75 kVA 3 Phase Transformer Specifications, Price & Applications | Complete Buying Guide

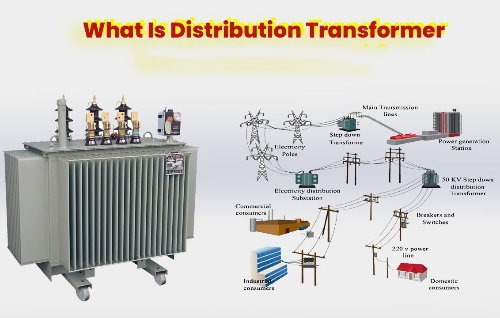

In practical power distribution systems, 75 kVA three-phase transformers are among the most widely used capacity transformers. They are favored for their compact size and high efficiency, while also being able to power commercial buildings, industrial facilities, and even small-scale renewable energy projects. From pad-mounted and pole-mounted units to dry-type, oil-immersed, and power transformers, a variety of designs are available to meet various project needs.

What is a 75 kVA 3 Phase Transformer?

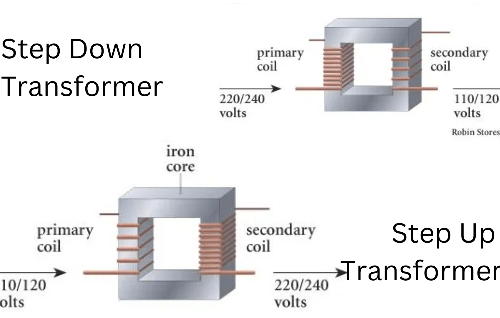

A 75 kVA three-phase transformer is an electrical device that steps up or steps down voltage in a three-phase power system, with a rated capacity of 75 kilovolt-amperes.

- Capacity meaning: 75 kVA = 75,000 volt-amperes, which indicates the apparent power rating.

- Power supply: Supports three-phase loads common in commercial and industrial applications.

- Voltage levels: Typically designed for configurations such as 480V to 208Y/120V, 11kV to 400V, or customized based on regional grid requirements.

This rating is ideal for medium-scale applications, bridging the gap between small distribution transformers and large industrial power transformers.

Technical Specifications of a 75 kVA Transformer

While exact specifications depend on manufacturer and design, a standard 75 kVA 3-phase transformer typically includes:

- Rated Power: 75 kVA

- Primary Voltage: 2.4 kV, 4.16 kV, 11 kV, 13.8 kV, or 33 kV (customizable)

- Secondary Voltage: 208Y/120V, 400V, 480V

- Frequency: 50 Hz or 60 Hz

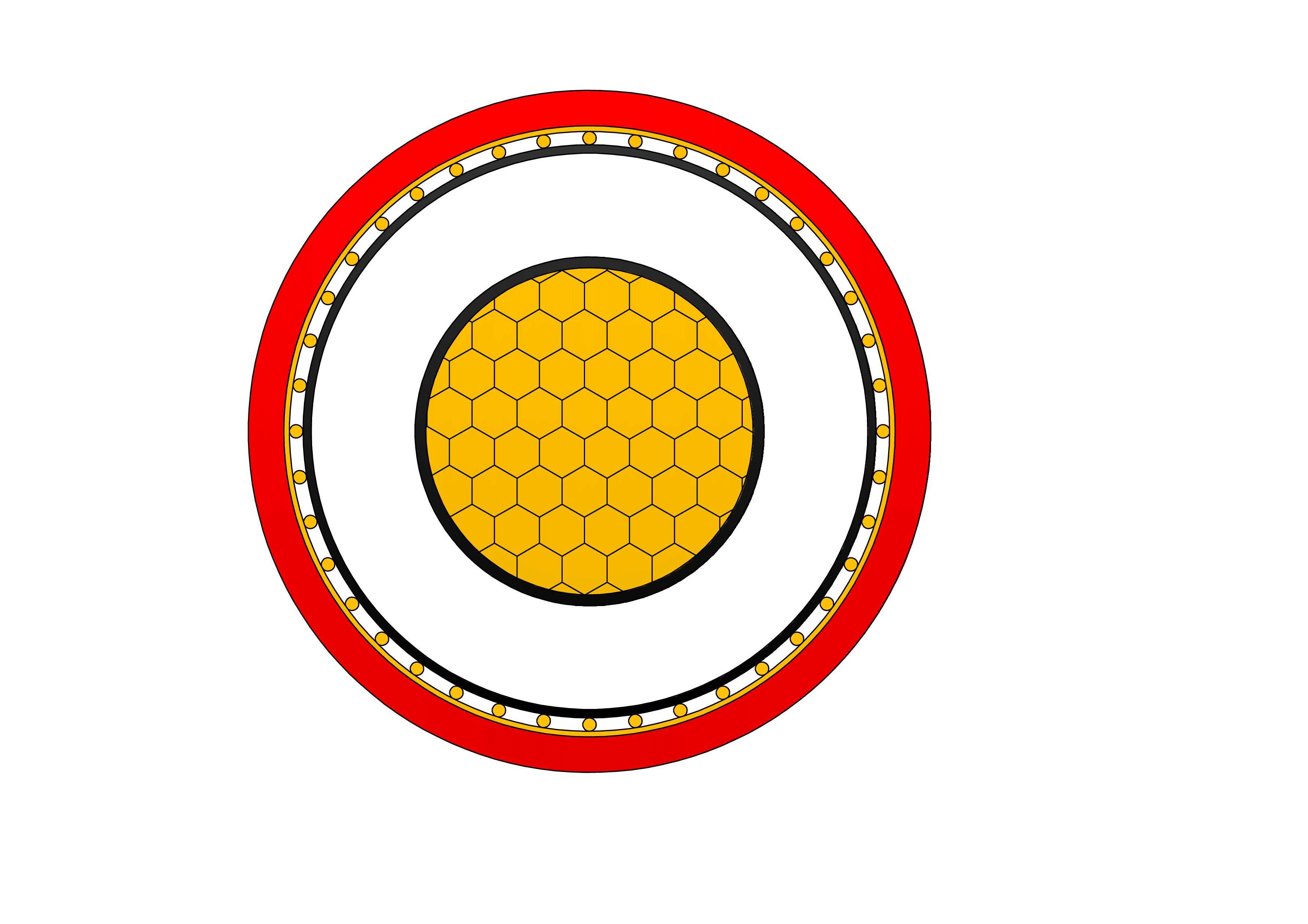

- Cooling Method: Air-cooled (dry type) or oil-immersed (liquid-cooled)

- Impedance: 4%–6% typical

- Insulation Class: Up to Class H (180°C) for dry type; oil-filled designs often use Class A (105°C) or Class B (130°C)

Types of 3 Phase Transformers

1. 75 kVA 3 Phase Pad-Mounted Transformer

- Installed at ground level in a tamper-proof cabinet.

- Commonly used in urban distribution networks, commercial plazas, and residential communities.

- Provides underground distribution, enhancing safety and aesthetics.

- Example use: Feeding a shopping mall with an underground power supply.

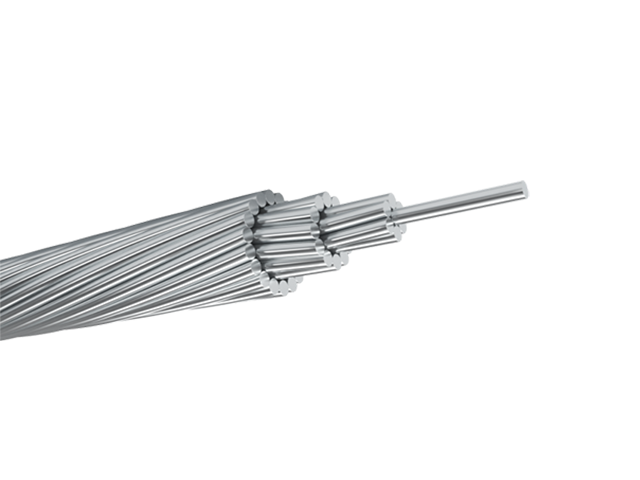

2. 75 kVA 3 Phase Pole-Mounted Transformer

- Installed on utility poles for overhead distribution networks.

- Widely used in rural areas, remote industrial facilities, and agricultural irrigation systems.

- Cost-effective for areas where underground cabling is not feasible.

- Example use: Powering farm equipment or small factories in rural zones.

3. 75 kVA 3 Phase Dry-Type Transformer

- Uses air as a cooling medium instead of oil.

- Ideal for indoor installations where fire safety is a concern.

- Common in hospitals, schools, commercial buildings, and data centers.

- Low maintenance and environmentally friendly, but generally higher in cost compared to oil-filled units.

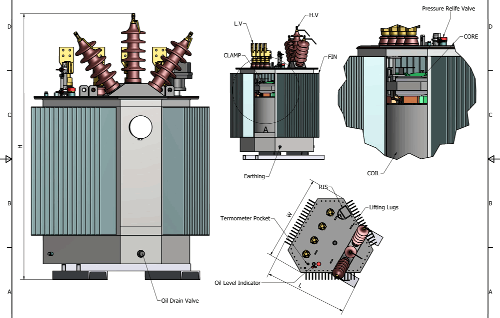

4. 75 kVA 3 Phase Oil-Immersed Transformer

- Uses mineral oil or synthetic ester oil for cooling and insulation.

- Provides excellent thermal management and higher overload capacity.

- Best suited for outdoor installations, substations, and industrial applications.

- Requires periodic oil testing and maintenance.

5. 75 kVA 3 Phase Power Transformer (Utility-Grade)

- Designed for grid-level voltage conversion and heavy-duty applications.

- A 75 kVA power transformer is typically used in distribution substations rather than transmission networks.

- Provides high reliability in continuous service conditions.

Transformer Type Comparison Table (75 kVA 3 Phase)

|

Type |

Cooling Method |

Installation Location |

Advantages |

Limitations |

Typical Applications |

|

Pad-Mounted |

Oil-Immersed / Dry |

Ground level (outdoor) |

Safe, tamper-proof, aesthetic |

Higher initial cost |

Residential communities, commercial complexes |

|

Pole-Mounted |

Oil-Immersed |

Utility pole (outdoor) |

Low cost, easy to install |

Exposed to weather, less aesthetic |

Rural distribution, farms, small factories |

|

Dry-Type |

Air-Cooled |

Indoor |

Fire-safe, low maintenance, eco-friendly |

More expensive, limited overload capacity |

Hospitals, schools, data centers |

|

Oil-Immersed |

Oil-Cooled |

Outdoor (substation, yard) |

High efficiency, better cooling |

Requires oil testing & fire safety measures |

Industrial plants, substations |

|

Power Transformer |

Oil / Dry (custom) |

Substation |

Reliable, designed for continuous duty |

Costly, larger footprint |

Utility distribution substations |

Real-World Applications of 75 kVA Three Phase Transformers

- Commercial Buildings – Office complexes, shopping malls, and hospitals require 75 kVA transformers for efficient distribution of 480V to 208/120V.

- Industrial Facilities – Medium-sized manufacturing plants, CNC machine shops, and warehouses often use 75 kVA units to run motors, conveyors, and lighting systems.

- Renewable Energy Projects – Solar farms and wind energy projects use transformers to step up voltage for grid connection.

- Data Centers – Dry-type 75 kVA transformers are used for safe indoor distribution in critical IT facilities.

- Residential Communities – Pad-mounted transformers supply safe and reliable power to multi-unit housing complexes.

Price of a 75 kVA 3 Phase Transformer

The cost of a 75 kVA transformer varies depending on design, cooling method, and application.

- Pole-Mounted Transformer: $3,000 – $5,000

- Pad-Mounted Transformer: $4,000 – $7,000

- Dry-Type Transformer: $6,000 – $10,000

- Oil-Immersed Transformer: $4,500 – $8,000

- Custom Utility-Grade Transformer: Higher, depending on specifications

Price Factors

- Design Type: Dry-type is more expensive than oil-immersed.

- Voltage Rating: Higher voltages increase cost.

- Cooling & Insulation: Advanced cooling systems and eco-friendly oils add to the price.

- Manufacturer & Certification: UL, ANSI, IEC, or ISO-certified units carry premium pricing.

Selection and Installation Tips

- Load Assessment: Ensure that the transformer capacity matches the load demand. A 75 kVA unit typically supports up to 208 amps at 208V three-phase.

- Environment: Use dry-type indoors (fire-safe) and oil-immersed outdoors (cost-effective).

- Cooling & Ventilation: Adequate airflow or an oil cooling system is critical for long service life.

- Safety Standards: Ensure compliance with IEEE, IEC, ANSI, and local grid codes.

- Future Expansion: Consider whether the transformer may need to handle additional load in the future.

Maintenance Considerations

- Dry-Type Transformer: Periodic inspection, dust removal, and insulation checks.

- Oil-Immersed Transformer: Oil level monitoring, dissolved gas analysis (DGA), dielectric strength testing.

- Pad/Pole-Mounted Units: Visual inspection for leaks, corrosion, and grounding integrity.

Proper maintenance can extend the service life of a 75 kVA three-phase transformer to 20–30 years.

Frequently Asked Questions (FAQ)

1. How many amps does a 75 kVA transformer handle?

- At 208V (three-phase), it can handle around 208 amps.

- At 480V (three-phase), it supports about 90 amps.

2. Which is better: dry-type or oil-immersed 75 kVA transformer?

- Dry-type: Safer for indoor use, less maintenance, but higher upfront cost.

- Oil-immersed: More cost-effective and efficient outdoors, but requires regular oil checks.

3. What is the lifespan of a 75 kVA transformer?

- With proper maintenance, 20–30 years is common for both dry-type and oil-filled units.

4. Can a 75 kVA transformer be used for renewable energy systems?

- Yes. They are widely used in solar PV and wind projects to step up voltage for grid integration.

5. How much does a 75 kVA 3 phase transformer cost?

- Typically $3,000 – $10,000 depending on design type (pole, pad, dry, or oil-immersed).

Final Thoughts

The 75 kVA 3-phase transformer is a versatile and essential component in electrical distribution networks. From powering commercial buildings and industrial facilities to supporting renewable energy systems, it ensures efficient voltage regulation and a reliable electricity supply.

When choosing between pad-mounted, pole-mounted, dry-type, oil-immersed, or power transformers, engineers should carefully evaluate the application environment, load capacity, budget, and safety requirements. By selecting the right design and maintaining it properly, a 75 kVA transformer can deliver decades of reliable service.

3GHSSHCH-mining-cable-2.webp)