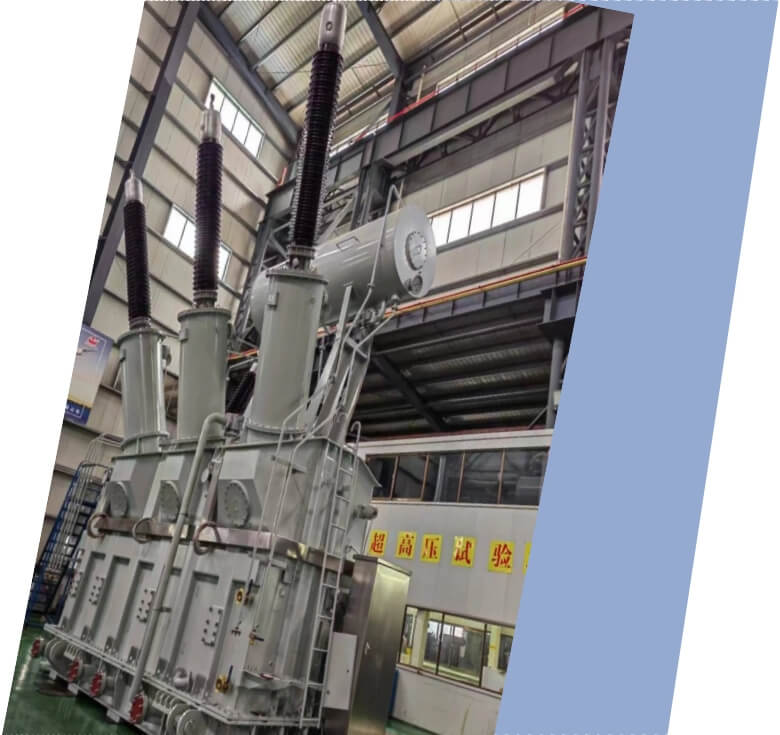

330kV 3-Phase 2-Winding Power Transformer

- Primary Voltage Ratings 220kV 230kV 330 kV

- Secondary Voltage Ratings 69/35/37/34.5/26.4./11/10.5/6.6/13.2 kV or others

- H.V. Tap Range ± 8×1.25% HV taps or others

- Type Oil-immersed power transformer

- BIL 900kV

- Standards IEEE, ANSI, IEC, GB

- Application regional substations, bolstering stability in wind-integrated grids

- Power Rating 500-250000kVA

- Certificate UL, ISO, CESI

- Cooling Method ONAN/ ONAF

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 500-250000kVA |

| Rating Primary Voltage | 220kV 230kV 330kV |

| Secondary Voltage |

69/35/37/34.5/26.4/11/10.5/6.6/13.2 kV Customized |

| Frequency | 50/60Hz |

| Vector Group | Dyn11, YD11, YNd11 or anothers |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE, CAS Std or Customized |

| Impedance Voltage | As IEC |

| Altitude | ≤1,000m or Customized |

| Enclosure material | Mid Steel |

| HV Bushing |

| LV Bushing |

| OLTC/NLTC |

| Lifting hook for complete transformer |

| Name plate |

| Oil temperature |

| Winding temperature |

| Radiators |

| Oil level |

| Pressure relief valve |

| CT |

Customization Optional

Packing and Shipping

To maintain total transparency regarding structural integrity, we install 3D digital impact recorders on the main tank. These devices log any significant G-forces or vibrations encountered during the journey, providing a time-stamped report upon arrival. At the destination port or site, our logistics experts coordinate "roll-on/roll-off" (Ro-Ro) operations or heavy-lift crane discharges. This meticulous handling ensures that the core-and-coil assembly remains perfectly aligned and free from mechanical stress throughout the entire supply chain.

Documentation and customs compliance are handled with extreme precision. Every shipment includes a comprehensive packing list, moisture level reports, and pressure certificates. For international sea freight, we apply VCI (Volatile Corrosion Inhibitor) packaging to all control cabinets and exposed metal parts to prevent salt-air corrosion. Our shipping partners are specifically vetted for their experience in moving EHV equipment, ensuring a seamless transition from our factory to your foundation.

The final stage of the shipping process involves a joint inspection upon delivery. Before the transformer is offloaded onto its permanent pad, our technicians verify the internal nitrogen pressure and audit the impact recorder data. This proactive verification ensures that any potential transit-related issues are identified immediately, allowing for a smooth transition into the installation and commissioning phase, effectively eliminating unforeseen project delays and ensuring the highest level of client satisfaction.

Manufacturer Test

Progress test

Throughout the production cycle, we perform rigorous Progress Tests to validate quality at every milestone. This starts with core loss and magnetic circuit testing once the laminations are stacked to verify the efficiency of the silicon steel. We then conduct winding resistance and turns ratio tests on individual coils prior to assembly. Once the "active part" is tanked, we perform insulation resistance checks between windings and to the ground. These intermediate steps allow for the detection of any deviations before final sealing, ensuring the transformer meets strict 330kV design tolerances.

Design Tests

All transformers will be tested after finishing the production test items as below:

♦ Leak testing with pressure for liquid-immersed transformers

♦ Test of transformer oil

♦ Measurement of voltage ratio and check of phase displacement

♦ Measurement of winding DC resistance

♦ Measurement of d. c. Insulation resistance between each winding to earth, and check of the core and frame insulation

♦ Capacitive bushing test

♦ Measurement of dissipation factor (tan δ) of the insulation system capacitances, and determination of capacitances windings-to-earth

♦ Measurement of no-load loss and current at 90%,100%,110% of rated voltage

♦ Operation test on on-load tap-changer

♦ Measurement of short-circuit impedance and load loss

♦ Lightning impulse test

♦ Induced-voltage test with partial discharge measurement

♦ Auxiliary wiring check

♦ Current transformer test

♦ Frequency response analysis test

Transformer Factory Acceptance Test

In this testing sequence, we prioritize the physical and chemical stability of the unit under load. Beyond standard ratio and polarity checks, we perform Sweep Frequency Response Analysis (SFRA) to establish a mechanical "fingerprint" of the internal windings. A Vacuum Leak Test is conducted on the fully assembled tank to ensure long-term hermetic sealing. Furthermore, we perform a complete Oil Dielectric Analysis, testing for breakdown voltage, moisture content, and DGA. Finally, Zero-sequence Impedance tests are conducted to ensure predictable behavior during grid fault conditions.

Routine Test - Transformer Turns Ratio/TTR (All Tap Voltages)

Voltage source: usually AC 10 V to 30 V , used to test different voltages for each tap.

Temperature and humidity meter: used to record environmental conditions during the test to ensure test accuracy.

Current probe: used to measure the load current of the winding and ensure the accuracy of the test results.

Perform the test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20-30°C). Avoid high humidity or bad weather that may affect the test accuracy.

The voltage ratio between the windings

Deviation of the measured value from the rated ratio

0.5% < Turns ratio error ≤ 1% (caution)

Turns ratio error > 1% (further inspection or corrective action required)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.