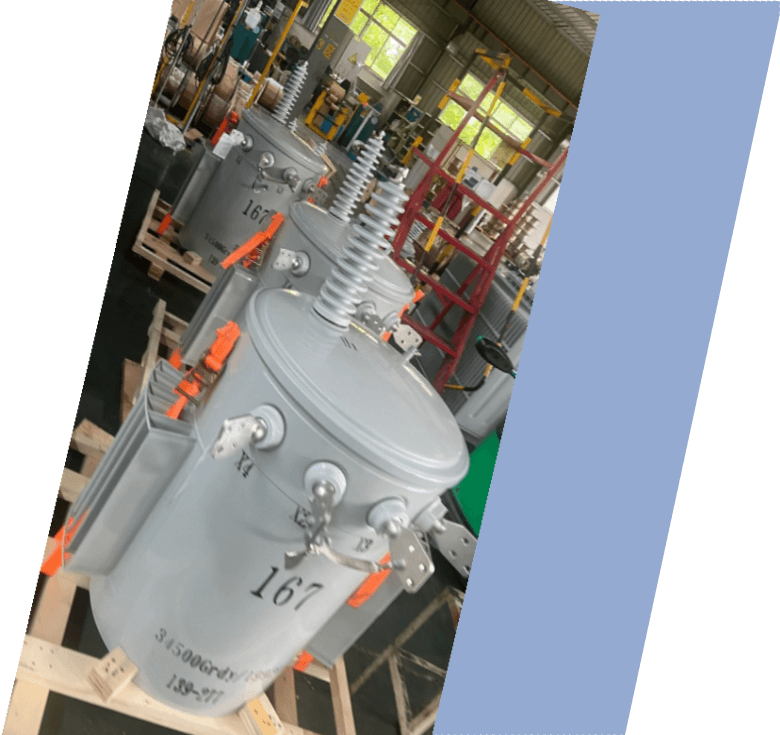

30kVA Single Phase Pole Mounted Transformer

- Primary Voltage Ratings 220V, 2.4kV,11kV, 33kV, 34.5kV

- Secondary Voltage Ratings 480-240/240-120 or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Conventional Type

- BIL 30-150kV

- Standards IEEE, ANSI, NEMA, ASTM

- Application farm irrigation power, small commercial users

- Power Rating 30kVA

- Certificate CE, ISO

- Cooling Method ONAN, KNAN

- Oil Mineral Oil or FR3

- Opeartion Step Down

Technical Specifications

| Rated Power | 30 kVA |

| Rating Primary Voltage | 12.4-34.5kV |

| Secondary Voltage | 480-240V 240-120V 277V Customized |

| Frequency | 50/60Hz |

| Vector Group | Ii0,Ii6 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 2% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 108 kg |

| Total Weight | 580 kg |

| Outline Dimensions(W×D×H) | 765×860×1305 (mm) |

| Lifting Lug |

| Tap Changer |

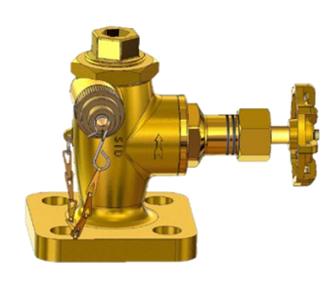

| Pressure Relief Valve |

| Tank Cover and clamp |

| L.V Bushing |

| HV Bushing |

| Ground Strap |

| Nameplate |

| Non-PCB decal |

| High Voltage Warning Signs |

| Suport lug |

| Oil fill valve |

Customization Optional

Packing and Shipping

Individual components receive specialized packaging: bushings wrapped in foam-lined boxes, radiators shielded with corrugated padding, fuses and switches in sealed pouches with desiccants. The main tank mounts on ISPM-15 compliant wooden pallets or steel frames with custom strapping, shock-absorbing cushions, and anti-tilt bracing rated for 3-4g forces. Weatherproof shrink-wrap, corrosion inhibitors, and humidity indicators are standard, along with tilt/shock recorders for transit monitoring.

For international shipping—common for utility exports—the transformer loads into standard 20ft/40ft containers or flat-racks with IMO-compliant tie-downs, salt-resistant covers, and fumigation-free treatments; overland uses flatbed trucks with tarps and secure chaining at lifting lugs. Documentation includes packing lists, invoices, origin certificates, test reports, dimensional diagrams, oil SDS, handling guides, and HS codes (8504.21 for single-phase transformers <650kVA).

We coordinate full logistics, offering FOB/CIF terms, customs support, insurance, and add-ons like third-party inspections, on-site delivery supervision, crane unloading at pole sites, oil top-up, and installation checks. This ensures safe, compliant arrival worldwide for rural and suburban deployments

Manufacturer Test

Progress Test

Progress testing for the 30kVA single phase pole mounted transformer begins with silicon steel core sheet inspection for lamination thickness uniformity coating quality magnetic orientation and edge smoothness via Epstein tester to ensure low no-load losses then core assembly progress verifies mitered joint precision clamping pressure balance and vibration resistance. Winding process progress monitors copper conductor resistivity insulation wrapping tension uniformity turn count accuracy and dielectric layer withstand after completion. Core-coil insertion progress confirms clearances spacer materials end-turn support and mechanical stability for overhead installation. Tank fabrication progress examines cylindrical welding seams hydrostatic pressure holds surface preparation galvanized coating thickness and weatherproofing validation pre-assembly progress checks bushing arrester fuse alignment accessory mounting and initial vacuum simulation to identify defects early advancing to full testing phases.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Load loss impedance voltage tests for the 30kVA single phase pole mounted transformer apply reduced voltage short secondary compute losses impedance (1.5-4%) efficiency at 75°C for regulation. Oil routine verifies dielectric (>45kV/2.5mm) water (<30ppm) acidity DGA baseline. Temperature rise simulation confirms limits (<65K). Functional checks include relief valve arrester fuse operation sound level (<50dB). Mechanical validation tank pressure leak-free bushing wiring. FAT reports calibration optional witnessing certify IEEE C57.12.20 compliance routine tests prior to release.

Routine Test - Applied Voltage

Voltage source: usually 1 kV, 5 kV, 10 kV, or customized according to customer needs

Temperature and humidity meter: used to record environmental conditions

Check the connection terminals and wiring to ensure that they are not loose or contaminated.

Test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20-30°C).

Properly connect the test equipment to the bushings or terminals of the device under test and ensure that all connection points are properly grounded.

Selecting the test voltage:

Select the appropriate applied voltage based on the rated voltage of the equipment.

Measuring leakage current

Applied voltage

Current stability

Any possible voltage fluctuations

The current value exceeded the allowable range and the equipment needs to be inspected or maintained (pending repair)

There was a serious fault or instability and the equipment could not continue to operate (unqualified)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.