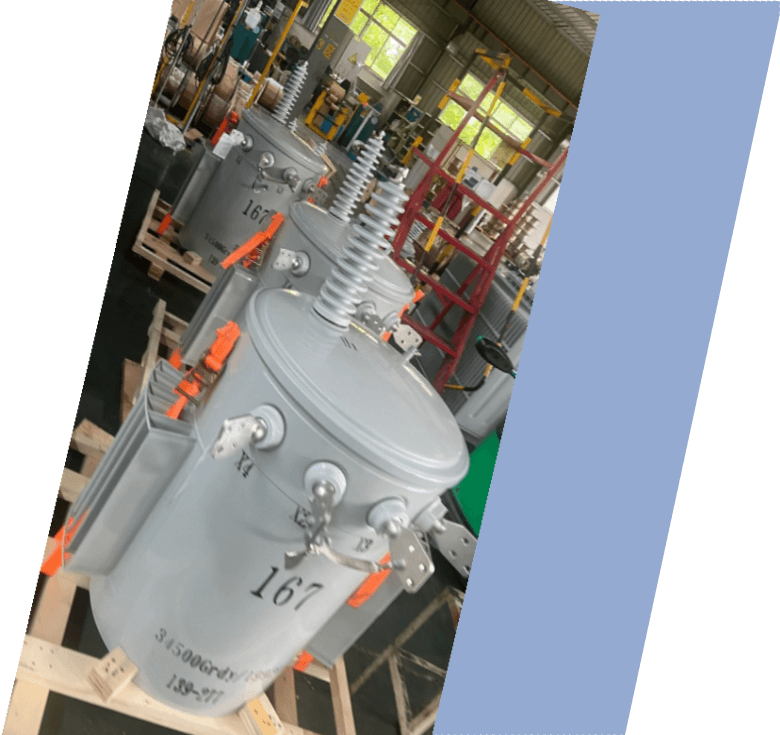

33kV Single Phase Pole Mounted Transformer

- Primary Voltage Ratings 10.5kV-33kV or others

- Secondary Voltage Ratings 230V、240V、220/440V 或 415V

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Conventional Type

- BIL 33kV

- Standards IEEE, ANSI, NEMA, ASTM

- Application retail centers, street lighting, municipal services

- Power Rating 5kVA - 333kVA

- Certificate CE, ISO

- Cooling Method ONAN, KNAN

- Oil Mineral Oil or FR3

- Opeartion Step Down

Technical Specifications

| Rated Power | 5kVA - 333kVA |

| Rating Primary Voltage | 12.4-34.5kV |

| Secondary Voltage | 480-240V 240-120V 277V Customized |

| Frequency | 50/60Hz |

| Vector Group | Ii0,Ii6 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 2% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Lifting Lug |

| Tap Changer |

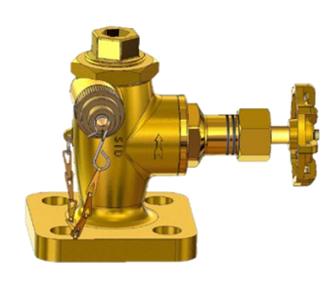

| Pressure Relief Valve |

| Tank Cover and clamp |

| L.V Bushing |

| HV Bushing |

| Ground Strap |

| Nameplate |

| Non-PCB decal |

| High Voltage Warning Signs |

| Suport lug |

| Oil fill valve |

Customization Optional

Packing and Shipping

Shipping logistics prioritize safety for this medium-voltage unit, employing specialized low-profile trailers with hydraulic stabilization for domestic road transport, secured via heavy-duty chains and full tarpaulin coverage against dust and precipitation. International shipments leverage flat-rack or open-top containers on container ships, with IMO-compliant lashing, corrosion inhibitors, and sea-worthy bracing for extended voyages. For priority deliveries, air options via cargo aircraft are feasible but less common due to size. Satellite-enabled tracking systems offer continuous monitoring, backed by comprehensive transit insurance. Full regulatory alignment with IEC, IEEE, and customs protocols accelerates clearance, minimizing hold times for worldwide deployment of the 33kV single phase pole mounted transformer.

Environmental responsibility shapes our packing, incorporating FSC-certified timber and reduced packaging waste while optimizing container loads to decrease carbon footprint. Crate-mounted impact and tilt recorders document handling conditions, facilitating inspections and claims resolution. Separate crating for accessories like arresters, gauges, or radiators includes itemized checklists for onsite verification. Trusted heavy-lift carriers, versed in electrical equipment logistics, secure necessary permits and adhere to strict safety standards across diverse routes.

Final delivery assistance encompasses route feasibility studies for remote pole sites, detailed unpacking protocols, oil replenishment guidelines, and connection torque specifications. Coordination with local installers ensures efficient pole mounting. This integrated approach protects the transformer's integrity throughout transit, accelerates commissioning, and upholds uninterrupted reliability in medium-voltage overhead power systems globally.

Manufacturer Test

Progress Test

In the early stages of producing the 33kV single phase pole mounted transformer, progress tests emphasize core material evaluation, checking grain-oriented silicon steel for precise lamination alignment, surface coating continuity, and low-loss characteristics via epstein frame analysis to target minimal no-load losses. Winding construction verifies conductor tension uniformity and inter-layer insulation strength through incremental hipot testing to identify potential defects promptly. Preliminary winding resistance measurements on HV and LV coils use Kelvin methods at controlled temperatures, confirming adherence to design tolerances within 0.4%. Turns ratio checks with digital instruments across tap positions ensure accuracy better than 0.2%. Core clamping force is validated to prevent deformation, and vibration testing simulates handling stresses. Oil quality verification includes dielectric breakdown above 40kV, low moisture, and acidity limits. Tank integrity inspections employ ultrasonic and magnetic particle methods on critical welds, while pole mounting brackets undergo structural load trials. All interim results are digitized for quality trend monitoring and corrective interventions.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Progressing in FAT for the 33kV single phase pole mounted transformer, lightning impulse withstand at 150-200kV BIL delivers full and chopped waves to prove insulation coordination without anomalies. Acoustic performance testing in isolated conditions ensures noise levels remain below specified thresholds. Temperature rise evaluation under simulated full-load conditions restricts top-oil and winding rises to 65°C. Functional checks on pressure relief devices, oil indicators, tap changers, and protective fuses confirm reliable activation. Sweep frequency response analysis detects any core/winding shifts. All test data compiles into traceable reports adhering to IEC 60076 and IEEE C57.12.90, incorporating calibration certificates, witnessed validations, and resolution of discrepancies prior to final acceptance and shipping authorization. Winding DC resistance is measured with high-precision equipment, temperature-corrected to reference values, maintaining results within 0.7% variance. Turns ratio and polarity validation across all taps uses automated TTR devices for errors below 0.25%. Dissipation factor and capacitance testing at 10-12kV restricts tan delta to under 0.4%, confirming dielectric integrity. No-load loss and exciting current at rated voltage align with guaranteed efficiency levels, limiting excitation to 1.5% maximum. Load loss and impedance are precisely quantified through short-circuit testing, achieving efficiency above 98%.

Routine Test - Impulse Tests

Voltage divider (used to measure impulse voltage waveform, resistor divider or capacitor divider)

Oscilloscope (used to record impulse waveform, common brands such as Tektronix, Keysight)

Calibrate and check the impulse voltage generator, measurement system, and control system to ensure that the instruments and equipment are in good condition and meet the test standards.

Connect the impulse voltage generator correctly to each winding terminal (high voltage terminal, ground terminal) of the device under test, and ensure that all test instruments are well grounded.

Apply Test Voltage:

Select the appropriate impulse voltage waveform and amplitude according to the rated voltage of the equipment

Front Time

Time to Half-Value

Peak Voltage

Distortion

Ambient temperature and humidity (especially when the test environment needs to be corrected)

If the waveform deviation is too large, adjust the impulse generator parameters and reapply the test.

In special cases, inter-winding impact, voltage-to-ground impact or coil corner impact are performed (according to the test plan).

Waveforms are stable and meet standard specifications.

Waveform variations between repeated tests are minimal (usually good waveform overlap with no noticeable abnormal excursions).

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.