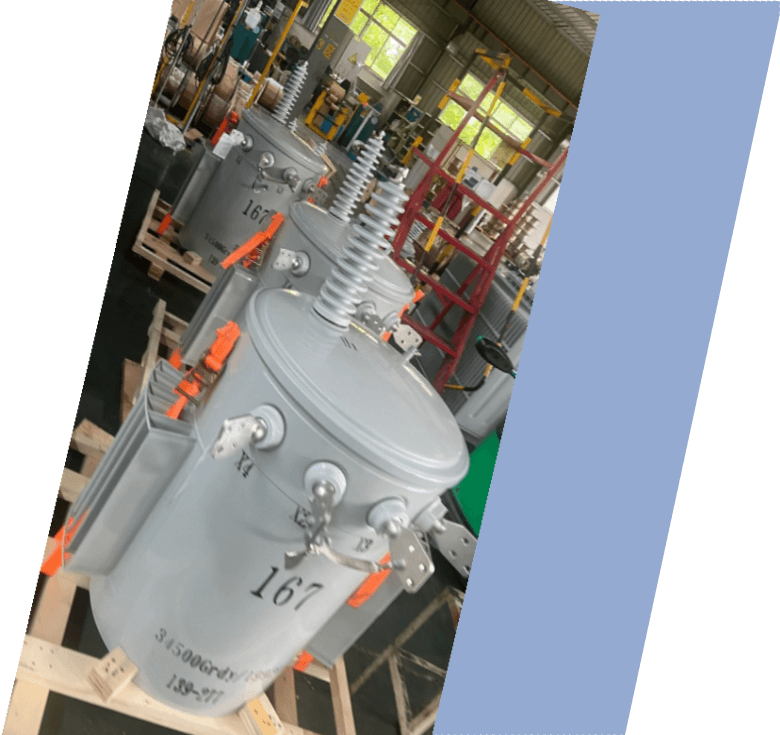

100kVA Conventional Type Single Phase Pole Mounted Transformer

- Primary Voltage Ratings 2.4-34.5kV

- Secondary Voltage Ratings 480-240/240-120 or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Conventional Type

- BIL 30-150kV

- Standards IEEE, ANSI, NEMA, ASTM

- Application Residential, commercial, agricultural and small industrial loads

- Power Rating 100kVA

- Certificate CE, ISO

- Cooling Method ONAN, KNAN

- Oil Mineral Oil or FR3

- Opeartion Step Down

Technical Specifications

| Rated Power | 100 kVA |

| Rating Primary Voltage | 12.4-34.5kV |

| Secondary Voltage | 480-240V 240-120V 277V Customized |

| Frequency | 50/60Hz |

| Vector Group | Ii0,Ii6 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 2% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 94 kg |

| Total Weight | 530 kg |

| Outline Dimensions(W×D×H) | 770×965×1135 (mm) |

| Lifting Lug |

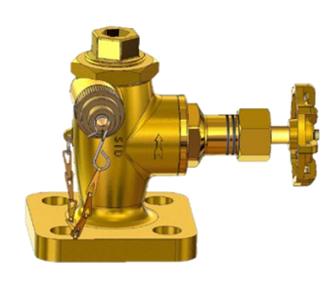

| Tap Changer |

| Pressure Relief Valve |

| Tank Cover and clamp |

| L.V Bushing |

| HV Bushing |

| Ground Strap |

| Nameplate |

| Non-PCB decal |

| High Voltage Warning Signs |

| Suport lug |

| Oil fill valve |

Customization Optional

Common choices for the high-voltage side of the rated voltage include 11kV, 13.2kV, 13.8kV, 15kV, 19.92kV, etc., which can be customized according to the grid standards. The low-voltage side can be selected from 120/240V, 240/480V, 277/480V, and other customized voltages can also be provided according to customer needs.

The insulation level can be selected from Class A, Class B, Class F or Class H insulation, and the specific choice depends on the use environment and temperature requirements of the transformer. The advanced insulation system can improve the high temperature resistance and extend the service life of the transformer, especially suitable for applications in high temperature environments. Mineral oil complies with IEC 60296 or ASTM D3487 standards, is suitable for most environments, and has good electrical insulation and heat dissipation effects. Silicone oil has higher fire resistance, is suitable for high temperature and flammable environments, and is often used in high-risk areas.

NPC ELECTRIC'S 100kVA Conventional Type Single Phase pole Mounted transformer provides a variety of optional specifications to meet different power grid requirements, working environments and application scenarios. Users can choose the appropriate electrical parameters, insulation materials, protection levels, cooling methods, intelligent monitoring functions, etc. according to their needs to ensure long-term stable operation of the transformer under high load and extreme environments. The transformer is widely used in residential, commercial, power, agricultural and light industrial fields, and is an efficient and reliable power distribution equipment.

Packing and Shipping

Transformers are usually packed on sturdy wooden pallets to ensure stable support during transportation. Pallets must meet international standards such as ISPM-15 to prevent the spread of pests. Transformers should be firmly fixed with wire ropes, wooden frames or tensioning straps to avoid shaking or tilting during transportation. When loading, the center of gravity of the transformer should be stable to avoid damage caused by improper transportation.

Inside the container, the transformer will be surrounded by shockproof materials (such as foam pads, EVA pads, cardboard brackets, etc.) to avoid vibration or impact during transportation. International shipping labels, including warning signs such as fragile, waterproof, and careful handling, will be posted on the outside of the container and on the transformer.

During transportation, especially sea transportation, we will purchase transportation insurance to ensure that the equipment can be compensated in case of accidental damage or loss.

The packaging and shipping of NPC ELECTRIC'S 100kVA Conventional Type Single Phase Pole Mounted transformer requires comprehensive consideration of waterproofing, shockproofing, anti-corrosion and other factors to ensure that the transformer is not affected by the external environment during transportation. By using professional packaging materials, reinforcement measures and transportation process management, it can ensure that the equipment arrives safely at the destination and is ready for use.

Manufacturer Test

Progress Test

Manufacturing process testing of NPC ELECTRIC'S 100kVA Conventional Type Single Phase pole Mounted transformer Testing usually includes strict inspection of the transformer's electrical performance, mechanical strength, insulation system and other aspects. During the manufacturing process, material inspection is first carried out to ensure that the selected materials meet the specifications, and then various preliminary electrical tests are carried out, such as high and low voltage tests, inter-winding insulation resistance tests, etc. Next, load tests and temperature rise tests are carried out to ensure the normal working performance of the transformer under different load conditions. Finally, after all tests are passed, the transformer enters the next stage of assembly and acceptance.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

The factory acceptance test of NPC ELECTRIC'S 100kVA Conventional Type Single Phase pole Mounted transformer includes rigorous testing of key parameters such as the transformer's electrical performance, dielectric strength, load capacity, temperature rise and short-circuit withstand to ensure it meets design requirements and international standards.

Routine Test - DC Insulation Resistance Test

Voltage source (usually 500V, 1000V, 2500V, or customized according to customer requirements)

Temperature and humidity meter (used to record the ambient temperature and humidity during the test to ensure that the test conditions meet the standard requirements.)

Perform the test under suitable environmental conditions. It is recommended to have a relative humidity below 75%, no rain, and a temperature range of 20-30°C to avoid moisture or temperature fluctuations affecting the test results.

Connect an insulation resistance tester to the high voltage terminal of the device under test and to ground.

Apply Test Voltage:

Select an appropriate test voltage based on the rated voltage of the equipment .

Insulation resistance value (MΩ)

Applied voltage

Ambient temperature and humidity during testing

500 MΩ ≤ Insulation resistance < 1000 MΩ (good)

100 MΩ ≤ Insulation resistance < 500 MΩ

Insulation resistance < 100 MΩ

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.