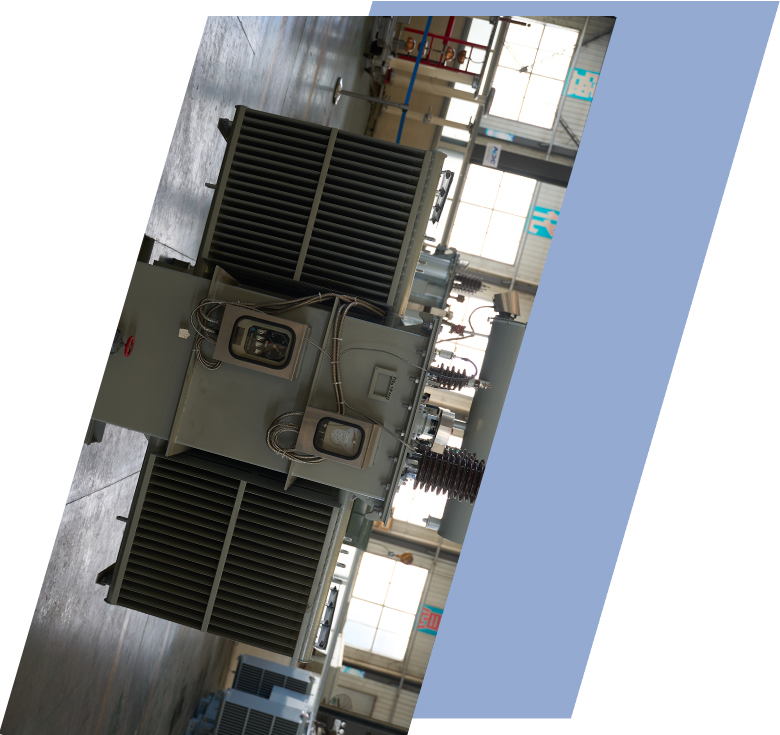

3000kVA Oil Immersed Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Oil immersed distribution transformer

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA, IEC, CE

- Application Temporary Power Supply Systems, Utilities

- Power Rating 3000kVA

- Certificate UL, CESI, IEEE

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 3000kVA | |

| Rating Primary Voltage | 2.4 - 34.5kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| Insulating Oil Weight | 1930 kg | |

| Total Weight | 7100 kg | |

| Outline Dimensions(L×W×H)in. | 2520 × 2000 × 2720(mm) | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

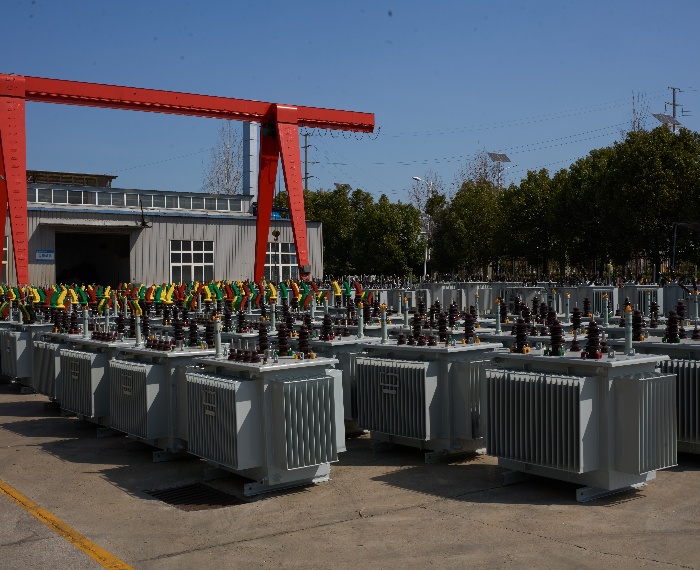

Packing and Shipping

Detached components are individually protected: radiators crated with anti-vibration foam and bracing, high-voltage bushings (RIP/porcelain) in custom shock-mounted enclosures, OLTC mechanisms locked and sealed, and control cubicles wrapped with desiccants. The main transformer body is secured to heavy steel skids or ISPM-15 compliant reinforced wooden/steel cradles featuring engineered blocking, lateral restraints, and impact-absorbing systems rated for 5–6g forces typical in multimodal transport. Packaging incorporates multi-layer weatherproof tarpaulins, volatile corrosion inhibitors (VCI), humidity/temperature recorders, and digital shock/tilt loggers for full handling traceability.

Ocean freight—the primary mode for export—utilizes flat-rack, open-top, or heavy-lift vessels with IMO-compliant lashing, salt-mist protective barriers, and full shrouding; inland road/rail transport employs specialized low-loader trailers with hydraulic suspension, weight-distributed cradles, and marked lifting lugs. Complete export documentation package includes commercial invoices, detailed packing lists, certificates of origin/conformity, routine/type test reports, dimensional/lifting drawings, oil safety data sheets, installation manuals, and HS code declarations (8504.22/8504.23 for power transformers in this capacity range).

We manage full-scope logistics coordination from factory to final destination, offering FOB/CIF/door delivery, customs clearance support, marine insurance, and value-added services such as third-party pre-shipment inspections, professional crane offloading supervision, on-site oil filtration/processing, transformer erection guidance, and commissioning assistance. This integrated process minimizes transit risks, maintains factory-calibrated performance, complies with international regulations, and ensures timely, damage-free delivery for utility, industrial, and renewable energy clients worldwide.

Manufacturer Test

Progress Test

Progress testing for the 3000kVA oil immersed transformer begins with high-permeability silicon steel lamination inspection for thickness consistency insulation coating integrity magnetic flux density and burr-free edges via Epstein frame testing to secure ultra-low core losses then core stacking progress verifies multi-step mitered joints precise yoke clamping torque flux shielding and vibration suppression measures. Winding fabrication progress monitors oxygen-free copper conductor purity insulation paper/enamel buildup automated winding tension control turn precision and high-voltage inter-turn dielectric testing post-winding. Core-coil assembly progress confirms radial axial clearances critical barrier placement end-insulation compression and short-circuit force withstand bracing structures. Tank production progress evaluates multi-layer weld seam NDT radiography hydrostatic overpressure holds surface preparation multi-coat epoxy/polyurethane painting thickness and corrosion resistance validation pre-integration progress audits bushing radiator conservator alignment accessory mounting and initial vacuum pressure cycle simulations to identify early assembly issues ensuring smooth progression to detailed qualification phases.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Load loss impedance voltage efficiency determination for the 3000kVA oil immersed transformer shorts secondary applies reduced primary voltage computes copper losses percentage impedance (6–10%) total losses at 75°C and regulation characteristics for overload assessment. Oil routine verifies dielectric strength (>60kV/2.5mm) moisture (<20ppm) acidity DGA baseline zero fault gases. Thermal indicators confirm top-oil winding temperature rise limits (<60K/<65K) through short-duration heat run simulation. Functional trials activate pressure relief devices Buchholz sudden pressure relays, temperature alarms OLTC full-cycle operation and sound power level (<65dB). Structural validation includes tank overpressure endurance, leak-free integrity bushing flashover margins wiring continuity. Detailed FAT reports with metrology-traceable certificates optional customer third-party witnessing, certify IEC 60076 GB1094 IEEE full compliance routine special test endorsement prior to shipment clearance.

Routine Test - No Load Loss Test

Voltage source (usually 230V, 400V or customized according to customer requirements to adapt to different equipment)

Power analyzer (used to measure power loss and efficiency)

Ammeter and voltmeter

Temperature and humidity meter

Please ensure that the test is carried out in a suitable environment with a relative humidity of less than 75% and avoid rainy days or extreme weather (recommended temperature range: 20-30°C).

Connect the test equipment to the high voltage side of the transformer, making sure the wiring is correct and the equipment is grounded.

Apply Test Voltage:

Usually it is 110% of the rated voltage, for example, if the rated voltage of the transformer is 33 KV, apply 36.3 KV (110%).

No Load Current

No Load Loss

Power Factor

Current

Voltage

Temperature and Humidity

No-load loss < 0.2% ≤ 0.5% rated power (good)

No-load loss > 0.5% rated power (further inspection or corrective action required)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.