Oil Immersed Power Transformer: Price, Specification & Buying Guide

In the fields of electrical engineering and power distribution, oil-immersed power transformers have always been the undisputed reliable mainstay equipment, widely used in power plant step-up substations, 220kV/110kV/35kV transmission and transformation hubs, and 10kV/20kV distribution terminals, undertaking the core tasks of voltage step-up and step-down, power distribution, and system isolation. Based on my years of practical experience participating in domestic and international substation projects, these transformers perform particularly well under continuous high loads, harsh outdoor environments, and frequent short-circuit impacts. Mineral oil not only serves as an insulating medium (dielectric strength ≥40kV/2.5mm), but also efficiently removes heat from the core and windings through natural circulation (ONAN) or forced circulation (OFAF), keeping hot spot temperatures below 95℃ and significantly extending the life of cellulose insulation and copper/aluminum windings to 35-45 years.

Compared to dry-type transformers, oil-immersed transformers are smaller in size and have a stronger overload capacity (150%-200% for short periods) for the same capacity, making them particularly suitable for the hot, humid, and salt-spray-prone coastal regions of the Caribbean and Southeast Asia. In the 110kV step-down substation in the Dominican Republic and the 35kV industrial park project in Indonesia that I led, oil-immersed transformers achieved zero-failure operation during typhoon and thunderstorm seasons, fully demonstrating their comprehensive advantages of high cooling efficiency, low noise (≤60dB), and excellent economic performance. Of course, this is contingent on strictly implementing regular oil chromatography (DGA), moisture detection, and breather maintenance, which are also crucial for ensuring long-term safe operation.

Understanding Oil Immersed Power Transformers

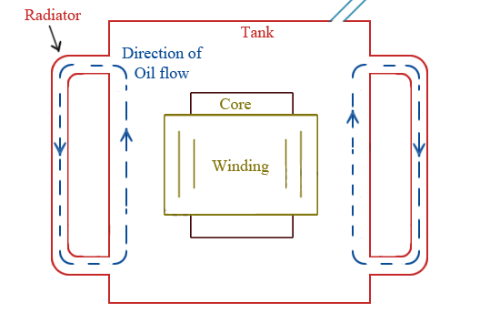

Oil-immersed power transformers, also known as oil-filled transformers, use insulating oil to cool the core and windings while providing electrical insulation. This design allows for efficient heat dissipation, making them ideal for continuous operation under heavy loads. Unlike dry-type transformers, which rely on air cooling, oil-immersed models can handle higher capacities—often up to 500 MVA or more—without overheating.

From a practical standpoint, these transformers are commonly deployed in outdoor substations or indoor vaults where space and fire risks are managed. Their oil acts as a dielectric medium, suppressing arcs and extending component life to 25-40 years with proper maintenance. However, they require spill containment and regular oil testing to prevent environmental hazards or breakdowns.

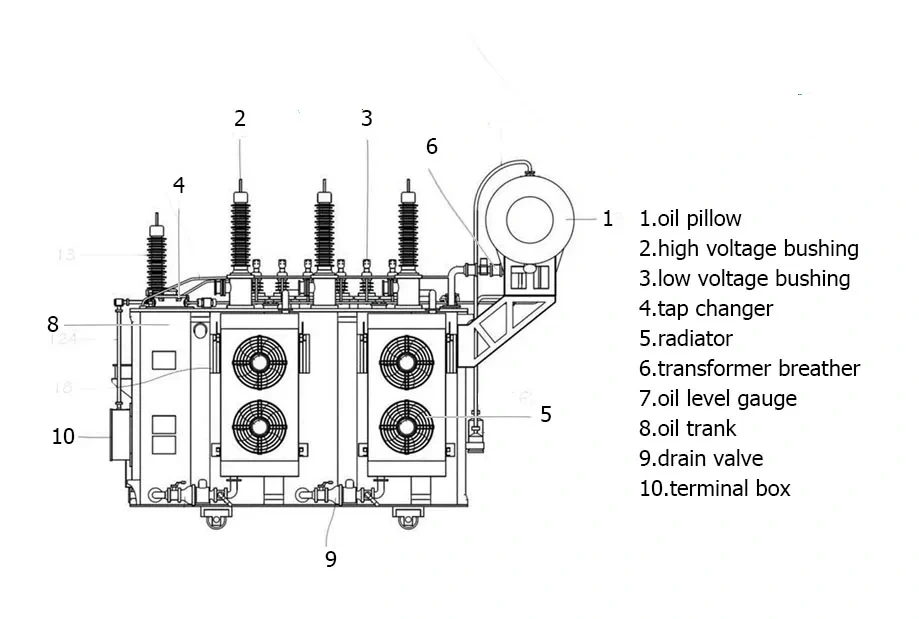

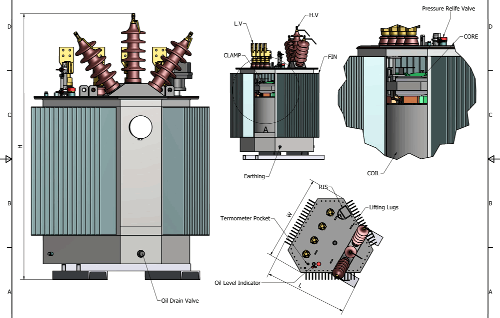

Key components include:

- Core: Made from high-permeability silicon steel laminations to minimize hysteresis losses.

- Windings: Copper or aluminum coils immersed in oil for optimal thermal management.

- Tank: Sealed steel enclosure filled with mineral oil, often with radiators for natural convection.

- Bushings: Porcelain or composite insulators for high-voltage connections.

- Tap Changer: On-load (OLTC) or off-load types for voltage regulation.

In actual installations, I've seen how these elements interact: the oil circulates via natural convection (ONAN) or forced air (ONAF), keeping temperatures below 95°C under full load to avoid insulation degradation.

Detailed Specifications for Oil Immersed Power Transformers

Specifications vary by application, but adherence to standards like IEEE C57.12.00, IEC 60076, and ANSI ensures reliability. Here's a breakdown from real-world data:

- Voltage Ratings: Low (up to 35kV), medium (35-110kV), high (110-220kV). For distribution, 12.47kV primary to 480V secondary is common; transmission units handle 230kV+.

- Capacity (kVA/MVA): Ranges from 10kVA for small pole-mounted units to 500MVA for grid interconnects. Efficiency typically exceeds 98% for modern designs.

- Cooling Systems: ONAN (Oil Natural Air Natural) for base loads; ONAF (Oil Natural Air Forced) adds fans for overloads; OFAF (Oil Forced Air Forced) for extreme conditions.

- Insulation and Oil: Class A insulation (105°C max hotspot); mineral oil with low acidity (<0.05 mg KOH/g) per ASTM D3487.

- Efficiency and Losses: DOE 2016 compliant models minimize no-load losses (e.g., 500W for 1000kVA) and load losses (e.g., 5000W at full load).

- Vector Group: Dyn11 or Yyn0 for three-phase units to manage phase shifts.

To illustrate, consider this table of typical specifications for distribution-level transformers:

|

Capacity (kVA) |

Primary Voltage (kV) |

Secondary Voltage (V) |

Cooling Type |

Efficiency (%) |

Weight (kg) |

Dimensions (L x W x H, m) |

|

100 |

11 |

400 |

ONAN |

98.5 |

800 |

1.5 x 1.0 x 1.8 |

|

500 |

33 |

480 |

ONAF |

99.0 |

2500 |

2.2 x 1.5 x 2.5 |

|

1000 |

66 |

600 |

OFAF |

99.2 |

4500 |

3.0 x 2.0 x 3.0 |

|

20000 (20MVA) |

110 |

11kV |

ONAF |

99.5 |

25000 |

5.0 x 3.5 x 4.5 |

These specs are derived from manufacturer guidelines and can be customized. For instance, in humid Caribbean installations, I've recommended stainless steel tanks to resist corrosion.

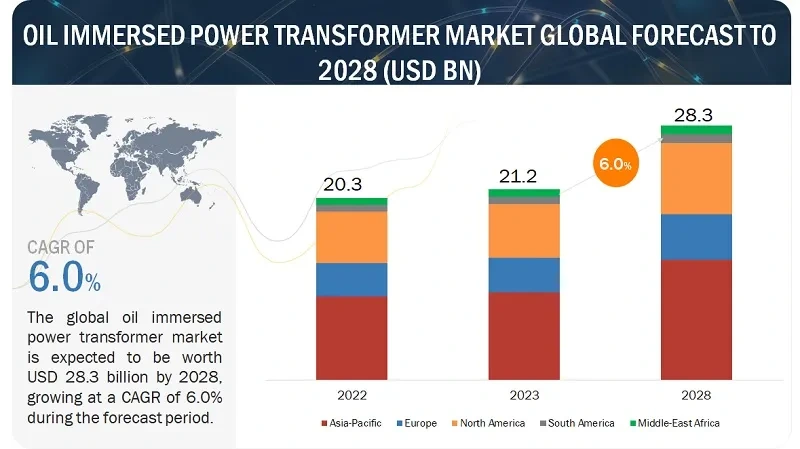

2025 Pricing Trends for Oil Immersed Power Transformers

Pricing in 2025 reflects raw material fluctuations (copper up 15% YoY), supply chain issues, and demand from renewable integrations. Based on market reports, oil-immersed units are 20-40% cheaper upfront than dry-type equivalents due to simpler manufacturing.

General price ranges (USD, ex-works, excluding shipping/taxes):

- 10-50kVA: $200-$800 (small distribution units).

- 100-500kVA: $1,000-$4,000 (medium industrial).

- 630-1250kVA: $5,000-$15,000.

- 20MVA: $150,000-$450,000 (high-voltage substation models).

Factors influencing cost:

- Materials: Copper windings add 20-30% over aluminum.

- Voltage/Features: Higher voltages (e.g., 138kV) increase prices by 50%; OLTC adds $10,000+.

- Certifications: UL-listed or KEMA-tested units cost 10-15% more.

- Market Trends: Global demand pushes prices up 5-10% annually; eco-friendly biodegradable oil options add 5-10%.

Here's a price comparison chart for reference:

In practice, total ownership cost (TCO) includes installation ($5,000-$20,000 for 1000kVA) and maintenance (annual oil tests at $500). I've advised clients to factor in energy savings—high-efficiency models recoup premiums in 3-5 years via reduced losses.

Buying Guide: Step-by-Step from an Engineering Perspective

Purchasing an oil-immersed power transformer isn't just about specs; it's about aligning with your system's demands. Here's a rigorous, field-tested process:

- Assess Needs: Calculate load (kVA), voltage requirements, and fault levels. Use software like ETAP for simulations. Consider future expansion—oversize by 20% for growth.

- Select Type and Standards: Opt for oil-immersed for outdoor/high-load; ensure IEC/ANSI compliance. For utilities, prioritize DOE efficiency.

- Request Quotes: Contact 3-5 manufacturers (e.g., ABB, Siemens, or Chinese exporters like NPC Electric). Provide detailed RFQs with vector group, impedance (5-10%), and BIL (Basic Impulse Level).

- Evaluate Features: Prioritize monitoring (DGA sensors for oil health) and protection (pressure relief valves). In seismic zones, add anti-vibration mounts.

- Compare Oil vs. Dry-Type: Oil-immersed offer better overload capacity (150% for 2 hours) but need fire barriers; dry-type transformers are safer indoors but cost more and run hotter.

- Inspect and Test: Demand factory acceptance tests (FAT) per IEEE C57.12.90, including partial discharge and impulse tests.

- Budget for Logistics: Shipping a 20MVA unit can add $10,000-$50,000; plan for cranes and permits.

- Maintenance Plan: Schedule annual dissolved gas analysis (DGA) to detect faults early—I've caught winding issues this way, averting outages.

From experience, skipping third-party inspections can lead to subpar units; always verify oil quality (dielectric strength >30kV/mm).

Maintenance and Future Trends

Routine maintenance is key: Check oil levels quarterly, test for moisture/acidity annually, and retrofit with smart sensors for predictive analytics. In 2025, trends include biodegradable oils (e.g., ester-based) for eco-compliance and digital twins for remote monitoring, reducing downtime by 30%.

In summary, oil-immersed power transformers remain cost-effective for demanding applications, with prices starting at $200 for small units and scaling based on specs. By following this guide, you can procure a unit that delivers reliable performance for decades. For tailored advice, consult certified engineers or suppliers—it's an investment in your grid's stability.

-AL-medium-voltage-power-cable-2.jpg)

H-medium-voltage-power-cable-2.jpg)