Inside a Power Pole Transformer: Components, Functions, and Design

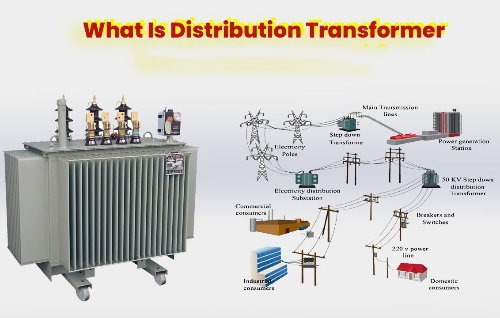

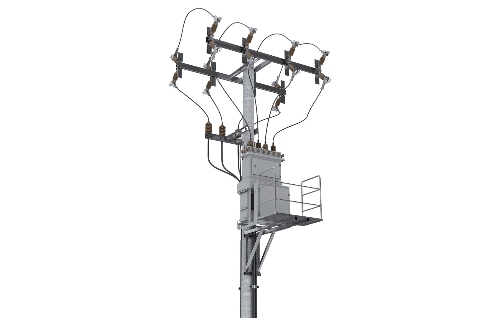

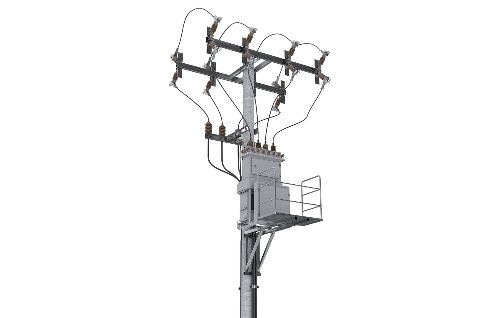

In modern cities and rural areas alike, the power pole transformer plays a crucial role in electrical distribution systems. Often mounted on wooden or concrete utility poles, this device is responsible for stepping down high voltage electricity from transmission lines to a safe output voltage for homes and businesses. While most people see them daily, few understand what is inside a transformer on a power pole or how it works.

Why Power Pole Transformers Are Needed

Electricity is generated at power plants and transmitted over long distances at high voltages—often tens or hundreds of kilovolts. This reduces energy loss during transmission. However, households and businesses use much lower voltages, typically 120/240 V in North America or 230 V in many other regions.

A power transformer mounted on a distribution pole serves as the critical link between the high voltage electricity in the distribution network and the lower voltages required for end users. Without pole-mounted transformers, the electrical system would be unsafe and unusable for everyday applications.

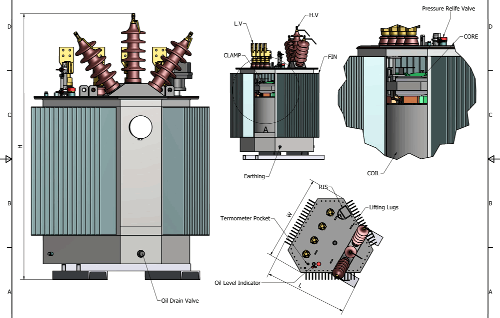

Major Components Inside a Power Pole Transformer

To understand its function, let’s examine the internal parts of a single-phase power pole transformer:

1. Core

At the heart of the transformer is the magnetic core, typically made of laminated silicon steel. The core provides a low-resistance path for magnetic flux, allowing efficient energy transfer between the primary winding and the secondary winding.

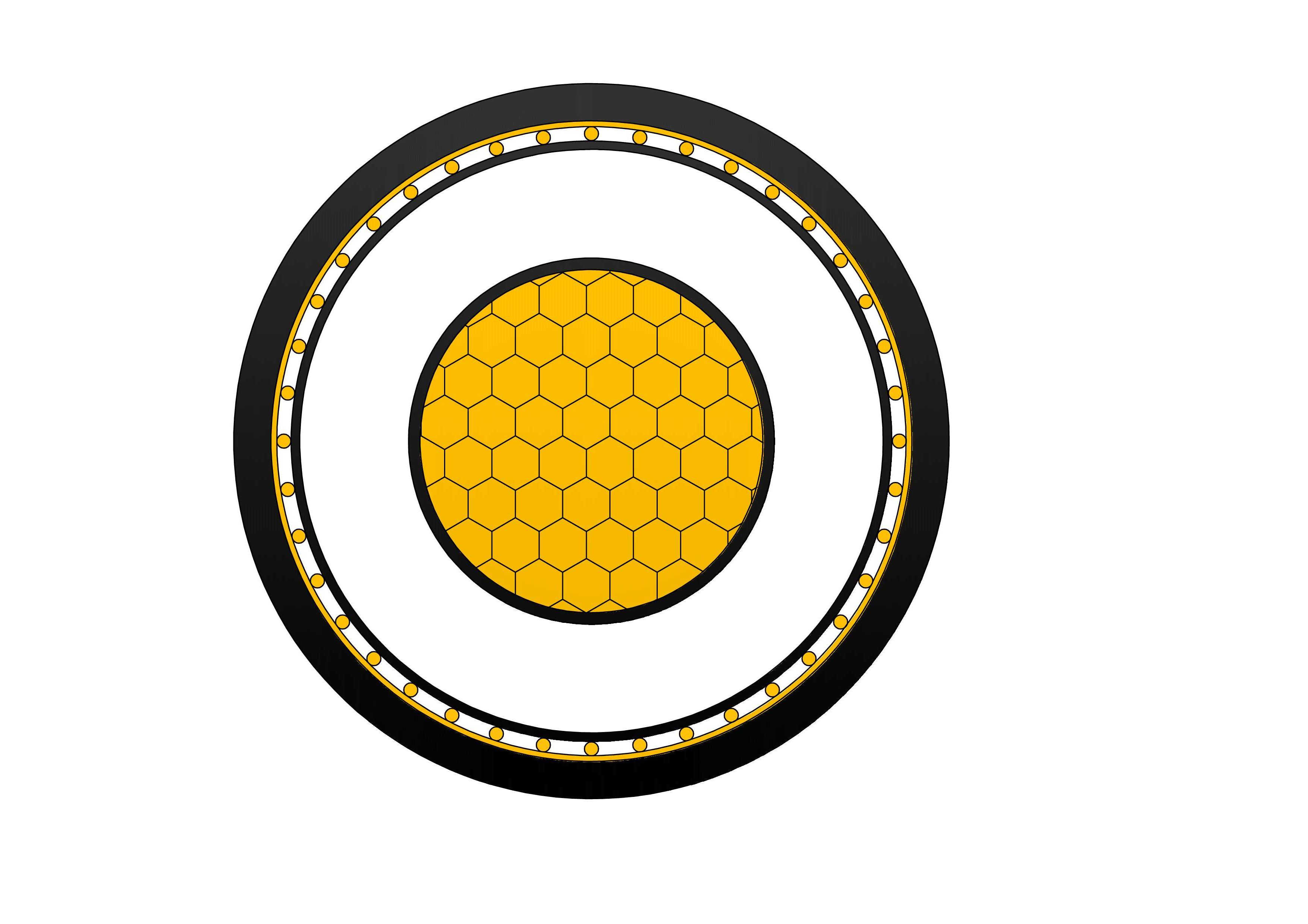

2. Primary and Secondary Windings

- Primary winding: Connected to the high voltage electricity supply (e.g., 7,200 V distribution line).

- Secondary winding: Delivers the stepped-down output voltage (e.g., 120/240 V) to end users.

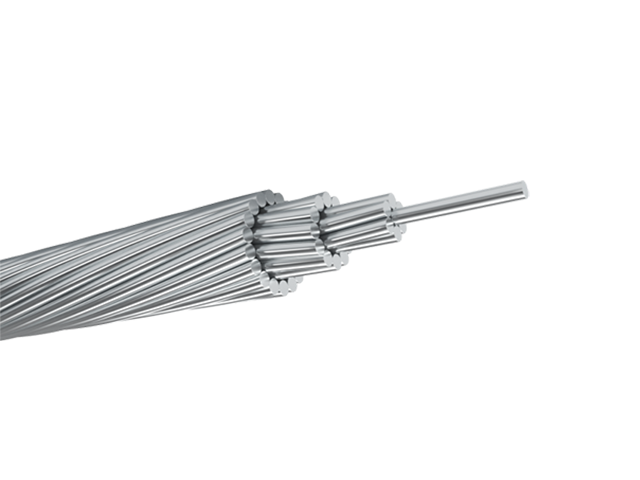

These windings are made of copper or aluminum conductors, carefully insulated to withstand electrical stress. The ratio of turns between the primary and secondary determines the voltage transformation.

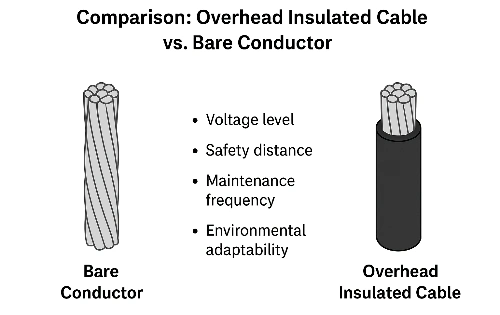

3. Electrical Insulation

Insulation ensures that high voltage does not cause dangerous arcing or short circuits. Pole transformers use solid insulation materials (such as paper, pressboard, or epoxy) along with insulating oil to enhance dielectric strength and cooling.

4. Insulating Oil

Most power line transformers are oil-filled. The insulating oil serves two purposes:

- Provides electrical insulation between internal components.

- Removes heat from the core and windings during operation.

5. Bushings and Terminals

Porcelain or polymer bushings connect the internal windings to the external electrical system. These bushings provide a safe passage for conductors while maintaining insulation.

6. Tank and Enclosure

The steel tank protects internal components from weather and mechanical damage. It is sealed to prevent leakage of oil and ingress of moisture.

7. Safety Devices

Some pole transformers include protective fuses, pressure-relief valves, or lightning arresters. These devices prevent failures due to surges, overloading, or internal faults.

How a Power Pole Transformer Works

The operation is based on Faraday’s law of electromagnetic induction. When high voltage electricity flows through the primary winding, it creates a magnetic field in the core. This changing magnetic flux induces a voltage in the secondary winding.

Because the secondary winding has fewer turns, the voltage is stepped down to a safe level for consumer use. For example:

- Input (primary): 7,200 V (distribution line)

- Output (secondary): 120/240 V (residential supply)

This process conserves power (minus small losses) and enables safe, reliable delivery of electric energy.

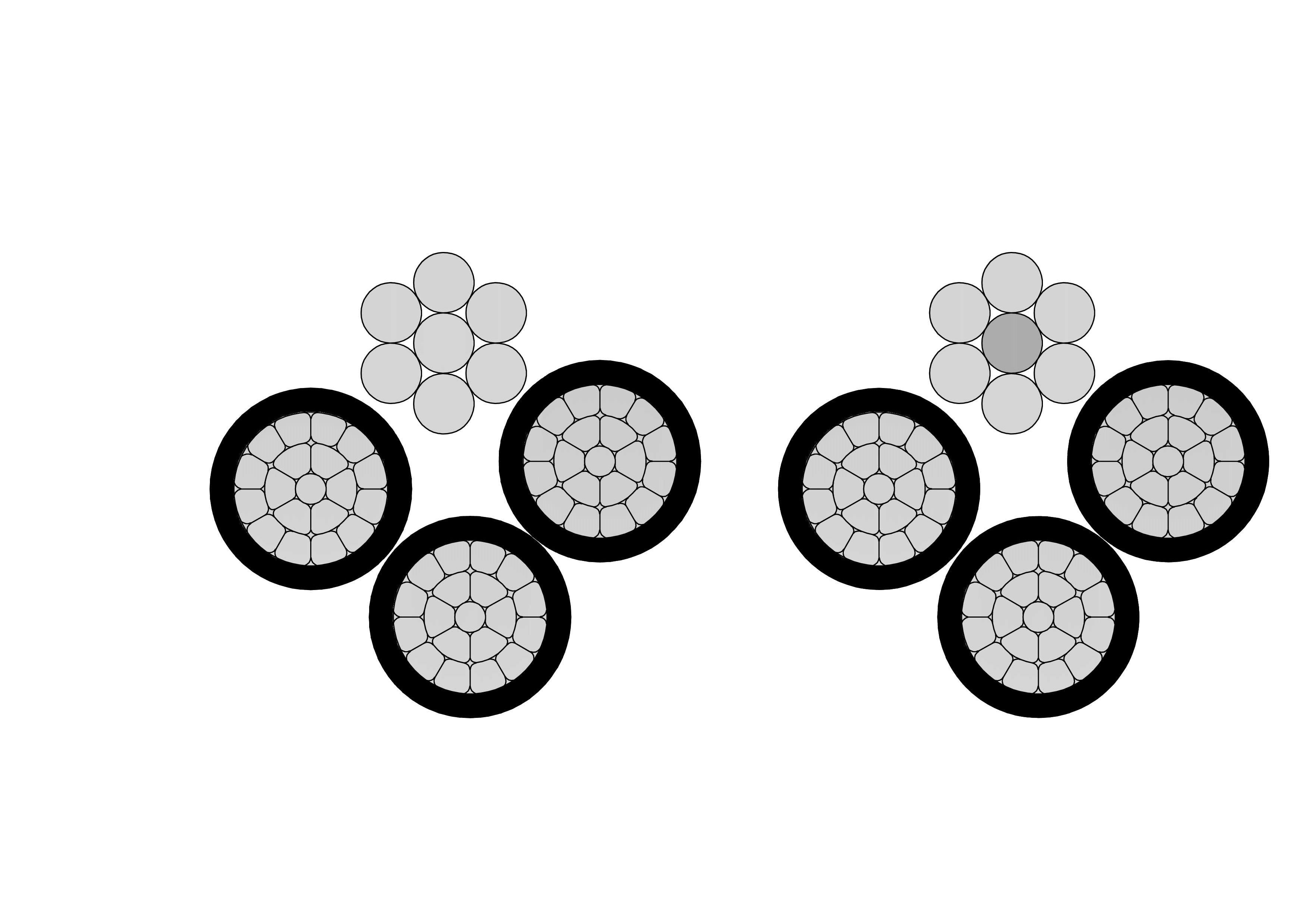

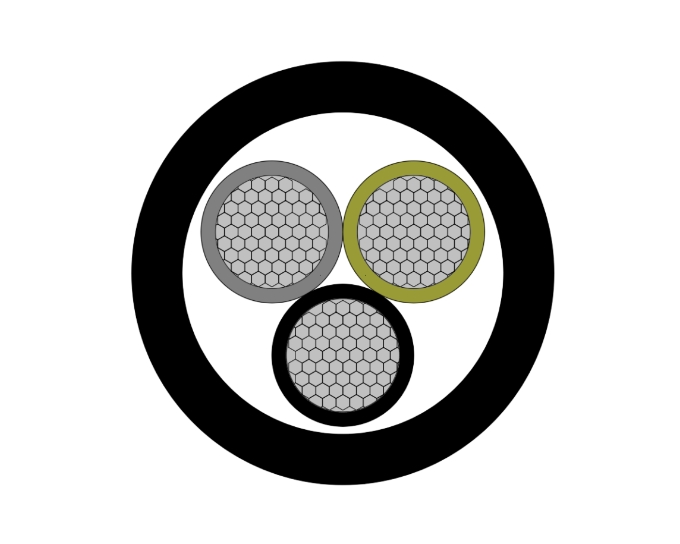

Single-Phase vs. Three-Phase Transformers

Most power pole transformers are single-phase, ideal for residential areas. They can provide two 120 V circuits or one 240 V circuit.

In industrial or commercial settings, multiple single-phase transformers may be combined, or larger three-phase power transformers are used. These systems support higher loads and three-phase machinery.

Role in the Electrical System

The transformer on a power pole is more than just a step-down device—it is an integral part of the electrical system. Its functions include:

- Voltage regulation: Matching supply levels with demand needs.

- Insulation: Isolating consumers from dangerous transmission voltages.

- Load balancing: Distributing energy efficiently across multiple users.

Maintenance and Reliability

Pole-mounted transformers are designed for decades of service, but they require periodic inspection. Common checks include:

- Oil level and quality (to ensure proper electrical insulation).

- Bushing condition.

- Load monitoring.

- External corrosion or leaks.

Failure of a pole transformer can cause localized blackouts, making preventive maintenance essential.

The power pole transformer may look like a simple metal drum on a utility pole, but inside lies a carefully engineered system. With its core and windings, electrical insulation, insulating oil, and protective devices, it ensures safe and efficient transformation of high voltage electricity into usable electric energy.

By understanding the design and functions of these power transformers, we gain a deeper appreciation for the hidden technology that powers modern life.

2Y-high-voltage-power-cable-2.webp)