AWG Conductor Cable Explained: Sizes, Applications, and Selection Guide

The American Wire Gauge (AWG) system is the most widely used standardized wire sizing method in North America. It provides a consistent way to classify the diameter of the wire, the cross-sectional area, and the current-carrying capacity of electrical conductors. Whether used in industrial automation, building wiring, power distribution, or electronic devices, AWG wire sizes serve as a universal reference that ensures safety, compatibility, and performance across a wide range of applications.

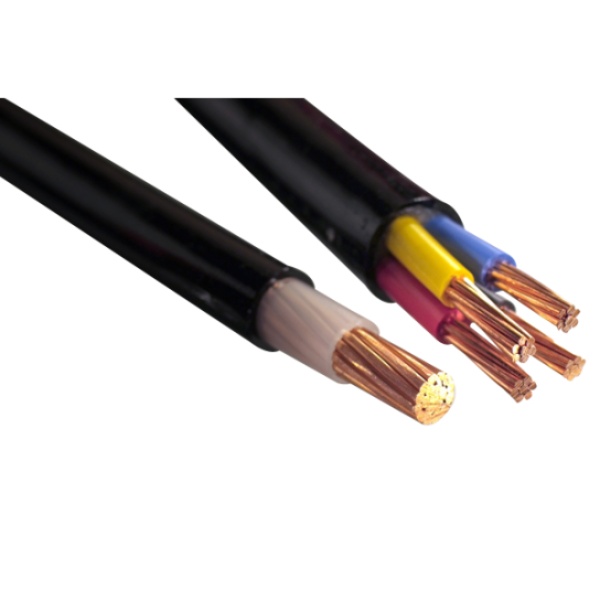

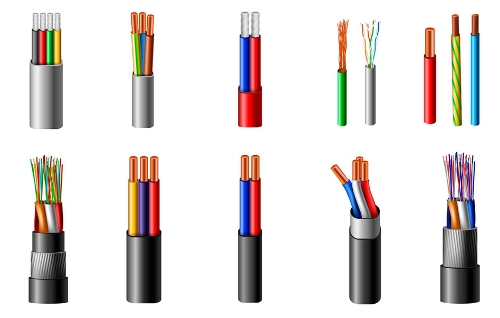

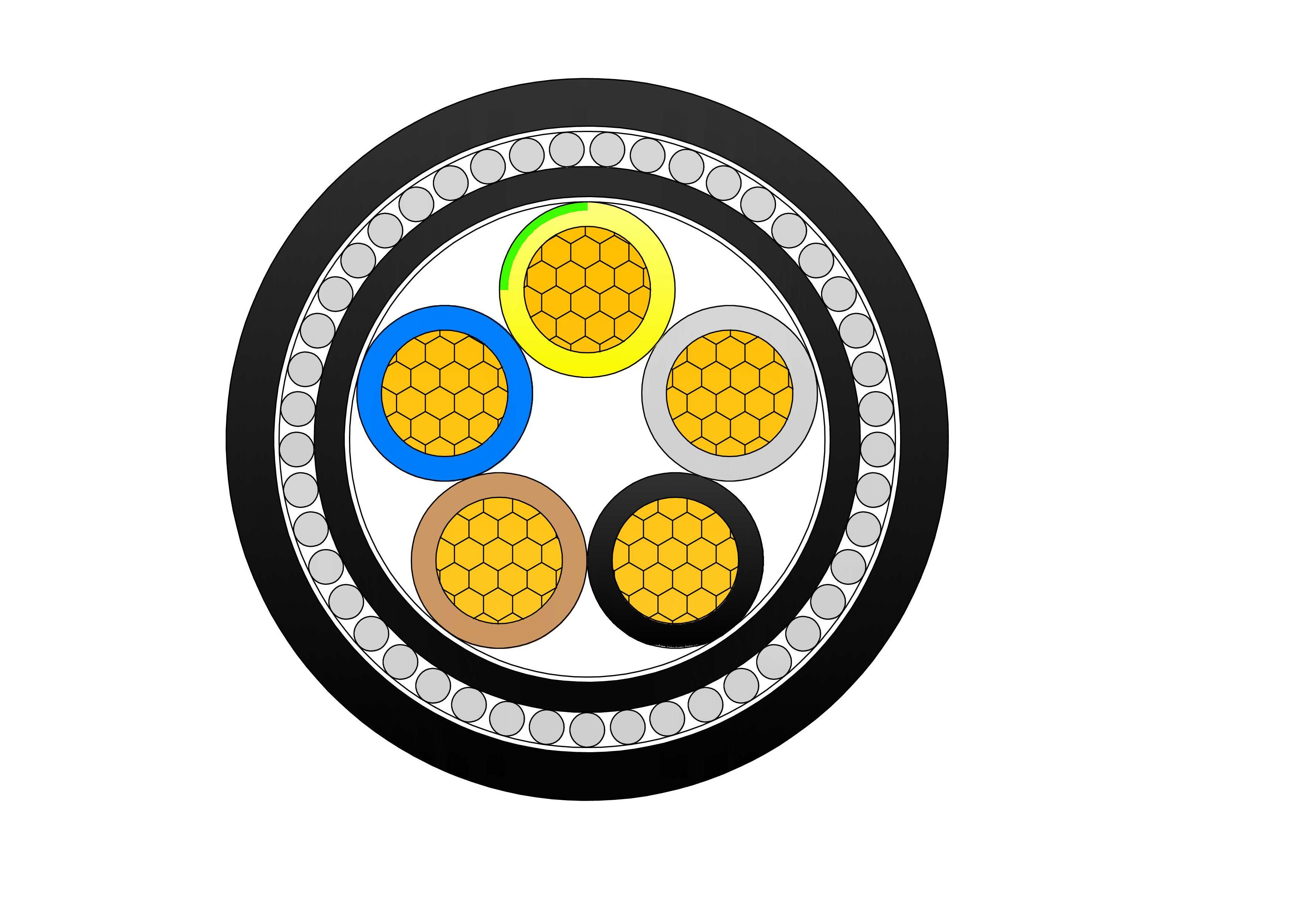

In electrical engineering and daily installation work, understanding how AWG sizes affect performance is crucial. The diameters and cross-sectional properties of cables directly influence electrical resistance, voltage drop, heat dissipation, and overall system efficiency. This is especially important for multi-conductor cables such as 4 AWG 4 conductor cable, 18 AWG 4 conductor shielded cable, 4 conductor 6 AWG cable, 8 AWG 4 conductor cable, 2 AWG 4 conductor cable, and 4 conductor 8 AWG cable, which are commonly used in both low-voltage and medium-power environments.

1. What Is the AWG Conductor Cable?

An AWG conductor cable refers to an electrical wire measured using the American Wire Gauge (AWG) system, a standardized method used to define the diameter of the wire, its cross-sectional area, and ultimately its current-carrying capability. AWG conductor cables come in a wide-ranging variety of sizes, from fine 18 AWG signal wires to heavy-duty 2 AWG and 4 AWG power conductors used in industrial and commercial installations.

In multi-conductor formats—such as 4 AWG 4 conductor cable, 18 AWG 4 conductor shielded cable, 4 conductor 6 AWG cable, 8 AWG 4 conductor cable, and 2 AWG 4 conductor cable—these wires are bundled to support more complex electrical systems, offering improved organization, reliability, and performance.

Because AWG defines the physical properties of the conductor, including diameters and cross-sectional area, it plays a critical role in determining voltage drop, heat generation, and safe operating limits. Whether used in low-voltage control circuits or high-power distribution, AWG conductor cables provide a universal, standardized wire classification system that helps engineers, installers, and electricians select the right wire size for each operating environment.

2. What Is the AWG System?

The AWG system defines wire size using gauge numbers: as the gauge number increases, the wire diameter decreases. For example:

-

2 AWG is much thicker than 18 AWG

-

Larger diameter = lower resistance = higher current capacity

The AWG system standardizes:

-

Diameter of the wire

-

Cross-sectional area

-

Weight per unit length

-

Electrical resistance

-

Current rating

Because AWG is a standardized wire measurement, engineers, manufacturers, and electricians can select the correct conductor for any operating system—from HVAC, solar energy, and electric vehicle charging, to sensitive electronics and communication systems.

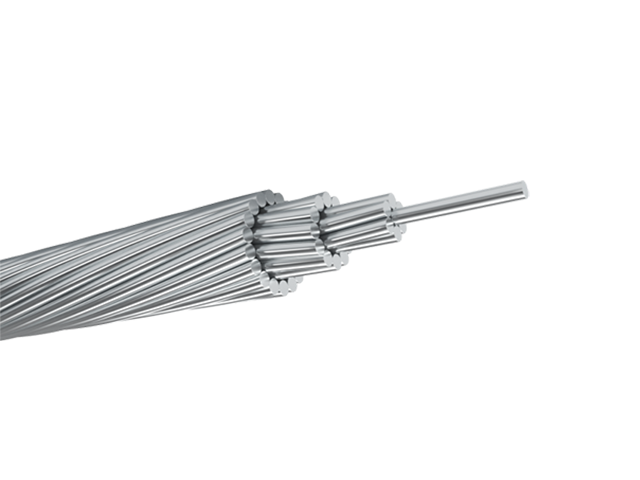

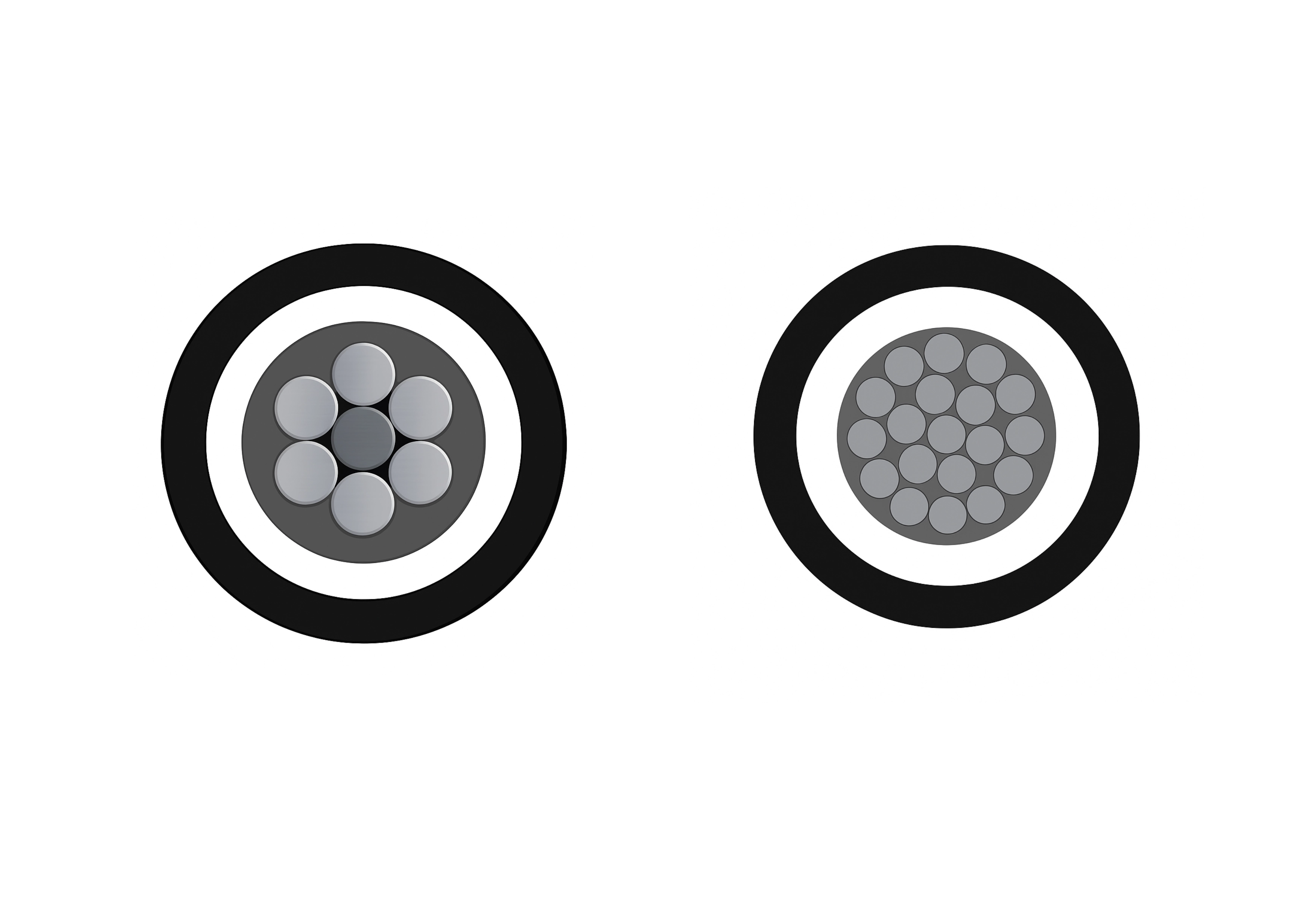

3. Solid vs. Stranded Wire

AWG applies to both solid wire and stranded wire. Although the overall gauge remains the same, stranded wire is more flexible because it is composed of several smaller strands bundled together.

Differences:

| Property | Solid Wire | Stranded Wire |

| Flexibility | Low | High |

| Durability under vibration | Lower | Higher |

| Performance at high frequency | Better skin effect efficiency | Slightly lower |

| Typical application | Building wiring | Cables, machinery, robotics |

For multi-conductor cables like 4 conductor 6 AWG cable or 8 AWG 4 conductor cable, stranded construction is preferred because it allows easier routing, bending, and vibration resistance.

4. Understanding AWG Wire Sizes

Every AWG number corresponds to a specific diameter and cross-sectional area. These values determine how much current the conductor can safely handle.

Example AWG Sizes (Commonly Used in Industry)

| AWG Size | Diameter (mm) | Cross-Sectional Area (mm²) | Typical Cable Example | Common Application |

| 18 AWG | 1.02 mm | 0.82 mm² | 18 awg 4 conductor shielded cable | Signal wiring, communication, audio |

| 8 AWG | 3.26 mm | 8.37 mm² | 8 awg 4 conductor cable / 4 conductor 8 awg cable | Solar, battery, medium-power distribution |

| 6 AWG | 4.11 mm | 13.3 mm² | 4 conductor 6 awg cable | Industrial motors, automation |

| 4 AWG | 5.19 mm | 21.2 mm² | 4 awg 4 conductor cable | Power distribution, EV charging |

| 2 AWG | 6.54 mm | 33.6 mm² | 2 awg 4 conductor cable | Heavy-duty feeders, commercial power |

These sizes are essential for selecting cables such as 18 AWG 4-conductor shielded cable, which is widely used in signal and communication systems requiring noise protection.

5. Applications of AWG Conductor Cables

AWG cables are used across virtually all electrical and electronic environments. Their applications include:

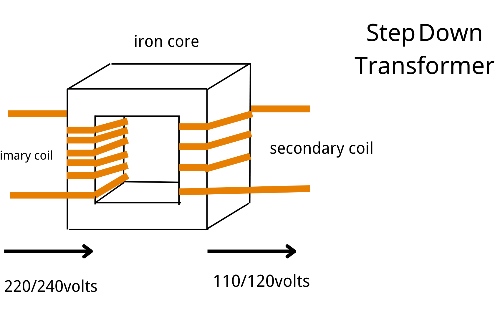

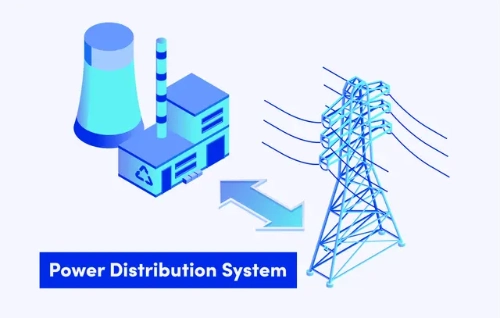

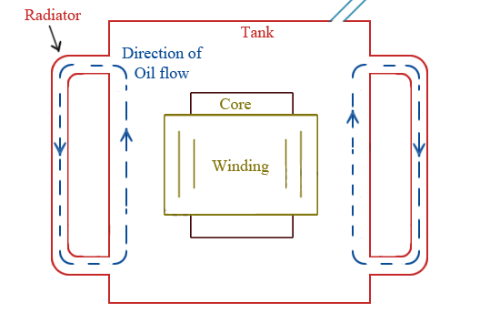

A. Power Distribution

Larger sizes, such as 2 AWG 4-conductor cable and 4 AWG 4-conductor cable, are ideal for:

-

Sub-panel feeds

-

Underground or exposed power runs

-

Solar photovoltaic systems

-

EV charger installation

-

Industrial machinery

Their large cross-sectional area enables efficient high-current transfer with minimal voltage drop.

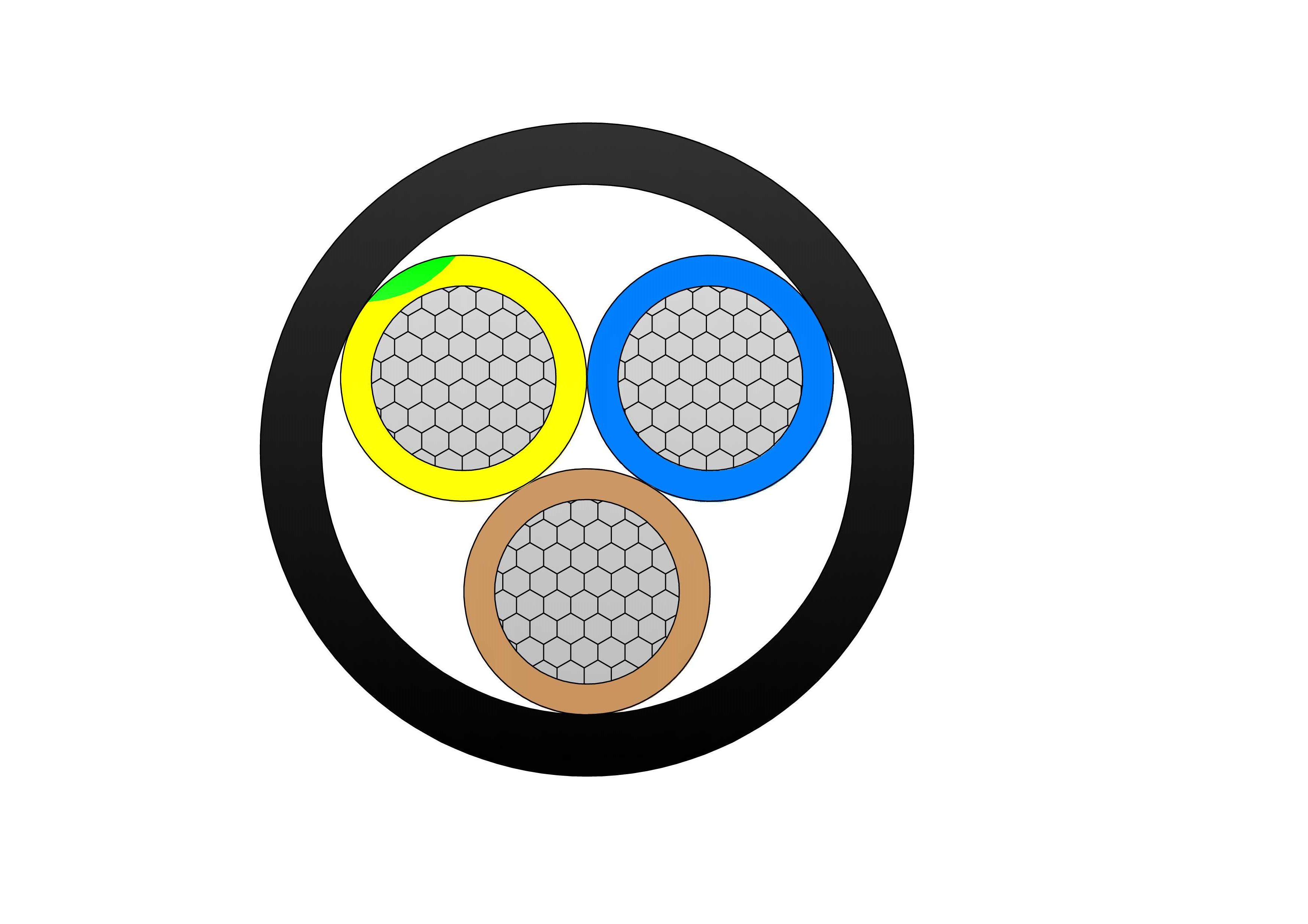

B. Industrial Controls & Automation

Cables such as 4-conductor 6 AWG cable or 4-conductor 8 AWG cable are commonly used in:

-

Motors and pump control

-

Conveyor systems

-

Robotics and automation

-

Three-phase power distribution

These cables support stable operation in demanding environments.

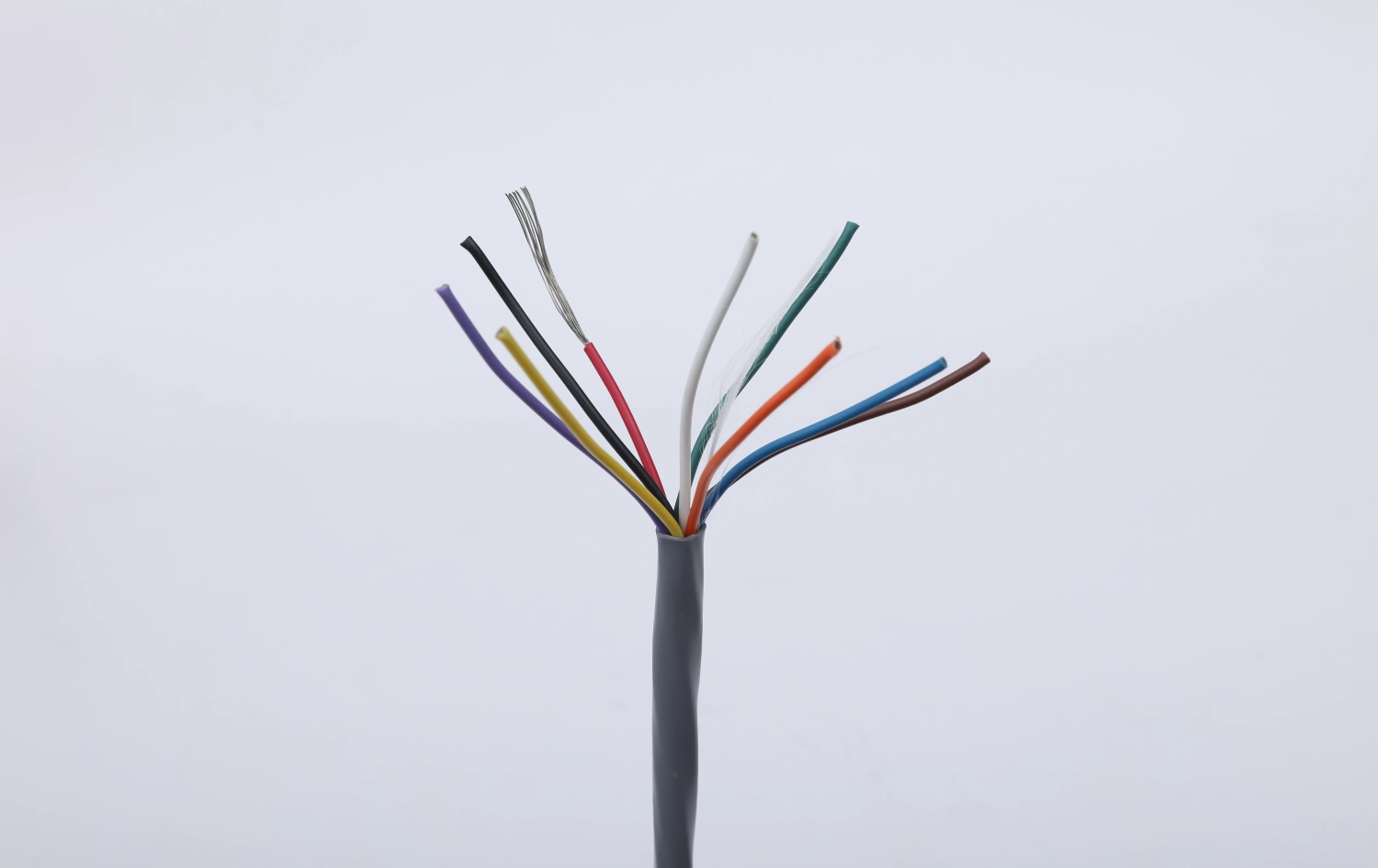

C. Electronics and Communication

18 AWG 4-conductor shielded cable is widely used for:

-

Audio systems

-

Security and fire alarms

-

Instrumentation signals

-

RS-485/PLC communication

-

Sensor wiring

The shielding reduces electromagnetic interference (EMI), ensuring signal integrity.

D. Residential and Commercial Wiring

AWG wires are essential in:

-

Home electrical wire installations

-

Commercial lighting

-

HVAC systems

-

Smart building systems

Because AWG is a standardized wire system, compatibility is ensured regardless of brand.

6. How to Select the Right AWG Wire Size

Choosing the correct AWG cable requires evaluating several technical factors.

1. Electrical Load (Current Requirement)

Higher loads require larger AWG sizes. Always check NEC or IEC tables for ampacity.

2. Voltage Drop

Longer cable runs increase resistance. For critical systems, voltage drop must be kept below 3%.

3. Operating System Requirements

The cable must comply with:

-

Voltage rating

-

Temperature rating

-

Environmental exposure

-

Mechanical strength

4. Installation Environment

Consider whether the system involves:

-

Underground routing

-

High vibration machinery

-

Areas with EMI

-

Outdoor UV exposure

Shielded cables, like 18 AWG 4-conductor shielded cable, are essential for noisy environments.

5. Number of Conductors

Multi-conductor cables (4-conductor, 6-conductor, etc.) streamline installation for complex control circuits.

6. Multi-Conductor AWG Cable Examples

1. 4 AWG 4 Conductor Cable

Used in heavy-load distribution, renewable energy, and marine power systems.

2. 8 AWG 4 Conductor Cable / 4 Conductor 8 AWG Cable

Suitable for medium-power circuits and industrial machine wiring.

3. 4 Conductor 6 AWG Cable

Common in motor circuits requiring balanced load distribution.

4. 2 AWG 4 Conductor Cable

For high-capacity feeder circuits and commercial electrical installations.

Each configuration supports efficient routing while maintaining AWG-based reliability.

7. Why AWG Standardization Matters

AWG ensures:

-

Universal compatibility

-

Predictable electrical performance

-

Safety and reliability

-

Simplified engineering design

-

Improved candidate experience for installers and engineers selecting cables

Because the AWG system defines the diameter of the wire and cross-sectional area, choosing the correct wire size becomes a straightforward engineering decision.

Understanding the AWG system is essential for selecting the right electrical wire for any application. Whether you are working with 4 AWG 4 conductor cable, 18 AWG 4 conductor shielded cable, 4 conductor 6 AWG cable, 8 AWG 4 conductor cable, or 2 AWG 4 conductor cable, knowing the relationship between AWG, conductor diameter, cross-sectional area, and electrical load ensures safe, reliable, and efficient operation.

AWG conductor cables remain a cornerstone of modern power distribution, automation systems, and electronic communication—providing standardized performance across the entire electrical industry.

2Y-high-voltage-power-cable-2.webp)