2 AWG vs 2/0 AWG Wire: Key Differences, Applications, and Electrical Performance Explained

In power systems, correctly selecting the conductor gauge is crucial for ensuring the system's safety, performance, and efficiency. Wire gauge determines the conductor's current-carrying capacity, i.e., the maximum current it can handle, thus directly affecting power transmission capability. For example, common 2 AWG and 2/0 AWG (pronounced "two zero") conductors may appear similar in appearance and application, but there are significant differences between them. 2 AWG conductors have a relatively small gauge and are suitable for lower current household distribution and small commercial facilities, typically used for 100-150 amp loads. 2/0 AWG conductors, on the other hand, have a larger gauge and are suitable for industrial equipment or large commercial buildings requiring higher currents, typically carrying 175-200 amps. Choosing the appropriate conductor gauge can effectively reduce voltage drop, improve power transmission efficiency, and prevent safety hazards such as fires caused by overload. Following standards such as the National Electrical Code (NEC) ensures that installation meets safety requirements, preventing electrical faults and equipment damage. A thorough understanding of the characteristics and uses of various conductors is essential in electrical design.

1. Understanding AWG Wire Sizing

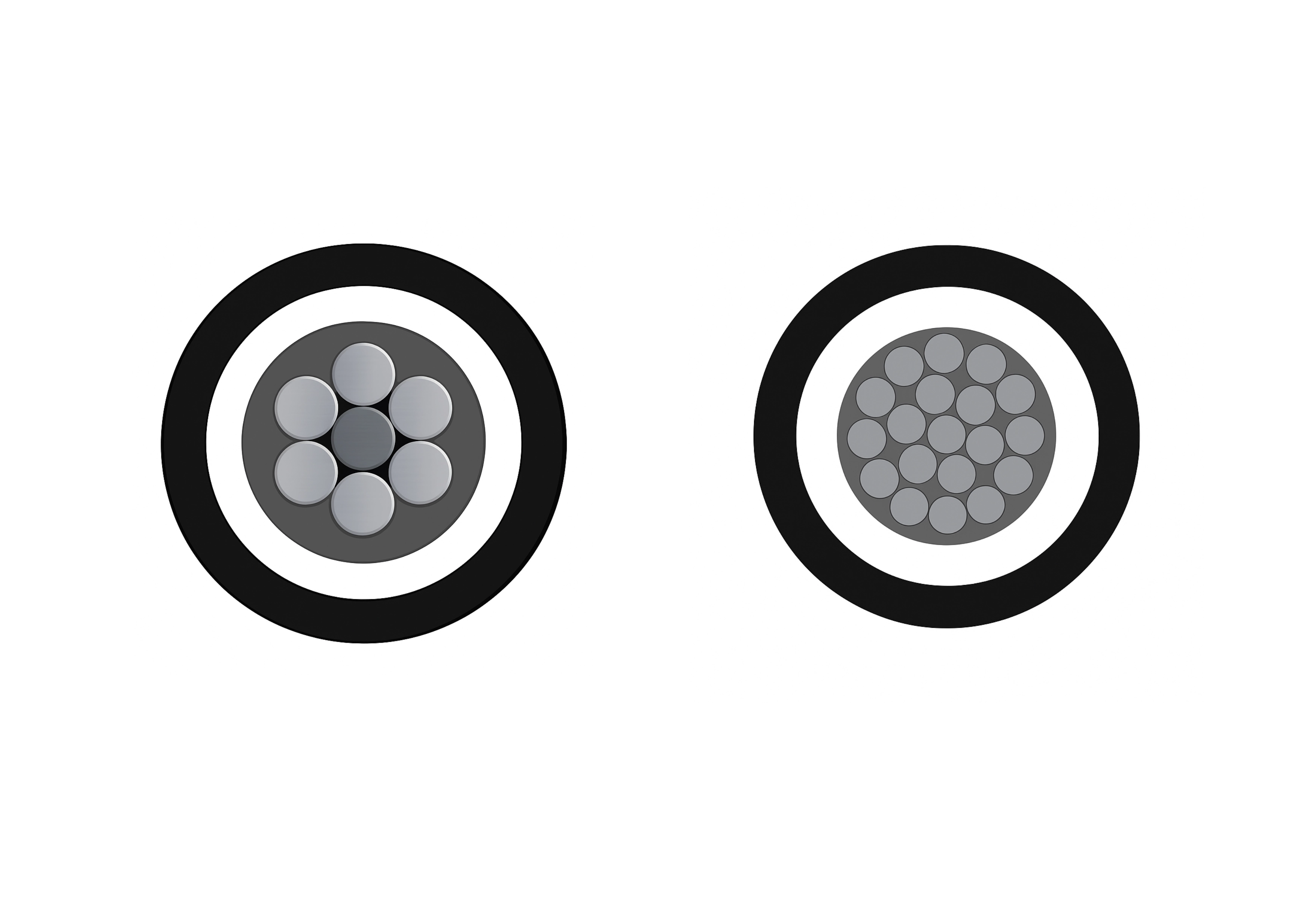

The American Wire Gauge (AWG) system defines wire sizes inversely — the smaller the AWG number, the larger the conductor diameter.

However, once the numbers reach zero, notation changes to “0” or “aught”, and the size increases with each additional zero.

For instance:

- 2 AWG wire is smaller than 1 AWG wire.

- 2/0 AWG wire is larger than both 1 AWG and 1/0 AWG.

This increase in conductor size allows for higher current-carrying capacity (ampacity) and lower resistance, which is vital for long-distance or high-load power transmission.

2. Physical and Electrical Characteristics

The table below highlights the key technical parameters that distinguish 2 AWG from 2/0 AWG conductors.

|

Property |

2 AWG Wire |

2/0 AWG Wire |

|

Diameter (Copper) |

~0.257 inch (6.54 mm) |

~0.365 inch (9.27 mm) |

|

Cross-sectional Area |

33.6 mm² |

67.4 mm² |

|

Typical Ampacity (Copper, 75°C) |

115–130 A |

175–195 A |

|

Typical Ampacity (Aluminum, 75°C) |

90–100 A |

135–150 A |

|

Resistance (Ω/km, Copper) |

~0.52 |

~0.32 |

|

Common Voltage Rating |

600 V – 2 kV |

600 V – 2 kV |

|

Weight (Copper) |

~0.63 kg/m |

~1.08 kg/m |

|

Applications |

Residential feeders, EV chargers |

Industrial panels, subpanels, main feeders |

These numbers clearly show that 2/0 AWG wire has roughly twice the cross-sectional area and significantly higher ampacity than 2 AWG, making it more suitable for heavy-duty applications.

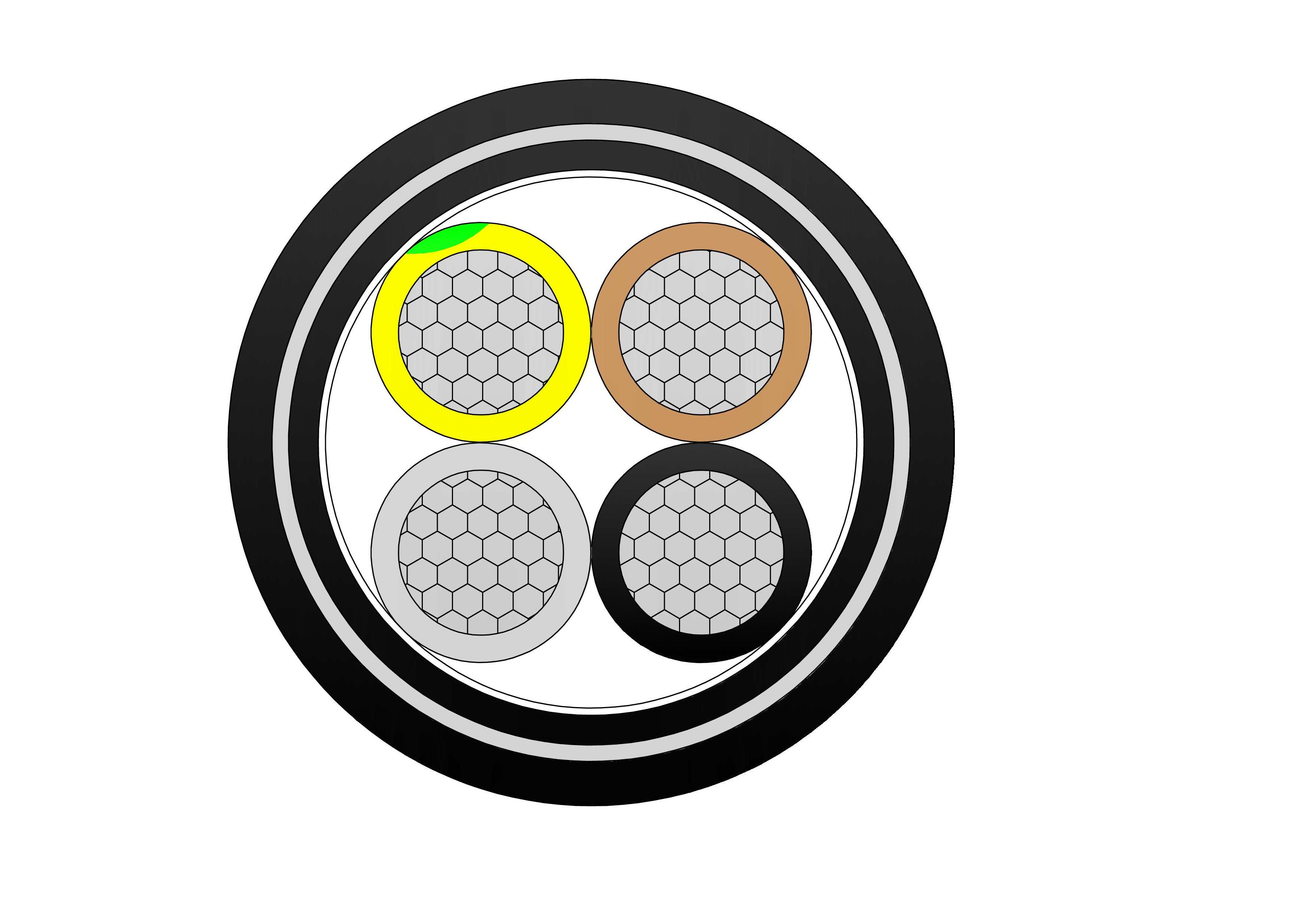

3. Material Comparison: Copper vs. Aluminum Conductors

Both copper and aluminum are widely used as conductor materials. Each has unique advantages depending on application, cost, and environmental conditions.

|

Conductor Type |

Advantages |

Disadvantages |

|

2/0 AWG Copper Wire |

High conductivity, excellent durability, minimal oxidation, smaller size for the same ampacity |

Higher cost, heavier, more rigid |

|

2/0 AWG Aluminum Wire |

Lightweight, cost-effective, easy to install, corrosion-resistant when coated |

Higher resistance, larger size needed, lower mechanical strength |

In practical engineering terms, 2/0 AWG copper wire is ideal for high-reliability installations such as data centers or hospitals, while 2/0 AWG aluminum wire is preferred in utility-scale power distribution where cost and weight are major factors.

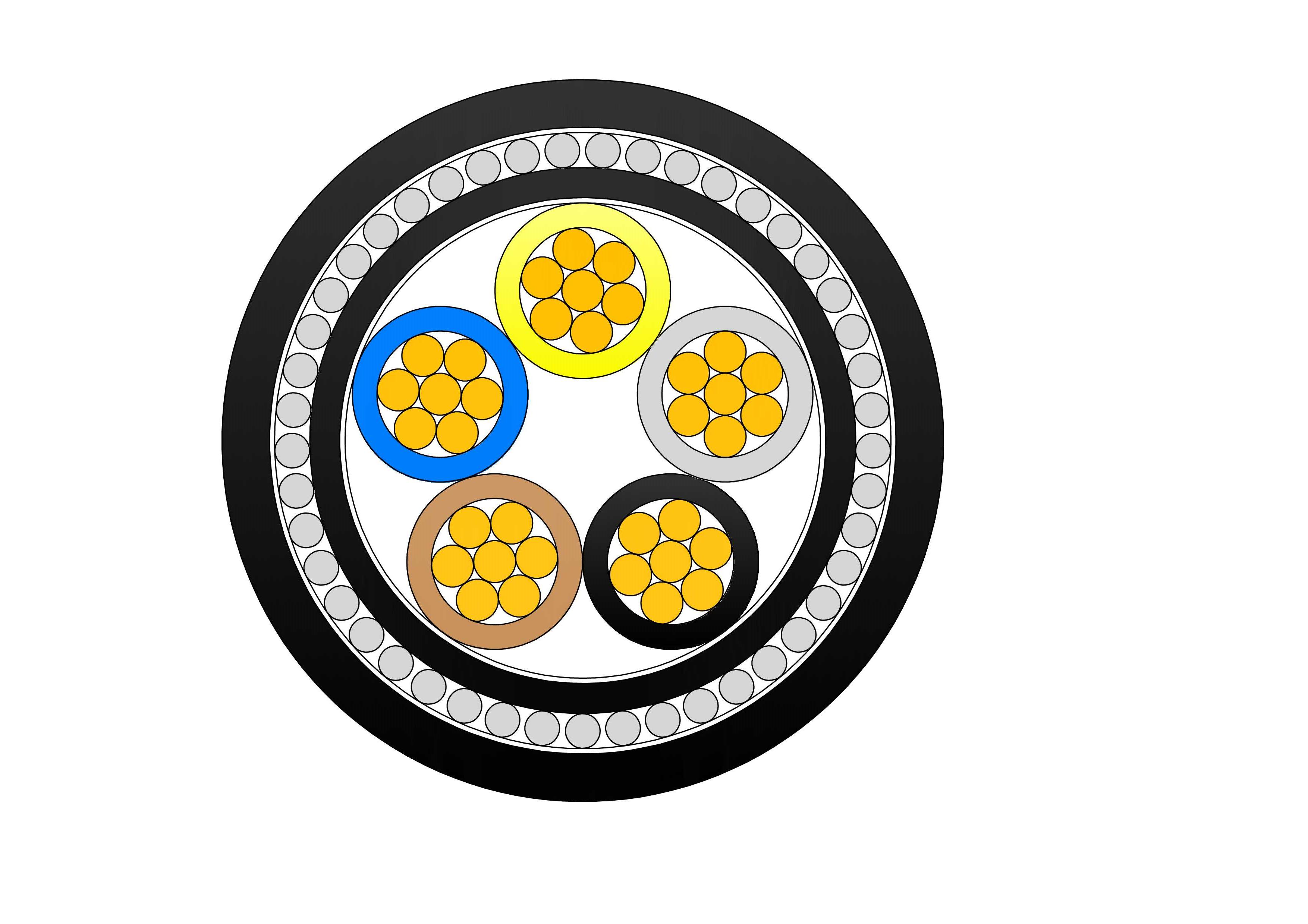

4. Engineering Applications

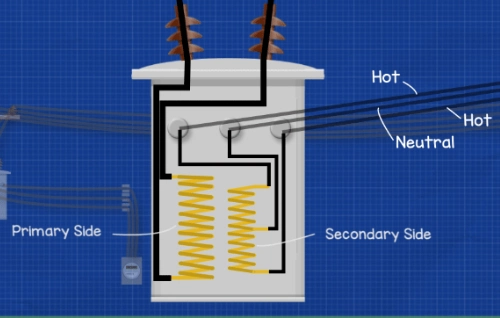

The choice between 2 AWG and 2/0 AWG wire depends on voltage, current, and installation environment.

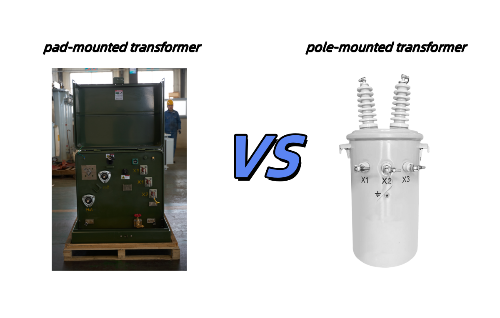

Residential and Commercial Systems

- 2 AWG wire is often used for 100–150 amp service panels, electric vehicle charging stations, or long branch circuits.

- 2/0 AWG wire is typically required for 200–250 amp main service feeders or for connecting large subpanels in multi-unit buildings.

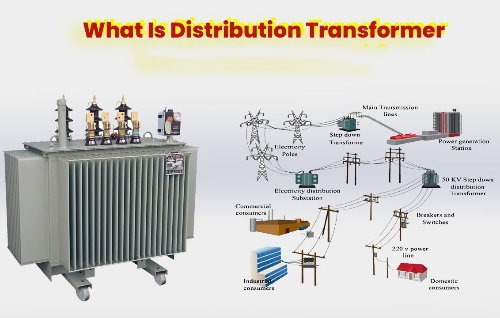

Industrial Power Distribution

- In industrial or manufacturing environments, 2/0 AWG copper wire ensures stable power flow to large motors, transformers, and switchgear.

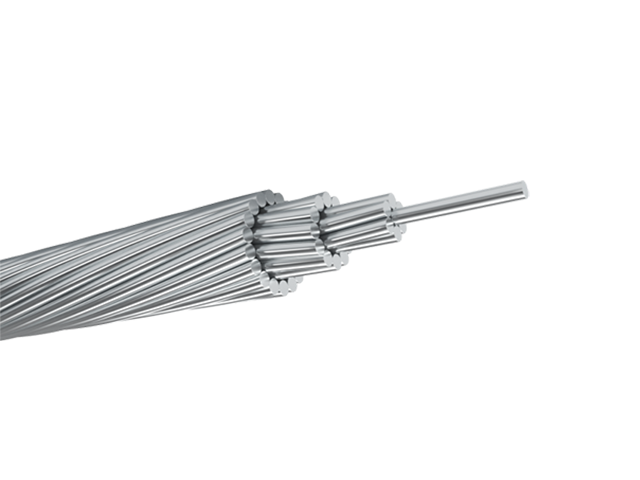

- 2/0 AWG aluminum wire is widely used for overhead feeders and bus duct connections, where weight reduction is crucial.

Renewable Energy Systems

- For solar or wind installations, 2/0 AWG wires provide better efficiency over long distances between inverters and power distribution centers, minimizing voltage drop and power loss.

5. Engineering and Safety Considerations

When choosing between wire sizes, engineers must consider several critical parameters:

- Ampacity (Current-Carrying Capacity) – Always refer to NEC Table 310.16 for allowable ampacity under different temperature and insulation ratings.

- Voltage Drop – Excessive voltage drop can cause equipment malfunction or energy waste; thicker wires like 2/0 AWG reduce losses.

- Thermal Management – Larger conductors dissipate heat more efficiently, improving long-term reliability.

- Conduit Fill and Flexibility – Larger wires require more installation space and may demand special fittings or bending allowances.

- Cost vs. Performance – Copper has better conductivity, but 2/0 AWG aluminum offers significant cost savings (up to 40%) for large-scale installations.

6. Summary Table: 2 AWG vs 2/0 AWG Overview

|

Parameter |

2 AWG |

2/0 AWG |

|

Relative Size |

Smaller |

Larger |

|

Ampacity (Cu) |

115–130 A |

175–195 A |

|

Material Options |

Copper / Aluminum |

Copper / Aluminum |

|

Typical Use |

Residential / Light Commercial |

Industrial / Utility |

|

Cost |

Lower |

Higher |

|

Weight & Flexibility |

Easier to handle |

Heavier, less flexible |

7. Conclusion

Choosing between 2 AWG and 2/0 AWG wires ultimately depends on electrical load, distance, and installation type.

For medium-load residential and commercial systems, 2 AWG copper wire offers a balance between performance and cost.

However, for high-load or long-distance power transmission, 2/0 AWG copper or aluminum wire provides superior ampacity, lower voltage drop, and enhanced safety margins.

By considering factors like ampacity, material, and environmental exposure, electrical engineers and installers can select the most efficient and reliable conductor for their specific project.

2Y-high-voltage-power-cable-2.webp)