Dry-Type vs. Oil-Immersed Transformers: Key Differences and How to Choose the Right One

In modern power systems, transformers are critical equipment—regulating voltages, stepping up or down power for transmission and distribution. Two main types dominate the market: the dry-type transformer and the oil-immersed transformer. Choosing between them means weighing factors such as safety, cooling medium, fire hazard, installation environment, cost and application scope. From a practical engineering standpoint—whether you’re specifying a 75 kVA transformer for a data centre, or a high-capacity oil-filled unit for a substation—the right selection matters.

1. What is a Dry-Type Transformer and an Oil-Immersed Transformer?

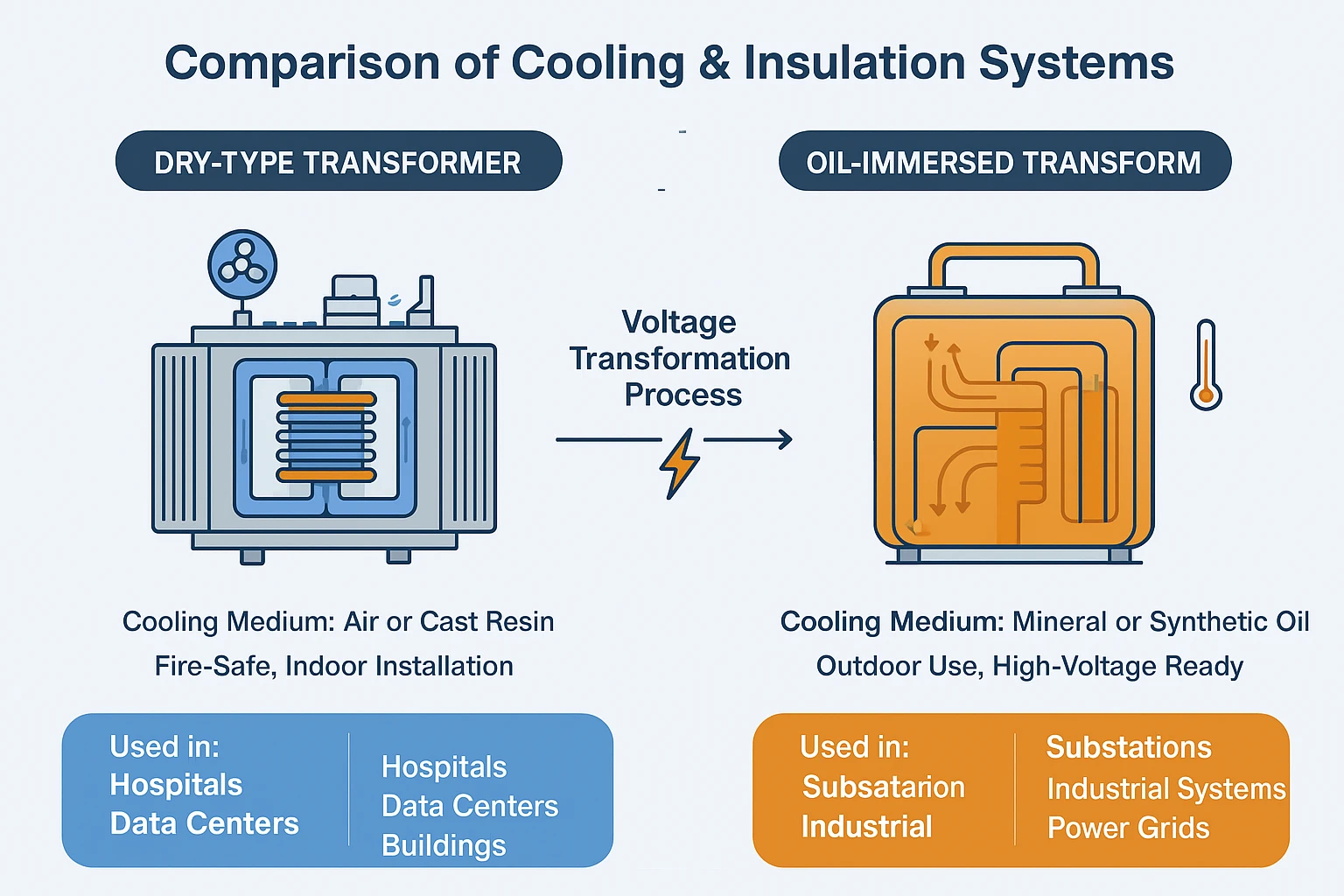

A dry-type transformer uses air (or solid insulation such as epoxy or cast resin) as its cooling medium, whereas an oil-immersed transformer uses insulating oil that both cools and insulates the winding and core. In practical terms, dry type units are often compact, flame-retardant, and suited to indoor installations; oil-immersed units are typically outdoor or large-scale, for high voltage applications.

2. Insulation & Cooling: The Core Technical Difference

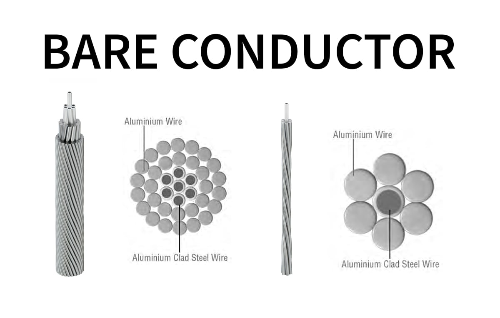

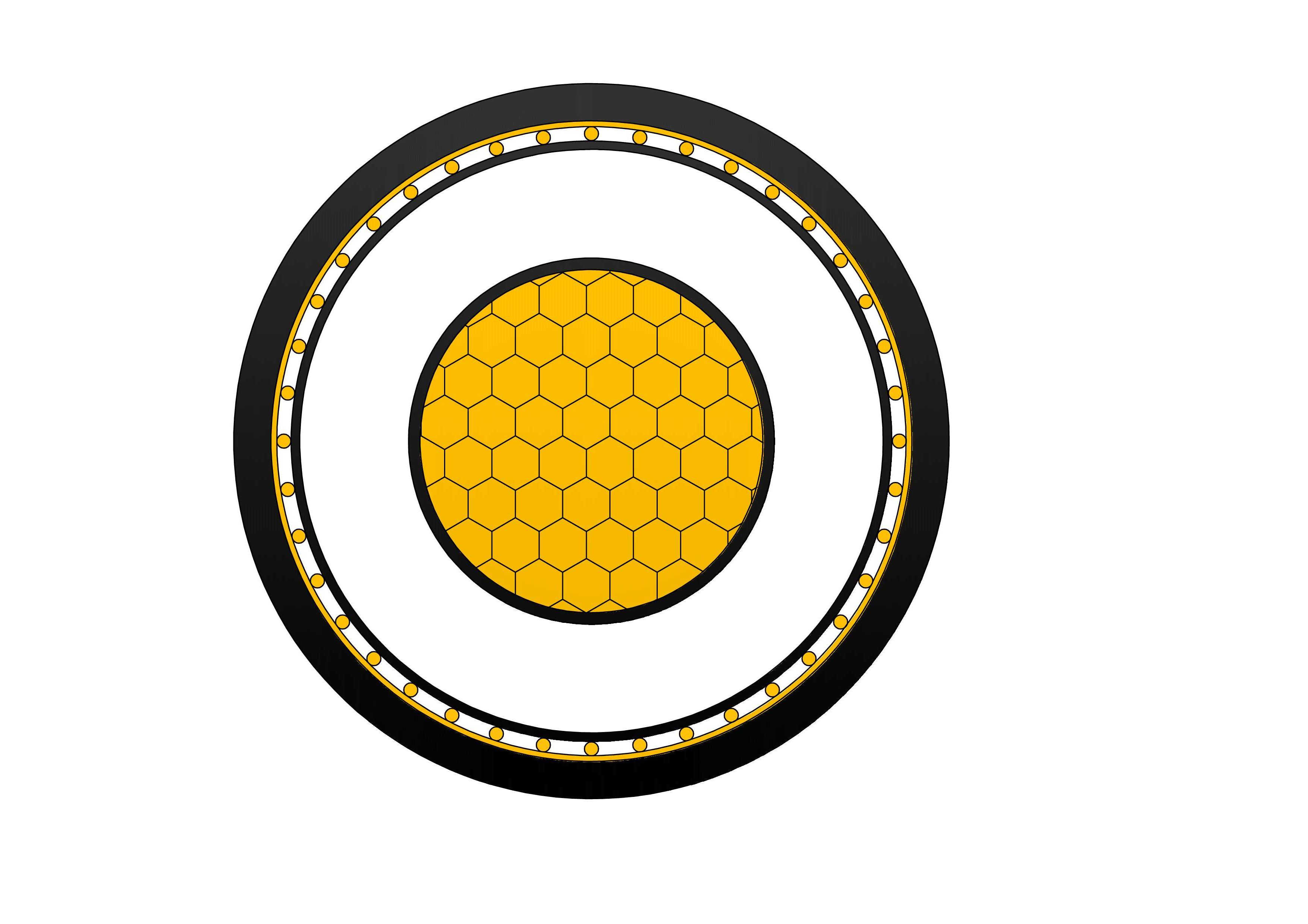

At the heart of the difference is insulation and cooling. Dry-type transformers rely on air or forced-air flow; some use cast resin or vacuum pressure impregnated insulation systems. In contrast, oil-immersed transformers have their windings submerged in oil; the oil circulates (naturally or forced) to carry heat away to radiators or fins.

Because of the superior heat dissipation and dielectric strength of oil, oil-immersed transformers are commonly used for high voltage power transmission lines or large distribution substations. Dry type transformers are often limited in voltage and capacity (for example, many stay under ~10 kV or in distribution applications) due to the cooling/insulation constraints.

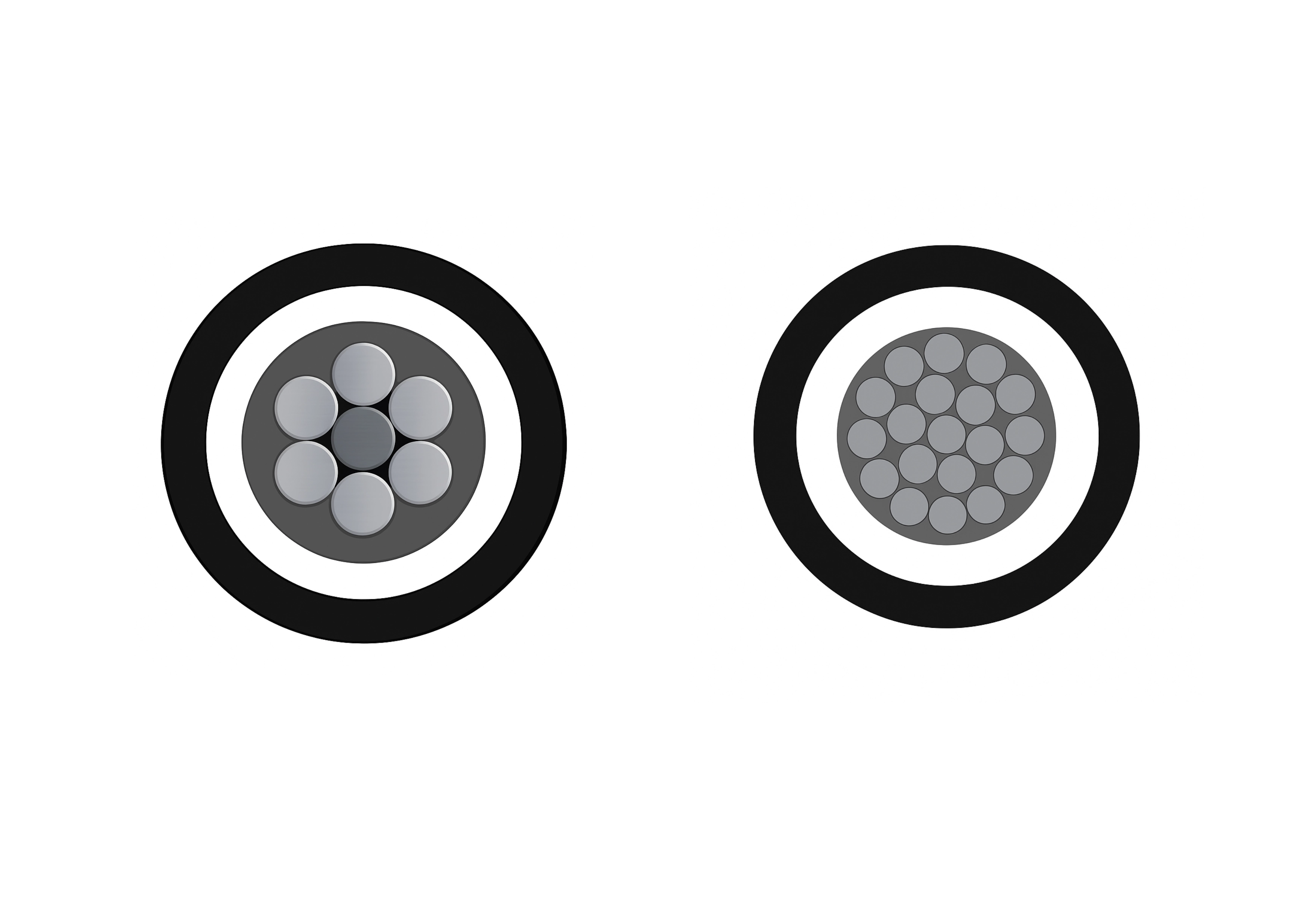

3. Types of Transformers: Dry-Type Transformer Types and Oil-Immersed Variants

Dry-type transformer types typically include: cast resin dry-type, vacuum pressure impregnated (VPI) dry-type, open frame dry-type. These are suitable for indoor applications, power systems in confined or fire-sensitive areas.

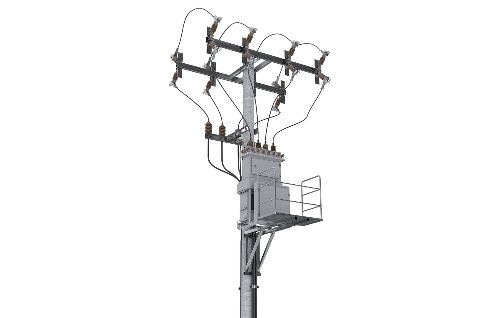

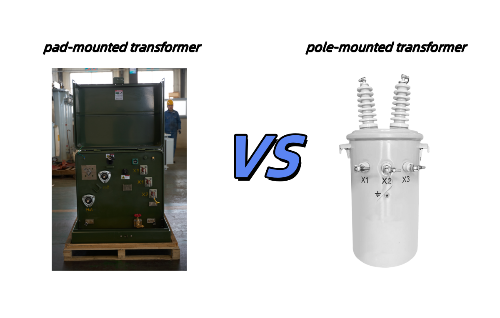

Oil-immersed transformers include various liquid-filled transformers, three-phase oil-immersed, outdoor pad-mounted, high voltage transmission transformers with OLTC (on-load tap changer) options. The broad variety enables outdoor, high-capacity, and high-voltage installations.

4. Advantages & Disadvantages

Dry-type transformer advantages:

-

Environmentally friendly (no oil spills, no fire-hazard fluid)

-

Safe for indoor applications and areas with high fire safety requirements (e.g., schools, hospitals, data centres)

-

Lower maintenance because no oil testing, leak checks, or oil handling.

Disadvantages of dry-type transformer:

-

Limited capacity and voltage rating compared to oil-filled units

-

Higher initial cost and possibly higher operational losses (due to less efficient cooling)

-

Often not as suitable for outdoor installations unless specially designed.

Oil-immersed transformer advantages:

-

Suitable for suitable for high voltage applications, large capacity, outdoor use

-

Better cooling and insulation properties allow higher power, longer lifespans.

Disadvantages of oil-immersed:

-

Risk of fire, oil leak, environmental contamination; typically requires oil containment, fire suppression.

-

Regular maintenance (oil testing, filtration, possible replacement), hence higher operational cost over time.

Dry-Type Transformer and an Oil-Immersed Transformer Table:

|

Feature |

Dry-Type Transformer |

Oil-Immersed Transformer |

|

Cooling & Insulation Medium |

Uses air or solid insulation (epoxy, cast resin) for cooling and insulation |

Uses mineral or synthetic insulating oil for cooling and insulation |

|

Installation Environment |

Best for indoor applications such as data centers, hospitals, offices |

Commonly used outdoors — substations, power plants, industrial zones |

|

Fire Safety |

Excellent — no flammable oil, ideal for confined or public areas |

Higher fire risk — requires fire barriers and containment systems |

|

Maintenance Requirement |

Low maintenance — no oil testing or replacement needed |

Requires periodic oil checks, leak prevention, and filtration |

|

Voltage & Capacity Range |

Typically used below 35 kV and for small-to-medium capacity (e.g., 75 kVA) |

Supports high-voltage applications (>35 kV) and large power capacities |

|

Efficiency & Losses |

Slightly higher losses due to air cooling limitations |

Higher thermal efficiency, better heat dissipation |

|

Environmental Impact |

Eco-friendly — no oil leakage or hazardous waste |

Potential for oil contamination and environmental risk |

|

Operational Cost |

Higher initial cost, lower maintenance cost |

Lower purchase cost, higher maintenance cost |

|

Recommended Applications |

Indoor, fire-sensitive zones, commercial and institutional buildings |

Outdoor substations, industrial facilities, long-distance power systems |

5. Application Scenarios: Indoor vs Outdoor, 75 kVA Transformer Example

From the real-world viewpoint, if you are specifying a 75kVA transformer for indoor use (e.g., an office high-rise, data centre, or retail space), a dry-type transformer often makes sense: lower fire risk, minimal fluid handling, compact footprint. For example, a cast resin dry-type transformer may be selected for a mechanical/electrical room inside a building.

Conversely, for an outdoor substation feeding high voltage power transmission lines, or large industrial loads, an oil-immersed transformer is often the default choice. Outdoor applications frequently involve higher voltages, longer distances, and rugged environmental conditions, where oil-filled cooling is beneficial.

In a hybrid scenario: when a facility needs an indoor-pad mount that connects to distribution lines but wants to avoid oil risk, some high-capacity dry-type models may be used—but that depends on size, voltage, and environment.

6. Practical Work Considerations & Power System Integration

From an engineer’s viewpoint, here are several practical considerations when specifying or selecting:

-

Fire Safety & Environment: In indoor installations or fire-sensitive zones, the fact that a dry-type transformer is oil-free and pose less fire hazard is a significant plus.

-

Installation Space & Maintenance: Dry type installations don’t need oil ponds, external radiators, or large tanks; oil transformers often require more civil works, spill trays, oil filtration systems.

-

Operational Cost & Lifecycle: While oil-immersed may have lower initial cost for large capacity, in indoor or confined spaces the oil risks and maintenance may drive up total cost of ownership.

-

Voltage & Capacity Needs: For high voltage transmission, oil-immersed is almost always more suitable. For distribution, or lower voltage indoor use, dry-type may suffice.

-

Cooling & Insulation Medium: As referenced in studies and technical articles, choice of cooling medium (air vs oil) directly impacts design limitations, thermal performance, and suitability.

7. Environment, Sustainability & Modern Power System Trends

In a world increasingly focused on sustainability and environmentally friendly solutions, dry-type transformers are gaining traction due to their absence of oil, reduced risk of spills and less environmental remediation. In urban centres, indoor data centres and commercial buildings, their lower maintenance profile is beneficial. On the other hand, the global power system expansion, growth of long-distance transmission, and integration of renewables still rely heavily on oil-immersed transformers for high-voltage lines and heavy industrial loads.

8. How to Choose the Right One?

Here’s a checklist for making a choice:

-

If you require indoor applications, close to load centre, limited space, and high fire-safety requirement → lean toward dry-type.

-

If you are dealing with outdoor pad-mounted, high voltage (transmission, substation), large capacity loads → oil-immersed.

-

Check the load rating (e.g., 75 kVA or higher), the voltage class, ambient environment (moisture, dust, temperature) and maintenance budget.

-

Factor in operational cost: although dry-type may cost more upfront, its lower maintenance and environmental compliance may offset over time.

-

Evaluate insulation & cooling capability relative to your system demands (air-cool vs oil-cool).

-

Consider future system changes: growth in power demand, shift to renewables, higher ambient temperatures might push design toward oil-immersed or special dry variants.

In sum, both dry-type and oil-immersed transformers have their place in modern electrical systems. Understanding key differences—cooling medium, insulation, fire safety, capacity and cost—is crucial. A precise decision helps ensure that your transformer meets technical, safety, environmental, and economic requirements. Whether you’re specifying a 75 kVA transformer for a building or a large oil-filled transformer for a power substation, choose wisely based on your system’s needs and constraints.