Dry Type Transformers: Comprehensive Guide to Types, Benefits, and Practical Applications

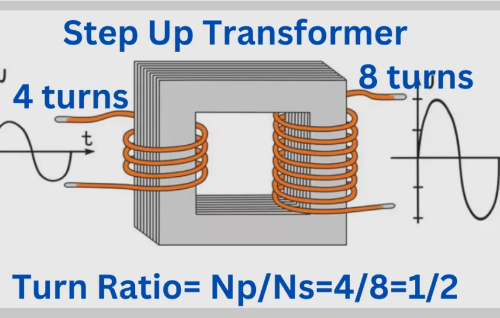

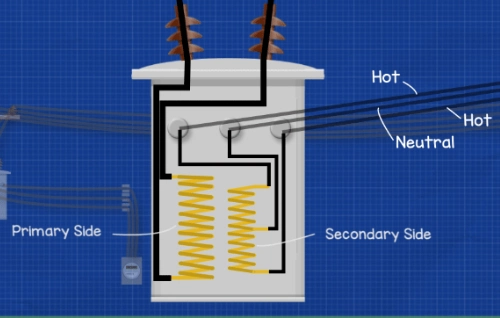

In modern power system design, transformers play an important role in achieving efficient power transmission and distribution by stepping up or down the voltage. Dry-type transformers are one of the most reliable and widely used types of transformers. Unlike oil-immersed transformers, dry-type transformers use air or resin for insulation and cooling, making them ideal for indoor installation, while oil-immersed transformers may pose safety risks when installed indoors. Therefore, dry-type transformers have safety advantages that other transformers do not have in terms of performance and safety.

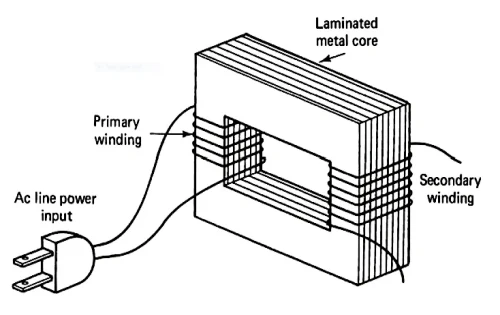

1. What is a Dry Type Transformer?

A dry-type transformer is an electrical transformer that uses air or solid insulating materials like cast resin or epoxy resin for insulation, instead of traditional mineral oil. The lack of oil as an insulating medium makes dry-type transformers much safer for use in indoor applications and areas where fire hazards must be minimized.

Dry-type transformers are used in applications where reliability, safety, and environmental considerations are paramount. They are designed to be efficient in terms of both electrical performance and energy consumption, making them a popular choice for commercial buildings, data centers, industrial facilities, and renewable energy systems.

2. Types of Dry Type Transformers

There are two primary types of dry-type transformers commonly used in electrical systems:

a. Cast Resin Transformers

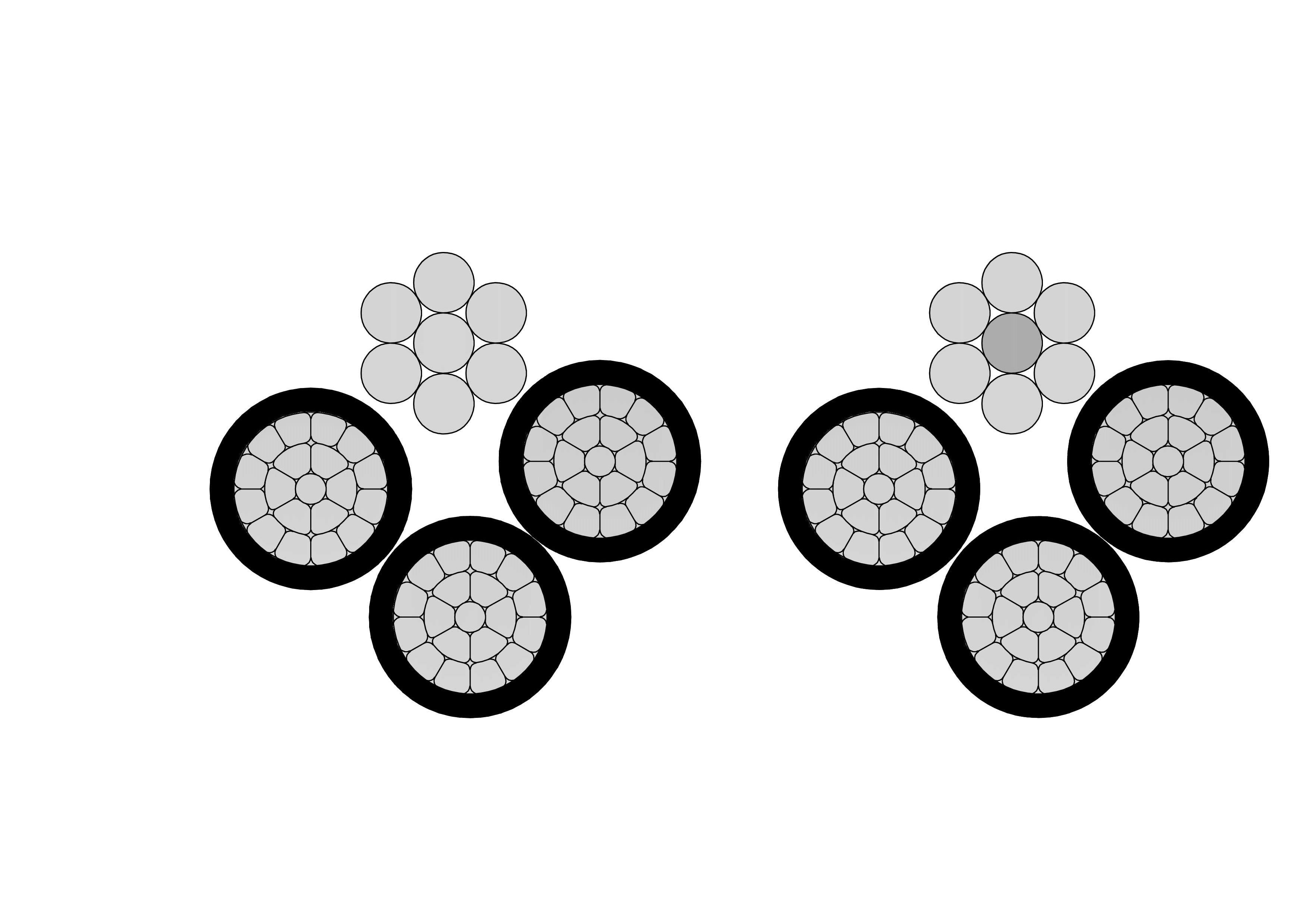

Cast Resin Transformers are a type of dry transformer where the primary and secondary windings are completely immersed in a resin-based insulation material. This insulating material provides excellent resistance to moisture, dust, and other environmental factors, making Cast Resin Transformers ideal for use in harsh and outdoor environments.

Advantages of Cast Resin Transformers:

-

High reliability and safety: The resin material provides good electrical insulation and is resistant to environmental influences.

-

Low maintenance: Due to the sealed insulation, cast resin transformers require minimal maintenance.

-

Fire resistance: Cast resin transformers are self-extinguishing, making them safer than oil-filled transformers.

Applications:

-

Power distribution in urban areas

-

Industrial machinery

-

Renewable energy installations like wind and solar farms

b. Epoxy Resin Transformers

Epoxy Resin Transformers are another type of dry transformer, where the windings are coated with epoxy resin. These transformers are less bulky than cast resin transformers but still offer a high level of insulation and reliability. Epoxy resin transformers are commonly used in smaller commercial applications or where space is a concern.

Advantages of Epoxy Resin Transformers:

-

Compact design for space-constrained installations.

-

Cost-effective: Lower cost compared to cast resin transformers.

-

High-temperature tolerance: Epoxy resin transformers can operate in environments with higher ambient temperatures.

Applications:

-

Small commercial buildings

-

Data centers

-

Electric vehicle charging stations

Dry Type Transformers Comparison Table

|

Type |

Cast Resin Transformers |

Vacuum Pressure Impregnated (VPI) Transformers |

|

Insulating Material |

Epoxy Resin |

Polyester or Epoxy Resin |

|

Structure |

Wound core immersed in resin |

Wound core impregnated with resin under vacuum pressure |

|

Cooling Method |

Air-cooled |

Air-cooled |

|

Applications |

Used in urban power distribution, industrial facilities, and high humidity environments |

Used in high-power power distribution, industrial environments, and long-term use |

3. Advantages of Dry Type Transformers

Dry-type transformers offer a range of benefits, particularly in terms of safety, environmental friendliness, and performance. Let’s explore some of the key advantages:

a. Safety and Fire Resistance

Unlike oil-filled transformers, dry-type transformers do not contain flammable liquids, making them less of a fire hazard. This is especially important in urban areas or indoor applications, where fire safety is a top priority. Cast resin transformers are self-extinguishing, which adds an extra layer of safety.

b. Environmental Benefits

Dry-type transformers are more environmentally friendly than oil-filled ones. They don’t require mineral oil for insulation, which reduces the risk of oil spills and contamination. Additionally, the use of eco-friendly insulation materials, such as epoxy resin, further enhances their environmental appeal.

c. Low Maintenance

With no oil to change and sealed insulation, dry-type transformers are easy to maintain. Their solid insulation materials protect the internal components from dust, moisture, and other contaminants, reducing the need for frequent inspections or repairs.

d. Versatility

Dry-type transformers are suitable for a wide range of applications, from small-scale commercial use to large industrial systems. Their versatility and adaptability make them an ideal choice for many power distribution projects.

4. Disadvantages of Dry Type Transformers

While dry-type transformers offer numerous advantages, they also come with some drawbacks that need to be considered when selecting the right transformer for a given application.

a. Limited Power Capacity

Dry-type transformers, particularly epoxy resin transformers, generally have lower power capacities compared to oil-filled transformers. This limits their use in large-scale, high-power applications where higher voltage levels and greater power handling are required.

b. Higher Initial Cost

While the maintenance costs for dry type transformers are lower, the initial cost of these transformers can be higher than oil-filled models. The advanced insulation materials and manufacturing processes used in dry type transformers contribute to this cost difference.

c. Size and Weight

Although epoxy resin transformers are compact, cast resin transformers tend to be bulkier and heavier than oil-filled transformers, making them more challenging to transport and install, especially in space-constrained environments.

5. Applications of Dry Type Transformers

Dry type transformers are used in a variety of applications across different industries. Some common application scenarios include:

a. Commercial Buildings

Dry type transformers are often used in commercial buildings for low-to-medium voltage power distribution. Their safety, compact design, and low maintenance make them ideal for indoor applications like office buildings, shopping malls, and hotels.

b. Industrial Facilities

In industrial settings, where large machines require stable and reliable power, dry type transformers ensure safe power distribution. They are particularly useful in factories or manufacturing plants, where fire safety is crucial.

c. Renewable Energy Systems

With the rise of renewable energy sources like solar and wind, dry type transformers are increasingly used in renewable energy systems for voltage regulation. Their environmentally friendly design makes them a good fit for solar farms, wind farms, and other clean energy projects.

d. Data Centers

Data centers require a continuous power supply to support their critical systems. Dry type transformers, particularly Cast Resin Transformers, are used in data centers to ensure the safe and reliable distribution of power.

Dry type transformers offer a safe, reliable, and environmentally friendly alternative to traditional oil-filled transformers. Whether you’re working in commercial, industrial, or renewable energy sectors, these transformers provide excellent performance, low maintenance, and safety advantages.

From Cast Resin Transformers to 75kVA transformers, the range of dry type transformer types ensures that engineers have the flexibility to choose the right transformer for specific power requirements.

By understanding their types, benefits, and limitations, professionals can make informed decisions when selecting transformers for electrical systems, contributing to efficient power distribution and enhanced safety in modern infrastructures.

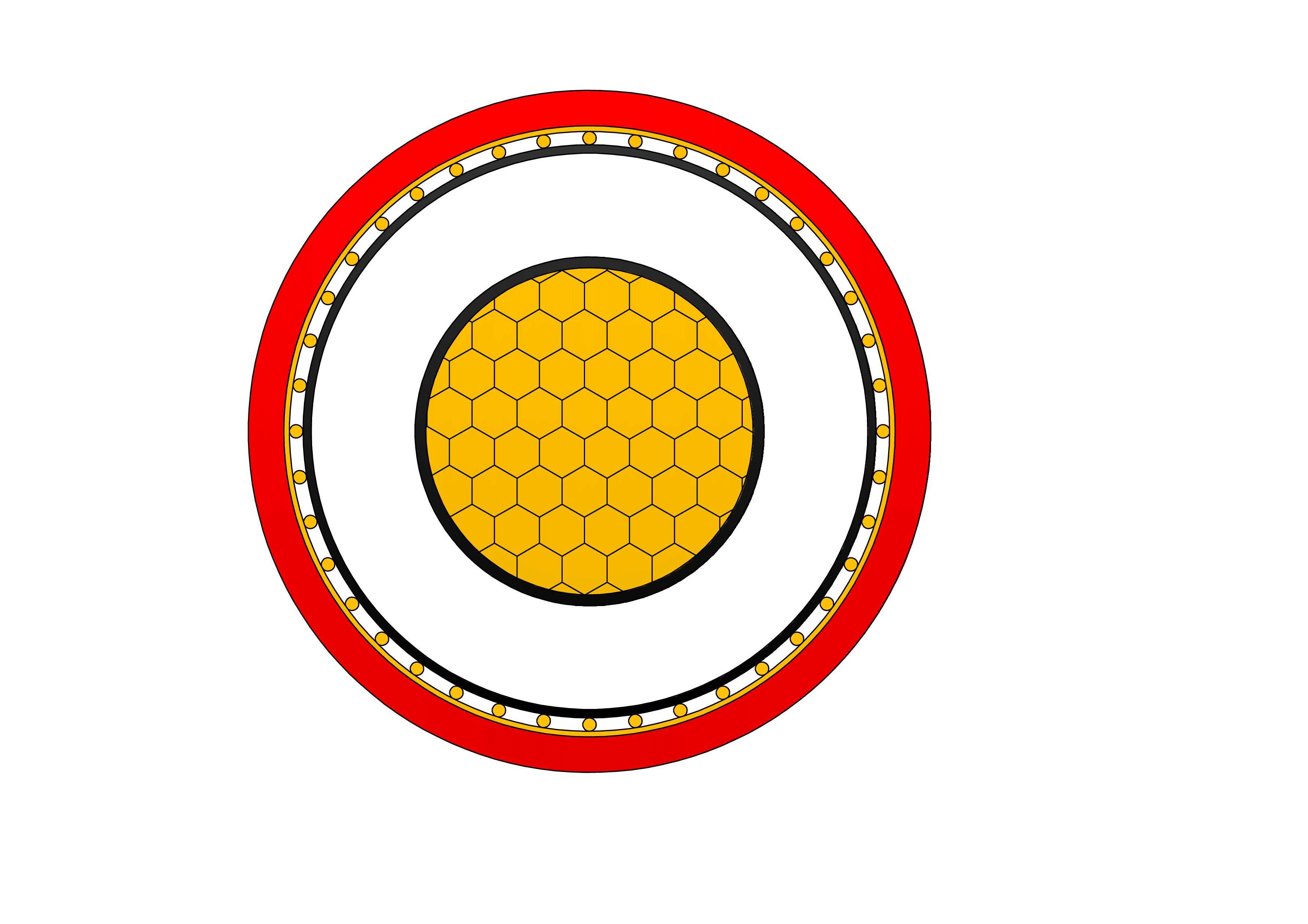

2Y-high-voltage-power-cable-2.webp)