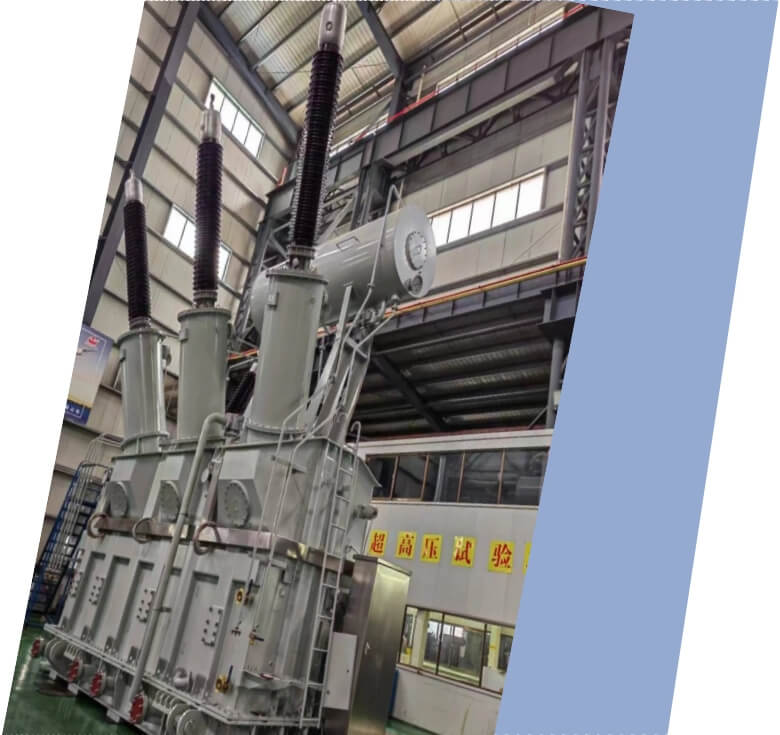

320 kV High Voltage Power Transformer

- Primary Voltage Ratings 220kV 230kV 320 kV

- Secondary Voltage Ratings 69/35/37/34.5/26.4./11/10.5/6.6/13.2 kV or others

- H.V. Tap Range ± 8×1.25% HV taps or others

- Type Oil-immersed power transformer

- BIL 900kV

- Standards IEEE, ANSI, IEC, GB

- Application high-voltage transmission substations, national grid interconnections

- Power Rating 500-250000kVA

- Certificate UL, ISO, CESI

- Cooling Method ONAN/ ONAF

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 500-250000kVA |

| Rating Primary Voltage | 220kV 230kV 320kV |

| Secondary Voltage |

69/35/37/34.5/26.4/11/10.5/6.6/13.2 kV Customized |

| Frequency | 50/60Hz |

| Vector Group | Dyn11, YD11, YNd11 or anothers |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE, CAS Std or Customized |

| Impedance Voltage | As IEC |

| Altitude | ≤1,000m or Customized |

| Enclosure material | Mid Steel |

| HV Bushing |

| LV Bushing |

| OLTC/NLTC |

| Lifting hook for complete transformer |

| Name plate |

| Oil temperature |

| Winding temperature |

| Radiators |

| Oil level |

| Pressure relief valve |

| CT |

Customization Optional

Packing and Shipping

The transformer's main body is mounted on a specially designed transport base engineered to distribute weight evenly and reduce mechanical stress during lifting and transit. Shock-absorbing materials and rigid securing systems are applied to protect against vibration, impact, and movement. For extended transport durations, preservation measures such as oil protection procedures and desiccants are employed to maintain the internal insulation condition.

Transportation methods are selected based on transformer dimensions, weight, route constraints, and site accessibility. Depending on project requirements, shipping may be arranged via flat-rack containers, open-top containers, or break-bulk cargo. All packing materials comply with international shipping and export standards, including ISPM-15 requirements for wooden packaging. Clear markings indicating lifting points, center of gravity, and handling instructions are applied to ensure safe loading and unloading.

Each shipment is accompanied by comprehensive documentation, including packing lists, quality certificates, factory test reports, drawings, and operation manuals. Upon delivery, customers receive guidance for inspection, storage, and installation. Optional services such as on-site supervision, oil filling, commissioning support, and technical training can be provided to ensure smooth project execution and reliable commissioning.

Manufacturer Test

Progress test

Progress testing for the 320 kV power transformer is implemented as a staged quality assurance process throughout manufacturing. Incoming materials, including magnetic core steel, copper conductors, insulation components, and insulating oil, are inspected to verify compliance with technical specifications. During core assembly, inspections focus on lamination alignment, clamping pressure, and magnetic circuit integrity. Winding production is monitored for insulation uniformity, conductor placement accuracy, and dimensional tolerances. After winding completion, the active part undergoes controlled drying and vacuum processing to achieve specified moisture limits. Intermediate electrical inspections, including winding resistance measurement and voltage ratio verification, are conducted prior to tank installation. Tank fabrication is examined for weld quality, dimensional accuracy, and surface coating integrity. Before oil filling, leak tests, and internal cleanliness inspections are performed. All progress test data are recorded to ensure traceability and manufacturing consistency before final acceptance testing.

Design Tests

All transformers will be tested after finishing the production test items as below:

♦ Leak testing with pressure for liquid-immersed transformers

♦ Test of transformer oil

♦ Measurement of voltage ratio and check of phase displacement

♦ Measurement of winding DC resistance

♦ Measurement of d. c. Insulation resistance between each winding to earth, and check of the core and frame insulation

♦ Capacitive bushing test

♦ Measurement of dissipation factor (tan δ) of the insulation system capacitances, and determination of capacitances windings-to-earth

♦ Measurement of no-load loss and current at 90%,100%,110% of rated voltage

♦ Operation test on on-load tap-changer

♦ Measurement of short-circuit impedance and load loss

♦ Lightning impulse test

♦ Induced-voltage test with partial discharge measurement

♦ Auxiliary wiring check

♦ Current transformer test

♦ Frequency response analysis test

Transformer Factory Acceptance Test

Factory Acceptance Testing ensures the operational readiness of the 320 kV oil-immersed transformer before delivery. Electrical routine tests verify resistance balance, voltage ratio accuracy, phase displacement, and insulation resistance levels. High-voltage dielectric testing confirms the transformer’s ability to withstand rated operating conditions and overvoltage stresses. Thermal performance is validated through temperature rise testing, while efficiency is confirmed by loss and impedance measurements. Partial discharge testing evaluates the internal insulation condition. Mechanical and functional inspections include oil leakage testing, pressure relief device verification, cooling equipment operation, and monitoring system functionality. Oil samples are analyzed for dielectric strength and moisture content. FAT documentation is completed for customer approval prior to dispatch.

Routine Test - Induced Voltage

AC voltage source, commonly 2 kV, 5 kV, 10 kV, or customized according to test requirements.

Environmental thermometer and hygrometer, used to record the temperature and humidity of the environment for appropriate test evaluation.

Check the connection wires and terminals to ensure they are secure and free of contamination.

Test under suitable environmental conditions: relative humidity below 75%, no rain (recommended temperature: 20-30°C).

Connect the test equipment to the appropriate terminals or bushings of the device under test, ensuring that the connections are secure and properly grounded.

Apply Test Voltage:

Select the appropriate induction voltage according to the rated voltage and standard of the equipment.

Induced Voltage

Applied Current

Voltage peak, stability and waveform (waveform analysis)

Any abnormal current or voltage changes during the measurement process.

1% < Inductive voltage ≤ 3% (Good): still within acceptable range.

Inductive voltage > 3% : faulty or not meet safety requirements and requires further analysis and repair.

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.