1250kVA Three Phase Pad Mounted Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2 or others

- Secondary Voltage Ratings 208GrdY/120;416GrdY/240 or Customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA, ASTM

- Application step-up systems, EV charging stations, and data center

- Power Rating 1250kVA

- Certificate UL

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 1250kVA |

| Rating Primary Voltage | 4.16-34.5kV or customized |

| Secondary Voltage | 480GrdY/277 208GrdY/120 400GrdY/230 Customized(208Y/120 V to 4,160 V) |

| Frequency | 50/60Hz |

| Vector Group | Dyn1/Yyn0/Dyn11/Dyn5 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 3.5% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 3500 kg |

| Total Weight | 9700 kg |

| Outline Dimensions(L×W×H)in. | 2880×2200×2100(mm) |

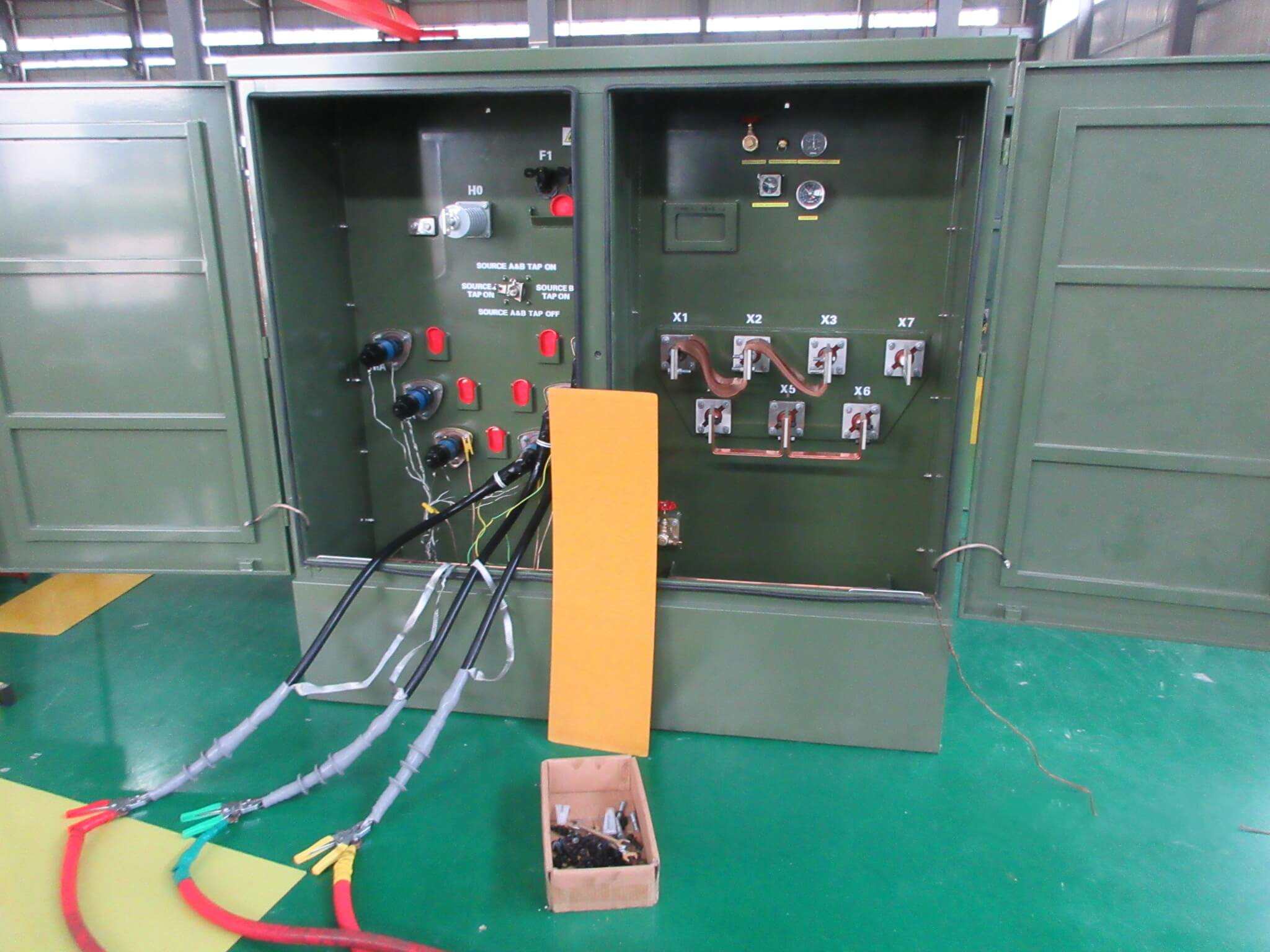

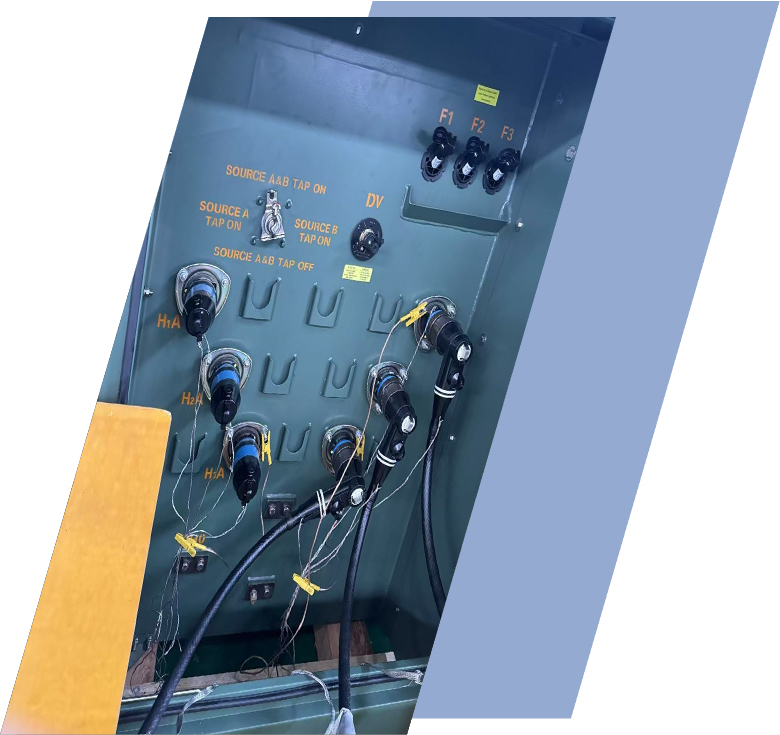

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | Terminal Box |

| Non-PCB decal | High Voltage Warning Signs |

Customization Optional

Packing and Shipping

Wooden crates or heavy-duty wooden cases enclose the transformer for ocean freight or long-haul trucking, constructed from fumigated, export-grade timber compliant with ISPM-15 standards to meet global phytosanitary regulations. Internal bracing, foam padding, and shock-absorbing materials secure the unit against vibrations, tilting, or rough handling. Sensitive components like tap changers, pressure relief devices, and oil level indicators receive additional shockproof packaging. For oil-filled units, the transformer is shipped with factory-filled dielectric oil (or dry-type equivalent), sealed under vacuum or nitrogen blanket to maintain insulation integrity and prevent oxidation. Oil drums for any supplementary fluid are packed separately in sturdy crates with absorbent materials.

Shipping methods prioritize safety and efficiency. For domestic North American deliveries, flatbed trucks or lowboy trailers with specialized securing straps and chains transport the transformer directly to the site, often with escort vehicles for oversized loads exceeding standard dimensions (typical weight ~3750-4500kg, dimensions approx. 2.2-2.5m length/width/height). International shipments utilize 20ft or 40ft open-top or flat-rack containers for RoRo vessels, with lashings and blocking to IMO standards for sea stability. Air-ride suspension trailers minimize road vibrations during inland transport. All shipments include comprehensive insurance coverage, real-time tracking via GPS, and detailed documentation (packing list, bill of lading, test reports, and customs declarations).

Upon arrival, the transformer undergoes visual inspection for transit damage, with any issues reported immediately for resolution under warranty. Proper packing and shipping practices extend the transformer's service life by preventing mechanical stress or contamination, ensuring reliable performance from day one in utility, commercial, or industrial installations.

Manufacturer Test

Progress test

The first set of progress tests (routine factory acceptance tests per IEEE C57.12.90 and ANSI standards) for the 1250kVA three-phase pad mounted transformer verifies core electrical integrity and performance before final assembly stages.

- Winding Resistance Measurement: DC resistance of all windings (high-voltage and low-voltage) is measured at ambient temperature using a bridge or voltage drop method. Values are corrected to 75°C reference and compared to design tolerances to confirm uniform connections, no open/short circuits, and proper conductor sizing.

- Turns Ratio Test (TTR): Voltage ratio is tested across all tap positions using a precision turns ratio meter. Results must match nameplate specifications within ±0.5% to ensure accurate voltage transformation and phase alignment.

- Polarity and Phase Relation Test: Polarity (additive/subtractive) and phase sequence are verified at rated voltage to confirm correct winding orientation and vector group (e.g., Dyn11).

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

The Factory Acceptance Test (FAT) for the 1250kVA three-phase pad-mounted transformer is a comprehensive series of routine tests performed on every unit prior to shipment, in full compliance with IEEE C57.12.90-2021 (Standard Test Code for Liquid-Immersed Distribution, Power, and Regulating Transformers), IEEE C57.12.00 (General Requirements), and IEEE C57.12.34 (specific requirements for pad-mounted compartmental-type distribution transformers). These tests verify electrical integrity, insulation quality, performance parameters, efficiency, and mechanical sealing to ensure reliable operation in underground distribution systems, while confirming adherence to DOE efficiency standards and UL-listing criteria.

Routine Test - Applied Voltage

Voltage source: usually 1 kV, 5 kV, 10 kV, or customized according to customer needs

Temperature and humidity meter: used to record environmental conditions

Check the connection terminals and wiring to ensure that they are not loose or contaminated.

Test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20-30°C).

Properly connect the test equipment to the bushings or terminals of the device under test and ensure that all connection points are properly grounded.

Selecting the test voltage:

Select the appropriate applied voltage based on the rated voltage of the equipment.

Measuring leakage current

Applied voltage

Current stability

Any possible voltage fluctuations

The current value exceeded the allowable range and the equipment needs to be inspected or maintained (pending repair)

There was a serious fault or instability and the equipment could not continue to operate (unqualified)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.