What Are Power Cables? Types, Applications, and Selection Guide

Power cables are a fundamental component of modern power systems, safely and reliably transmitting electrical energy from power sources to loads. From residential buildings and industrial plants to renewable energy facilities and high-voltage transmission networks, power cables form the backbone of power transmission.

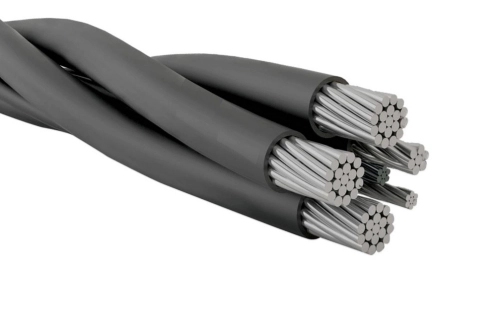

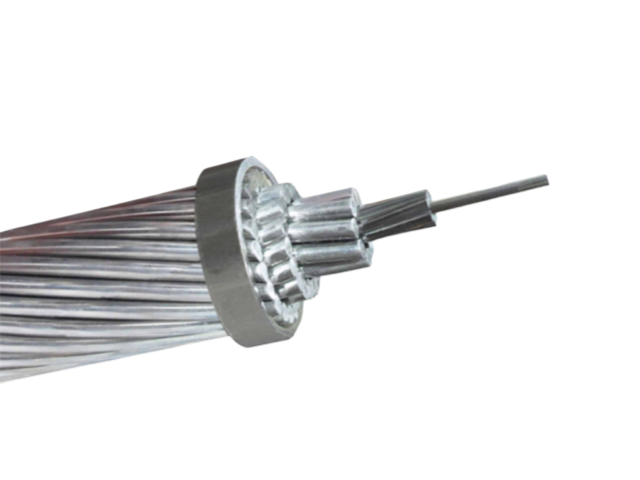

The basic structure of a power cable typically includes a conductor, insulation layer, sheath, and armor layer. The conductor is usually made of copper or aluminum to ensure good conductivity; the insulation layer (such as XLPE, cross-linked polyethylene, or PVC polyvinyl chloride) prevents leakage and withstands high voltage; the outer sheath provides mechanical protection and environmental resistance. Based on voltage level and application, power cables can be classified into low-voltage cables (below 1kV), medium-voltage cables (1-35kV), high-voltage cables (35-220kV), and ultra-high-voltage cables (above 220kV). In addition, there are different laying types such as overhead cables, underground cables, and submarine cables.

In the context of today's energy transition, the role of power cables is becoming increasingly prominent. With the rapid development of renewable energy sources such as wind power and photovoltaics, submarine high-voltage direct current (HVDC) cables have become a key technology for connecting offshore wind farms to onshore power grids, enabling long-distance, low-loss power transmission. Simultaneously, urbanization is driving underground cables to replace traditional overhead lines, improving urban aesthetics and power supply reliability. Under environmental trends, low-smoke halogen-free and flame-retardant cables are gradually becoming mainstream, reducing fire risks and meeting sustainable development requirements.

In the future, with the widespread adoption of smart grids and electric vehicle charging infrastructure, power cables will evolve towards higher voltage, greater intelligence, and greater environmental friendliness, ensuring efficient, safe, and green operation of the power system.

What Is a Power Cable?

A power cable is an electrical cable designed to transmit electrical power, typically at low, medium, or high voltage levels. Unlike signal or communication cables, power cables are engineered to carry significant current while maintaining insulation integrity, mechanical strength, and thermal stability.

In practical electrical engineering work, power cables are selected not only based on voltage and current ratings, but also on installation conditions, environmental exposure, and long-term operating system reliability.

Basic Structure of Power Cables

Basic Structure of Power Cables

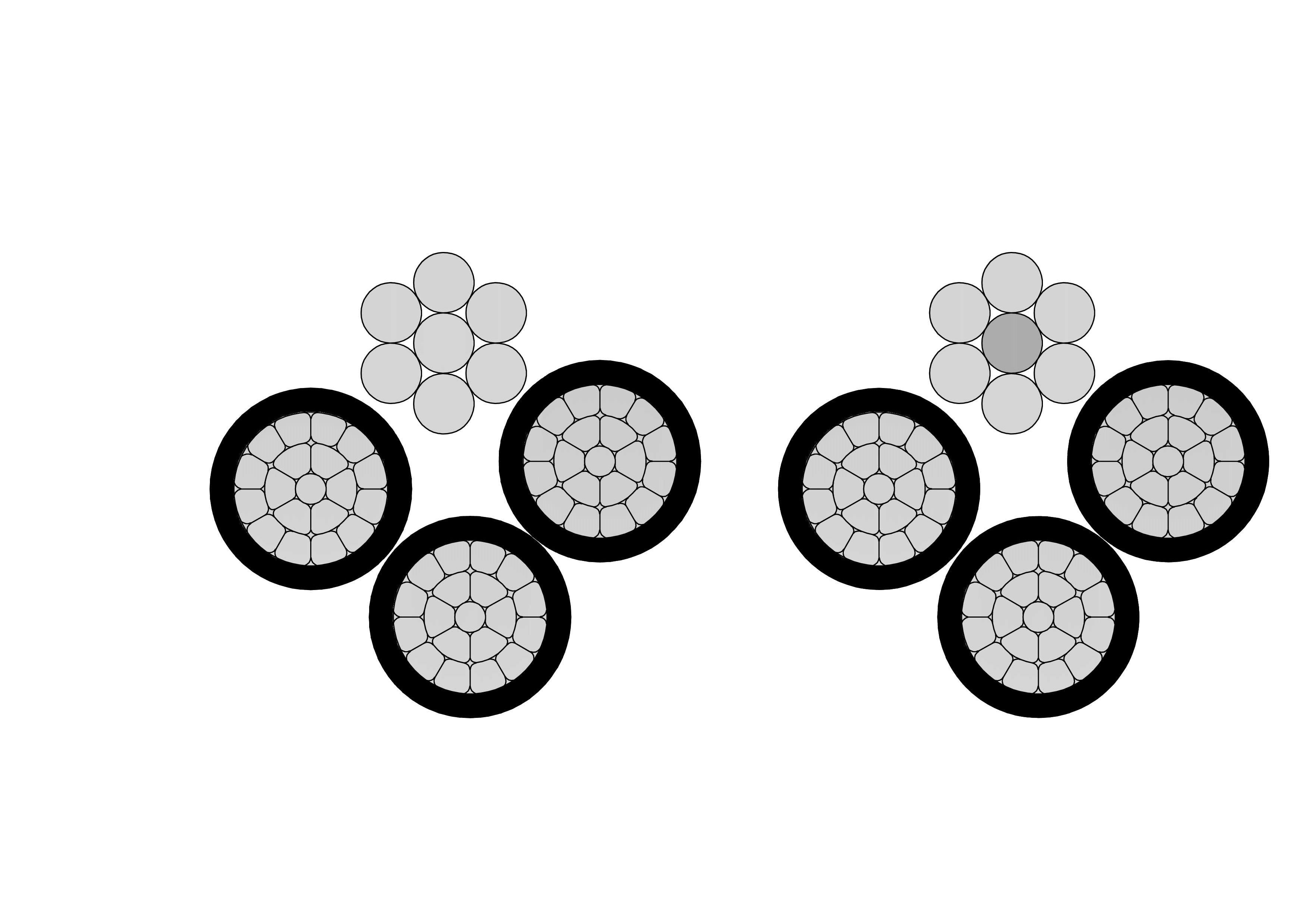

Although designs vary, most power cables share common structural elements:

-

Conductor

- Made of copper or aluminum

-

Responsible for carrying electrical current

-

Can be solid or stranded (stranded wire improves flexibility)

-

Insulation Layer

- Prevents electric shocks and short circuits

-

Common materials: PVC, XLPE, EPR

-

Determines voltage rating and thermal performance

-

Sheath / Jacket

- Provides mechanical protection and environmental resistance

-

Protects against moisture, chemicals, and abrasion

-

Optional Armor or Shielding

- Used in industrial, underground, or high-risk installations

-

Enhances durability and safety

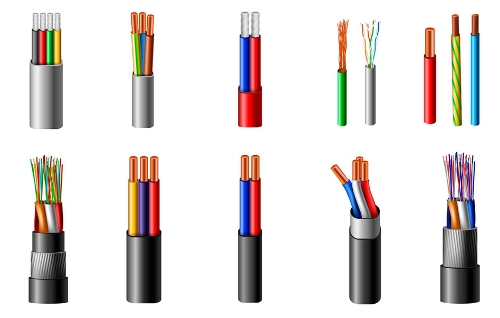

Common Types of Power Cables

1. Low Voltage Power Cables

Used in residential and commercial electrical systems, typically up to 1 kV.

Applications include lighting, socket circuits, and small machinery.

Examples:

-

PVC insulated electrical cable

-

Flexible cable for appliances and extension cords

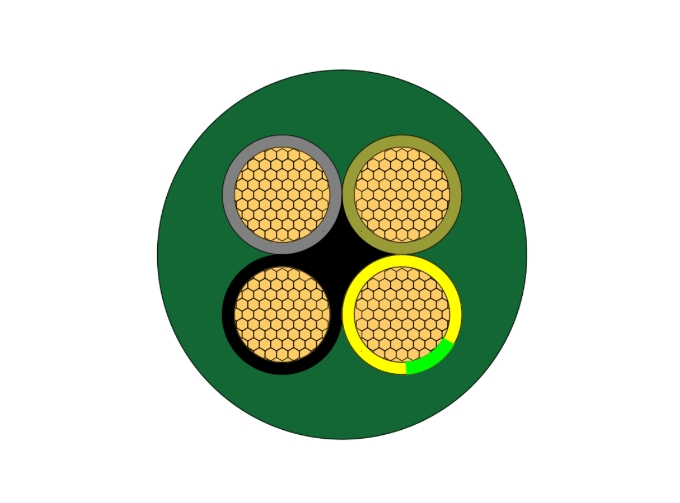

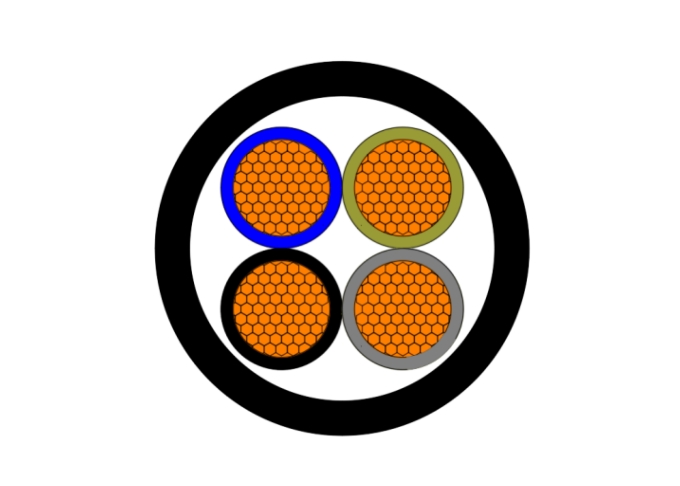

2. Medium Voltage Power Cables

Operating between 1 kV and 35 kV, it is commonly used in industrial plants, substations, and distribution networks.

Typical uses:

-

Factory power distribution

-

Utility feeders

-

Renewable energy collection systems

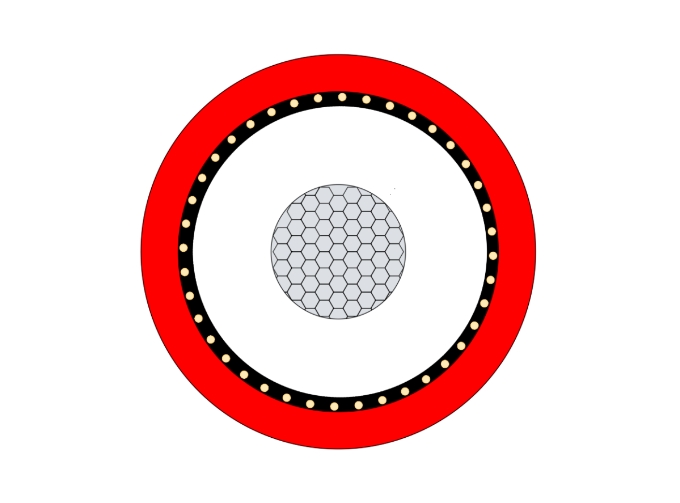

3. High Voltage Power Cables

Designed for high voltage transmission above 35 kV, often exceeding 110 kV.

Key applications:

-

Grid interconnections

-

Large-scale infrastructure projects

High-voltage power cables require advanced insulation systems and strict installation standards to manage electric field stress.

4. AC Power Cables

Most power cables in buildings and industries are designed for AC power, which dominates global power generation and distribution. AC power cables must handle alternating current, thermal cycling, and electromagnetic effects.

5. Flexible Power Cables

Flexible cables use fine stranded conductors to allow movement and bending. They are critical in:

-

Mobile equipment

-

Industrial machinery

-

Temporary power supplies

In real-world operations, flexible cables directly impact job performance by reducing downtime caused by cable fatigue or breakage.

Common Power Cable Types and Practical Applications

| Power Cable Type | Voltage Range | Conductor Material | Insulation Type | Typical Applications | Key Practical Advantages |

| Low Voltage Power Cable | ≤ 1 kV | Copper or Aluminum | PVC / XLPE | Residential wiring, commercial buildings, lighting circuits | Easy installation, cost-effective, suitable for standard electrical systems |

| Medium Voltage Power Cable | 1 kV – 35 kV | Copper or Aluminum | XLPE | Industrial plants, substations, distribution networks | High current capacity, stable performance, reduced power losses |

| High Voltage Power Cable | ≥ 35 kV | Copper or Aluminum | XLPE / EPR | Power transmission lines, grid interconnections | Strong insulation, low electrical stress, reliable long-distance transmission |

| Flexible Power Cable | ≤ 1 kV | Stranded Copper | PVC / Rubber | Mobile equipment, machinery, temporary power supply | High flexibility, vibration resistance, improved job performance |

| Armored Power Cable | Low–Medium Voltage | Copper or Aluminum | XLPE / PVC | Underground installations, industrial facilities | Enhanced mechanical protection, reduced risk of damage |

| AC Power Cable | Low–High Voltage | Copper or Aluminum | PVC / XLPE | General AC power systems, utilities, factories | Designed for alternating current, thermal stability |

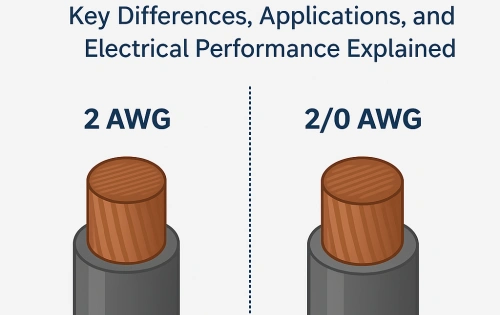

Power Cable Materials: Copper vs. Aluminum

Copper Conductors

-

Higher electrical conductivity

-

Smaller diameter for the same current

-

Better mechanical strength

-

Higher cost

Aluminum Conductors

-

Lighter weight

-

Lower material cost

-

Widely used in power distribution and utility projects

-

Requires careful termination to avoid connection issues

In actual engineering practice, the choice between copper and aluminum depends on project budget, installation method, and long-term maintenance strategy.

Power Cables in Electrical Systems

Power cables are integral to the overall operating system of electrical installations. Improper cable selection can lead to:

-

Excessive voltage drop

-

Overheating

-

Increased risk of electric shocks

-

Reduced system efficiency

Correctly designed cable systems ensure stable power flow, protect equipment, and enhance operational safety.

Safety Considerations in Power Cable Use

From field experience, most cable-related failures result from improper installation rather than manufacturing defects.

Key safety factors include:

-

Correct current rating selection

-

Adequate insulation thickness

-

Proper grounding and bonding

-

Mechanical protection in harsh environments

Power cables play a direct role in preventing electric shocks, fire hazards, and system outages.

Practical Applications of Power Cables

Power cables are used across a wide range of sectors:

-

Residential wiring and building infrastructure

-

Industrial production lines

-

Data centers and utilities

-

Transportation and public infrastructure

Each application imposes different mechanical, thermal, and electrical demands on wires and cables.

How to Select the Right Power Cable

When selecting power cables in real projects, engineers consider:

-

Voltage Level – Low, medium, or high voltage

-

Current Capacity – Load demand and future expansion

-

Installation Environment – Indoor, outdoor, underground

-

Mechanical Stress – Movement, vibration, or impact

-

Regulatory Standards – IEC, IEEE, NEC, or local codes

Selecting the right cable directly affects system reliability, energy efficiency, and long-term maintenance costs.

Power Cables and Future Electrical Infrastructure

With the growth of renewable energy, smart grids, and electrification, demand for high-performance electrical cable solutions continues to increase. Modern power cables are expected to deliver:

-

Higher power density

-

Improved thermal performance

-

Longer service life

-

Enhanced environmental resistance

From a working engineer’s perspective, power cables are no longer passive components—they are critical enablers of modern electrical systems.

Power cables are essential elements of electrical infrastructure, enabling safe and efficient energy transmission across industries and applications. Understanding types of power cables, materials, operating conditions, and selection principles is vital for system designers, installers, and operators.

By approaching cable selection from a scientific, practical, and experience-driven standpoint, organizations can improve safety, optimize job performance, and ensure reliable operation of electrical systems for decades to come.

2Y-high-voltage-power-cable-2.webp)