How to use guard wire to protect the wire?

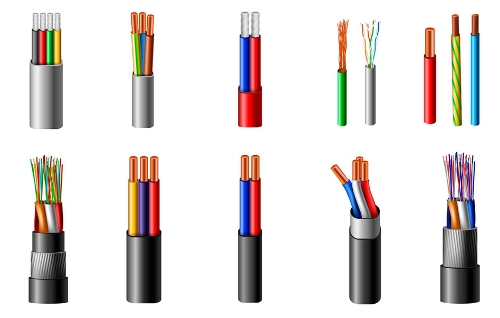

In modern power grid projects, wires and cables are almost the backbone of infrastructure. Whether for residential, commercial, or industrial purposes, it is crucial to protect these wires from physical damage, environmental hazards, and operational risks. Therefore, wire protection systems are one of the most effective and widely used solutions.

But what is wire guard, and how do you use it effectively to safeguard your wiring infrastructure? This comprehensive guide will answer that question and provide step-by-step instructions on how to use guard wire to protect electrical wiring, including exposed bare conductors and critical cable systems.

What Is Wire Guard?

A wire guard, sometimes referred to as a guard wire, is a mechanical protection system used to shield wires and cables from damage caused by impact, abrasion, weather exposure, or accidental contact. It typically consists of durable materials like metal or rigid plastic that are installed over or around wiring systems.

Wire guard systems are commonly used in areas with high foot traffic, outdoor installations, machinery setups, and environments with safety compliance requirements. These systems can be found in various forms, including trays, covers, enclosures, mesh guards, and conduit-like pathways.

Why Use Wire Guard Systems?

There are several compelling reasons to implement wire guard systems in any electrical installation:

- ✅ Safety: Prevents electrical hazards caused by exposed or damaged wires

- ✅ Compliance: Meets occupational safety standards in industrial settings

- ✅ Durability: Protects wires from environmental factors such as UV rays, moisture, dust, and rodents

- ✅ Organization: Helps keep wiring clean, tidy, and accessible for maintenance

- ✅ Longevity: Extends the service life of cables and reduces replacement costs

Organizations like Wire Guard Systems Inc. specialize in the design and manufacturing of high-quality wire protection solutions tailored to different industrial and commercial needs.

Types of Wire Guards

Here are some of the most commonly used wire guard systems:

1. Mesh Wire Guards

Used for covering fans, lights, or cable clusters, these guards provide airflow while protecting cables from impact.

2. Conduit and Tubing Guards

These encase the wires fully and are typically used in high-risk environments like factories or outdoor settings.

3. Cable Trays and Ladders

Ideal for organized routing of wires and cables across ceilings and walls in industrial facilities.

4. Surface-Mounted Channel Guards

Used in commercial and office environments to keep exposed wiring along floors and walls neat and protected.

5. Wire Machine Guards

Installed on machinery to shield electrical connections from accidental contact or mechanical wear.

Comparison Table: Types of Wire Guard Systems

|

Type |

Best Use Cases |

Features |

Common Materials |

|

Mesh Wire Guards |

Fans, light fixtures, exposed boxes |

Ventilation-friendly, medium-duty |

Wire mesh, steel |

|

Conduit & Tubing Guards |

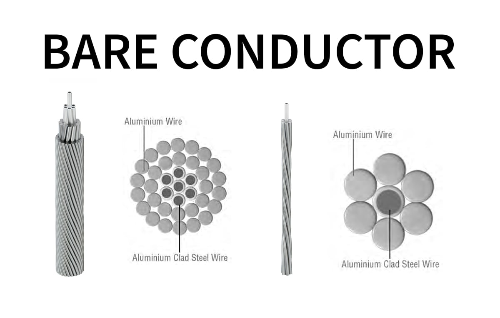

Outdoor cables, bare conductors |

Fully enclosed, waterproof, dustproof |

PVC, galvanized steel |

|

Cable Tray & Ladder |

Data centers, factories, and ceiling runs |

Organized routing, scalable |

Metal, polycarbonate |

|

Surface Channel Guards |

Offices, retail spaces, schools |

Aesthetic, trip-proof, surface-mounted |

ABS plastic, aluminum |

|

Wire Machine Guards |

Factory machinery, industrial systems |

Prevents accidental contact or injury |

Steel plates, perforated metal |

Step-by-Step: How to Use Guard Wire to Protect the Wire

Now let’s break down how to use guard wire effectively in any installation:

Step 1: Assess the Wiring Environment

Determine the location, wire type (e.g., insulated or bare conductor), exposure risks, and physical constraints. Outdoor installations, machinery environments, and high-traffic areas all require tailored solutions.

Step 2: Choose the Right Wire Guard System

Based on your assessment, select an appropriate guard system. For example:

- Use mesh guards for exposed fans or lighting wiring

- Use rigid conduit for outdoor exposed bare conductors

- Use wire machine guards for factory environments

Refer to safety and compliance standards such as OSHA or IEC when making your decision.

Step 3: Measure and Prepare the Area

Measure the length and routing path of your wires and cables. Ensure you have the correct dimensions and fastening materials. Clean the installation area to avoid interference with guard fittings.

Step 4: Install the Wire Guards

Follow the manufacturer's instructions for installation. General tips include:

- Secure guards using brackets, clamps, or wall anchors

- Ensure no sharp edges come into contact with the wires

- Leave adequate space for wire heat dissipation

- Route wires neatly through the guard system to prevent tangling

Step 5: Test for Safety and Accessibility

Once installed, inspect the system for stability, proper protection, and accessibility. If you're using guards for power cables, ensure there's no chance of overheating. For bare conductors, verify there's sufficient insulation space.

Risk Comparison: Before and After Using Wire Guard

Properly installed wire guard systems significantly improve operational safety. Here's a direct comparison:

📉 Before vs. After Using Wire Guard

|

Factor |

Without Wire Guard ⚠️ |

With Wire Guard ✅ |

|

Risk of Electric Shock |

High |

Low |

|

Cable Wear and Tear |

Rapid aging |

Slower degradation |

|

Safety Incident Frequency |

Higher |

Greatly reduced |

|

Maintenance Difficulty |

Messy, harder to identify |

Organized and accessible |

|

Replacement / Repair Cost |

Expensive |

More cost-efficient |

Maintenance Tips for Wire Guard Systems

To ensure your wire guard systems continue to function optimally:

- 🛠️ Inspect regularly for signs of wear, rust, or damage

- 🧹 Clean guards to prevent the buildup of dust and debris

- 🔧 Tighten fasteners and replace any broken parts immediately

- 📋 Log maintenance checks for safety audits and compliance

Common Use Cases

Guard wire systems are used in a wide range of industries, including:

- Construction Sites: For protecting temporary power cables

- Manufacturing Plants: Wire machine guards prevent contact with moving parts

- Data Centers: Cable trays with cover guards keep high-density cable installations safe

- Public Spaces: Surface-mounted guards shield wires in schools, malls, and offices

- Utilities and Power Distribution: Protect bare conductors on poles or in substations

Wire Guard vs. Ground Wire – Know the Difference

It’s important to note that a guard wire is not the same as a ground wire. While both contribute to electrical safety, they serve different functions:

- Guard Wire: Provides physical protection

- Ground Wire: Provides electrical grounding and surge protection

Make sure you are not confusing the two when planning your installations.

Final Thoughts

Whether you're an engineer, contractor, or facility manager, understanding how to use guard wire to protect the wire is essential for ensuring long-term electrical safety and system integrity.

A well-chosen wire guard system does more than protect — it contributes to workplace safety, compliance, and operational efficiency. For high-performance protection, consider products from trusted manufacturers like Wire Guard Systems Inc., known for their durability and design excellence.