Best AC Transformer Solutions for Power Utilities and Industrial Facilities

In modern power systems, AC transformers play a crucial role in voltage regulation, energy distribution, and electrical safety. Whether in large substations or industrial production lines, selecting the right AC transformer ensures stable power quality, protects critical equipment, and improves overall operational efficiency. As power grids continue to expand and equipment loads increase, transformers not only need high-efficiency energy conversion capabilities but must also maintain long-term reliable operation in complex environments such as high temperature, high humidity, dust, and high load impacts.

Today, power companies and industrial users have increasingly stringent requirements for transformers. They prefer modern AC transformers with high reliability, flexible configuration, remote monitoring capabilities, and low maintenance requirements. Simultaneously, to meet the development trends of smart grids and automated factories, transformer design is increasingly emphasizing intelligence, including functions such as temperature monitoring, oil quality monitoring, load management, and fault early warning, ensuring the power system maintains safe and stable operation under various conditions.

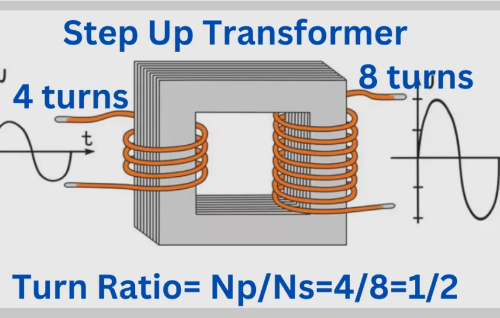

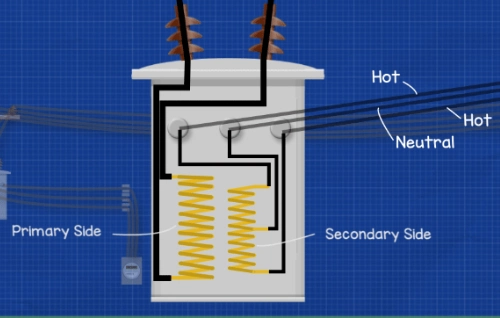

1. What Is an AC Transformer?

An AC transformer is a device that transfers electrical energy between two AC circuits through electromagnetic induction. It adjusts voltage levels while maintaining electrical isolation. AC transformers are widely used in:

-

Power utilities

-

Industrial equipment

-

HVAC systems

-

Security and control systems

-

Low-voltage electronics

-

Commercial buildings

Because of their efficiency and scalability, AC transformers remain essential in both medium-voltage and low-voltage environments.

2. AC Transformer Solutions for Power Utilities

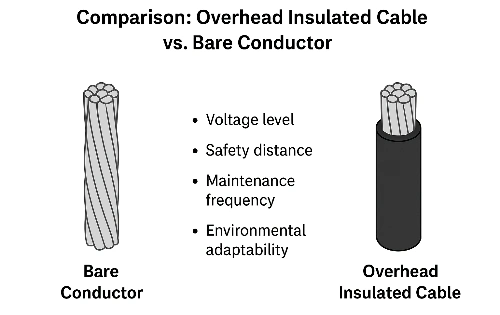

1) Medium-Voltage Distribution Transformers

Used in substations and distribution networks, these transformers step the voltage down from transmission levels to utility distribution levels.

Benefits:

-

High reliability

-

Energy-efficient core designs

-

Low noise & reduced losses

-

Suitable for continuous operation

2) AC Transformer for Industrial Switchgear

Industrial plants rely on robust transformers to feed motors, automation systems, and control units. These transformers can handle harsh conditions, variable loads, and long duty cycles.

3) Units Supporting AC–DC Conversion

With the rising use of renewable energy and DC-based equipment, AC transformers work together with converters to support systems that transform DC to AC and regulate voltage in hybrid networks.

3. Low-Voltage AC Transformer Solutions for Industrial Facilities

1) 24V AC Transformer

Common in:

-

HVAC systems

-

Access control

-

Fire alarm panels

-

Industrial sensors

The 24V AC transformer provides safe, low-voltage power ideal for control circuits.

2) 12V AC Transformer

Used in:

-

Security cameras

-

Lighting systems

-

Gate openers

-

Electronic devices

The 12V AC transformer is widely chosen for compact, low-power applications.

3) AC Adaptor Class 2 Transformer

A Class 2 transformer is designed with safety and power limitations (typically 100 VA or less), making it suitable for:

-

Doorbell systems

-

Thermostats

-

Consumer electronics

-

Residential devices

These transformers provide safe, stable voltage while limiting short-circuit and overload risk.

4. AC to DC Power Transformer Solutions

Although technically the transformer handles AC only, an AC to DC power transformer refers to a transformer combined with:

-

Rectifier

-

Filter

-

Regulator

Together, they convert AC power into a stable DC output. Applications include:

-

Industrial control cabinets

-

Communication equipment

-

LED drivers

-

Automation systems

-

Battery chargers

This is commonly used when a facility needs stable, low-ripple DC power.

5. Transformer for AC Unit (HVAC Applications)

Large commercial and industrial HVAC systems require a transformer for AC units to:

-

Step down high-voltage supply

-

Power control boards

-

Supply thermostats

-

Enable smart HVAC control systems

A reliable transformer ensures continuous HVAC operation, especially in 24/7 facilities such as hospitals, data centers, and manufacturing lines.

6. Choosing the Best AC Transformer Solution

Key Selection Criteria

| Selection Factor | Importance | Notes |

| Voltage & Power Rating | ★★★★★ | Choose 12V / 24V / MV depending on load requirements |

| Application Environment | ★★★★★ | Industrial sites require reinforced insulation & cooling |

| Efficiency | ★★★★☆ | Reduces operating cost and power loss |

| Thermal Performance | ★★★★☆ | HVAC, industrial loads require stable temperature management |

| Certification | ★★★★★ | UL, CE, Class 2 compliance ensures safety |

| Noise Level | ★★★☆☆ | Important in commercial and indoor installations |

| Manufacturer Capability | ★★★★★ | Experience and material quality determine the lifetime |

Recommended Applications

-

Utility-grade step-down transformers for substations

-

Control transformers for machinery

-

24V/12V AC transformers for low-voltage circuits

-

AC adaptor Class 2 transformers for electronics

-

AC to DC power transformers for automation systems

-

Transformers for AC units in HVAC systems

Modern utilities and industrial facilities rely heavily on a wide range of AC transformer solutions to ensure safe, stable, and efficient power distribution. From large-scale power transformers to compact low-voltage units such as 12V AC transformers, 24V AC transformers, and AC adaptor Class 2 transformers, each type plays a critical role in maintaining a continuous power supply. As industries increasingly integrate digital controls, renewable energy, and hybrid AC–DC systems, transformers capable of AC to DC conversion and supporting systems that transform DC to AC are becoming even more essential.

Selecting the right transformer not only improves operational efficiency but also reduces downtime, enhances equipment protection, and supports long-term reliability—making it a key investment for any utility or industrial facility.

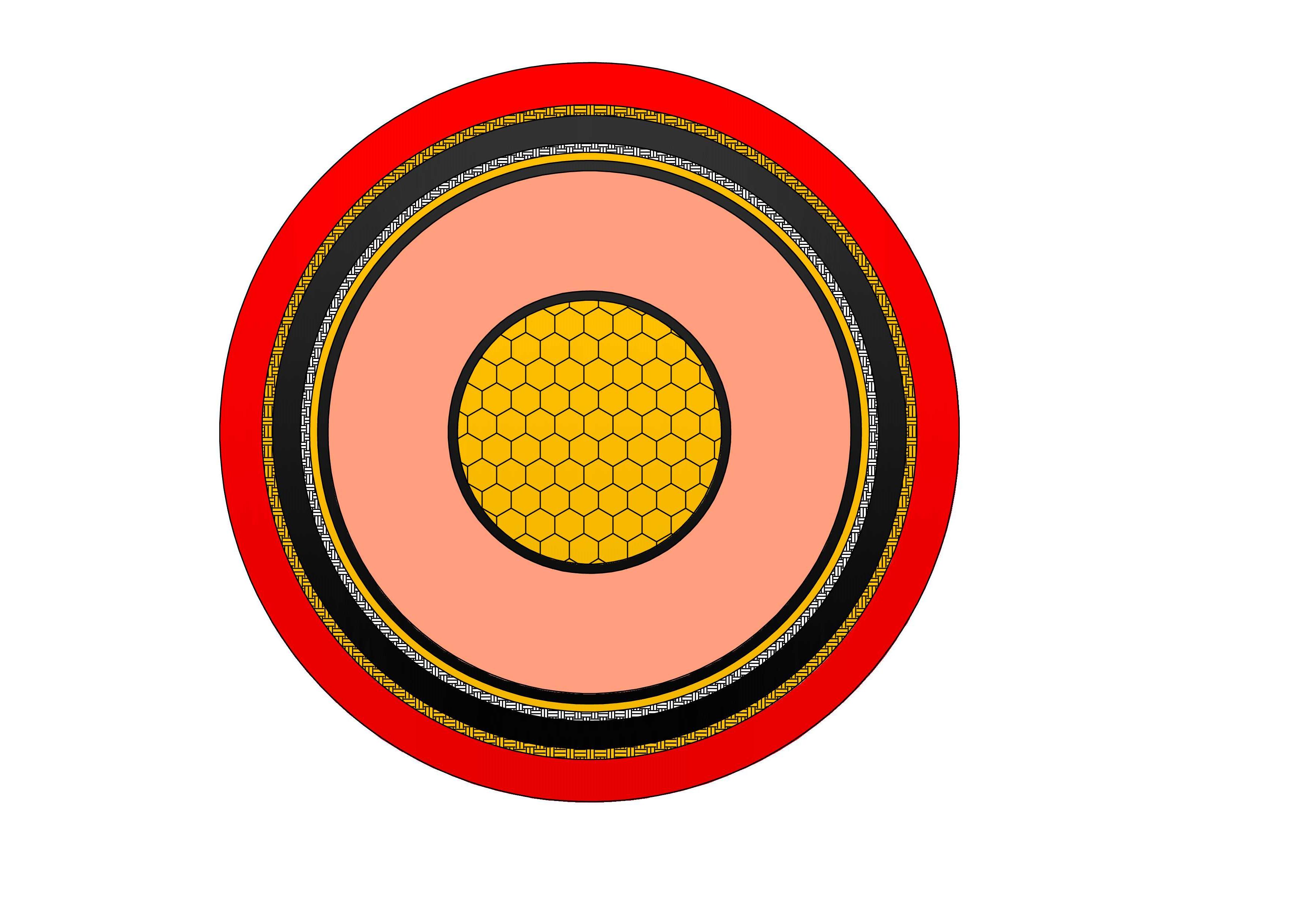

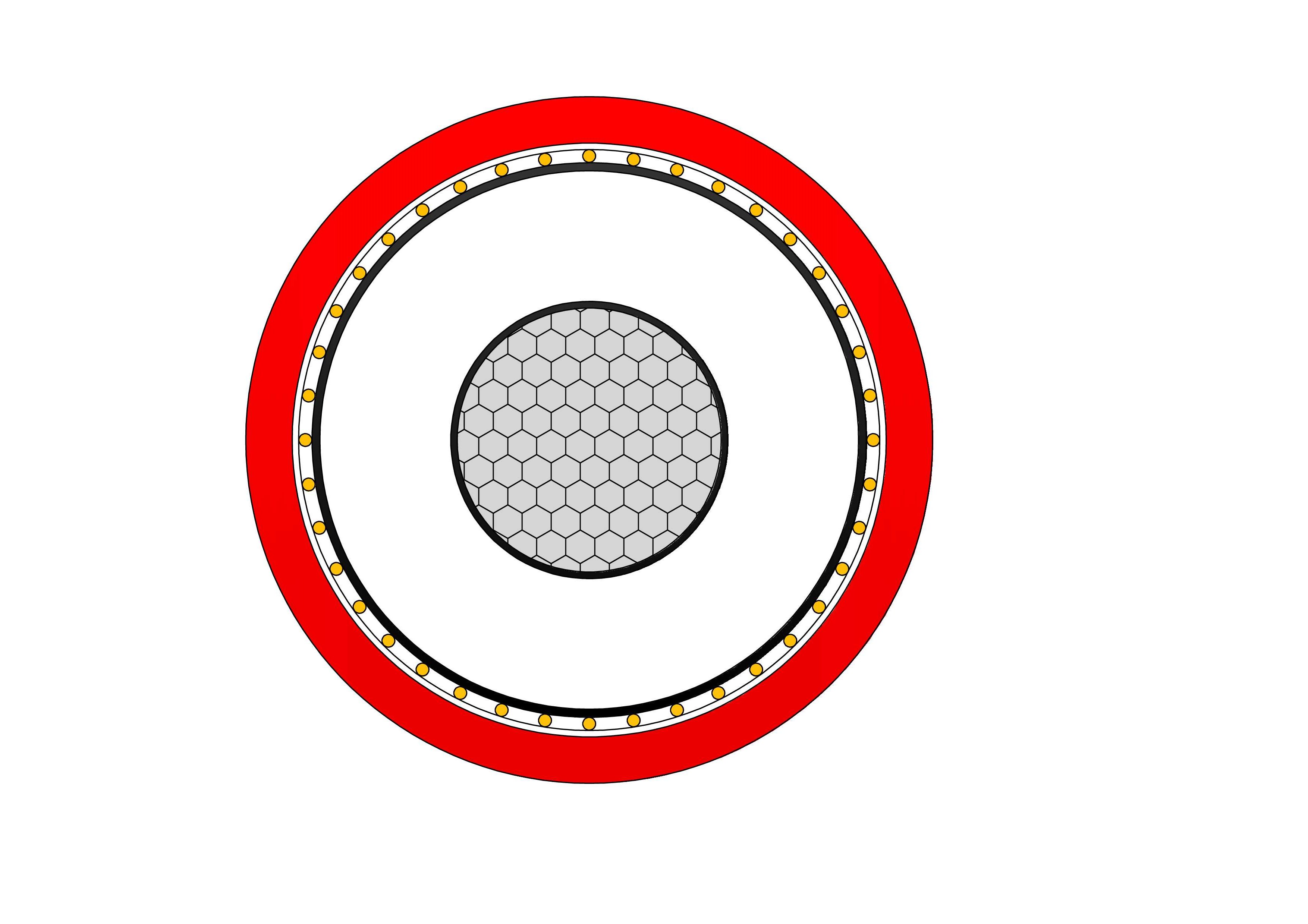

2Y-high-voltage-power-cable-2.webp)