Dry-Type Transformers: From Basics to Technical Specifications

What Is a Dry-Type Transformer?

A dry-type transformer is an electrical transformer that uses solid insulation materials instead of oil or liquid for cooling and insulation. Unlike oil-immersed transformers, dry-type units are air-cooled and operate without flammable liquids, making them inherently safer and environmentally friendly. They are commonly used in buildings, industrial plants, renewable energy systems, and areas where fire safety is critical.

How Dry-Type Transformers Work

Dry-type transformers rely on natural air circulation or forced ventilation to dissipate heat generated during operation. The core and windings are encapsulated in high-temperature-resistant insulation systems, such as epoxy resin. The principle remains the same as other transformers: the magnetic flux transfers energy between primary and secondary windings. However, because they use solid insulation and no oil, the design prioritizes thermal management and insulation integrity.

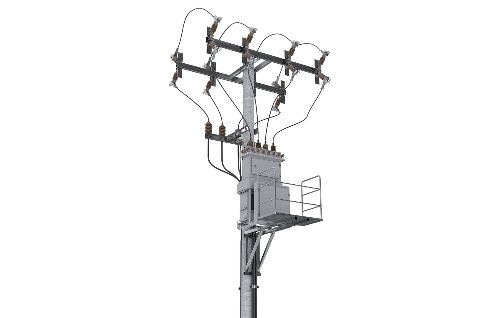

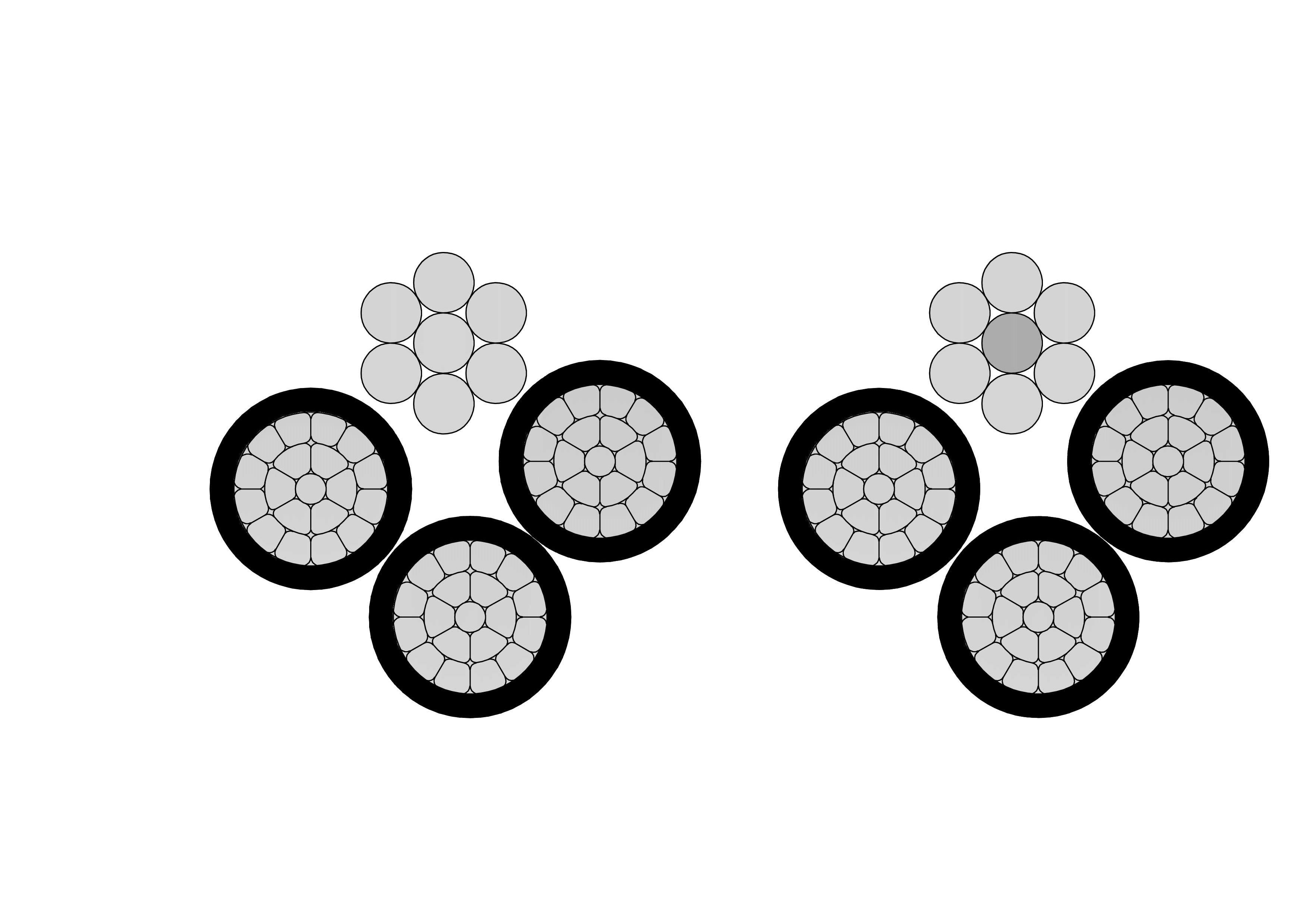

Key components include:

- Magnetic core: Laminated steel core to minimize losses.

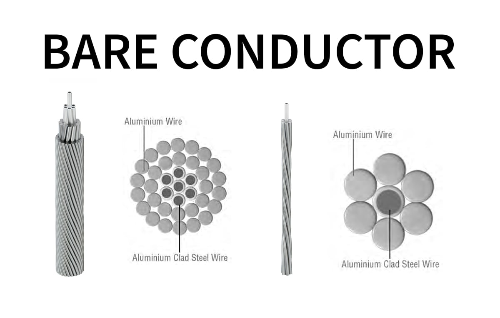

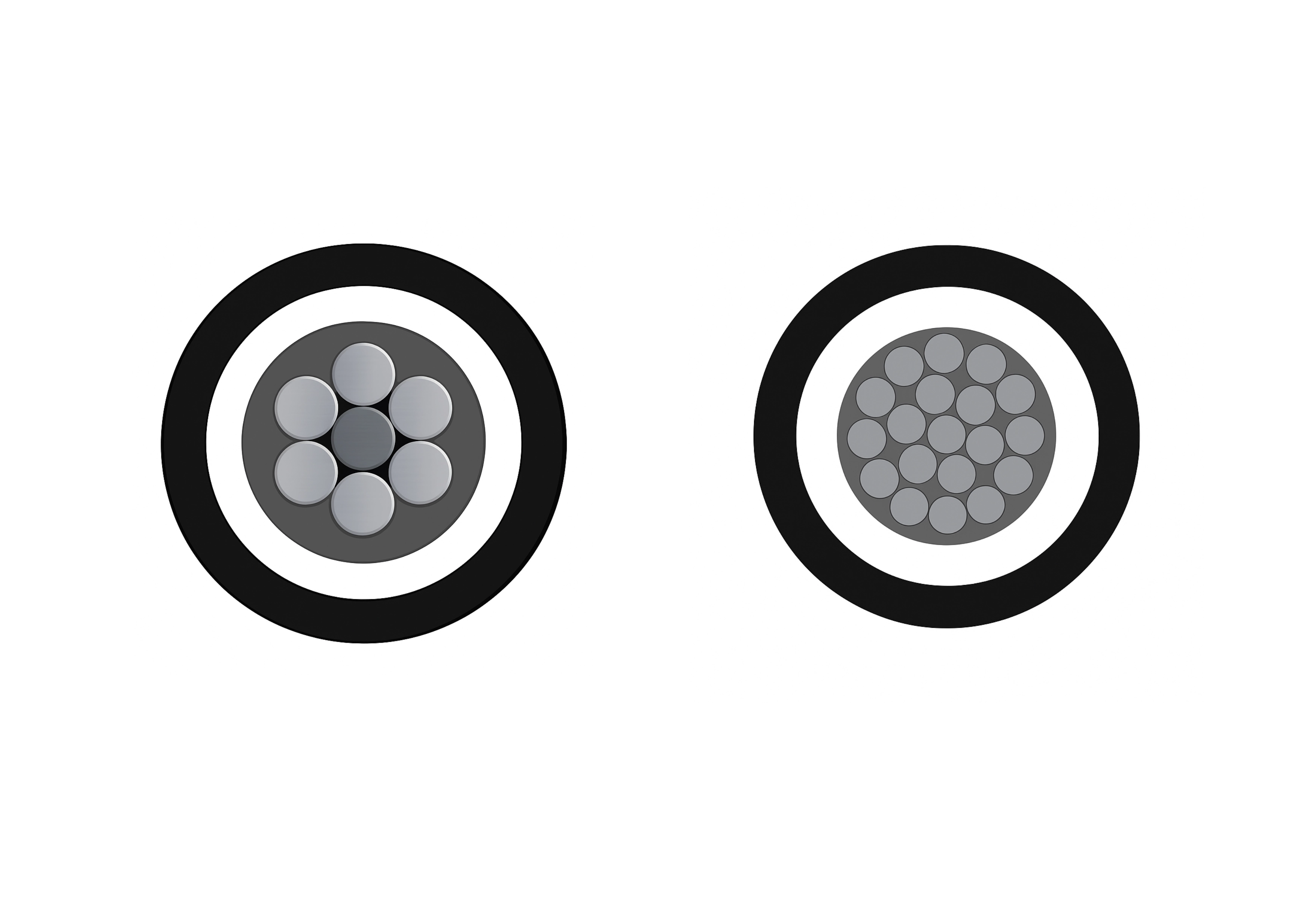

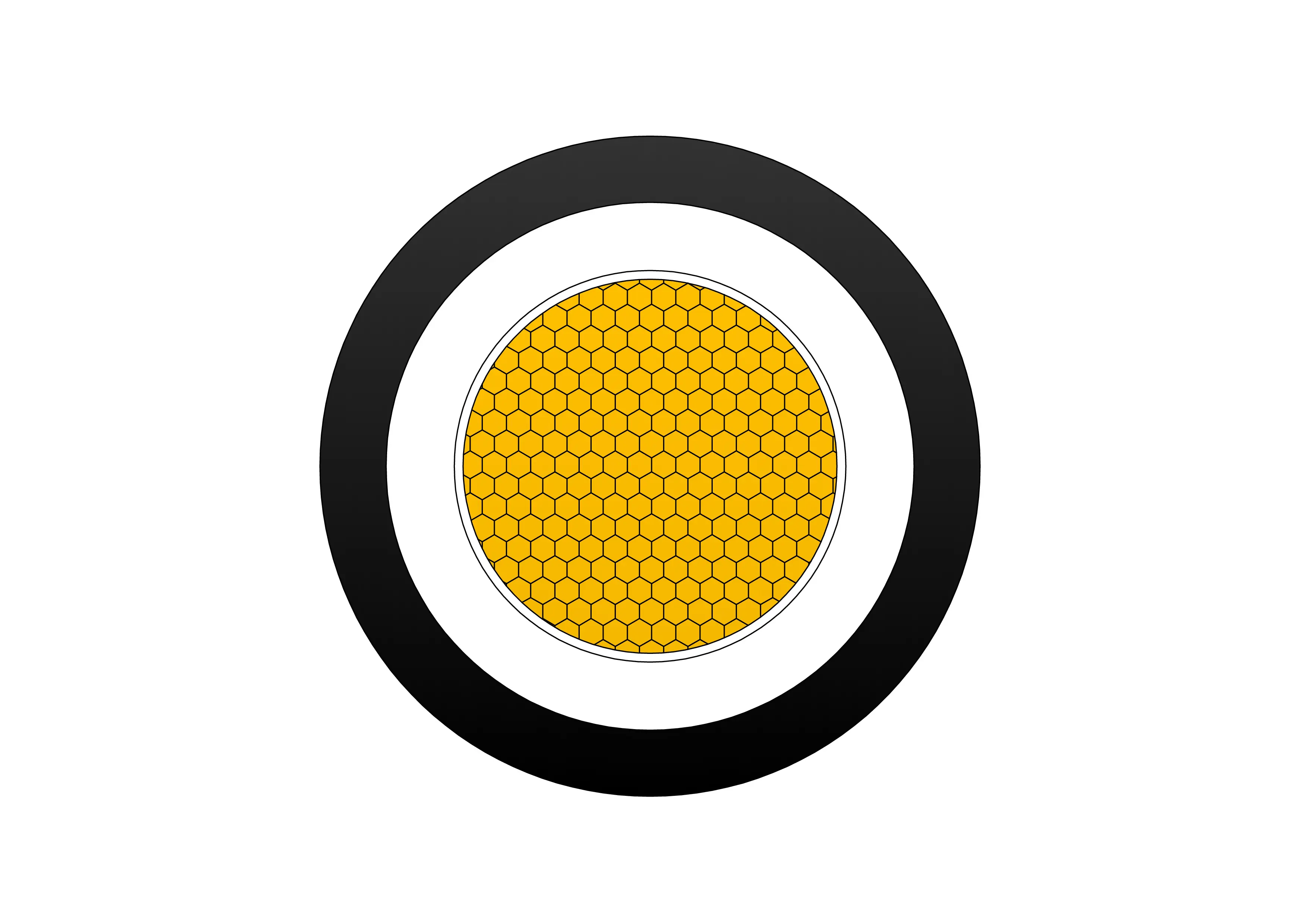

- Windings: Copper or aluminum conductors insulated with epoxy or polyester resin.

- Cooling system: Either natural air (AN) or forced air (AF) for higher ratings.

VPI Technology: Enhanced Reliability and Performance

One advanced manufacturing process for dry-type transformers is VPI (Vacuum Pressure Impregnation). VPI involves impregnating the windings with resin under vacuum and pressure, ensuring deep penetration of insulation and superior bonding.

Benefits of VPI:

- Moisture resistance: Extends service life even in humid environments.

- Improved thermal performance: Handles higher temperature rise.

- Mechanical strength: Withstands short-circuit forces better.

- Reduced partial discharge: Enhances dielectric reliability.

VPI dry-type transformers are widely used in hospitals, data centers, offshore platforms, and renewable energy projects, where long-term reliability is essential.

Fire Safety and Environmental Advantages

Fire safety is a key reason dry-type transformers are selected for indoor installations, tunnels, subways, airports, and high-rise buildings. Unlike oil-filled transformers, dry-type units contain no flammable liquids, reducing fire hazards significantly.

Fire safety features include:

- Flame-retardant insulation: Epoxy resin and Class F/H materials comply with UL 1561 and IEC 60076-11.

- Low smoke emissions: Enhances safety in enclosed spaces.

- Self-extinguishing properties: Minimizes propagation risk in case of thermal events.

Additionally, dry-type transformers are eco-friendly since they eliminate the risk of oil leakage, reducing soil and water contamination.

Technical Specifications & Applications

Dry-type transformers are available in a wide range of ratings and configurations:

- Capacity: 30kVA to 7500kVA

- Voltage classes: Up to 36 kV

- Insulation class: Class F (155°C) or Class H (180°C)

- Cooling methods: AN (Air Natural) or AF (Air Forced)

Applications include:

- Commercial buildings

- Hospitals and healthcare facilities

- Data centers and IT infrastructure

- Renewable energy plants

- Chemical and offshore installations

Explore Our 30kVA–7500kVA Dry-Type Transformer Series

We offer a comprehensive range of 30kVA–7500kVA dry-type transformers designed for industrial, commercial, and renewable energy applications.

Key features include:

- Advanced VPI insulation technology for superior protection

- Compliance with IEC 60076 and ANSI/IEEE C57 standards

- Low noise and low partial discharge design

- High efficiency, eco-friendly operation

- Optional temperature monitoring and smart control systems

Why Choose a Dry-Type Transformer?

Dry-type transformers combine safety, environmental compliance, and operational reliability, making them the ideal choice for modern electrical infrastructure. Whether you require fire-safe solutions for urban buildings or robust performance for renewable energy projects, VPI dry-type transformers deliver outstanding performance and durability.