11kV – 33kV Solar Inverter Duty Transformer Up to 20MVA

- Primary Voltage Ratings 11kV - 33kV or others

- Secondary Voltage Ratings 0.315kV, 0.38kV, 0.48kV, 0.6kV, 0.69kV, 0.8kV or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Solar Step-up Transformer

- BIL 30/200kV, 30/170kV, 30/150, 30/95 or others

- Standards IEEE, ANSI, NEMA, IEC, GB

- Application renewable energy substations, solar-plus-storage systems

- Power Rating Up to 20MVA

- Certificate UL ,CESI

- Cooling Method ONAN, KNAN

- Opeartion Step-up

Technical Specifications

| Rated Power | Up to 20MVA | |

| Rating Primary Voltage | 11kV - 33kV | |

| Secondary Voltage | Customized | |

| Frequency | 50/60Hz | |

| Vector Group | Dyn11,Ynd11,Dyn11yn11,YNd11d11 | |

| Winding Material | Aluminum/Copper | |

| Zero-Sequence Impedance | Customized | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| CT |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

| Terminal box |

Customization Optional

Packing and Shipping

Before packing, the transformer undergoes a final surface inspection and cleaning process. All external fittings, bushings, radiators, and accessories are securely fastened or separately packed as required. Critical components such as tap changers, monitoring devices, and terminal connections are protected with reinforced covers to prevent impact damage and contamination during transportation.

For overseas or long-distance shipments, the transformer tank is treated with anti-corrosion coatings and wrapped using moisture-proof materials. Depending on project requirements, the unit may be shipped oil-filled, nitrogen-filled, or vacuum-sealed to preserve insulation performance and prevent moisture ingress. Oil-filled transformers are sealed with pressure-tested gaskets to ensure leak-free transport under varying temperatures and altitudes.

The main body is mounted on heavy-duty steel skids or wooden bases designed to support the transformer’s weight and maintain balance during lifting and transit. Shock-absorbing pads and internal bracing are applied to reduce vibration and mechanical stress. For containerized transport, dimensions and weight distribution are carefully calculated to comply with port and carrier regulations.

Export packaging materials comply with international standards such as ISPM 15 for wooden components. Clear handling marks, center-of-gravity indicators, lifting points, and safety labels are applied to facilitate correct handling at ports, warehouses, and construction sites. Special instructions for lifting, stacking, and storage are clearly marked on the package. Comprehensive shipping documentation is prepared for each transformer, including packing lists, commercial invoices, certificates of origin, factory test reports, and operation manuals. Photos of the packing process may be provided upon request to enhance shipment transparency. This systematic packing and shipping approach ensures that the transformer arrives on site in optimal condition, ready for installation with minimal preparation.

Manufacturer Test

Progress Test

Progress testing is conducted at defined manufacturing milestones to ensure consistent quality throughout production. Incoming inspections verify core steel properties, conductor specifications, and insulation material compliance. During winding fabrication, dimensional accuracy and conductor tension are closely monitored to prevent mechanical stress.

Intermediate electrical checks such as resistance measurement and insulation resistance testing are performed before assembly continues. Core and coil assembly inspections confirm alignment and structural integrity. Oil processing parameters, including filtration level and moisture content, are recorded to ensure dielectric reliability. These progress tests enable early identification of potential issues and ensure manufacturing stability.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

Transformer Factory Acceptance Test

The Transformer Factory Acceptance Test (FAT) is a critical quality assurance procedure conducted to verify that the solar inverter duty transformer fully meets technical specifications, contractual requirements, and applicable international standards prior to shipment. All FAT activities are performed in a controlled factory environment by qualified testing engineers.

The FAT begins with a comprehensive visual and dimensional inspection to confirm correct assembly, workmanship quality, and conformity of nameplate data. Electrical routine tests follow, including winding resistance measurement to verify conductor integrity and contact reliability. Voltage ratio and polarity tests ensure accurate transformation performance and correct phase relationships. Vector group verification is carried out to confirm compatibility with solar inverter systems and grid interconnection requirements. No-load loss and load loss measurements are conducted to validate efficiency targets and thermal design performance. Insulation resistance tests assess the condition of the insulation system before high-voltage testing.

Routine Test - Applied Voltage

Voltage source: usually 1 kV, 5 kV, 10 kV, or customized according to customer needs

Temperature and humidity meter: used to record environmental conditions

Check the connection terminals and wiring to ensure that they are not loose or contaminated.

Test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20-30°C).

Properly connect the test equipment to the bushings or terminals of the device under test and ensure that all connection points are properly grounded.

Selecting the test voltage:

Select the appropriate applied voltage based on the rated voltage of the equipment.

Measuring leakage current

Applied voltage

Current stability

Any possible voltage fluctuations

The current value exceeded the allowable range and the equipment needs to be inspected or maintained (pending repair)

There was a serious fault or instability and the equipment could not continue to operate (unqualified)

Application

Technical Advantages

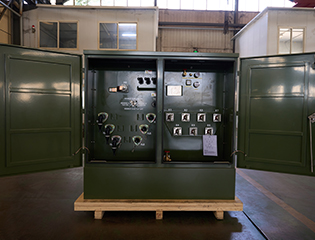

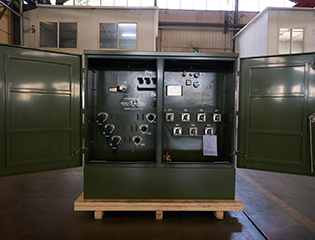

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.