Overhead Insulated Cable vs. Bare Conductor – Differences, Applications, and Performance Explained

Electric power systems depend on efficient and reliable conductors to carry electricity from generation plants to end users. Among the most widely used technologies in modern grids are the overhead insulated cable and the bare conductor.

1. What Are Bare Conductors and Overhead Insulated Cables?

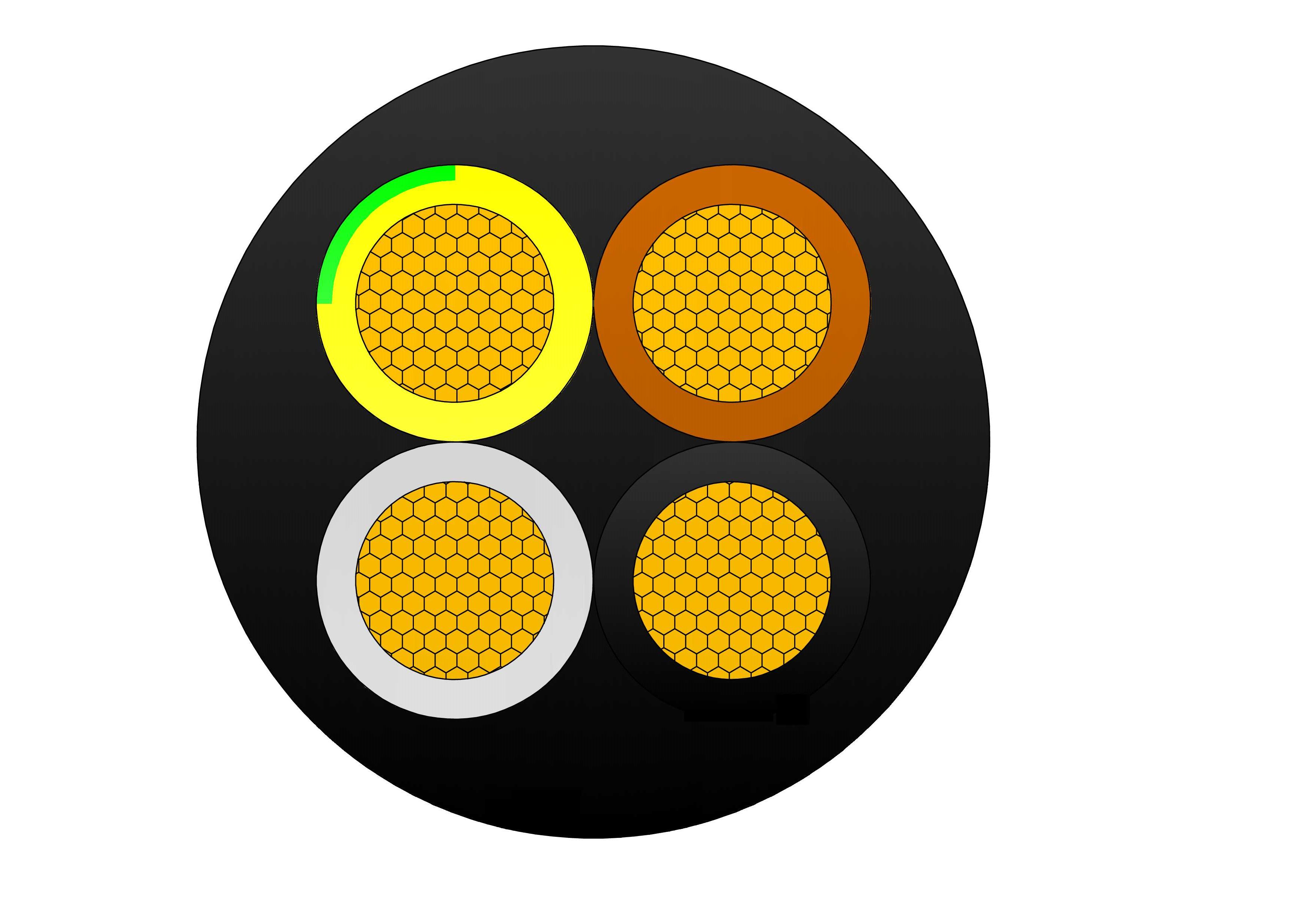

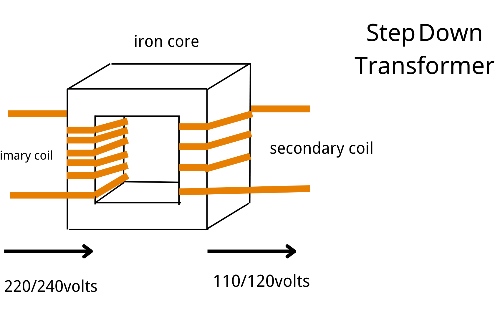

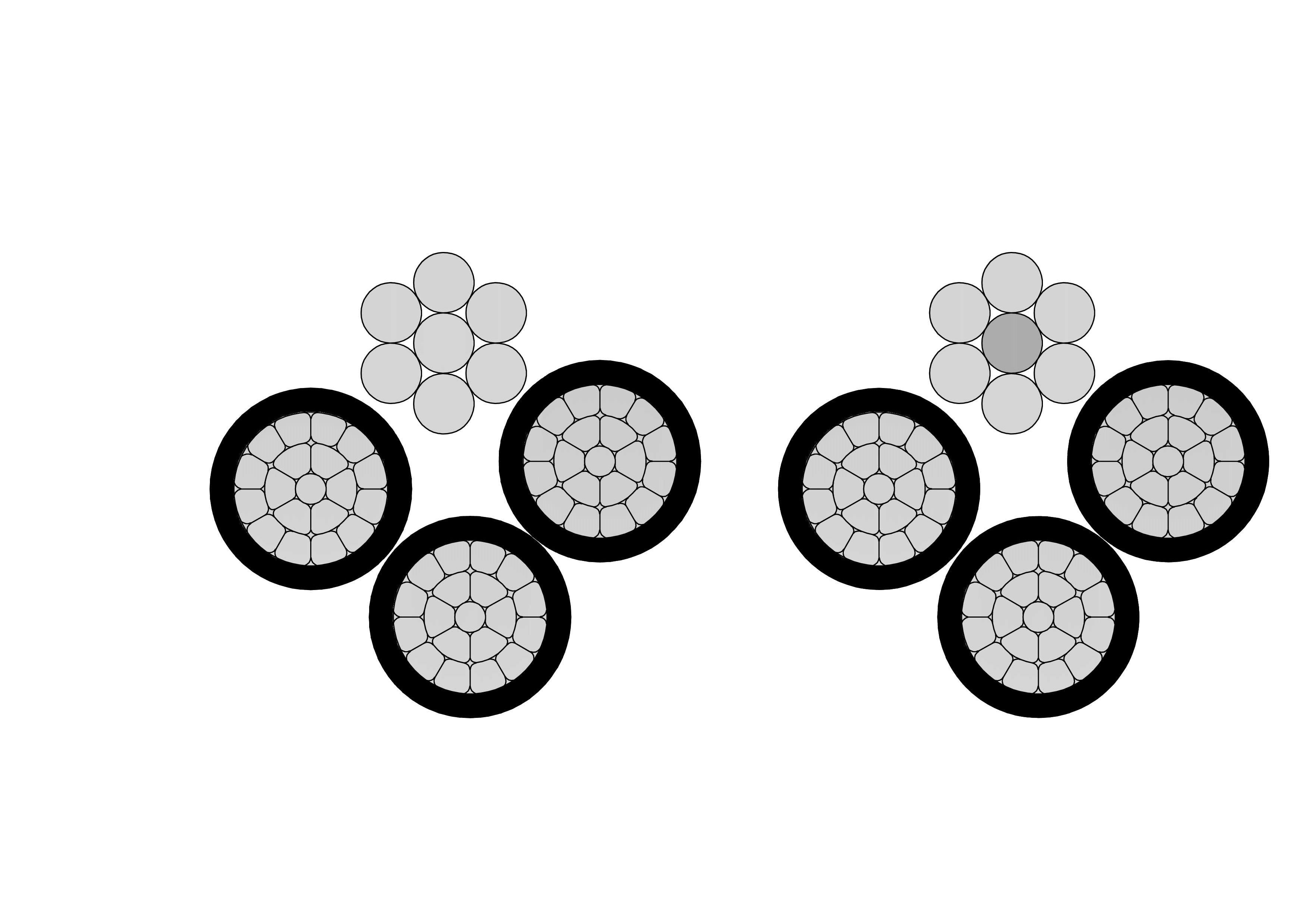

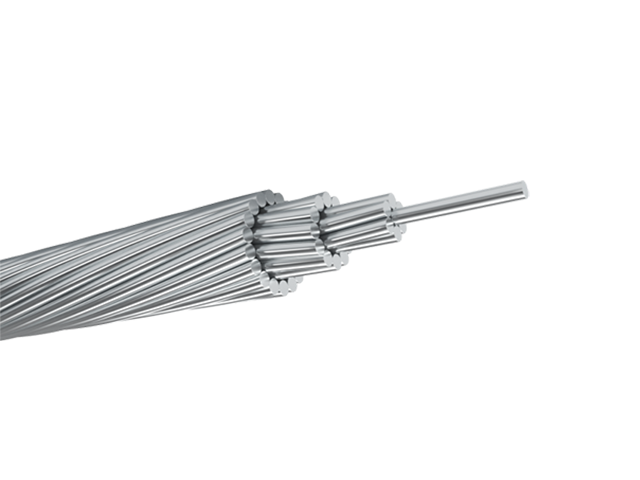

A bare conductor (or bare wire) is a metallic conductor—typically made of aluminum (AAC, AAAC, ACSR) or copper—used without any insulating layer. Bare conductors are most common in overhead transmission lines and high voltage transmission systems, where the air itself acts as the primary insulator.

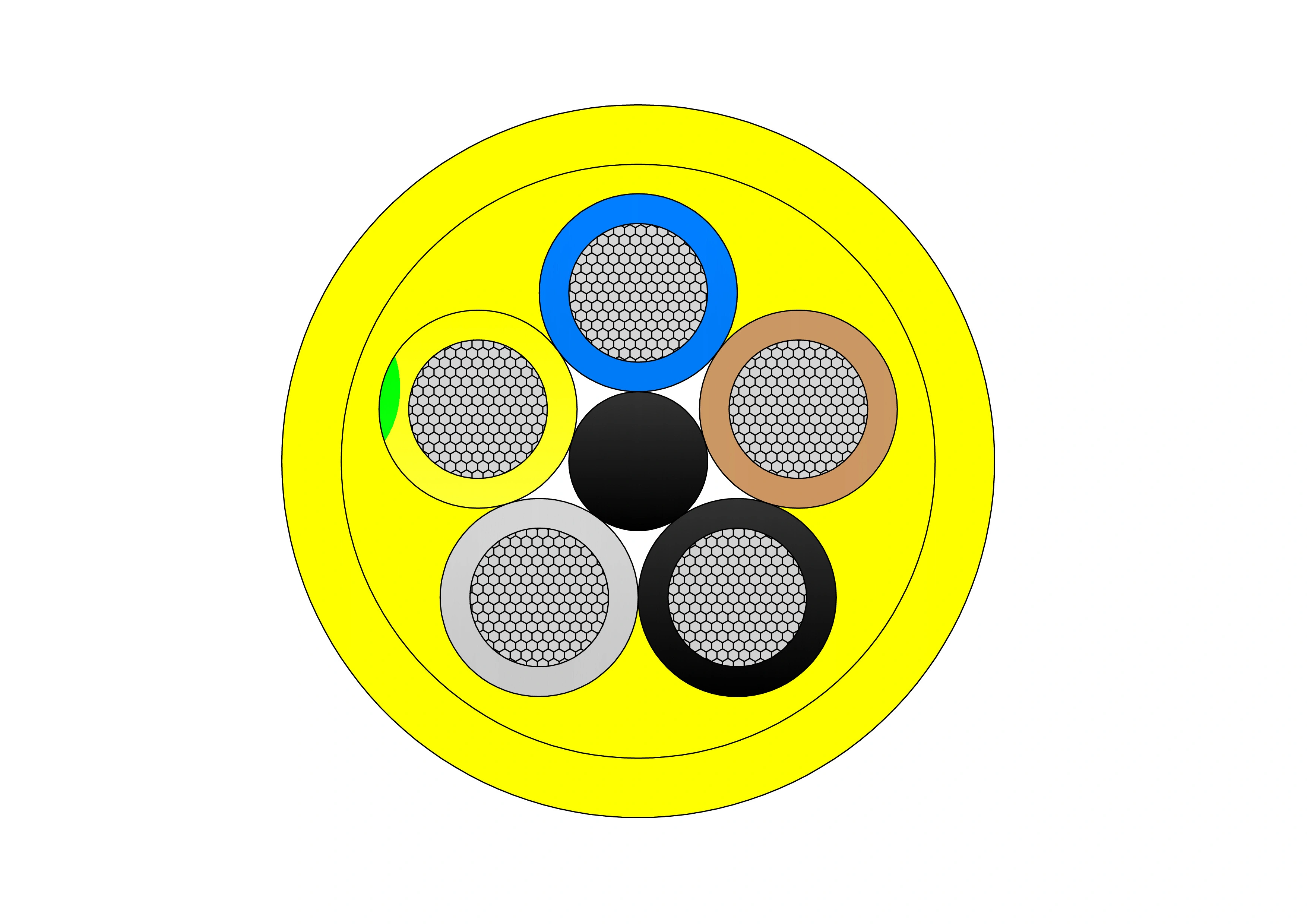

An overhead insulated cable, by contrast, features a conductor wrapped in an insulating material such as cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR). The insulation provides additional protection against short circuits, moisture, and accidental contact with trees or structures. These cables are widely used in power lines, distribution networks, and urban electrical systems where safety and reliability are paramount.

2. Structural and Material Differences

|

Feature |

Bare Conductor |

Overhead Insulated Cable |

|

Insulation |

None; exposed metal |

Covered with polymer insulation (e.g., XLPE) |

|

Material |

Aluminum or copper |

Aluminum or copper with insulation |

|

Cooling |

Naturally air-cooled |

Slightly reduced cooling efficiency due to insulation |

|

Maintenance |

Requires clearance and regular inspection |

Lower maintenance frequency |

|

Safety |

Requires distance from ground and vegetation |

Safer for public and wildlife environments |

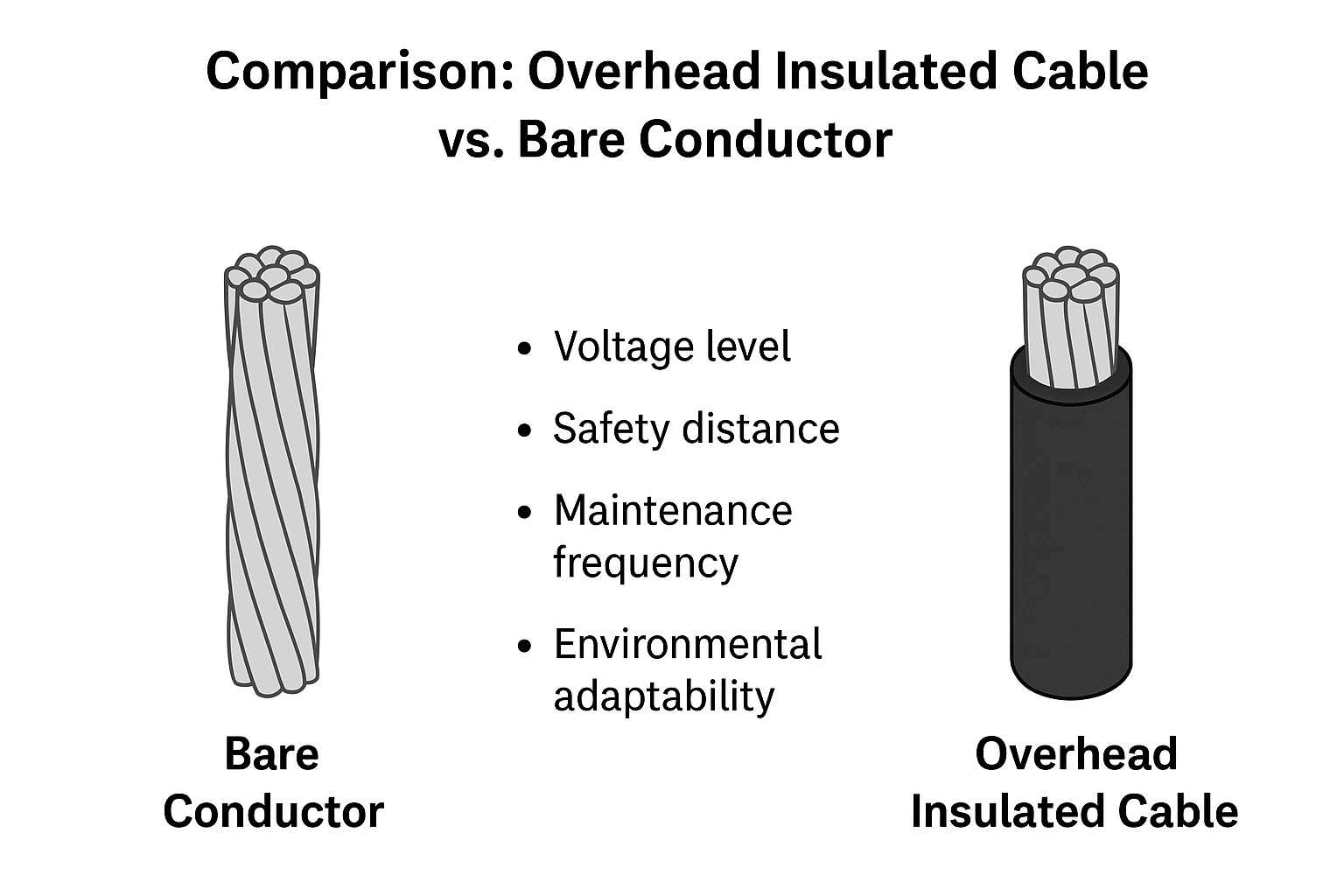

In high-voltage applications, bare wires are preferred for their simplicity and cost-efficiency. However, in areas prone to short circuits or electrical interference—such as urban or forested regions—overhead insulated cables offer superior safety and environmental adaptability.

3. Performance and Electrical Characteristics

Both types are designed to carry electricity efficiently, but their performance differs under specific conditions.

- Current Capacity: Bare conductors can dissipate heat more easily, allowing slightly higher current ratings at the same cross-section.

- Voltage Levels: Bare conductors dominate in high voltage transmission (69 kV and above), while insulated cables are common in low- to medium-voltage systems (up to 33 kV).

- Mechanical Strength: Stranded aluminum conductors provide excellent tensile strength for long overhead transmission lines.

- Dielectric Performance: Insulated cables provide better resistance to arcing, corona discharge, and environmental contamination.

From an engineering perspective, the selection depends on balancing electrical efficiency, safety, and installation cost.

4. Applications in Real-World Power Systems

Bare Conductors

Used primarily in:

- High-voltage transmission networks over long distances

- Rural power lines with wide clearances

- Substation busbars and grounding systems

Bare conductors are lightweight and cost-effective, ideal for areas with low population density and minimal vegetation.

Overhead Insulated Cables

Used in:

- Urban distribution lines and residential networks

- Coastal or forested regions with a higher risk of short circuits

- Medium-voltage feeders in solar farms, industrial parks, and mining sites

In dense urban zones, insulated overhead wires significantly reduce outages caused by environmental contact. Their use also aligns with modern standards for power cable safety and reliability.

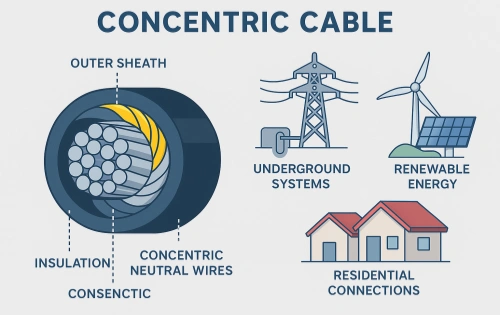

Underground Cables

While not the focus here, underground cables are increasingly used for aesthetic and safety reasons in cities. They provide a clean appearance but come with higher installation and maintenance costs compared to overhead cables.

5. Environmental and Safety Considerations

Safety is a key factor in selecting between bare and insulated options.

Overhead insulated cables reduce the risk of electric shock, bird strikes, and line-to-tree faults. They are also easier to maintain in congested areas where power lines cross buildings or roads.

On the other hand, bare conductors require larger clearance and careful line design to avoid contact hazards. They perform best in open environments, such as desert or mountain regions, where high voltages can be safely managed without insulation.

6. Economic and Operational Factors

From a cost perspective:

- Bare conductors offer lower material and installation costs, making them ideal for large-scale high-voltage transmission systems.

- Overhead insulated cables are more expensive per meter but reduce maintenance downtime, vegetation trimming, and risk of service interruption—yielding long-term operational savings.

When considering the total life-cycle cost, insulated systems may prove more economical in dense or high-risk environments despite their higher initial expense.

7. The Future of Overhead Power Transmission

With increasing focus on renewable energy and grid reliability, both technologies continue to evolve.

Advanced materials, such as heat-resistant aluminum alloys and improved XLPE insulation, are expanding the voltage range of insulated systems.

Meanwhile, innovations in bare wire surface coatings and corrosion-resistant conductors enhance the lifespan of traditional overhead systems.

The future grid will likely use a hybrid approach—combining insulated distribution cables for urban networks and bare conductors for long-distance transmission—to achieve an optimal balance of performance, safety, and cost.

8. Engineering Considerations for Modern Power Systems

In modern power infrastructure, choosing between overhead insulated cables and bare conductors involves balancing mechanical design, electrical performance, and environmental impact.

Engineers must account for:

- Voltage class and line length: Bare conductors perform best in extra-high-voltage lines above 110 kV.

- Installation terrain: Hilly or forested areas benefit from insulated systems that reduce vegetation clearance.

- Climatic conditions: Salt spray, pollution, and UV exposure accelerate conductor degradation, making insulated options more durable in coastal and tropical regions.

- System losses: Modern aluminum alloys and improved surface treatments reduce resistance and power loss in both conductor types.

9. Emerging Technologies and Materials

Recent advances in materials science are bridging the gap between traditional and insulated solutions:

- High-Temperature Low-Sag (HTLS) conductors enable higher current capacity without upgrading towers.

- Self-supporting insulated cables (ABC systems) are increasingly adopted in smart grid distribution.

- Hybrid transmission lines, combining bare and insulated segments, optimize cost and safety for large renewable projects.

- Smart monitoring systems integrated with IoT sensors help utilities track conductor temperature, load, and vibration in real time.

These innovations show that the evolution of overhead transmission systems is not just about conductor type—but about integrating advanced materials and data intelligence into the grid.

10. Future Outlook: Toward Sustainable Power Delivery

As global demand for electricity grows—driven by electrification, renewable energy, and electric mobility—utilities must enhance both efficiency and sustainability.

Future power lines will rely on conductors that combine low loss, high reliability, and environmental resilience.

Overhead insulated cables will continue to play a vital role in urban and renewable energy applications, while bare wires will remain indispensable in long-distance transmission.

Together, they form the backbone of a cleaner, smarter, and more reliable energy future.

Both overhead insulated cables and bare conductors are indispensable to modern electrical infrastructure.

- Bare wires remain the preferred choice for long-distance, high-voltage transmission due to their simplicity and cost-effectiveness.

- Overhead insulated cables dominate in urban, industrial, and environmentally sensitive areas, where safety and reliability are critical.

As power systems continue to evolve, the integration of advanced materials and design standards will further enhance how these overhead cables, voltage lines, and power cables efficiently carry electricity across global networks.

2Y-high-voltage-power-cable-2.webp)