Choosing the Right XLPE Cable for High-Voltage Applications

With the continuous growth of electricity demand, selecting suitable power transmission and distribution solutions has become particularly important. Cross-linked polyethylene (XLPE) cables are an ideal choice for modern high-voltage applications due to their excellent electrical insulation properties, high temperature resistance, corrosion resistance, UV resistance, and mechanical strength. Their cross-linked structure allows XLPE cables to remain stable under long-term high-load operation and possesses extremely high voltage resistance and aging resistance.

Whether in industrial power systems, renewable energy projects, or urban power distribution, the widespread application of XLPE cables provides efficient and reliable power transmission for power systems. Especially in high-voltage applications, XLPE cables can effectively reduce energy loss during power transmission and improve system efficiency. At the same time, they can also reduce power outages or failures caused by changes in the external environment, ensuring the long-term stability and safety of the system. Therefore, selecting suitable XLPE cables is crucial for the sustainable development of the power industry.

What is XLPE Cable?

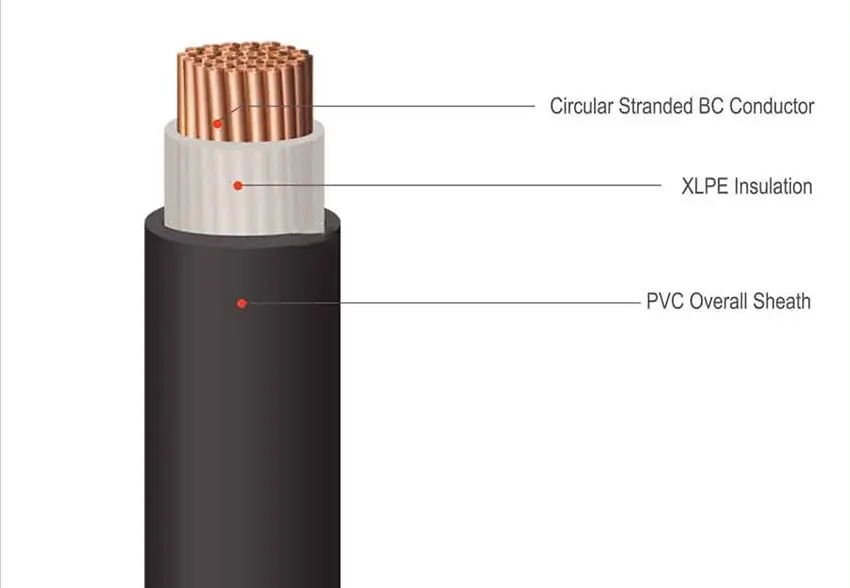

XLPE (Cross-Linked Polyethylene) is a type of insulated cable that has undergone a cross-linking process, which enhances its performance compared to regular polyethylene. In the cross-linking process, the polymer molecules are chemically bonded, creating a three-dimensional network of molecules that give XLPE cables their high durability, improved heat resistance, and better electrical properties.

These cables are widely used in high-voltage power distribution and industrial power systems due to their superior electrical insulation and physical properties, such as:

-

High thermal stability: XLPE cables can withstand temperatures of up to 90°C continuously and 130°C during short circuits.

-

Enhanced mechanical properties: The cross-linking improves the cable's resistance to physical stress and reduces the risk of cable failure under mechanical stress.

-

Environmental resistance: XLPE is resistant to moisture, UV radiation, and chemicals, making it ideal for both underground and overhead installations.

-

Superior electrical properties: XLPE insulation ensures a low dielectric loss, improving energy efficiency over long distances.

Key Benefits of XLPE Cables for High-Voltage Applications

When choosing an XLPE-insulated cable for high-voltage applications, several critical factors contribute to its optimal performance and suitability. These include:

1. High Voltage Endurance

XLPE cables are ideal for high-voltage power distribution due to their excellent dielectric strength. The XLPE insulated power cable can handle a broad range of voltages, including 110 kV, 220 kV, and even 400 kV in some configurations, making them suitable for long-distance transmission and high-capacity applications.

2. Reduced Energy Losses

One of the main advantages of the electrical cable XLPE is the reduced energy loss over long distances. XLPE cables offer lower resistance compared to traditional cables, leading to improved energy efficiency. This makes them a perfect choice for long-distance power transmission in industrial power systems and power grids, where reducing losses is a key concern.

3. Improved Safety and Reliability

The cross-linking process significantly improves the electrical and mechanical properties of the cables, ensuring safer operation and fewer failures in high-voltage environments. XLPE cables have excellent fire resistance, preventing the spread of fire in case of an electrical fault. The XLPE insulated power cable design also provides enhanced protection from environmental damage, ensuring more reliable performance in harsh conditions.

4. Flexibility in Installation

XLPE cables are much more flexible than conventional cables, allowing easier handling during installation. Their lightweight nature also reduces labor costs and time required for installation, making them highly suitable for industrial power systems, renewable energy projects, and urban infrastructure.

5. Resistance to External Factors

Because of their excellent resistance to moisture, chemicals, and other environmental elements, XLPE cables can be used in diverse applications, including underground installations, offshore wind farms, and outdoor environments. These properties ensure that the cables maintain their performance even under harsh conditions, making them ideal for renewable energy systems, such as wind or solar power installations.

How to Choose the Right XLPE Cable for High-Voltage Applications

Selecting the right XLPE cable for high-voltage applications depends on several factors. Here’s a guide to help you make the right choice:

1. Voltage Rating

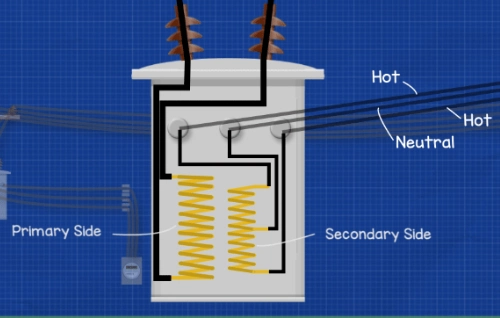

The voltage rating of the XLPE cable is one of the most important considerations. The cable should be rated for the highest operating voltage in your system. For example, for power transmission systems requiring voltages above 100 kV, 1100 kV XLPE transformers may be needed for optimal performance.

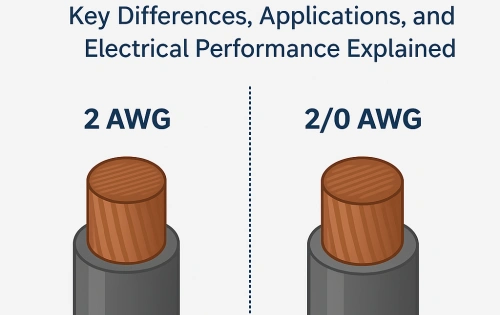

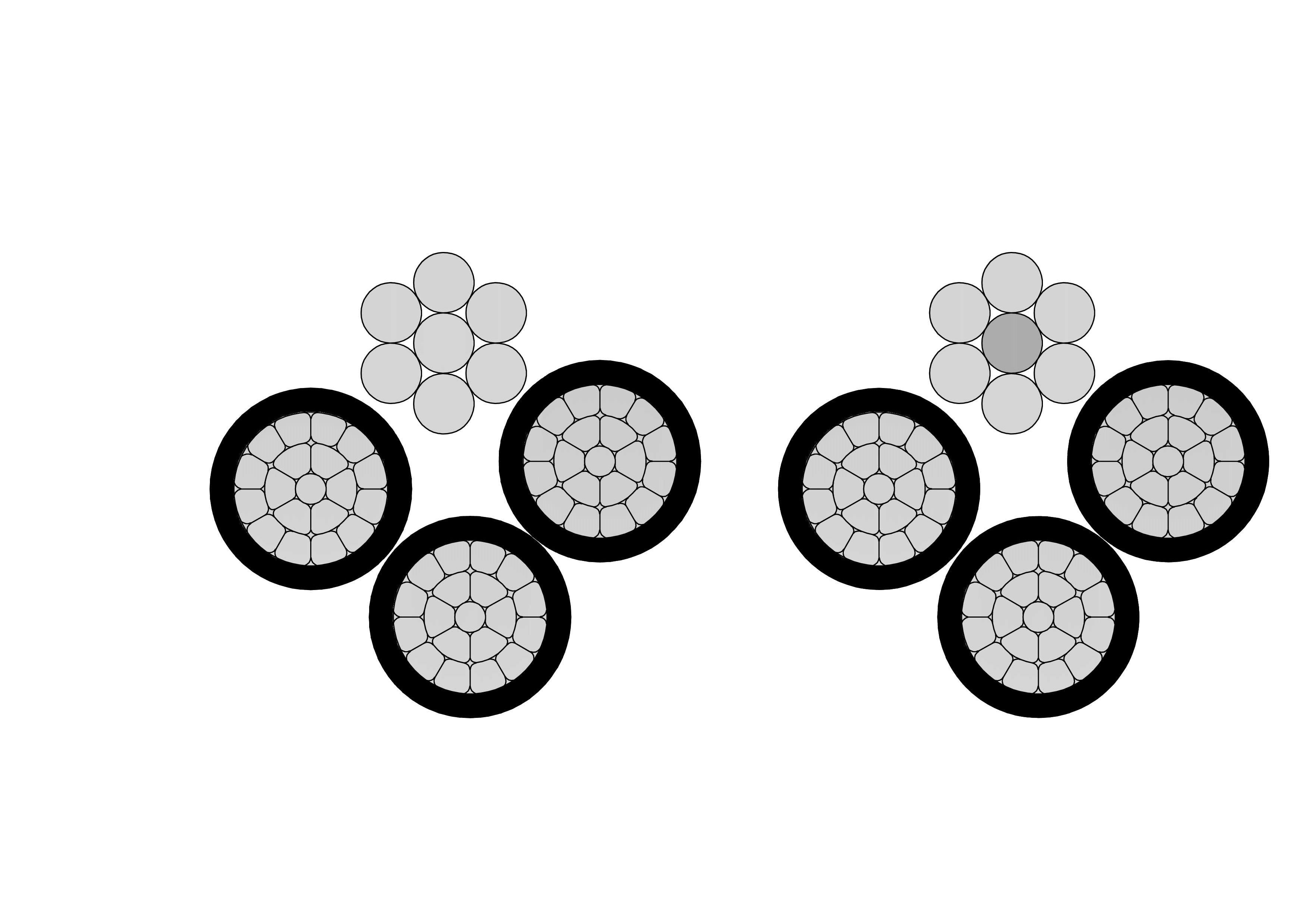

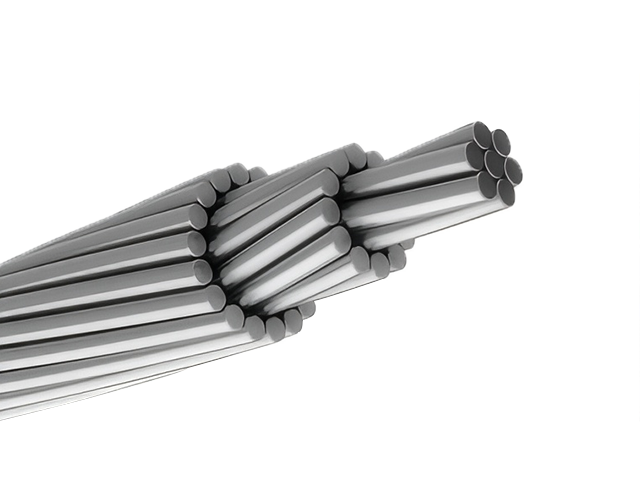

2. Conductor Material

The most common materials used for the conductors of XLPE cables are copper and aluminum. Copper conductors offer lower resistance and better performance in high-power applications but are more expensive. Aluminum conductors are lighter and less expensive but may require a larger cross-sectional area to achieve the same electrical performance.

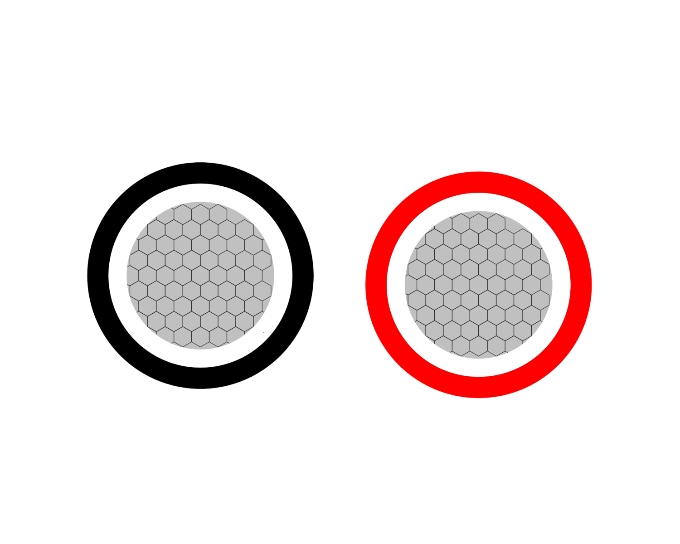

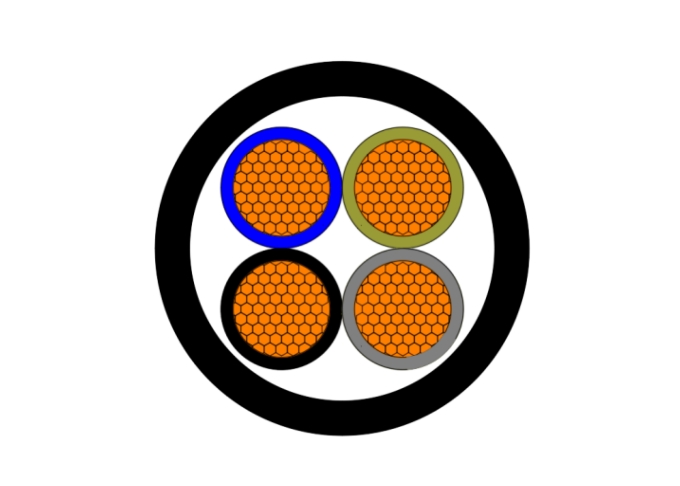

3. Cable Design

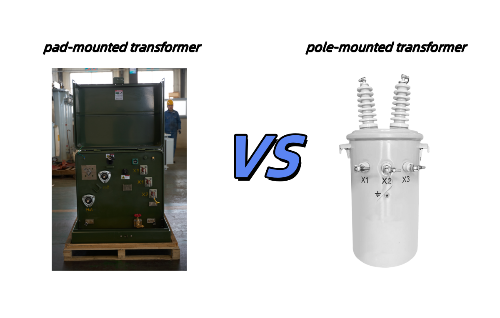

Different applications require different cable designs. For example, XLPE-insulated cables for overhead power lines require additional considerations for mechanical strength, such as the use of steel-reinforced conductors. XLPE cables for underground installations may require special coatings to protect against moisture and other environmental conditions.

4. Installation Environment

Consider the environment in which the XLPE cable will be installed. Underground cables must be robust and resistant to moisture and physical stress, whereas overhead cables must be weatherproof and able to withstand extreme temperatures and high wind speeds.

5. Manufacturer and Standards Compliance

Choosing a reputable transformer manufacturer or cable supplier is crucial. Ensure the XLPE cables comply with industry standards such as IEC 60502, IEC 60840, and ANSI standards for safety and performance. Leading manufacturers like Siemens, ABB, and General Cable provide high-quality XLPE cables designed to meet stringent global requirements.

XLPE Cable Factor Table:

|

Factor |

Description |

Considerations for High-Voltage Applications |

|

Voltage Rating |

The maximum operating voltage the cable can handle. |

Choose cables with a voltage rating higher than the system’s operating voltage. Example: 1100 kV XLPE cables for large transmission systems. |

|

Conductor Material |

The material used for the conductor (typically copper or aluminum). |

Copper offers lower resistance and is more efficient for high-power applications, while aluminum is lighter and more cost-effective. |

|

Cable Design |

The physical construction of the cable, including the number of layers and insulation. |

Ensure the design matches the installation environment (e.g., underground, overhead). Reinforced conductors may be needed for overhead installations. |

|

Insulation Material |

The material that insulates the conductors, providing electrical separation. |

XLPE insulation provides superior dielectric strength, heat resistance, and mechanical durability compared to PVC. |

|

Environmental Resistance |

The cable's ability to withstand external factors such as moisture, chemicals, and temperature. |

XLPE is resistant to moisture and UV radiation, making it ideal for both underground and outdoor applications. |

|

Application Type |

The intended use of the cable, such as in power distribution, industrial applications, or renewable energy systems. |

For renewable energy projects, XLPE cables are perfect for connecting offshore wind farms or solar panels to the grid. |

|

Manufacturer and Standards |

The quality assurance and compliance with international standards. |

Ensure the cables meet standards like IEC 60502, IEC 60840, and ANSI to guarantee performance and safety. |

Applications of XLPE Cables in Modern Power Systems

XLPE insulated cables are versatile and used in various applications, including:

-

High-voltage transmission lines: XLPE cables are ideal for long-distance power transmission with minimal loss.

-

Renewable energy systems: XLPE cables connect offshore wind farms, solar farms, and other renewable installations to the grid.

-

Industrial facilities: For feeding large machinery and ensuring smooth power flow in factories and plants.

-

Underground power networks: XLPE cables offer superior resistance to environmental hazards, making them perfect for underground installations in cities.

-

Utility and commercial infrastructure: XLPE cables ensure reliable electricity distribution across residential, commercial, and urban areas.

In high-voltage power systems, XLPE cables offer unmatched performance in terms of electrical efficiency, safety, and durability. The ability of XLPE insulated power cables to withstand harsh environmental conditions, coupled with their low energy losses and flexible installation, makes them the preferred choice for power utilities, industrial power systems, and renewable energy projects. By considering factors such as voltage rating, conductor material, and the installation environment, you can select the right XLPE electrical cable to ensure efficient, reliable, and safe power transmission in your system.

As modern infrastructure continues to evolve, XLPE cables will remain central to enabling the next generation of power distribution and energy solutions.