Service Drop Cable Explained: Types, Installation, and Safety in Power Distribution

In every electrical distribution network, the final link that connects the utility power line to a building or facility is known as the service drop cable. This cable plays a critical role in safely delivering low-voltage electricity from overhead power lines to residential, commercial, or industrial users.

Despite being relatively short in length compared to transmission lines, service drop cables must withstand challenging environmental conditions — including ultraviolet radiation, temperature fluctuations, wind load, and mechanical stress — while maintaining stable electrical performance.

1. What Is a Service Drop Cable?

A service drop cable is a type of overhead electrical cable used to connect a utility distribution pole to a customer's service entrance. It typically carries voltages below 600V for secondary distribution systems.

Most overhead service drop cables consist of several conductors — one or more insulated phase conductors and a bare or insulated neutral conductor — twisted together to form a compact, weather-resistant cable assembly.

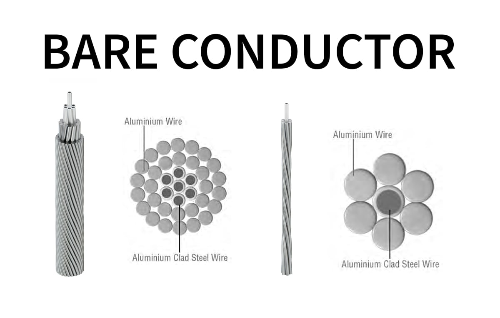

The design minimizes sagging and tension, ensuring mechanical strength under wind, snow, and ice loading. In modern distribution systems, the majority of these cables are made from aluminum conductors, which combine excellent conductivity with lightweight performance.

2. Construction and Materials

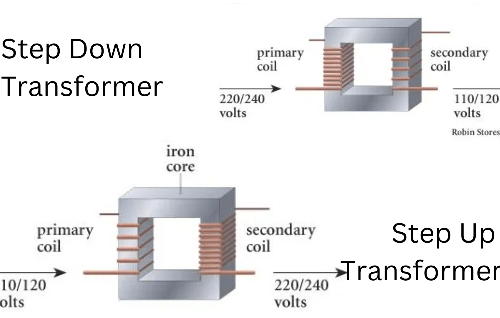

The core of a service drop cable is its conductor, typically made of AAC (All Aluminum Conductor), AAAC (All Aluminum Alloy Conductor), or ACSR (Aluminum Conductor Steel Reinforced). Each conductor is stranded to improve flexibility and tensile strength.

Common insulation materials include:

- XLPE (Cross-Linked Polyethylene): Resistant to heat, UV, and chemical corrosion.

- PE (Polyethylene): Economical, durable, and moisture-resistant.

Sheathing may include additional layers for abrasion and weather protection, particularly in urban installations where cables are exposed to pollution and mechanical contact.

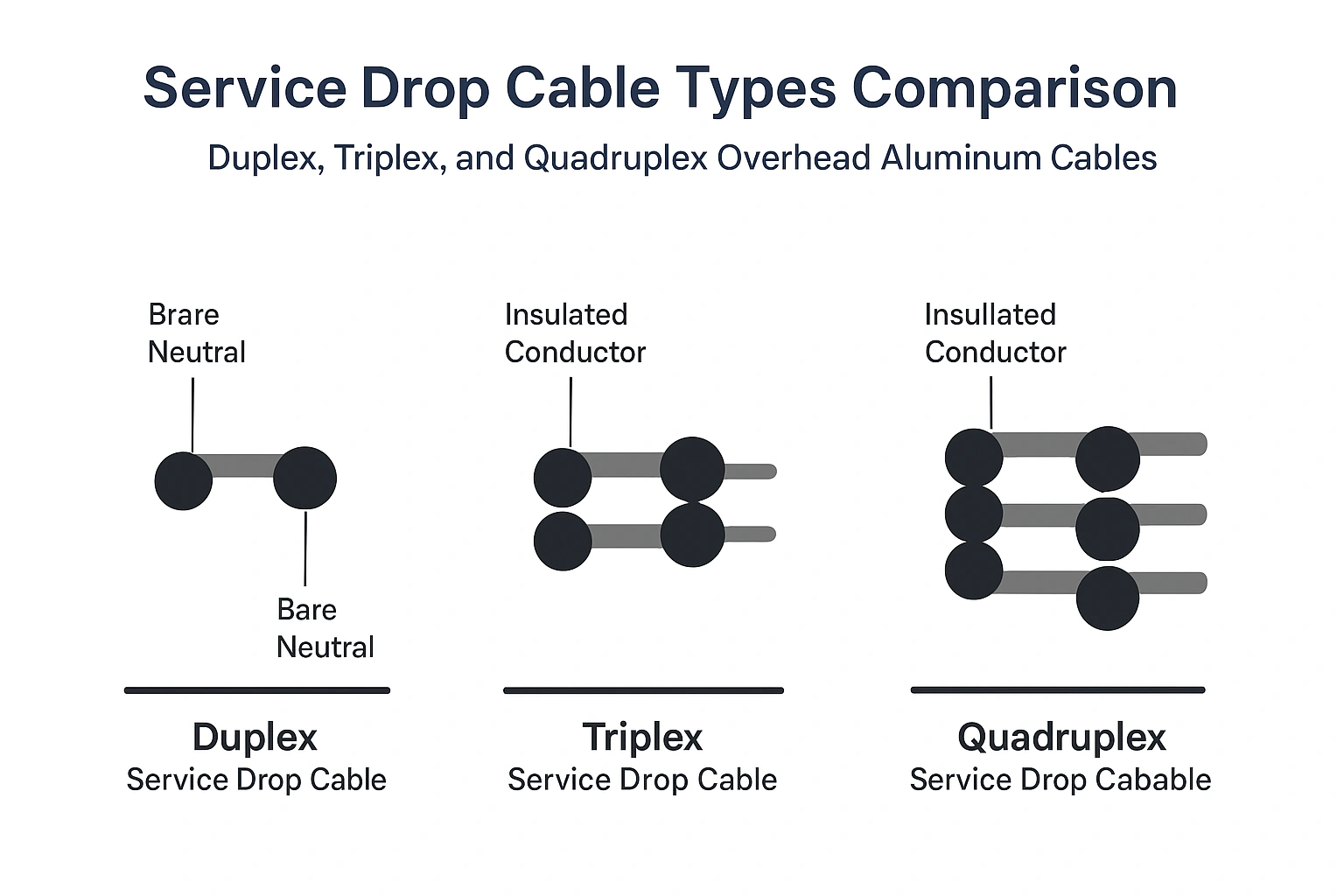

3. Types of Service Drop Cables

The classification of service drop cables is based on the number of conductors and their intended phase configuration. The most widely used types are as follows:

a. Duplex Service Drop Cable

A duplex service drop cable consists of one insulated phase conductor and one bare neutral conductor.

- Use: Single-phase, two-wire systems (120V or 120/240V).

- Application: Common in residential overhead connections.

- Material: Often aluminum service drop cable with XLPE insulation.

b. Triplex Service Drop Cable

A triplex service drop cable includes two insulated phase conductors and one bare or neutral messenger conductor.

- Use: Single-phase, three-wire systems.

- Application: Homes, small commercial buildings.

- Material:Aluminum triplex service drop cable is the industry standard for lightweight strength and corrosion resistance.

c. Quadruplex Service Drop Cable

The quadruplex service drop cable has three insulated phase conductors and one neutral conductor, typically used for three-phase, four-wire systems.

- Use: Industrial facilities, small substations, or apartment complexes.

- Application: Suitable for both overhead service drop cable and short-distance power distribution.

|

Type |

Conductor Configuration |

Number of Conductors |

Typical Voltage Level |

Material |

Common Applications |

|

Duplex Service Drop Cable |

One insulated phase + one bare neutral (messenger) |

2 |

120V / 120-240V (Single Phase) |

Aluminum or Aluminum Alloy |

Residential power supply, rural areas |

|

Triplex Service Drop Cable |

Two insulated phase conductors + one bare neutral (messenger) |

3 |

120/240V (Single Phase, 3-Wire) |

Aluminum Triplex Service Drop Cable (XLPE insulated) |

Homes, small commercial buildings |

|

Quadruplex Service Drop Cable |

Three insulated phase conductors + one neutral conductor |

4 |

208V / 480V (Three Phase) |

Aluminum Quadruplex Service Drop Cable |

Industrial facilities, apartment complexes |

|

Overhead Service Drop Cable (General) |

One or more insulated conductors twisted with a bare neutral |

2–4 |

600V and below |

Aluminum Service Drop Cable (XLPE/PE insulation) |

Utility poles to service entrances |

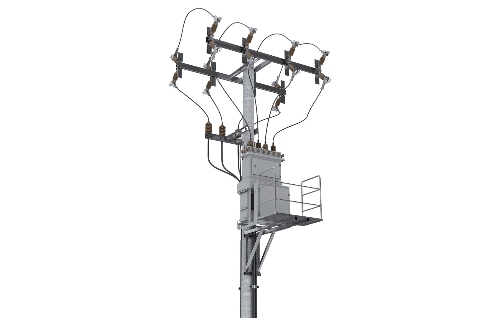

4. Installation Considerations

Proper installation of a service drop cable is essential to ensure long-term performance, electrical safety, and compliance with local regulations (e.g., NEC, IEC 60502, or IEEE 1584).

a. Sag and Tension Control

The cable must maintain adequate sag between poles to allow for expansion and contraction due to temperature changes. Excessive tension can lead to mechanical failure.

b. Clearance and Safety Distance

Minimum clearance above ground, rooftops, and structures must comply with national electrical codes to prevent electrical hazards.

c. Service Drop Connection

Connections between the service drop and the customer’s service head should use compression connectors or insulated piercing connectors (IPC) to ensure conductivity and weather sealing.

d. Grounding and Bonding

The neutral conductor (messenger wire) serves both as the mechanical support and the grounded neutral return path. It must be properly bonded to maintain system safety.

5. Practical Applications and Performance

From rural power supply lines to urban distribution networks, service drop cables are used in various configurations depending on environmental and mechanical conditions.

- Residential Use: Duplex and triplex cables deliver low-voltage service from utility poles to houses.

- Commercial and Industrial: Quadruplex configurations handle higher loads for three-phase service.

- Coastal and High-Temperature Areas: Use aluminum service drop cables with enhanced UV and salt resistance.

The overhead service drop cable design offers ease of installation, reduced right-of-way cost, and lower maintenance compared to underground distribution systems, making it a practical choice for most global markets.

6. Safety and Maintenance

Although service drop cables are designed for outdoor durability, periodic maintenance ensures continued safety:

- Inspect for conductor corrosion, insulation cracks, or strand separation.

- Verify connection tightness and insulation integrity at service heads.

- Avoid vegetation contact that can lead to abrasion or electrical leakage.

- Ensure proper tension and clearance during re-tensioning or pole replacement.

Safety protocols must always include de-energization before service work and the use of insulated tools and protective gear.

7. Advantages of Aluminum Service Drop Cables

Modern aluminum service drop cables are preferred over copper equivalents for several reasons:

- Lightweight: Easier handling and installation on poles.

- Cost-Effective: Lower material cost without compromising conductivity.

- Corrosion Resistance: Especially suitable for coastal or humid environments.

- Mechanical Strength: Alloy reinforcement enhances tensile performance.

- Thermal Stability: Maintains performance under load fluctuations and temperature extremes.

Variants like aluminum triplex and quadruplex service drop cables combine flexibility, mechanical integrity, and long service life for diverse power distribution needs.

8. Future Trends and Innovations

As smart grids and renewable energy systems expand, service drop cables are evolving to include:

- Integrated sensors for current and temperature monitoring.

- Enhanced XLPE insulation for higher voltage ratings and longer life.

- Environmentally sustainable materials with recyclable sheathing.

Hybrid configurations may also emerge, combining overhead service drop cable with underground connections for improved aesthetics and resilience in urban areas.

The service drop cable remains one of the most essential yet often overlooked components of modern power distribution systems. Whether in a duplex, triplex, or quadruplex configuration, these cables provide the crucial connection between utilities and consumers, ensuring reliable and efficient delivery of electrical energy.

By understanding their structure, installation, and safety requirements, engineers and installers can optimize performance, minimize maintenance, and extend service life — keeping the lights on safely and efficiently for communities worldwide.