The Principles of Transformer Operation: A Comprehensive Guide

Transformers are at the heart of electrical distribution systems, playing a critical role in stepping up or stepping down voltage levels to ensure efficient power delivery. They are vital in everything from power generation plants to industrial manufacturing facilities, and even in everyday consumer electronics. This article aims to explore the principles of transformer operation, providing a detailed understanding of how transformers work, the different types of transformers available, and their practical applications in modern electrical systems.

What is a Transformer?

A transformer is an electrical device that transfers electrical energy between two or more circuits through electromagnetic induction. It changes the voltage level in an alternating current (AC) signal, either increasing or decreasing the voltage, without changing the frequency. The basic principle of operation is based on Faraday’s law of induction, which states that a changing magnetic field can induce an electromotive force (EMF) or voltage in a nearby conductor.

Types of Transformers

There are several types of transformers, each designed for specific applications. Some of the most commonly used types include:

-

Power Transformers: These are used to step up or step down voltages in large power transmission systems. They are typically used in substations and are designed to handle high voltage levels, often found in power grids.

-

Dry Type Transformers: Unlike oil-filled transformers, dry-type transformers use air or other non-flammable insulating materials for cooling. These are commonly used in urban environments, industrial facilities, and commercial buildings due to their safety and environmental benefits.

-

Distribution Transformers: These transformers reduce the voltage from transmission levels to a level suitable for consumer use, delivering power to homes and businesses.

-

Isolation Transformers: These are used to isolate different parts of an electrical system, providing safety by preventing electric shock or reducing noise interference.

The Principle of Transformer Operation

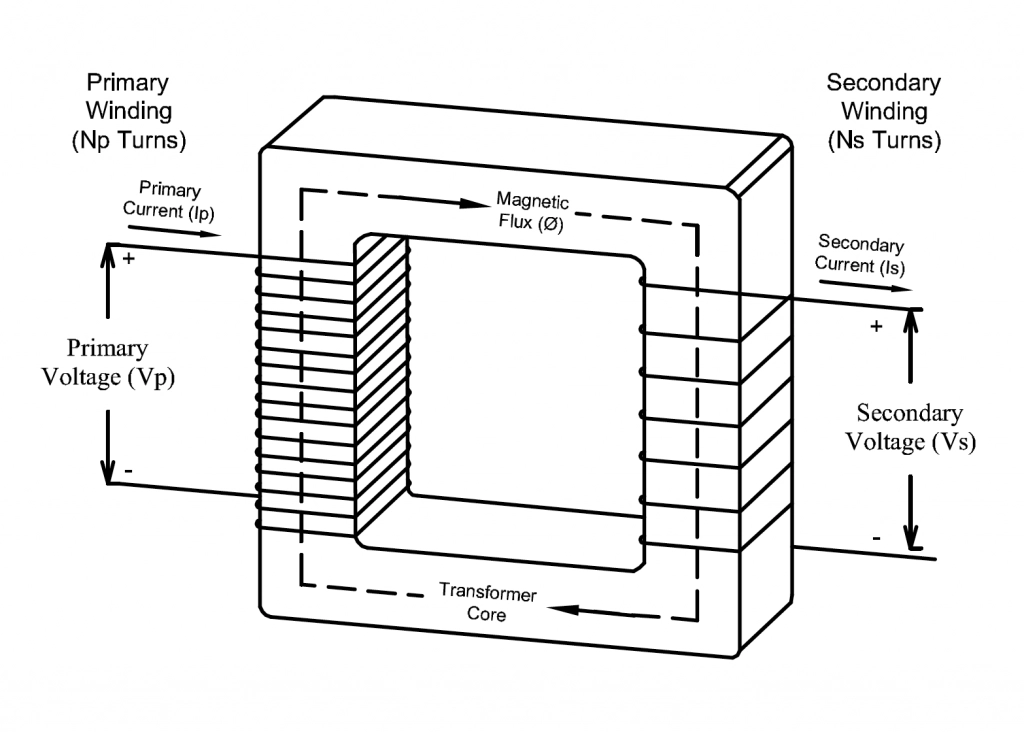

The operation of a transformer is based on electromagnetic induction. The transformer consists of two main parts: the primary coil and the secondary coil, both wound around a core. When an alternating current flows through the primary coil, it generates a magnetic field that is constantly changing in strength and direction. This changing magnetic field induces an electric current in the secondary coil, which is then used to power devices or further equipment.

The principal operation of a transformer depends on the relationship between the number of turns of wire on the primary and secondary coils, which determines the voltage ratio between the input (primary) and output (secondary) sides of the transformer.

Understanding the Working of Transformers

At a fundamental level, a transformer works by transferring electrical energy via a magnetic field. When current flows through the primary coil, it creates a magnetic field in the transformer core. The core serves as a path for this magnetic field, ensuring it links both the primary and secondary coils. As the magnetic field changes, it induces a voltage in the secondary coil. This induced voltage depends on the number of turns on the secondary coil relative to the primary coil, which is determined by the voltage transformation ratio.

Efficiency of Transformer Operation

One of the key aspects of transformer operation is efficiency. A good transformer operates with minimal energy loss, which is a critical feature in high-power transmission systems. The primary sources of energy loss in transformers are core losses (hysteresis and eddy currents) and copper losses (due to the resistance of the windings).

To reduce core losses, modern transformers use silicon steel laminations that minimize eddy current losses. For copper losses, the resistance of the copper windings is minimized by using thicker wire or high-conductivity materials. Dry-type transformers, due to their insulation and cooling systems, often have slightly higher losses compared to oil-filled models but are favored for their safety and environmental friendliness.

Applications of Transformers

Transformers are used in a wide variety of applications in the electrical industry:

-

Power Transmission: Transformers are essential for stepping up voltage in power plants to allow electricity to be transmitted over long distances efficiently. Without transformers, power transmission would be highly inefficient due to energy losses.

-

Industrial Applications: In factories and industrial plants, transformers are used to supply the required voltage levels for machinery. Dry-type transformers are particularly suitable for industrial environments due to their robust construction and fire-resistant properties.

-

Residential Power Supply: Transformers play a crucial role in converting high-voltage electricity from the grid to the lower voltage used in homes and businesses.

-

Renewable Energy: With the growing adoption of renewable energy sources, transformers are increasingly used to integrate renewable power generation into the existing electrical grid. They help in adjusting the voltage levels from solar panels or wind turbines to be compatible with the grid.

Principle and Working of Dry-Type Transformers

A dry-type transformer operates on the same fundamental principle as other transformers but uses air or synthetic materials like resin for insulation instead of oil. These transformers are particularly well-suited for indoor installations in commercial and residential settings, where fire hazards need to be minimized. The principle of transformer operation in dry-type units is the same as oil-filled transformers, but the cooling mechanism is different.

Dry-type transformers are advantageous in environments where flammable materials are present, such as in buildings with high occupancy. They also require less maintenance and are more environmentally friendly since they don’t involve the use of oil.

The principle and working of transformers form the backbone of electrical power systems worldwide. Whether stepping up voltage for transmission or stepping down voltage for end-user applications, transformers are critical in ensuring the efficient and safe delivery of electrical power. Understanding the principles of transformer operation is essential for selecting the right transformer for specific applications, whether it’s a power transformer, dry-type transformer, or another variation.

As technology continues to evolve, transformers will remain at the forefront of the energy transition, helping to meet the growing demand for more efficient and sustainable power solutions.

2Y-high-voltage-power-cable-2.webp)