20kV Oil Immersed Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Oil immersed distribution transformer

- BIL 20kV

- Standards IEEE, ANSI, NEMA, IEC, CE

- Application Temporary Power Supply Systems, Utilities

- Power Rating 30kVA - 5000kVA

- Certificate UL, CESI, IEEE

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 30kVA - 5000kVA | |

| Rating Primary Voltage | 2.4 - 34.5kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| Insulating Oil Weight | 850 kg | |

| Total Weight | 5000 kg | |

| Outline Dimensions(L×W×H)in. | 2650 × 1650 × 2450(mm) | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

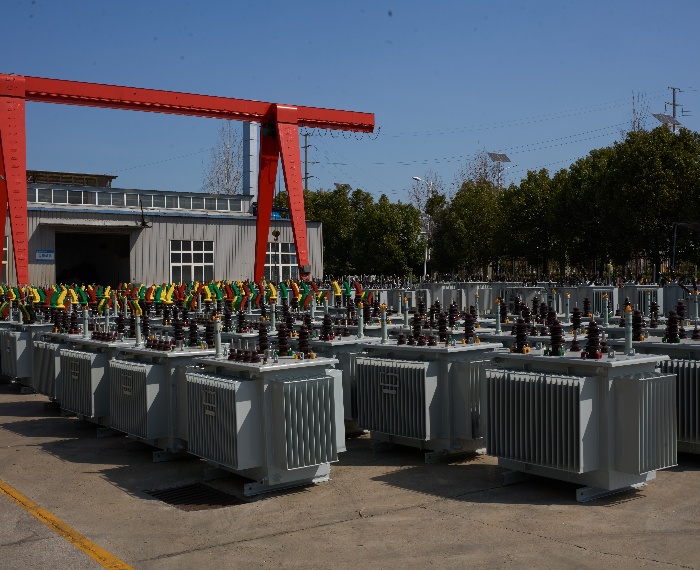

Packing and Shipping

Disassembly protects detachable parts—radiators crated with foam/vibration dampers, porcelain/polymer bushings in shock-mounted boxes, OLTC/control panels shrink-wrapped with silica gel. Main tank secures on steel skids or ISPM-15 wooden cradles, braced against 5G shocks, with tilt/shock loggers, VCI inhibitors, and hygrometers. Corrugated tanks get weatherproof tarps; pole-mount variants use galvanized frames for stackability.

Sea export dominates via flat-rack/open-top containers or RoRo, lashed to IMO specs with salt-fog coatings; overland uses lowboys for weight balance at marked lugs. Full docs bundle: FAT reports, PSI certificates, BOMs, HS codes (8504.22), CoO, SDS for oils, CAD drawings, and unload manuals. Customs prep includes RoHS/REACH for EU/NL markets like Barry's Amsterdam base.

Logistics orchestration covers FOB/CIF to door, with third-party PSI/FAT witnessing options. Arrival protocols: crane unload at 4-point lifts, oil processing (<20ppm H2O), N2 purge hold, and 24-month warranty activation—zero-defect delivery assured for global utilities.

Manufacturer Test

Progress Test

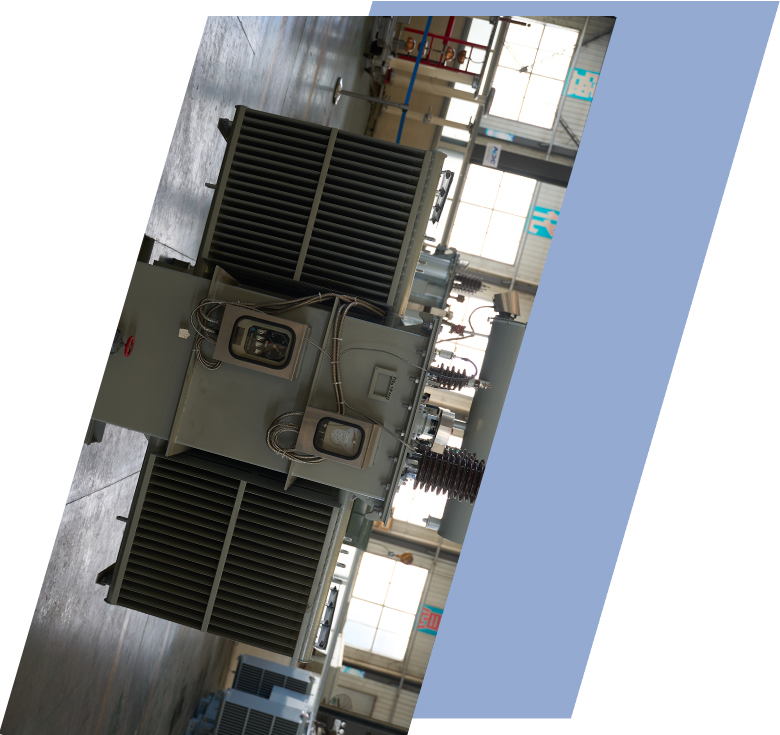

Progress tests commence with silicon steel lamination audits for thickness uniformity magnetic permeability burr elimination via Epstein testing to optimize core flux density and cut hysteresis losses then core stacking verifies step-lap miters yoke clamping torque electromagnetic shielding against strays. Winding fabrication tracks enameled copper resistivity layer-paper insulation buildup turn-count precision via automated winders dielectric bridges for inter-layer strength post-coil drying oven logs dew points <-45°C vacuum impregnation confirms resin penetration uniformity. Core-coil assembly progress scans axial/radial clearances pressboard spacers end-rings for short-circuit force resistance tank fab checks seam X-rays hydrostatic pressure 0.5MPa holds surface blast/paint DFT>80μm corrosion spec adherence pre-oil fill mockups detect alignments.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

Transformer Factory Acceptance Test

FAT per IEC60076-1/2 IEEE C57.12.90 opens with visual/dimensional conformity nameplate scan paint adhesion accessory fixation then insulation metrics megger PI >2000MΩ@20°C separate-source AC withstand 75kV/1min induced 2xUn/150% freq/7200s for PD<10pC BIL 250kV full wave. DC winding resistance 75°C corrected verifies joints polarity turns-ratio tester validates ±0.5% accuracy phase displacement Dyn11 across taps no-load routine rated Un loss< spec exciting I%<2% harmonics THD<5%.

Routine Test - Insulation Power Factor

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.