What Is Overhead Insulated Cable? A Complete Guide for Power Distribution

Power distribution networks are evolving rapidly to meet modern demands for safety, reliability, and efficiency. For engineers working in the field, one challenge is finding conductor systems that minimize risks while improving performance. Overhead Insulated Cable (OHC), also known as Aerial Bundled Cable (ABC), has become a preferred choice in many countries, gradually replacing traditional bare conductors.

What Is Overhead Insulated Cable?

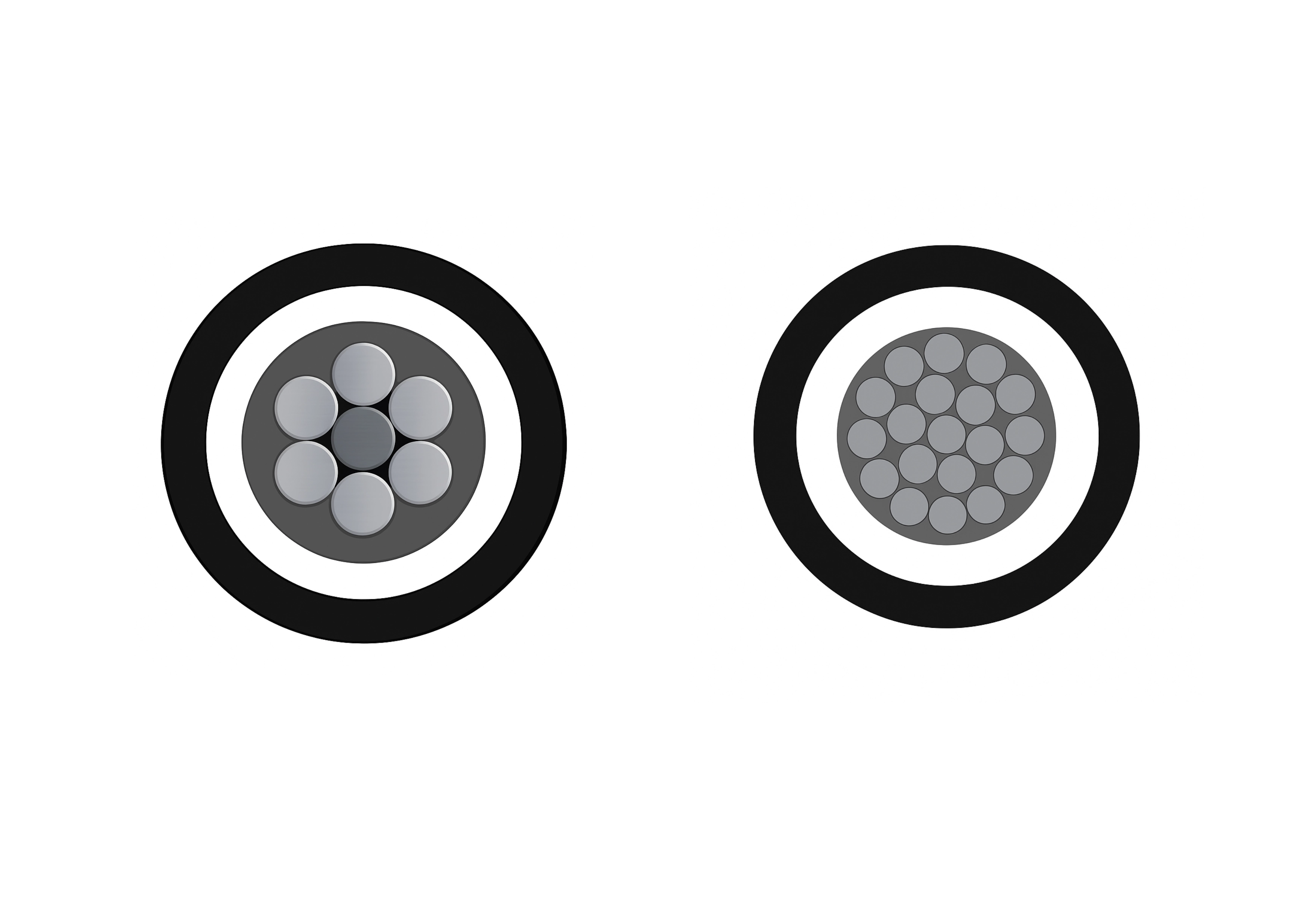

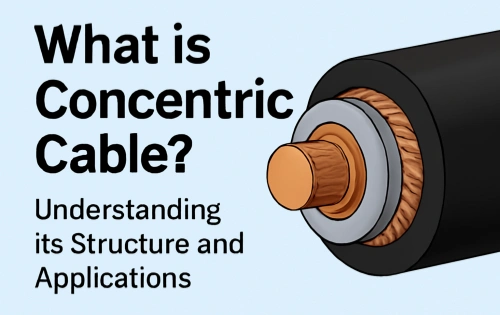

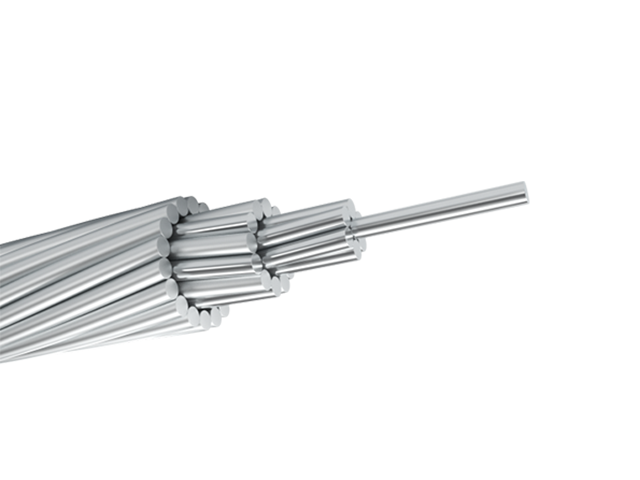

Overhead insulated cable is an aluminum or aluminum-alloy conductor covered with weather-resistant insulating material, typically cross-linked polyethylene (XLPE). It is designed for low- and medium-voltage power distribution, providing a safer and more reliable alternative to bare conductors.

From an engineer’s perspective, OHC can be summarized by three key aspects:

-

Material: Aluminum strands for conductivity, XLPE for insulation.

-

Configuration: Single-core or bundled (commonly 3-phase conductors plus a neutral).

-

Voltage Class: Typically used up to 36 kV in distribution networks.

This structure ensures mechanical strength while maintaining insulation integrity in outdoor environments.

Benefits of Using Overhead Insulated Cable

Improved Safety

For engineers, one of the biggest concerns with bare conductors is accidental contact by people, animals, or tree branches. OHC significantly reduces these risks, lowering the chances of outages or injuries.

Reliability in Harsh Environments

In regions with high humidity, pollution, or heavy vegetation, OHC outperforms bare conductors. The XLPE insulation prevents flashovers, making the system more robust against short circuits caused by external factors.

Reduced Maintenance Costs

From a utility perspective, trimming trees near lines is expensive. With OHC, clearances can be smaller, and fewer outages mean reduced operation and maintenance (O&M) expenses.

Urban and Rural Applications

OHC is highly adaptable:

- Urban areas: safer for densely populated zones with limited corridor space.

- Rural areas: ideal for long-distance distribution with minimal supervision.

Applications of Overhead Insulated Cable

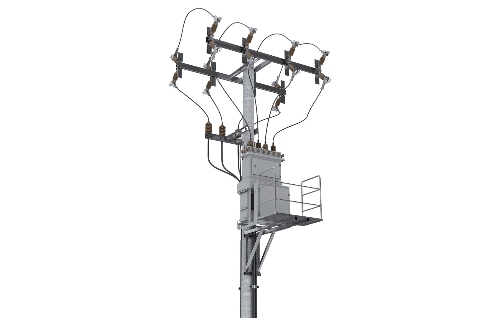

Urban Power Distribution

OHC minimizes visual impact and is safer for residential areas. Engineers can design compact networks with reduced right-of-way requirements.

Rural Electrification

In rural electrification projects, especially in developing regions, OHC provides a cost-effective solution with fewer interruptions caused by vegetation or wildlife.

Industrial Power Supply

Industries that require stable power benefit from OHC’s reliability, ensuring fewer shutdowns and lower maintenance.

Temporary Power Supply

On construction sites and temporary installations, OHC can be deployed quickly while maintaining safety standards.

Types of Overhead Insulated Cable

Low Voltage Aerial Bundled Cable (LV ABC)

- Voltage: up to 1 kV

- Commonly used for service drops and secondary distribution.

Medium Voltage Overhead Insulated Cable (MV OHC)

- Voltage: 6–36 kV

- Used in feeders and primary distribution networks.

Service Drop Cable

- Connects utility poles to customer premises.

- Ensures safety in residential connections.

Installation and Standards

Key Installation Considerations

Engineers must account for:

- Clearances: Safe distances from trees, buildings, and roads.

- Accessories: Correct use of clamps, connectors, and suspension hardware.

- Tension Control: Maintaining mechanical strength without damaging insulation.

International Standards and Compliance

Overhead insulated cables must comply with standards such as:

- IEC 60502 – Power cables with extruded insulation.

- ASTM B231/B232 – Aluminum conductors.

- National grid codes depending on region.

Maintenance and Inspection

Routine inspection includes checking for:

- Insulation wear or cracking.

- Loose hardware or improper tension.

- Environmental damage (UV exposure, pollution).

Overhead Insulated Cable vs. Bare Conductor

|

Feature |

Bare Conductor |

Overhead Insulated Cable |

|

Safety |

High risk of contact faults |

Insulated, safer for public and workers |

|

Maintenance |

Frequent trimming & fault repair |

Lower maintenance needs |

|

Reliability |

Sensitive to trees, animals, weather |

Resistant to external influences |

|

Cost |

Lower initial investment |

Higher initial, but lower lifecycle cost |

|

Applications |

Rural, open areas |

Urban, rural, industrial, temporary |

For engineers, the key takeaway is that OHC offers long-term savings despite higher upfront costs.

Choosing the Right Overhead Insulated Cable

When specifying OHC, engineers should consider:

- Voltage rating: LV or MV depending on the grid design.

- Conductor size: Based on load current and distance.

- Environmental conditions: UV exposure, salt, pollution, or vegetation.

- Standards compliance: Ensuring compatibility with local regulations.

A proper selection balances technical performance, safety, and lifecycle cost.

Overhead insulated cables represent a modern, safe, and reliable solution for power distribution. For engineers, they offer significant advantages over bare conductors, particularly in urban areas, rural electrification, and industrial supply.

By reducing outages, lowering maintenance, and improving public safety, OHC contributes to a smarter and more sustainable grid. As power networks evolve, insulated conductors will continue to play a crucial role in delivering efficient and dependable energy.

SSCHOU-mining-cable-2.webp)