What Are the Safety Precautions for Wires and Cables?

Electrical safety is paramount. Properly handling wires and cables is crucial for protecting both professional electricians and everyday users. From homes and businesses to factories, improved wire and cable safety dramatically reduces the risk of shocks, fires, and injuries.

This guide outlines essential safety precautions for anyone involved in cable installation, focusing on practices that promote safety and health, prevent hazards, and comply with industry standards.

1. Understanding the Hazards of Wires and Cables

Before diving into preventive measures, it’s important to recognize the risks associated with improper handling of electric wires:

- Electrical Shock: Caused by direct contact with live wires.

- Fire Hazards: Overloaded or damaged wires can lead to overheating and fire.

- Trip and Fall Accidents: Loose or unorganized cables present a serious physical hazard.

- Equipment Damage: Incorrect cable installation can harm expensive electronic devices.

2. Pre-Installation Safety Measures

Before beginning any work involving wires and cables, installers should perform a thorough risk assessment. This includes:

a) Site Inspection

Examine the area where the electric wires will be installed. Identify:

- Wet or humid environments (which increase shock risk)

- Existing electrical panels and infrastructure

- Foot traffic zones that may pose trip and fall hazards

b) Proper Planning and Design

Design a layout that ensures wire and cable safety, including:

- Minimum bending radius and spacing between cables

- Clear separation of high- and low-voltage wiring

- Future-proof routing for maintenance and expansion

3. Using the Right Tools and Equipment

Quality tools are essential to ensure electrical safety and installation integrity:

- Use insulated tools to prevent electrical shock

- Wear rubber gloves and safety boots

- Always use a voltage tester before touching any electric wire

Using substandard tools can compromise both the quality of the cable installation and the installer’s safety and health.

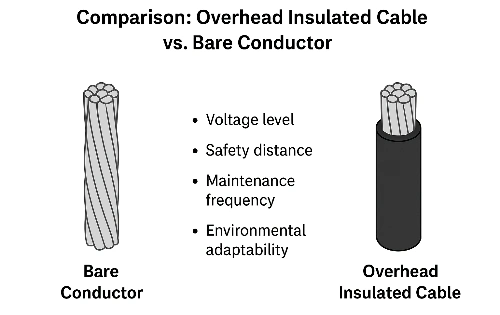

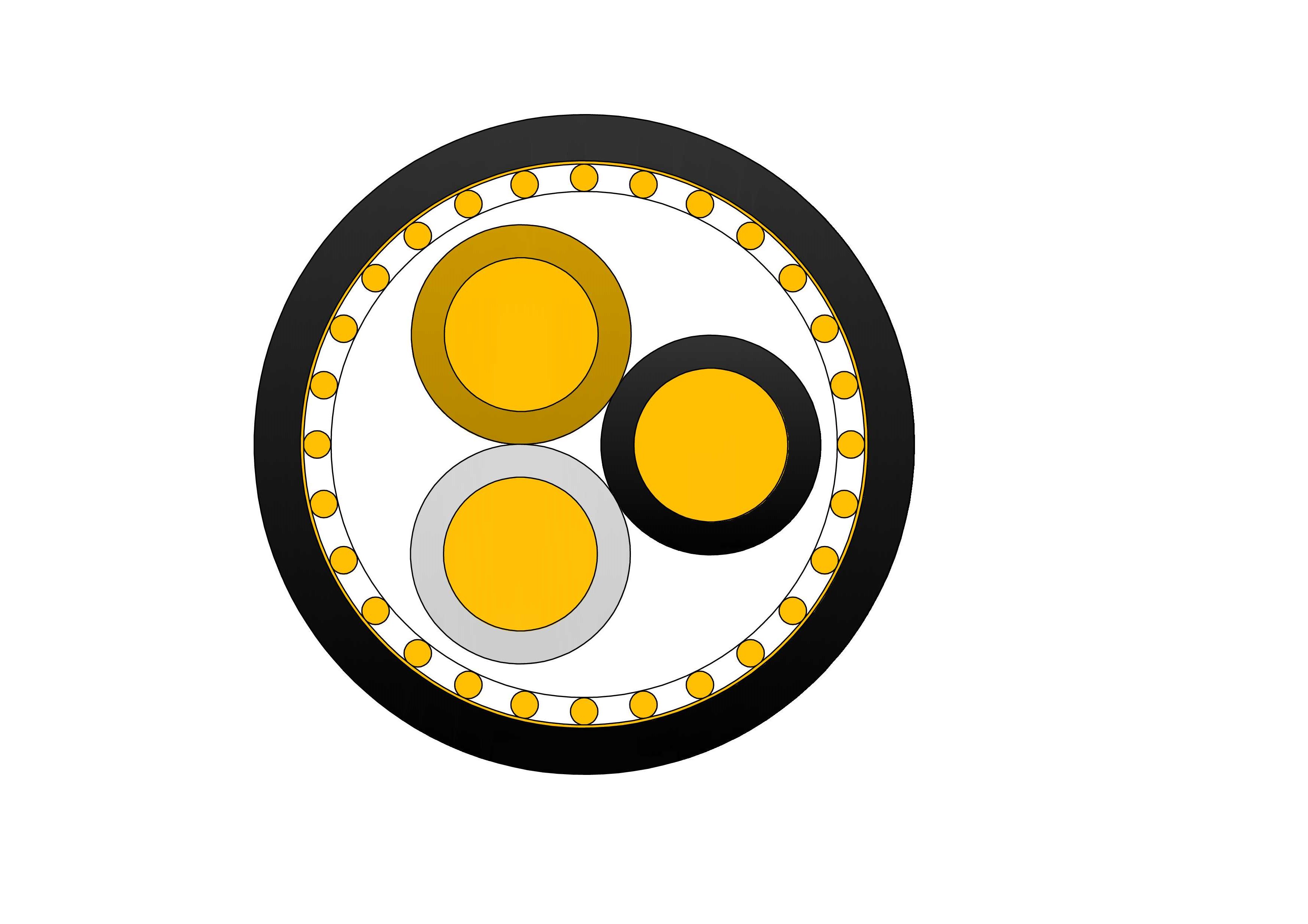

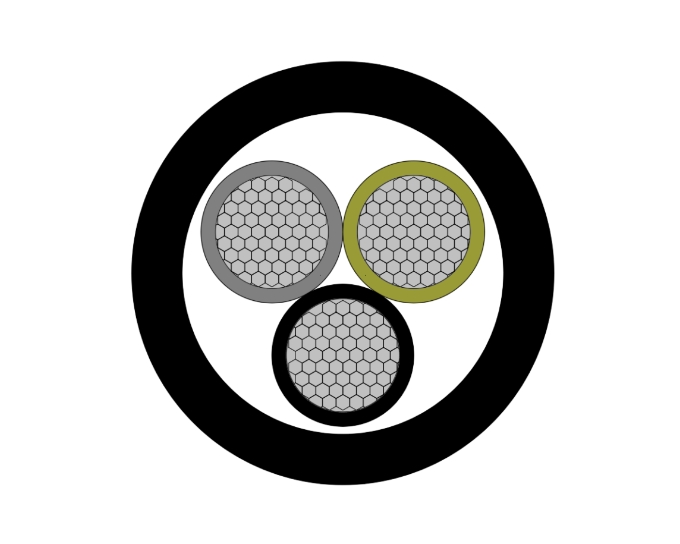

4. Choosing the Right Type of Wire and Cable

Selecting appropriate wires and cables for the job is crucial. Consider the following:

- Load Requirements: Ensure wires can handle the electrical current without overheating

- Insulation Rating: Use wires rated for the environment (e.g., waterproof cables for wet areas)

- Certification: Use only certified wires that meet national electrical codes

Proper selection ensures wire and cable safety and reduces long-term risks.

5. Safe Installation Practices

During cable installation, follow these guidelines to maintain electrical safety:

a) Turn Off Power Supply

Always shut off the main power before working on any circuit. Use lockout/tagout procedures where applicable.

b) Secure and Organize Cables

Use cable trays, ties, or conduits to:

- Keep electric wires off the ground

- Avoid loose cables that may cause trip and fall accidents

- Prevent cable damage from bending, crushing, or moisture

c) Avoid Overloading Circuits

Overloading leads to overheating and increases fire risk. Calculate total circuit load and ensure it stays within safe limits.

d) Label All Cables

Clearly label wires during installation to avoid confusion during maintenance and reduce the chance of cross-wiring or improper connections.

6. Post-Installation Inspection and Testing

Once the installation is complete, conduct a comprehensive inspection:

- Check connections for tightness and proper insulation

- Test circuits using multimeters and insulation resistance testers

- Verify compliance with local and national electrical codes

This final step is critical for confirming the overall electrical safety of the system.

7. Ongoing Safety and Maintenance

Wire and cable safety doesn’t end with installation. Regular maintenance ensures continued safety and health for all occupants.

- Visual Inspections: Periodically inspect exposed wires and cables for wear or damage

- Re-secure loose wires to eliminate trip and fall risks

- Upgrade aging systems that no longer meet modern load demands

If faults are found, repairs should be done immediately by qualified personnel.

8. Training and Awareness

All personnel involved in handling wires and cables should undergo proper safety training. Topics should include:

- Recognizing electrical hazards

- Emergency response procedures

- Safe work practices during cable installation

Creating a safety-first culture ensures that both new and experienced workers prioritize electrical safety.

9. Compliance with Safety Standards

Installers should adhere to local regulations such as:

- National Electrical Code (NEC) in the United States

- IEC standards internationally

- Occupational safety guidelines for safety and health

Failure to comply can result in legal liability and increased accident risk.

10. Common Mistakes to Avoid

To further reinforce wire and cable safety, avoid these frequent errors:

- Using indoor-rated electric wires in outdoor or wet areas

- Running power cables too close to heat sources

- Ignoring manufacturer's installation recommendations

- Failing to use protective gear

- Leaving unsecured wires that can cause trip and fall injuries

Being mindful of these pitfalls can significantly improve safety outcomes.

In conclusion, wire and cable safety is a shared responsibility that begins with the installer. By understanding the risks and following strict electrical safety protocols, you can ensure that your cable installation projects are both safe and durable.

Whether you're working with residential wiring or complex industrial systems, taking the proper safety precautions protects both life and property. Remember: a safe installation is a successful installation.