Wires and Cables

Service Drop Cable(ANS/CEA S-76-474)

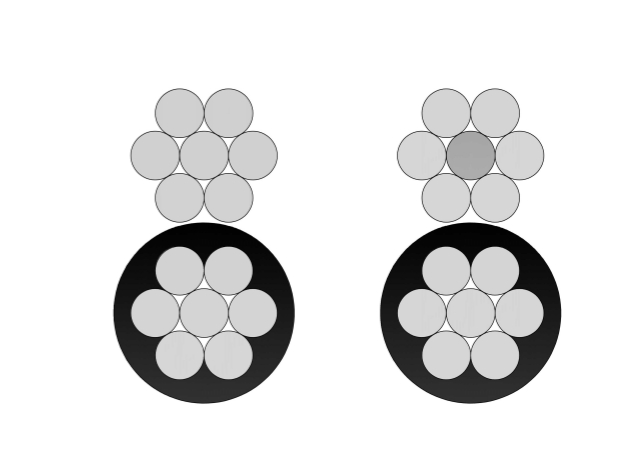

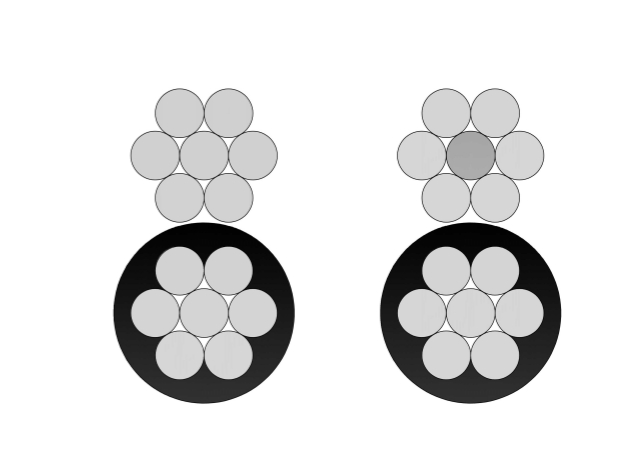

Duplex Overhead Service Drop Cable

Duplex Overhead Service Drop Cable is a reliable aerial cable for secondary power distribution from utility poles to service entrances. Available with aluminum or copper conductors (phase and neutral, stranded) insulated with XLPE or PE and assembled in duplex configuration, it offers excellent mechanical strength and weather resistance. Compliant with ASTM B-230, B-231, ICEA S-76-474, and ANSI/ICEA standards, this cable supports 600V applications with superior UV, moisture, and abrasion protection. The self-supporting design ensures reduced sag and easy installation over medium spans. The Duplex Overhead Service Drop Cable delivers low power losses, high current capacity, and long service life in harsh outdoor conditions. Lightweight and flexible, it is widely used for single-phase service drops in residential, commercial, and rural electrification projects requiring safe, cost-effective overhead connections worldwide.

NS75/NS90 Duplex Unjacketed Overhead Neutral Supported Cable

Our NS75/NS90 Duplex Unjacketed Overhead Neutral Supported Cable provides economical self-supporting overhead distribution. Consisting of an XLPE-insulated aluminum phase conductor (75 mm² or 95 mm²) supported by a bare ACSR or AAAC neutral messenger without an overall jacket, it meets AS/NZS 3560 and utility requirements. The design reduces material costs while delivering high tracking resistance and mechanical strength for spans up to 100m. Excellent UV and moisture performance ensures longevity in exposed conditions. The NS75/NS90 Duplex Unjacketed Overhead Neutral Supported Cable offers low installation effort, minimal sag, and reliable power delivery for 600/1000V networks. Widely favored in Australia and New Zealand for residential, commercial, and rural service drops requiring lightweight, neutral-supported overhead cables with proven compliance and durability in diverse climates.

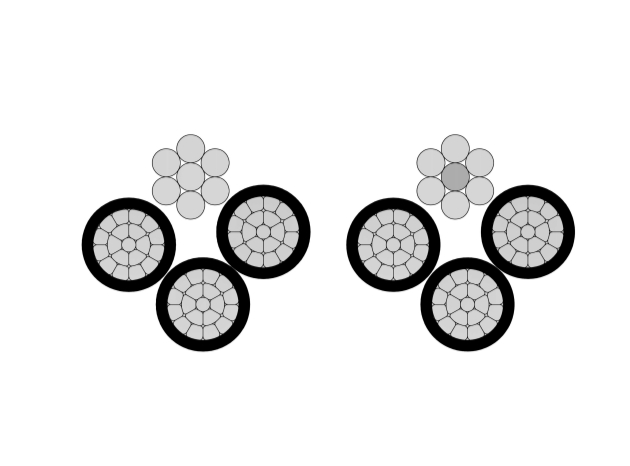

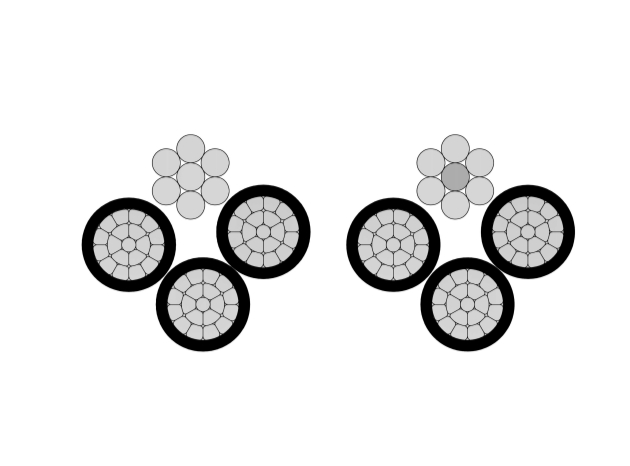

2 Palomino Aluminum Conductor Quadruplex Overhead Service Drop Cable

2 Palomino Aluminum Conductor Quadruplex Overhead Service Drop Cable is designed for delivering 3-phase power from pole-mounted transformers directly to the user's service entrance. Built with three 2 AWG aluminum phase conductors and one neutral messenger (7-strand) insulated with polyethylene or XLPE and formed into a quadruplex assembly, it meets ASTM and ICEA requirements for 600V service. The tough insulation offers outstanding protection against UV rays, moisture, tree contact, and abrasion. Self-supporting messenger design ensures easy pulling and reduced sag during installation. The 2 Palomino Quadruplex Service Drop Cable supports efficient power transfer with low voltage drop and high durability in extreme temperatures. Popular for its lightweight construction and reduced installation time, it is the choice for electricians and utilities. Widely deployed in housing developments, commercial services, and temporary power setups, this cable ensures safe, long-lasting overhead connections from distribution transformers to customer service entrances worldwide.

4 Hackney Aluminum Conductor Quadruplex Overhead Service Drop Cable

4 Hackney Quadruplex Service Drop Cable is a robust overhead cable for three-phase secondary power distribution with neutral. Featuring three 4 AWG aluminum phase conductors and one neutral messenger (7-strand) insulated with XLPE or PE and assembled in quadruplex configuration, it offers excellent mechanical strength and weather resistance. Compliant with ASTM B-230, B-231, ICEA S-76-474, and ANSI/ICEA standards, this cable supports 600V applications with superior UV, moisture, and abrasion protection. The self-supporting messenger reduces sag and simplifies installation over medium spans. The 4 Hackney Quadruplex Service Drop Cable ensures low power losses, high current capacity, and long service life in harsh outdoor conditions. Lightweight and flexible, it is widely used for three-phase service drops in residential subdivisions, commercial buildings, and rural areas requiring safe, cost-effective aerial connections from utility poles to service entrances.

6 Chola Aluminum Conductor Quadruplex Overhead Service Drop Cable

Introducing the 6 Chola Quadruplex Service Drop Cable, a versatile overhead solution for three-phase secondary distribution with neutral. Built with three 6 AWG aluminum phase conductors and one neutral messenger (7-strand) insulated with polyethylene or XLPE and formed into a quadruplex assembly, it meets ASTM and ICEA requirements for 600V service. The tough insulation offers outstanding protection against UV rays, moisture, tree contact, and abrasion. Self-supporting messenger design ensures easy pulling and reduced sag during installation. The 6 Chola Quadruplex Service Drop Cable supports efficient power transfer with low voltage drop and high durability in extreme temperatures. Popular for its lightweight construction and reduced installation time, it is the choice for electricians and utilities. Widely deployed in housing developments, commercial services, and temporary power setups, this cable ensures safe, long-lasting overhead connections from distribution transformers to customer service entrances worldwide.

1/0 Costena Aluminum Quadruplex Overhead Service Drop Cable

The 1/0 Costena Quadruplex Service Drop Cable is a robust overhead cable for three-phase secondary power distribution with neutral. Featuring three 1/0 AWG aluminum phase conductors and one neutral messenger (7-strand) insulated with XLPE or PE and assembled in quadruplex configuration, it offers excellent mechanical strength and weather resistance. Compliant with ASTM B-230, B-231, ICEA S-76-474, and ANSI/ICEA standards, this cable supports 600V applications with superior UV, moisture, and abrasion protection. The self-supporting messenger reduces sag and simplifies installation over medium spans. The 1/0 Costena Quadruplex Service Drop Cable ensures low power losses, high current capacity, and long service life in harsh outdoor conditions. Lightweight and flexible, it is widely used for three-phase service drops in residential subdivisions, commercial buildings, and rural areas requiring safe, cost-effective aerial connections from utility poles to service entrances.

1/0 Shetland Aluminum Conductor Quadruplex Overhead Service Drop Cable

1/0 Shetland Aluminum Conductor Quadruplex Overhead Service Drop Cable is engineered to deliver three-phase electrical power from pole-mounted transformers to service entrances in residential, agricultural, and light commercial settings. Designed for overhead installation, this cable is rated for 600 volts phase-to-phase and can operate at temperatures up to 90°C with cross-linked polyethylene (XLP) insulation, or 75°C with polyethylene (PE) insulation. The cable includes three phase conductors constructed from 1350-H19 series aluminum, either stranded or compressed, and a neutral messenger made of bare AAAC (All Aluminum Alloy Conductor). Optional constructions are available with AAC or ACSR messengers, allowing adaptability for varying mechanical or electrical needs. XLP insulation offers superior durability, weather resistance, and thermal stability, making this cable ideal for challenging outdoor environments.

2/0 Grullo Aluminum Conductor Quadruplex Overhead Service Drop Cable

2/0 Grullo Aluminum Conductor Quadruplex Overhead Service Drop Cable is a high-performance solution for delivering three-phase electrical power from pole-mounted transformers to residential or commercial service entrances. It is specifically engineered for 600-volt phase-to-phase operations and supports conductor temperatures up to 90°C with cross-linked polyethylene (XLP) insulation, or 75°C when using standard polyethylene (PE) insulation. This cable consists of three phase conductors made from 1350-H19 aluminum, either stranded or compressed, and a bare ACSR (Aluminum Conductor Steel Reinforced) neutral messenger. Alternate messenger materials include AAC or 6201 alloy for different mechanical load and corrosion resistance preferences. With rugged black XLP insulation, this quadruplex cable provides exceptional weather resistance, UV protection, and thermal endurance, making it ideal for overhead outdoor installations in a wide variety of environments.

3/0 Suffolk Aluminum Conductor Quadruplex Overhead Service Drop Cable

The 3/0 Suffolk Quadruplex Service Drop Cable is a robust overhead cable for three-phase secondary power distribution with neutral. Featuring three 3/0 AWG aluminum phase conductors and one neutral messenger (7-strand) insulated with XLPE or PE and assembled in quadruplex configuration, it offers excellent mechanical strength and weather resistance. Compliant with ASTM B-230, B-231, ICEA S-76-474, and ANSI/ICEA standards, this cable supports 600V applications with superior UV, moisture, and abrasion protection. The self-supporting messenger reduces sag and simplifies installation over medium spans. The 3/0 Suffolk Quadruplex Service Drop Cable ensures low power losses, high current capacity, and long service life in harsh outdoor conditions. Lightweight and flexible, it is widely used for three-phase service drops in residential subdivisions, commercial buildings, and rural areas requiring safe, cost-effective aerial connections from utility poles to service entrances.In-Depth Analysis

Comparative Analysis of Efficiency and Loss

Compared to the industry average, NPC Overhead Insulated Cable exhibit lower losses and higher efficiency across the entire load range.

Load Efficiency Comparison(%)

No-load Loss Comparison(W)

High Conductivity Design

High-purity oxygen-free copper or high-quality aluminum conductors are used with smooth surface and low resistance to ensure efficient power transmission and reduce energy loss.

Insulation Protection System

Use flame-retardant, wear-resistant and corrosion-resistant polymer insulation materials to meet the safe operation requirements in different environments.

Weather-Resistant & Durable Technology

The outer sheath is made of UV-resistant, heat-resistant, and oil-resistant materials, making it suitable for high and low temperatures, humidity, and long-term outdoor use.

Safe Flame Retardant System

The multi-layered flame-retardant structure effectively slows the spread of flames and releases low-smoke, halogen-free gases during combustion, reducing secondary hazards.

Easy Installation & Maintenance

The flexible core and flex-resistant outer sheath provide a small bend radius and high installation efficiency. Color coding and length markings reduce installation and maintenance costs.

Intelligent Monitoring

An optional remote monitoring system is available to monitor operating status, temperature, load and other parameters in real time, and supports fault warning and remote diagnosis.

Environmental Adaptability Analysis

NPC Service Drop Cable have been rigorously tested and can operate stably under various harsh environmental conditions.

Temperature Range

-40℃ ~ +55℃

Can work normally in extreme high and low temperature environments

Humidity Adaptation

0 ~ 100% RH

Including condensation environment, no frost requirement

Weather Resistance Grade

UV/IEC 60811-501

The outer sheath has excellent UV resistance and aging resistance

Chemical Corrosion Resistance

Oil / Acid / Alkali

Resistant to oil, acid, alkali and some chemical corrosion environments

Why Choose Us

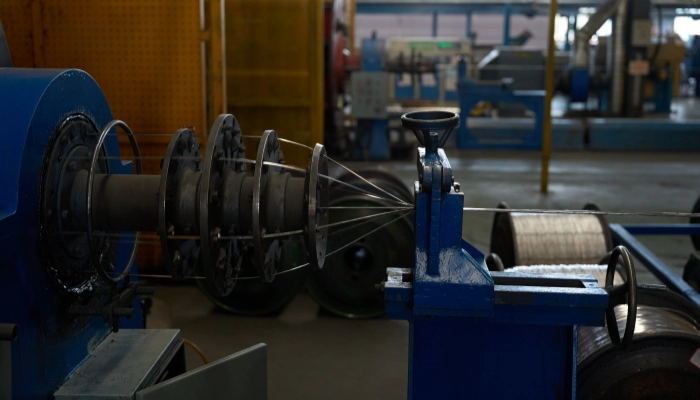

Overhead Insulated Cable Manufacturer

Overhead Insulated Cable Benefits

Overhead Insulated Cable Installation

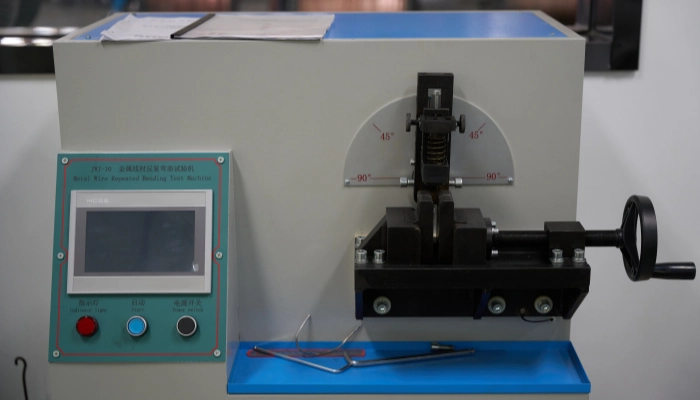

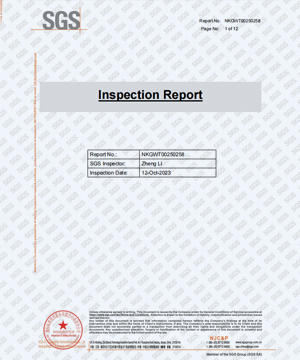

Testing and Certification

Product Show

Testing and Certification

Bare Cable Test Report

SGS Inspection Report

Certificate of Acceptance

ISO Quality Certificate

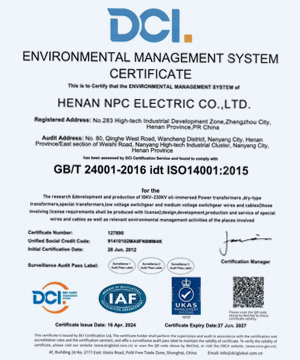

ISO Environmental Certificate

ISO Occupational Certificate

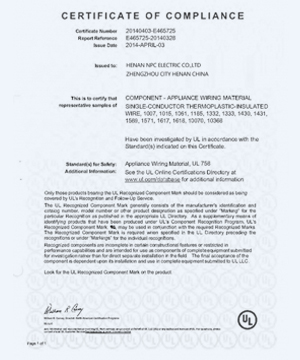

UL Laboratory Certificate

UL Product Certificate

Project Cases

Peru Solar PV Project

CompletedNPC Electric Delivers Medium-Voltage Cables for Peru Solar PV Project

Country:Peru

Model:HEPRZ1(AS) 1x630 mm² 19/33kV x 6km

Chile El Project

CompletedReliable 19/33kV MV cables ensuring safe, stable, and efficient power transmission for critical projects.

Country:Chile

Model:19/33kV MV Power Cables x 5km

Dominican Edenorte Project

CompletedProvide outdoor power solutions for urban main road reconstruction projects to adapt to complex environments.

Country:Dominican

Model:NPC AAAC Cable & Triplex Cable x 10km

Technical Advantages

FAQ From Customers

-

What is a service drop cable?

A service drop cable is an electrical cable that connects overhead power lines from the utility's distribution system to a residential or commercial building’s main electrical panel. Typically made of aluminum or copper, the cable serves as the final connection between the utility provider and the consumer, delivering electricity safely and reliably. It is often used for low-voltage power distribution to homes and businesses. -

What is a drop cable used for?

A drop cable is used to connect electrical service lines from a utility pole or transformer to the customer’s property. It provides the final connection for residential or commercial electrical service. Drop cables can be overhead service drop cables or underground service cables, depending on the installation method. These cables ensure safe and efficient delivery of electricity from the electricity distribution network to the meter and main breaker panel of a building. -

What type of wire is used for a service drop?

The type of wire used for a service drop depends on the voltage and installation method. Commonly, aluminum conductors are used in overhead service drop cables because of their lightweight and high conductivity. Duplex, triplex, and quadruplex cables are typically used, with triplex cables often being the most common for three-phase systems. These wires are designed to withstand environmental stress and provide safe power distribution for residential connections. -

What is an overhead service drop cable?

An overhead service drop cable is a type of drop cable that connects the utility pole to the house or building through overhead power lines. This cable is usually aluminum or copper and is designed to carry low voltage electricity from the distribution network to the customer's property. Overhead service drop cables are commonly used in residential areas and can be subjected to weather and environmental challenges, so they are built with durable, weather-resistant materials. -

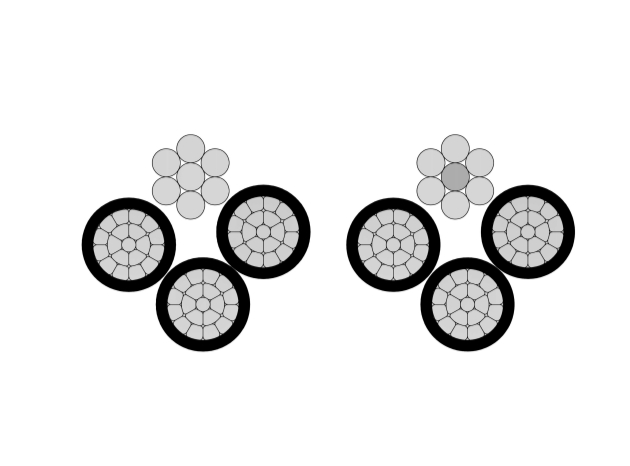

What is the difference between Duplex, Triplex, and Quadruplex service drop cables?

Duplex, triplex, and quadruplex service drop cables differ in their construction and use:

1. A duplex cable consists of two wires and is typically used for single-phase connections in residential service drops.

2. Triplex cable includes three conductors and is used for three-phase connections, commonly in larger residential or commercial installations.

3. Quadruplex cable includes four wires and is used for three-phase service with an additional neutral conductor. This makes it ideal for larger, more complex service drops and higher voltage applications. Each cable type provides reliable electrical service and safe connections between the utility and the building.