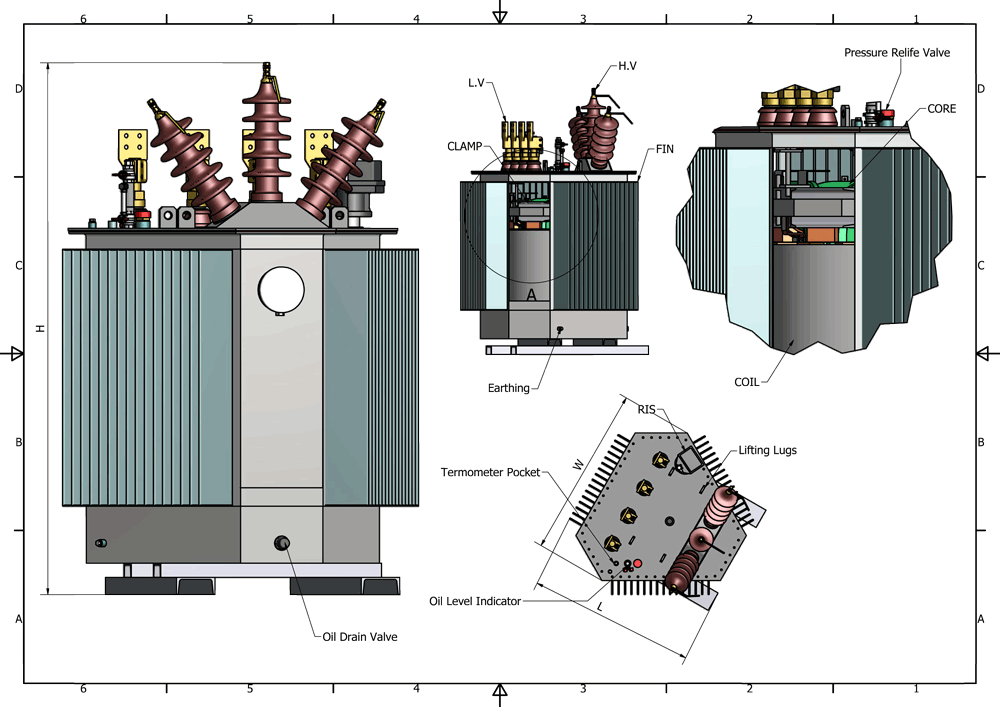

The Structure and Design of Oil Immersed Transformers

While dry-type transformers are becoming increasingly popular, oil-immersed transformers still dominate medium and high voltage applications due to their high efficiency, reliability, and long lifespan. They continue to provide better support for the stable operation of modern power systems and transmission and distribution networks.

1. Introduction to Oil Immersed Transformers

An oil-immersed transformer is an electrical transformer in which the core and windings are fully submerged in insulating oil. The oil serves two primary purposes:

- Insulation – It enhances the dielectric strength between live parts and the transformer tank.

- Cooling – It absorbs and transfers heat generated in the windings and core to external radiators.

Compared with dry-type transformers, oil-immersed units offer higher overload capacity, better cooling efficiency, and lower cost for large power ratings. For this reason, both oil-immersed distribution transformers and oil-immersed power transformers are extensively used in transmission and distribution networks across the globe.

2. Types of Oil Immersed Transformers

The classification of oil-immersed transformers depends on their voltage level, application, and cooling system. The main types of oil-immersed transformer include:

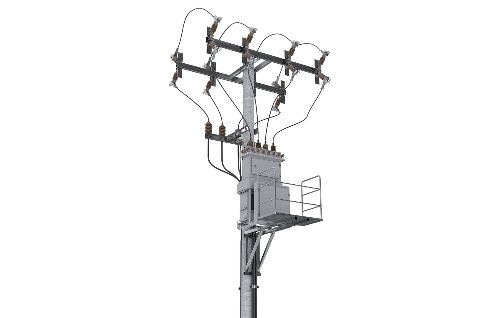

- Oil Immersed Distribution Transformer – Typically rated below 36 kV, designed for local distribution in urban and rural grids. Compact design, high efficiency, and long-term reliability are key.

- Oil Immersed Power Transformer – High-voltage transformers used in transmission substations, often exceeding hundreds of MVA. Advanced cooling and insulation systems are necessary.

- Sealed Tank Transformers – Fully sealed to prevent contact between insulating oil and external air, reducing oxidation and moisture absorption.

- Free-Breathing Transformers – Equipped with conservators that allow oil expansion and contraction, often using silica gel breathers to reduce moisture ingress.

Each design must comply with international standards such as IEC 60076 or IEEE C57, ensuring safety, performance, and compatibility in global power systems.

3. Structural Design Considerations

The structure of an oil-immersed transformer integrates several key components, each designed for durability and performance.

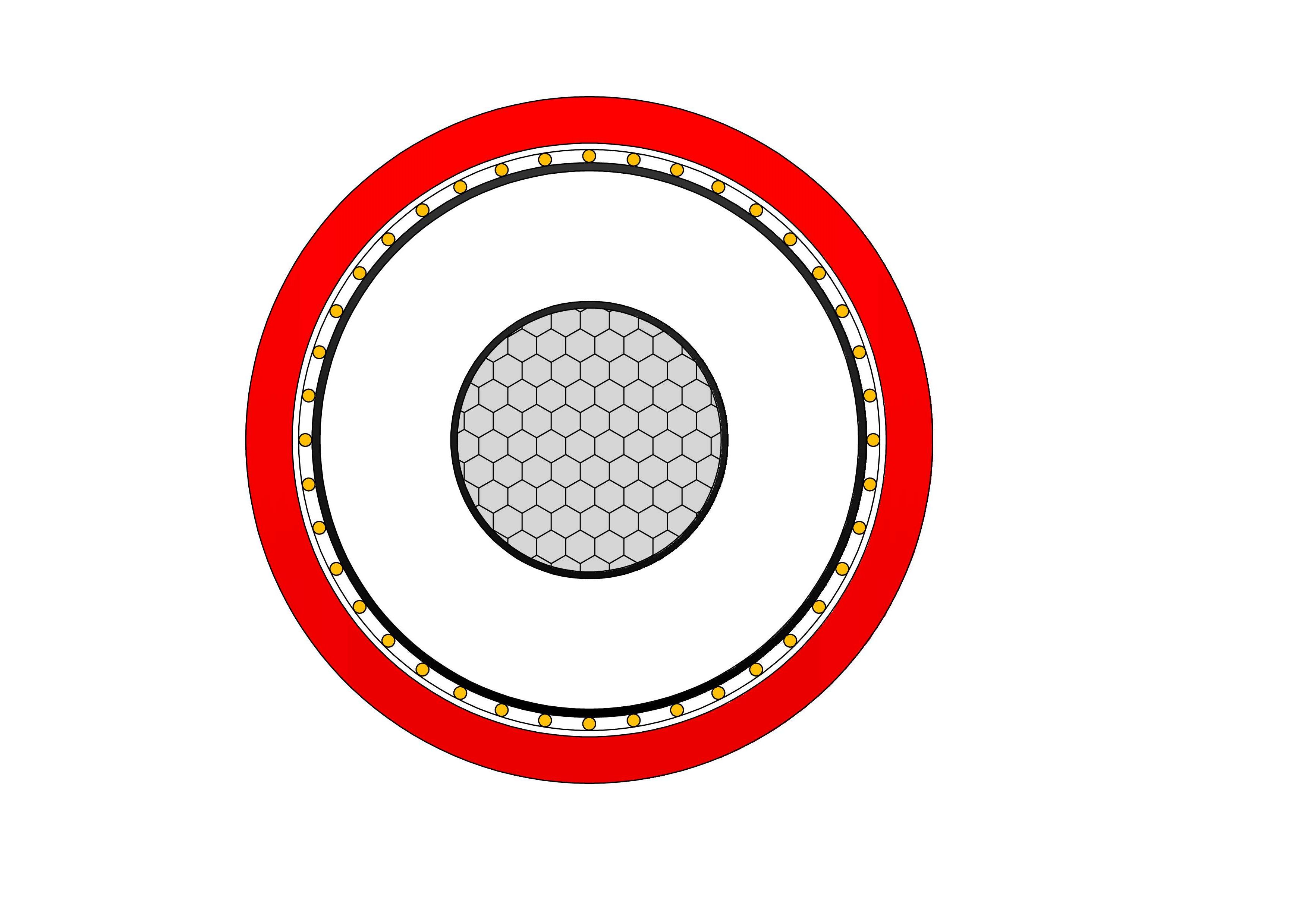

3.1 Transformer Core

- Constructed from cold-rolled, grain-oriented silicon steel laminations to minimize hysteresis and eddy current losses.

- The core structure determines efficiency and magnetic flux distribution, directly affecting transformer losses.

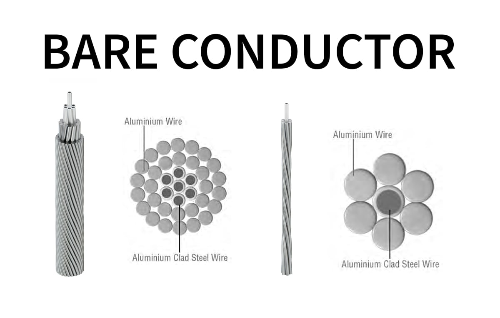

3.2 Transformer Winding

- Typically made of copper or aluminum conductors.

- Windings are insulated with high-quality paper or pressboard, then impregnated with insulating oil.

- Design focuses on reducing short-circuit stresses and optimizing current distribution.

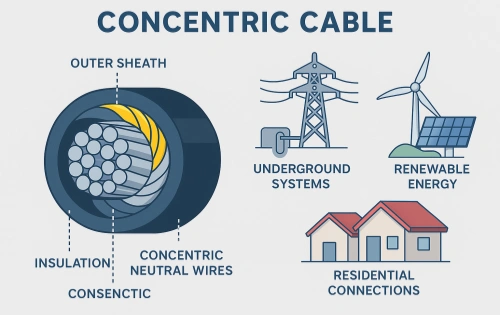

3.3 Insulating Oil

- Mineral oil remains the most common insulating medium due to its cost-effectiveness, availability, and proven reliability.

- Advanced alternatives, such as natural esters and synthetic oils, are increasingly adopted for eco-friendly solutions.

- The oil must meet dielectric strength, moisture content, and thermal stability requirements specified in international standards.

3.4 Cooling System

Cooling efficiency defines the performance of power transformers. The main cooling methods are:

- ONAN (Oil Natural, Air Natural) – Passive cooling through natural convection.

- ONAF (Oil Natural, Air Forced) – Uses fans to accelerate air cooling.

- OFAF/ODAF – Forced oil and forced air circulation for high-capacity units.

- OFWF/ODWF – Forced oil with water cooling for large, high-voltage transformers.

3.5 Tank and Conservator

- The tank houses the active parts and provides mechanical protection.

- Conservator systems accommodate oil expansion and contraction during load variations.

- Modern sealed tank designs improve reliability and minimize maintenance.

4. Modern Design Approaches

With increasing demand for high efficiency, environmental safety, and grid stability, transformer designs have evolved significantly. Key design trends include:

- Eco-Friendly Oils – Natural ester and synthetic insulating oils are replacing traditional mineral oil in sensitive environments.

- Digital Monitoring – Online dissolved gas analysis (DGA), oil moisture sensors, and thermal sensors improve predictive maintenance.

- Compact Design – Optimized magnetic cores and advanced winding structures reduce footprint while enhancing performance.

- High Voltage Applications – For ultra-high-voltage (UHV) systems above 800 kV, advanced insulation coordination and robust mechanical design are critical.

- Integration with Smart Grids – Oil-immersed transformers are increasingly designed to communicate with digital platforms, supporting smart monitoring and grid stability.

5. Oil-immersed Transformer vs Dry Type Transformers

While dry-type transformers are suitable for indoor and fire-sensitive environments, oil-immersed units remain the preferred option for outdoor and high-voltage applications. The main advantages of oil immersed transformers include:

- Higher Efficiency – Better cooling leads to reduced load and no-load losses.

- Longer Service Life – Oil reduces thermal stress on windings and insulation.

- High Voltage Capability – Suitable for large-scale power systems and long-distance transmission networks.

|

Comparison Item |

Oil-immersed Transformer |

Dry Type Transformer |

|

Cooling Medium |

Mineral oil / synthetic oil / natural ester oil |

Air or cast resin |

|

Cooling Efficiency |

Excellent (oil provides strong heat dissipation, supports high overload capacity) |

Limited, depends on air circulation; overheating risk under high loads |

|

Voltage & Capacity Range |

Suitable for medium to ultra-high voltage (up to 1000 kV+), large capacities |

Mainly for low to medium voltage, typically below 36 kV |

|

Installation Environment |

Outdoor, substations, industrial plants |

Indoor, commercial buildings, hospitals, tunnels, fire-sensitive areas |

|

Maintenance |

Requires periodic oil testing, filtration, and replacement |

Minimal; no oil maintenance, lower routine inspection |

|

Service Life |

30–40 years with proper maintenance |

20–30 years, depends on insulation aging |

|

Safety |

Fire risk due to flammable oil; explosion-proof design needed |

High fire safety (no oil); better for enclosed spaces |

|

Size & Weight |

More compact for same rating (better cooling efficiency) |

Bulkier due to air insulation and resin encapsulation |

|

Environmental Impact |

Risk of oil leakage and contamination; eco-friendly ester oils available |

Environmentally safer; no oil leakage |

|

Initial Cost |

Generally lower for high ratings |

Higher, especially for medium/high capacity units |

|

Applications |

Transmission & distribution networks, power systems, industrial loads |

Commercial buildings, metro stations, offshore platforms, renewable integration indoors |

However, dry-type transformers are advantageous where fire safety and environmental risks outweigh efficiency concerns.

6. Compliance with International Standards

Oil-immersed transformers must meet rigorous international standards to ensure safety and interoperability. Major guidelines include:

- IEC 60076 – Design, testing, and performance requirements for power transformers.

- IEEE C57 – North American standard for distribution and power transformers.

- ISO 14000 Series – Environmental standards for eco-friendly insulating oils and emissions.

Adherence to these standards ensures that oil-immersed distribution transformers and power transformers operate safely in diverse climates and electrical infrastructures.

7. Practical Engineering Considerations

In real-world engineering projects, the design of oil-immersed transformers must account for:

- Load Profiles – Seasonal and peak load variations in distribution networks.

- Ambient Temperature – Cooling system design tailored for tropical, desert, or arctic environments.

- Fault Tolerance – Mechanical strength of windings to withstand short-circuit currents.

- Maintenance Strategy – Oil testing, filtration, and replacement schedules to maintain insulation quality.

- Cost vs. Efficiency – Balancing capital investment with long-term operational efficiency.

8. Conclusion

The design and structure of oil-immersed transformers continue to evolve in response to modern engineering challenges. From compact oil-immersed distribution transformers for local grids to large oil-immersed power transformers serving high voltage transmission networks, their role in stable and efficient power systems is irreplaceable. With the integration of eco-friendly insulating oil, advanced cooling, digital monitoring, and strict compliance with international standards, oil-immersed transformers remain a cornerstone of global electrical infrastructure.

As the energy sector moves towards sustainability and smart grids, the oil-immersed transformer is not only adapting but also setting benchmarks for the next generation of transformer designs.