PVC Cable: Durability, Cost-Effectiveness, and Versatility

Polyvinyl chloride (PVC) has long been one of the most widely used materials in the manufacturing of electrical cables. Whether it is PVC-coated MC cables, PVC jacketed MC cables, or PVC electrical cables, PVC cables have earned a reputation for their durability, versatility, and cost-effectiveness in a wide range of electrical applications. The combination of abrasion resistance, heat resistance, and fire-resistant properties makes PVC an excellent choice for both residential and industrial power distribution systems.

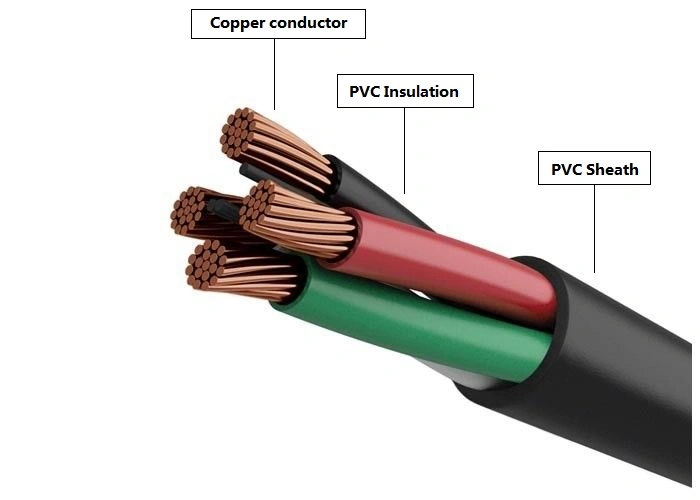

What is PVC Cable?

PVC cables are electrical cables with a polyvinyl chloride (PVC) outer jacket or insulation. PVC insulation is commonly used in wires and cables because of its high dielectric strength, abrasion resistance, heat resistance, and low cost. This insulation type is found in various electrical products, ranging from electric wire used in residential homes to large industrial power cables.

PVC-coated cables are often chosen because they provide temperature range flexibility and can endure harsh environments. This is particularly useful in outdoor installations, where cables must withstand physical wear, exposure to chemicals, and UV radiation.

Key Properties of PVC Cables

The success of PVC cables can be attributed to the unique combination of materials used, giving them distinct advantages over other types of cables.

1. Durability and Abrasion Resistance

One of the most significant benefits of PVC cables is their abrasion resistance. PVC-coated cables can withstand mechanical wear and tear, which makes them an ideal choice for high-traffic areas where cables may be subject to physical damage.

This durability ensures a longer lifespan for the cable, reducing the frequency of replacements and maintenance costs. Whether used in industrial power systems or residential buildings, PVC insulation offers superior protection against physical stresses.

2. Cost-Effectiveness

PVC cables are a highly cost-effective solution compared to other types of insulation materials. The production of polyvinyl chloride PVC is relatively inexpensive, and the material is readily available. This results in lower production costs for insulated cables, making them more affordable for a wide range of applications. As such, PVC electrical cables are commonly used in both low and medium-voltage applications, offering a great balance of cost and performance.

3. Fire Resistance and Flame Retardancy

In many installations, fire-resistant cables are crucial for safety. PVC cables are inherently flame-retardant, making them less likely to catch fire and spread flames compared to cables with less robust insulation. This property is critical in residential, commercial, and industrial applications where fire safety is a top priority.

For additional protection, PVC-coated MC cables (Metal Clad cables) are designed with both fire-resistant properties and the capability to withstand high temperatures, making them suitable for high-voltage environments. These cables are often installed in areas with high fire risks, such as power plants, factories, and chemical plants.

4. Heat Resistance

PVC cables are capable of withstanding elevated temperatures, making them versatile in many applications where the cables are exposed to heat. They perform well within a temperature range of about -15°C to 70°C. For installations that require even more resistance to heat, PVC-insulated cables can be enhanced with additional protective layers to increase their thermal stability.

Variety of Applications for PVC Cables

One of the standout features of PVC electrical cables is their ability to be adapted for a wide range of applications. Below are some of the most common uses of PVC-insulated cables:

1. Residential Wiring

In residential environments, PVC cables are often used for general wiring purposes due to their cost-effectiveness, ease of installation, and safety features. PVC-insulated cables are commonly used in power supply systems, lighting circuits, and appliance connections.

2. Industrial Power Systems

In industrial settings, PVC jacketed MC cables are often used for powering machinery and equipment. These cables are designed to handle heavy-duty operations and offer protection from mechanical damage, environmental conditions, and electrical hazards. The PVC insulation ensures that the cables remain safe and functional even in high-stress environments.

3. Renewable Energy Projects

As the renewable energy sector continues to grow, PVC cables are increasingly used in solar power and wind power systems. These systems require durable and reliable cables that can handle fluctuating voltages and temperatures while maintaining safety standards. PVC-insulated cables are commonly found in solar panel connections, wind turbine systems, and energy storage solutions.

4. Underground Cable Systems

PVC-coated MC cables are ideal for underground installations due to their robust construction and excellent resistance to moisture and physical damage. These cables are used to connect power lines across long distances and are especially useful in urban infrastructure, where space is limited.

Advantages of PVC Coated Cables

PVC-coated MC cables have an additional layer of polyvinyl chloride PVC that enhances their resistance to moisture, chemical corrosion, and physical wear. This makes them ideal for harsh environments, such as outdoor installations or areas exposed to chemicals and oils.

These cables are frequently used in:

-

Utility grid connections

-

Outdoor lighting systems

-

Communication infrastructure

The outer PVC jacket protects the inner wires and insulation, ensuring a long-lasting and reliable power delivery system, even in challenging environments.

|

Feature |

Description |

Application |

|

Voltage Rating |

Suitable for low to medium voltage applications, typically ranging from 600V to 35kV |

Residential, commercial, and industrial power distribution |

|

Insulation Material |

Uses PVC insulation, offering excellent electrical properties, high temperature resistance, chemical resistance, and UV stability |

Power transmission, substations, wind power, solar power, etc. |

|

Temperature Range |

Can operate stably between -15°C and 70°C, with some specialized cables handling higher temperatures |

Indoor wiring, underground cables, outdoor power equipment |

|

Abrasion Resistance |

PVC insulation has high abrasion resistance, preventing performance degradation due to mechanical wear |

Industrial equipment, machinery connections, cable trays |

|

Fire Resistance |

Flame-retardant properties that help reduce the risk of fire spread |

High-risk areas (such as power equipment, building interiors) |

|

Corrosion Resistance |

PVC material is highly resistant to moisture, oils, and chemicals |

Underground power distribution, chemical industries, offshore platforms |

|

Typical Applications |

Used in a variety of applications such as residential wiring, industrial power distribution, and renewable energy projects |

High-voltage power transmission, equipment connections, electrical control systems, construction projects |

Choosing the Right PVC Cable for Your Needs

When selecting the right PVC cable, it is essential to consider the following factors:

-

Voltage requirements: Ensure that the cable’s voltage rating matches your system’s requirements.

-

Environmental conditions: Choose cables with adequate protection based on whether the installation is indoors, outdoors, or underground.

-

Temperature and heat resistance: Consider the temperature range that the cables will be exposed to.

-

Flame-retardant properties: For installations requiring fire safety, select cables with flame-retardant or fire-resistant properties.

PVC cables are a versatile, durable, and cost-effective solution for various electrical systems. Whether used in residential wiring, industrial power systems, or renewable energy projects, PVC electrical cables provide reliable performance and long-lasting durability. Their abrasion resistance, heat resistance, and flame-retardant properties make them ideal for a wide range of applications.

By understanding the unique advantages of PVC insulation, PVC-coated MC cables, and PVC jacketed MC cables, you can make informed decisions about which cable type best suits your specific electrical needs. Choose the right PVC-insulated cable to ensure safe, efficient, and reliable power transmission in your next project.