal variance. Polarity checks employ DC methods for correct orientation. Thermal previews via current heating monitor temperature gradients. Vacuum drying verifies moisture removal below 0.5%. Tap changer cycling tests mechanical reliability and contact resistance under 1 milliohm. Cooling circuit flow simulation confirms unobstructed paths. Wiring insulation megger tests exceed 500 megohms at 1000V. Protective device simulations validate response. Reports align with IEC 60076, enabling pre-final adjustments. Inter-layer insulation hipot testing applies stepped voltages to detect weaknesses early. Turns ratio preliminary verification uses ratio meters to confirm accuracy within 0.2% across taps. Core flux density is gauged with meters to avoid saturation. Oil quality sampling ensures breakdown voltage above 30kV and low acidity.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Factory acceptance testing for the 11kV single phase pole mounted transformer opens with visual and dimensional inspections against drawings, verifying tank quality, bushing positions, and labeling. Winding DC resistance uses precise bridges, temperature-corrected to reference, within 1% tolerance. Turns ratio and polarity across taps confirm with TTR accuracy to 0.3%. Power factor/dissipation at 10kV limits tan delta below 0.5%. No-load loss and current at rated voltage meet efficiency specs, excitation under 2%. Load loss and impedance via short-circuit method yield accurate efficiency. Power frequency withstand applies 28kV for one minute without breakdown. Induced voltage tests insulation at higher frequency. Oil tests include dielectric over 35kV and low DGA gases. Advancing FAT for the 11kV single phase pole mounted transformer, impulse testing at 75kV BIL checks waveform integrity. Noise levels measure below standards in controlled settings. Temperature rise test simulates load, capping oil/winding rises at 60°C. Accessory functions verify gauges, relief valves, and taps. Frequency response analysis ensures mechanical stability. All results per IEC 60076/IEEE C57 compile in reports with calibration traceability, client witnessing, and corrective actions for approval before shipment.

Routine Test - DC Insulation Resistance Test

Voltage source (usually 500V, 1000V, 2500V, or customized according to customer requirements)

Temperature and humidity meter (used to record the ambient temperature and humidity during the test to ensure that the test conditions meet the standard requirements.)

Perform the test under suitable environmental conditions. It is recommended to have a relative humidity below 75%, no rain, and a temperature range of 20-30°C to avoid moisture or temperature fluctuations affecting the test results.

Connect an insulation resistance tester to the high voltage terminal of the device under test and to ground.

Apply Test Voltage:

Select an appropriate test voltage based on the rated voltage of the equipment .

Insulation resistance value (MΩ)

Applied voltage

Ambient temperature and humidity during testing

500 MΩ ≤ Insulation resistance < 1000 MΩ (good)

100 MΩ ≤ Insulation resistance < 500 MΩ

Insulation resistance < 100 MΩ

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.