Current Transformer vs. Voltage Transformer: Key Differences Explained

Transformers are crucial components in electrical power systems, used to step up or step down voltage levels for efficient energy distribution. While both current transformers (CTs) and voltage transformers (VTs) play essential roles, they serve different purposes and operate under distinct principles. Understanding the key differences between these two types of transformers is vital for selecting the right one based on your specific needs.

In this article, we will compare current transformers and voltage transformers, focusing on their applications, design features, and operational characteristics from a practical, real-world perspective.

1. What is a Current Transformer (CT)?

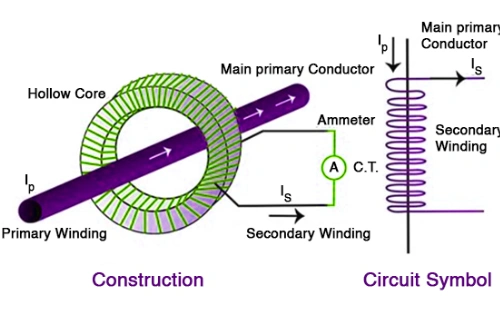

A current transformer (CT) is a type of transformer primarily used to measure or monitor electrical current in a conductor. The CT provides an accurate, scaled-down representation of the current flowing through a circuit. It does so by using a magnetic core to induce a secondary current proportional to the primary current.

Key Features of Current Transformers:

-

Primary Function: Measure current, provide feedback for protection and metering systems.

-

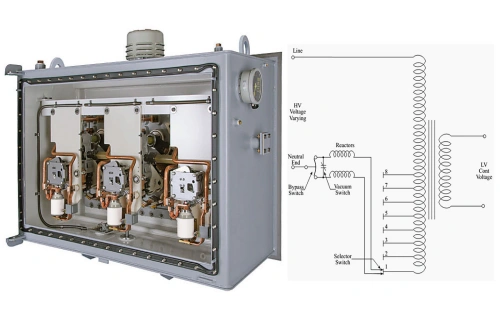

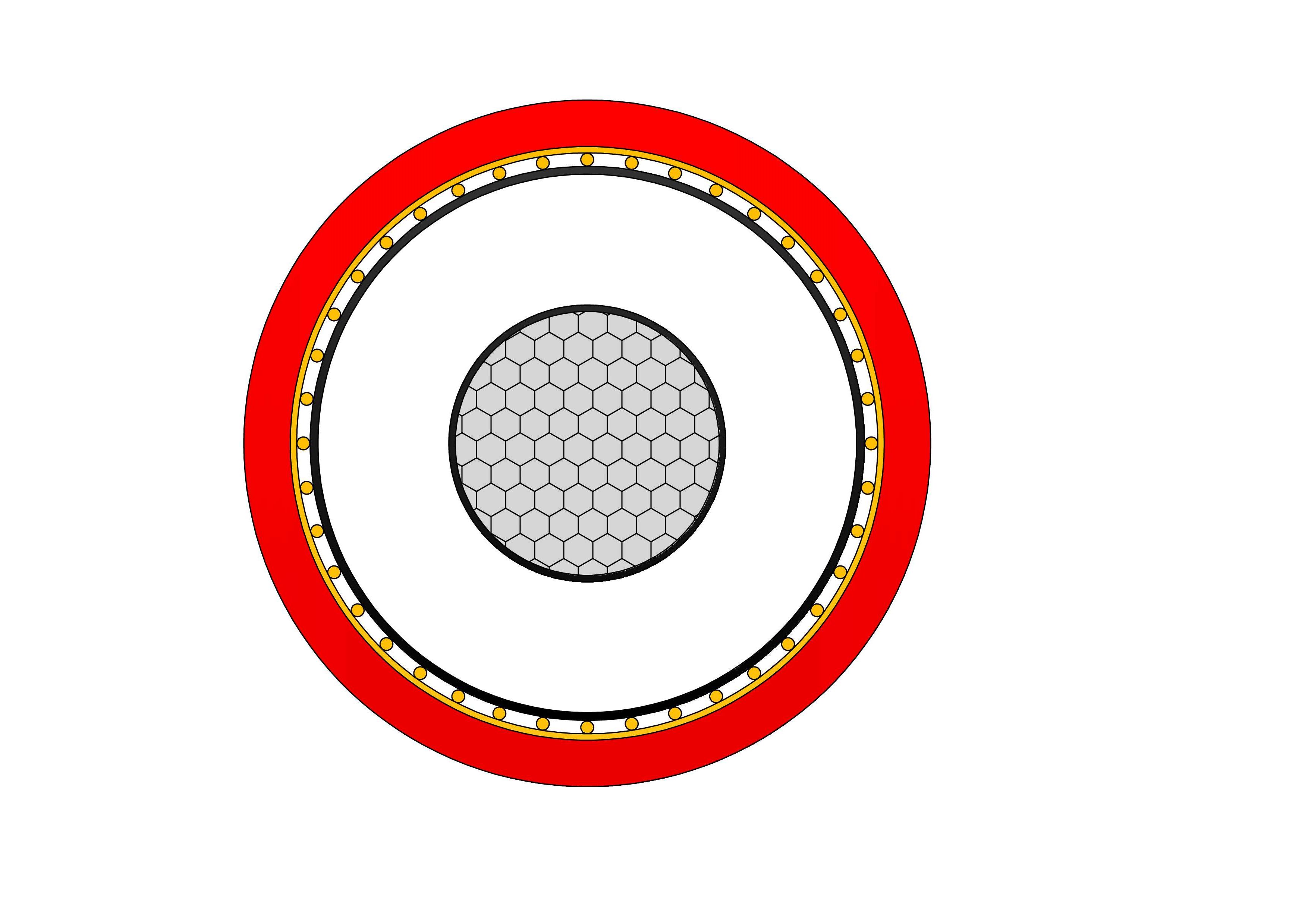

Design: Typically consists of a core (often toroidal) through which the primary conductor passes, with a secondary winding that produces a proportional output.

-

Applications: Current transformers are widely used in electrical metering, protection systems, and monitoring circuits. For example, in industrial settings, CTs are critical in ensuring the proper functioning of overcurrent protection devices.

2. What is a Voltage Transformer (VT)?

A voltage transformer (VT), also known as a potential transformer (PT), is used to measure voltage levels in high-voltage electrical circuits. The VT steps down the voltage to a safer, more manageable level for measurement or for providing voltage feedback to control systems.

Key Features of Voltage Transformers:

-

Primary Function: Measure voltage, provide a reference for protection devices, and metering systems.

-

Design: Similar to an ordinary step-down transformer, with a primary winding connected across the high-voltage circuit and a secondary winding producing a scaled-down voltage.

-

Applications: Voltage transformers are used in control panels, protection relays, and voltage metering systems to monitor and regulate voltage levels.

3. Core Differences Between Current Transformers and Voltage Transformers

3.1 Functionality

The most fundamental difference between a current transformer and a voltage transformer lies in their purpose:

-

Current Transformers: Measure current and provide an electrical signal proportional to the primary current. They are typically used in protection and metering circuits, where accurate current measurement is crucial.

-

Voltage Transformers: Measure the voltage across a circuit, providing a scaled-down version of the voltage for measurement or monitoring. Voltage transformers are primarily used in metering, voltage monitoring, and control systems.

3.2 Construction and Design

The physical construction of these two transformers differs significantly:

-

Current Transformers: Most CTs have a core that is usually made from a high-permeability magnetic material (such as silicon steel), and they are typically constructed as toroidal (doughnut-shaped) cores. The primary winding is often the conductor passing through the core itself. This design enables the CT to measure current without needing to directly interrupt the current flow.

-

Voltage Transformers: VTs, on the other hand, have a more traditional transformer design with separate primary and secondary windings wound around a magnetic core. They are designed to handle the high-voltage potential between two points, with insulation rated to withstand the voltage levels being measured.

3.3 Connection and Wiring

The way each transformer is connected in an electrical circuit also differs:

-

Current Transformer Connections: Current transformers are typically connected in series with the conductor being measured. The secondary winding is often connected to measuring instruments or protection relays, where the output is directly proportional to the current flowing in the primary circuit.

-

Voltage Transformer Connections: Voltage transformers are connected in parallel across the voltage to be measured. The secondary winding is then connected to measuring devices or control systems that can use the reduced voltage signal to assess system health and performance.

Current Transformer vs Voltage Transformer Table:

|

Feature |

Current Transformer (CT) |

Voltage Transformer (VT) |

|

Primary Function |

Measures current, provides proportional secondary current |

Measures voltage, provides proportional secondary voltage |

|

Design |

Typically a toroidal core with a conductor passing through |

Traditional transformer design with primary and secondary windings |

|

Connection Type |

Connected in series with the primary circuit |

Connected in parallel across the voltage source |

|

Typical Applications |

Protection systems, metering, industrial automation |

Voltage measurement, control systems, metering |

|

Accuracy |

High accuracy for current measurement, low burden |

High accuracy for voltage measurement, can experience higher burden |

|

Core Material |

High-permeability magnetic core (e.g., silicon steel) |

Magnetic core designed for voltage step-down and isolation |

|

Output |

Proportional current for metering or protection relays |

Proportional voltage for measurement and regulation |

|

Installation |

Easy to install by passing the conductor through the core |

Installed by connecting the primary circuit to the transformer |

|

Burden |

Low burden, minimal impact on the primary current flow |

Higher burden, needs to maintain voltage step-down ratio |

|

Key Advantages |

Ideal for current monitoring and protection systems |

Ideal for voltage monitoring and control systems |

4. Operational Differences

4.1 Load and Burden

-

Current Transformers: CTs are designed to have a very low burden (the load placed on the secondary circuit), meaning they produce accurate measurements with minimal power loss. The low burden ensures that CTs do not affect the flow of current through the primary conductor.

-

Voltage Transformers: VTs, however, have a higher burden, since they need to step down the voltage while maintaining accuracy. This means they typically have a higher internal impedance and can experience some power loss, although this is mitigated in designs tailored for high-precision applications.

4.2 Accuracy

-

Current Transformers: The accuracy of current transformers is primarily influenced by the design of the core and the burden on the secondary winding. Core current transformers are widely used in precision applications where the current measurement needs to be highly accurate, such as in protection relays and industrial automation systems.

-

Voltage Transformers: Accuracy for VTs is determined by the proportion of voltage step-down and the quality of the secondary windings. VTs must maintain the exact voltage ratio over a range of loads and frequencies to ensure reliable voltage monitoring.

5. Applications of Current and Voltage Transformers

Both current transformers and voltage transformers are essential for the safe and efficient operation of electrical systems. However, they are deployed in different scenarios:

-

Current Transformers: Used in protection systems (such as for overcurrent protection), metering applications, and control circuits. They are critical in monitoring electrical distribution in industrial plants, substation networks, and power plants.

-

Voltage Transformers: Commonly found in voltage monitoring systems, control panels, and metering devices. VTs are also used in substations to provide accurate voltage measurements for regulatory compliance and system monitoring.

While current transformers and voltage transformers both serve critical roles in electrical systems, they are distinctly different in their functions, designs, and applications. Understanding these differences ensures that engineers and technicians can select the right transformer for the job, whether it’s for current measurement and protection or voltage monitoring and regulation.

In industrial and utility systems, the correct use of both current transformers and voltage transformers is essential for maintaining operational efficiency, safety, and reliability. When choosing between the two, it is important to consider factors like load conditions, measurement accuracy, and system requirements to ensure optimal performance.

By understanding these differences, you can make informed decisions about transformer selection and avoid potential inefficiencies or failures in your electrical systems.