10kV Oil Immersed Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

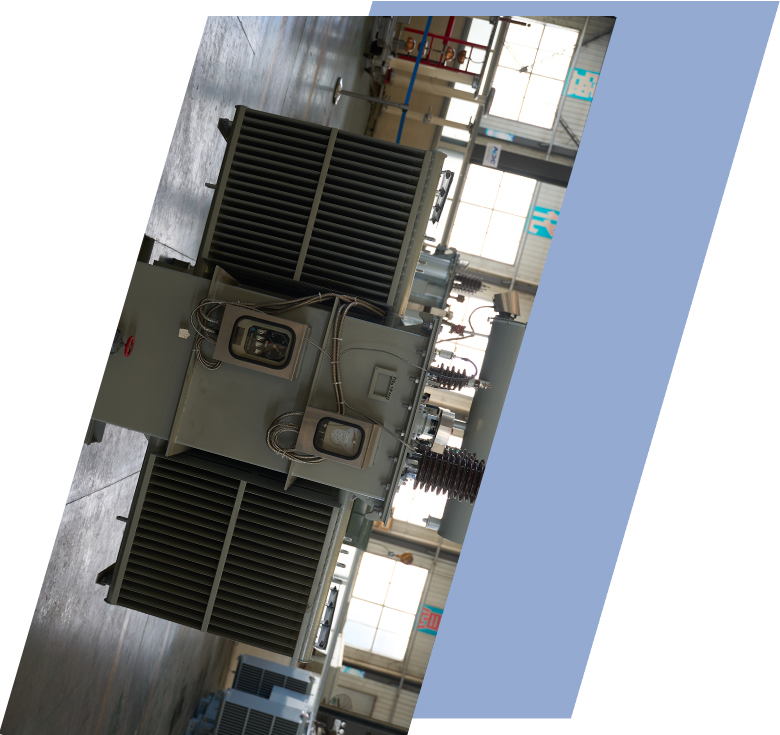

- Type Oil immersed distribution transformer

- BIL 10 kV

- Standards IEEE, ANSI, NEMA, IEC, CE

- Application industrial parks and factories, rural power grid

- Power Rating 30kVA - 5000kVA

- Certificate UL, CESI, IEEE

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 30kVA - 5000kVA | |

| Rating Primary Voltage | 2.4 - 34.5kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| Insulating Oil Weight | 850 kg | |

| Total Weight | 5000 kg | |

| Outline Dimensions(L×W×H)in. | 2650 × 1650 × 2450(mm) | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

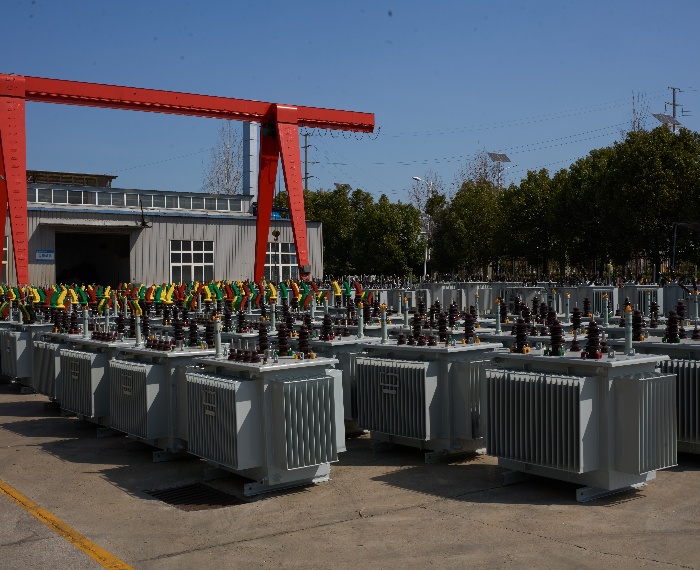

Packing and Shipping

Export-grade packaging employs robust wooden crates or steel frames compliant with ISPM-15 standards, featuring custom blocking, bracing, and shock-absorbing materials to withstand vibrations, impacts, and tilting. Desiccant packs, rust inhibitors, and humidity indicators are included to monitor conditions. Shock recorders and tilt indicators are attached to log any excessive movement, ensuring accountability. For sea freight—common for international shipments—transformers are secured on flat-rack containers, open-top containers, or RoRo vessels with salt-fog-resistant coatings and weatherproof sheathing.

Documentation accompanies every shipment, including packing lists, commercial invoices, certificates of origin, test reports, installation manuals, lifting diagrams, and bills of lading. Customs HS codes, export permits, and oil handling declarations are prepared to facilitate smooth clearance. Upon arrival, buyers receive guidance for inspection, storage (avoid direct sunlight, maintain positive pressure if oil-filled), and professional unloading using cranes at marked lift points.

We coordinate multimodal logistics—road to port, then ocean or rail—tailored to destination constraints, offering optional services like on-site supervision, oil processing, and commissioning. This comprehensive approach minimizes risks, preserves transformer performance, and ensures timely delivery worldwide.

Manufacturer Test

Progress Test

During core production, the progress test includes silicon steel sheet inspection for burr-free edges, grain orientation and stacking quality to minimize eddy current losses, followed by core assembly check for mitered joints tightness and clamping pressure verification to prevent vibration noise. Coil winding progress test verifies conductor material purit,y tension control layer insulation application and turn accuracy using precision counters, dielectric withstand between layers. After winding insertion into core assembly test measures inter-winding clearances and secures compression bands for mechanical stability. Tank fabrication progress test examines corrugated wall welding seams for leak-proof integrity pressure resistance and surface treatment against corrosion. Final pre-assembly progress test confirms all components alignment bushings radiators valves installation and preliminary oil filling simulation to detect any assembly defects early ensuring seamless transition to full testing phase.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Factory Acceptance Test (FAT) for 10kV oil immersed transformer begins with routine dielectric tests including applied voltage withstand and induced voltage test to verify insulation integrity between windings and ground per IEC 60076 standards. Winding resistance measurement uses the DC bridge method at the reference temperature to confirm conductor continuity and detect manufacturing anomalies. Voltage ratio and polarity/phase displacement check via turns ratio tester ensures accurate transformation ratios and vector group compliance (e.g. Dyn11). No-load loss and current test at rated voltage measures core performance exciting current harmonics, confirming low no-load losses and efficient magnetization. Load loss and impedance voltage test applies reduced voltage to the short-circuited secondary, calculating copper losses, short-circuit impedance for overload and stability assessment.

Routine Test - Leak Test

Voltage source (usually 500V, 1 KV or 2.5 KV, customized according to test requirements)

Temperature and humidity meter

Ground electrode

Properly connect the test equipment (such as a leak detector) to the pipe, container or sealing structure of the device under test.

Apply Test Voltage:

Apply the appropriate test pressure (e.g. 10 bar, 15 bar, etc.) depending on the equipment's operating pressure or test standard.

Applied test pressure

Leakage (can be monitored by flow meter or other equipment)

Time record (to ensure that the test time meets the standard requirements)

Initial pressure and final pressure (if any changes)

Minor leakage (good): Very small leakage is allowed, and it is necessary to judge whether it is qualified according to industry standards.

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.