AAC, AAAC, ACSR Bare Conductor Cable Structure & Properties

Bare conductor cables are essential components of modern transmission lines, ensuring the long-distance transmission of electricity. AAC cables (all-aluminum conductor), AAAC cables (all-aluminum alloy conductor), and ACSR cables (aluminum stranded steel conductor) are widely used due to their unique structural characteristics and mechanical advantages. From a manufacturing perspective, each type of bare copper or bare aluminum conductor cable presents unique requirements in terms of material selection, mechanical design, and performance testing.

1. Basic Materials of Bare Conductor Cables

The core of any bare copper cable or bare aluminum conductor lies in the choice of raw materials:

-

Bare Copper Cable

- High electrical conductivity, exceeding 97% IACS.

- Excellent corrosion resistance, suitable for short-span distribution lines.

- Heavier and more costly, which limits its application in long-distance overhead transmission.

-

Bare Aluminum Wires

- Lower density compared to copper, reducing cable weight.

- Cost-effective and easier to handle during installation.

- Requires specific designs to balance strength and conductivity.

-

Aluminum Alloy

- Applied in AAAC Cable manufacturing.

- Provides higher tensile strength and better corrosion resistance than pure aluminum.

- Maintains good conductivity while improving mechanical durability.

-

Steel Wire

- Used as a reinforcing core in ACSR Cable.

- Significantly enhances tensile strength, allowing for longer spans in overhead transmission lines.

- Requires galvanization to prevent rust and degradation.

2. Structural Characteristics of AAC Cable

AAC (All-Aluminum Conductor) Cable is made exclusively of aluminum strands.

- Cross Sectional Area: Determines current-carrying capacity. Factories carefully calculate strand diameter to maximize conductivity.

- Electrical Conductivity: High, due to the use of pure aluminum.

- Mechanical Properties: Relatively weak tensile strength, limiting AAC systems to urban or short-span installations.

- Factory Considerations: Precision stranding machines ensure uniform tension, preventing micro-cracks in the aluminum wires.

Typical Application: Short-distance distribution lines, where high conductivity is prioritized over mechanical strength.

3. Structural Characteristics of AAAC Cable

AAAC (All Aluminum Alloy Conductor) improves on the limitations of AAC through the use of aluminum alloy strands.

- Material Advantage: Alloy composition increases tensile strength and corrosion resistance.

- Cross Sectional Area Optimization: Factories design strand geometry to balance conductivity with mechanical performance.

- Electrical Conductivity: Slightly lower than AAC due to alloying elements, but still efficient for most transmission lines.

- Production Focus: Continuous extrusion and heat treatment processes enhance wire uniformity and resistance to environmental stress.

Typical Application: Coastal regions or industrial areas where corrosion resistance and strength are essential.

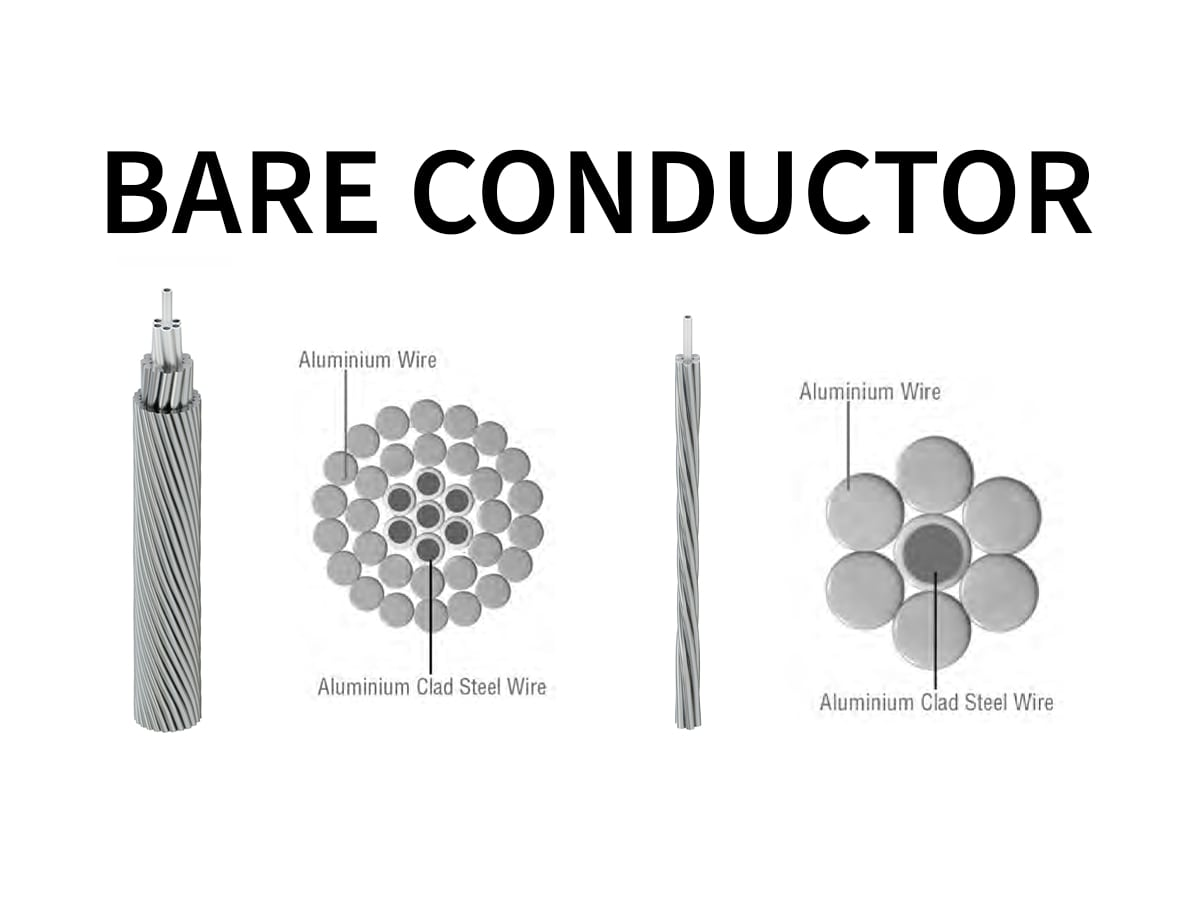

4. Structural Characteristics of ACSR Cable

ACSR (Aluminum Conductor Steel Reinforced) is one of the most widely used conductor types in high-voltage transmission networks.

- Composite Structure: Outer layers of aluminum conductors provide conductivity, while the inner steel wire core delivers mechanical strength.

- Electrical Conductivity: Optimized by maximizing aluminum content.

- Mechanical Strength: Steel core supports long spans and heavy ice or wind loads.

- Manufacturing Challenges: Factories must ensure perfect bonding between aluminum strands and steel wire to prevent slippage under load.

- Protective Measures: Steel wire is hot-dip galvanized to resist corrosion.

Typical Application: Long-distance overhead transmission lines and areas exposed to extreme weather.

5. Key Factory Manufacturing Considerations

When producing bare copper conductor cable or aluminum-based conductors, manufacturers must address several critical aspects:

-

Stranding Process

- Accurate stranding ensures balanced stress distribution.

- Advanced machines prevent wire surface damage, which could reduce conductor lifespan.

-

Cross Sectional Area Control

- Each conductor type requires strict tolerance limits.

- Even slight deviations in strand diameter affect electrical conductivity and mechanical reliability.

-

Surface Treatment

- Bare aluminum conductors are polished to minimize oxidation.

- Steel wires undergo galvanization to prevent rust.

-

Quality Testing

- Tensile tests confirm strength.

- Resistance tests measure electrical performance.

- Long-term aging tests simulate environmental conditions.

6. Practical Considerations in Real Transmission Systems

- AAC Systems: Suitable for urban power grids with shorter spans.

- AAAC Systems: Provide a balance of conductivity and corrosion resistance, widely applied in coastal regions.

- ACSR Systems: The dominant choice for extra-high-voltage transmission, capable of spanning rivers, mountains, and vast open areas.

Although the acronym “AAC” can also refer to augmentative and alternative communication AAC and speech-generating devices, within the context of electrical engineering, AAC Cable specifically denotes All Aluminum Conductor. This distinction is important for engineers and technical documentation.

From AAC Cable to AAAC Cable and ACSR Cable, each type of bare conductor cable has unique structural features that align with specific transmission needs. Factories play a crucial role in fine-tuning aluminum wires, aluminum conductors, steel wire cores, and cross sectional area control to achieve optimal electrical conductivity and mechanical reliability. In real-world applications, careful material selection and precise manufacturing processes ensure the safe and efficient operation of global power transmission lines.

2Y-high-voltage-power-cable-2.webp)

3GHSSYCY-mining-cable-2.webp)