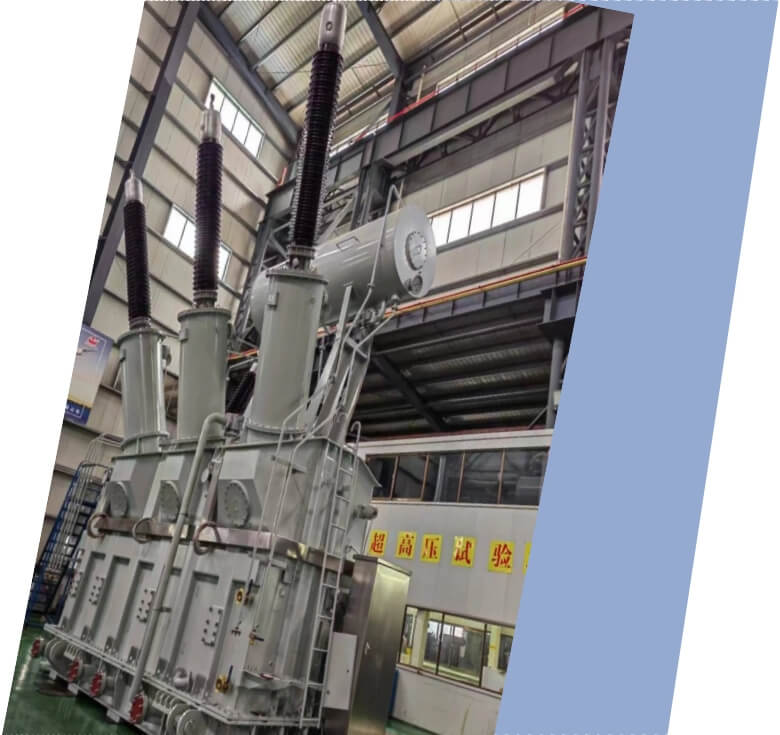

400kV Power Transformer: High-Voltage Substation Solutions

- Primary Voltage Ratings 220kV 230kV 400 kV

- Secondary Voltage Ratings 69/35/37/34.5/26.4./11/10.5/6.6/13.2 kV or others

- H.V. Tap Range ± 8×1.25% HV taps or others

- Type Oil-immersed power transformer

- BIL 900kV

- Standards IEEE, ANSI, IEC, GB

- Application Renewable Energy Mega-Hubs, Ultra-High-Demand Industrial Zones, Data Centers

- Power Rating 500-250000kVA

- Certificate UL, ISO, CESI

- Cooling Method ONAN/ ONAF

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 500-250000kVA |

| Rating Primary Voltage | 220kV 230kV 400kV |

| Secondary Voltage |

69/35/37/34.5/26.4/11/10.5/6.6/13.2 kV Customized |

| Frequency | 50/60Hz |

| Vector Group | Dyn11, YD11, YNd11 or anothers |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE, CAS Std or Customized |

| Impedance Voltage | As IEC |

| Altitude | ≤1,000m or Customized |

| Enclosure material | Mid Steel |

| HV Bushing |

| LV Bushing |

| OLTC/NLTC |

| Lifting hook for complete transformer |

| Name plate |

| Oil temperature |

| Winding temperature |

| Radiators |

| Oil level |

| Pressure relief valve |

| CT |

Customization Optional

Packing and Shipping

The inland transportation phase utilizes heavy-duty hydraulic modular trailers (Goldhofer or similar) to navigate the journey from the factory to the port. Our logistics team performs a comprehensive route survey to account for bridge load-bearing capacities and overhead clearances. The transformer is secured to the trailer or vessel deck using high-tensile lashing chains and anti-slip mats. For international sea freight, we prioritize "Heavy Lift" vessels or Ro-Ro (Roll-on/Roll-off) ships. To protect against the corrosive effects of salt air, all machined surfaces and electrical terminals are coated with a specialized peelable plastic or Tectyl anti-rust compound.

During the entire voyage, the transformer is monitored by multiple three-axis electronic impact recorders. These devices provide a continuous log of longitudinal, lateral, and vertical accelerations, ensuring that the internal core-and-coil assembly has not been subjected to forces beyond the design limit. GPS tracking units provide real-time location data to the project management team. Upon arrival at the destination port, a specialized heavy-lift crew manages the transfer, ensuring the unit is handled with extreme care to maintain the mechanical integrity established during factory assembly.

The final "last-mile" delivery to the substation pad often requires specialized "jacking and rolling" equipment if the site does not allow for large crane access. Once the transformer is positioned on its foundation, the nitrogen is purged, and the unit is refilled with hot, degassed insulation oil under a high vacuum. This meticulous process ensures that no air pockets remain in the windings. Our end-to-end shipping protocol guarantees that the 400kV transformer arrives on-site in factory-perfect condition, ready for final assembly and the high-voltage testing phase prior to energization.

Manufacturer Test

Progress test

Following the Vapor Phase Drying (VPD) process, we conduct an Insulation Resistance (IR) and Polarization Index (PI) Test to confirm the cellulose materials are bone-dry. A Vacuum Drop Test is performed on the tank to ensure its hermetic integrity before oil filling. Finally, a Pre-seal Dielectric Test of the insulation oil is carried out to verify that the breakdown voltage (BDV) meets the strict 70kV+ threshold required for 400kV EHV equipment.

Design Tests

All transformers will be tested after finishing the production test items as below:

♦ Leak testing with pressure for liquid-immersed transformers

♦ Test of transformer oil

♦ Measurement of voltage ratio and check of phase displacement

♦ Measurement of winding DC resistance

♦ Measurement of d. c. Insulation resistance between each winding to earth, and check of the core and frame insulation

♦ Capacitive bushing test

♦ Measurement of dissipation factor (tan δ) of the insulation system capacitances, and determination of capacitances windings-to-earth

♦ Measurement of no-load loss and current at 90%,100%,110% of rated voltage

♦ Operation test on on-load tap-changer

♦ Measurement of short-circuit impedance and load loss

♦ Lightning impulse test

♦ Induced-voltage test with partial discharge measurement

♦ Auxiliary wiring check

♦ Current transformer test

♦ Frequency response analysis test

Transformer Factory Acceptance Test

This test sequence focuses on efficiency and structural stability. We perform No-load and Load Loss Measurements to verify compliance with guaranteed efficiency values. Sweep Frequency Response Analysis (SFRA) is used to create a baseline for internal winding geometry. Furthermore, we conduct a Temperature Rise Test under full-load conditions to ensure the cooling system maintains oil and winding temperatures within design limits. Finally, a Zero-sequence Impedance Test is performed for fault calculation accuracy.

Routine Test - Induced Voltage

AC voltage source, commonly 2 kV, 5 kV, 10 kV, or customized according to test requirements.

Environmental thermometer and hygrometer, used to record the temperature and humidity of the environment for appropriate test evaluation.

Check the connection wires and terminals to ensure they are secure and free of contamination.

Test under suitable environmental conditions: relative humidity below 75%, no rain (recommended temperature: 20-30°C).

Connect the test equipment to the appropriate terminals or bushings of the device under test, ensuring that the connections are secure and properly grounded.

Apply Test Voltage:

Select the appropriate induction voltage according to the rated voltage and standard of the equipment.

Induced Voltage

Applied Current

Voltage peak, stability and waveform (waveform analysis)

Any abnormal current or voltage changes during the measurement process.

1% < Inductive voltage ≤ 3% (Good): still within acceptable range.

Inductive voltage > 3% : faulty or not meet safety requirements and requires further analysis and repair.

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.