150kVA Three Phase Pad Mounted Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 208GrdY/120;416GrdY/240 or Customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards IEEE/ANSI, DOE, CSA

- Application BESS, Bitcoin mining, Industry, Renewable energy

- Power Rating 150kVA

- Certificate UL/cUL, CSA, CESI, and other certificates.

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 150 kVA |

| Rating Primary Voltage | 4.16-34.5kV or customized |

| Secondary Voltage | 480GrdY/277 208GrdY/120 400GrdY/230 Customized(208Y/120 V to 4,160 V) |

| Frequency | 50/60Hz |

| Vector Group | Dyn1/Yyn0/Dyn11/Dyn5 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 3.5% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 350L |

| Total Weight | 2400 kg |

| Outline Dimensions(L×W×H)in. | 1250×1480×1750 (mm) |

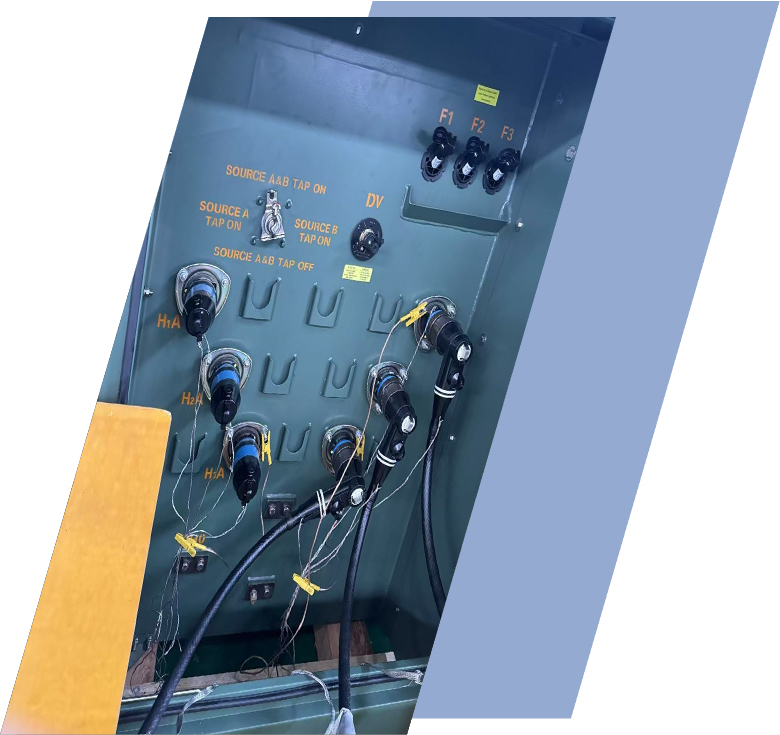

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | Terminal Box |

| Non-PCB decal | High Voltage Warning Signs |

Customization Optional

Packing and Shipping

Packing involves custom-engineered wooden crates or reinforced skids sized precisely to the unit's dimensions, reinforced with steel strapping, internal supports, and weight-distributing blocks to accommodate the typical dry weight of 1800–2400 lbs (higher when oil-filled). Export shipments comply with ISPM 15 heat-treated wood standards, incorporating vapor barrier films, desiccant materials, and humidity indicators for moisture control. Oil-filled deliveries include reinforced seals around fittings, leak-absorbent padding, and adherence to international hazardous substance rules for insulating fluids, complete with regulatory labeling and supporting paperwork.

Shipping strategies focus on secure, efficient delivery tailored to location and requirements. Domestic U.S. shipments use specialized heavy-haul carriers with lowboy trailers, secure tie-down systems, and route planning for oversize loads. International transport combines road haulage to ports, ocean freight in 20ft/40ft open-top or flat-rack containers (or break-bulk arrangements for multiple units), and final destination trucking. Full insurance coverage, traceable GPS monitoring, and comprehensive documentation (packing lists, test certificates, installation guides) ensure transparency and smooth logistics.

At the delivery site, immediate inspection for any transit-related issues, seal checks, and oil level confirmation is advised prior to unloading. Professional crane or forklift handling with spreader bars is essential to avoid tank deformation. Our logistics coordination includes freight quoting, export compliance (certificates of origin, commercial invoices), and customs facilitation to reduce delays, delivering the transformer prepared for prompt concrete pad placement, cable termination, and energization with maximum reliability.

Manufacturer Test

Progress test

The progress test for the 150kVA Three-Phase Pad Mounted Transformer is conducted to ensure that the transformer meets all technical and safety specifications throughout the manufacturing process. This includes testing at various stages of production, starting from the core assembly to the final testing of the complete unit. Key tests typically include:

Dielectric Strength Test: Ensuring the insulation system is capable of withstanding the required voltage levels.

Winding Resistance Test: Verifying the resistance of the windings to ensure proper conductivity and low loss.

Temperature Rise Test: Confirming that the transformer operates within the acceptable temperature limits during load conditions.

Oil Test (if applicable): Checking the oil quality for proper dielectric properties and ensuring the oil level is adequate.

These tests are performed to verify that the transformer will operate reliably and safely under normal operating conditions. Any issues identified during the progress test are addressed before the transformer is delivered to the customer.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Dielectric withstand testing applies separate-source potential and induced voltage at increased levels without flashover or abnormal discharge. Impedance voltage and load loss are measured under short-circuit to match guaranteed figures. Oil properties including breakdown voltage, moisture, and acidity are tested for filled units. Functional demonstrations confirm fuse blowing, pressure relief operation, indicator accuracy, valve performance, and bushing condition. Additional tests such as sound level assessment, simulated temperature rise, or special impulse may be conducted per contract. Results are compiled in formal reports, open to client/third-party witnessing, certifying full adherence to IEEE C57.12.34, C57.12.00, ANSI, and efficiency regulations before shipment authorization, assuring superior field reliability and performance. Winding resistance DC measurements are taken and temperature-adjusted. No-load loss, excitation current, and core performance data at rated voltage validate DOE 2016 efficiency and low-noise criteria.

Routine Test - Transformer Turns Ratio/TTR (All Tap Voltages)

Voltage source: usually AC 10 V to 30 V , used to test different voltages for each tap.

Temperature and humidity meter: used to record environmental conditions during the test to ensure test accuracy.

Current probe: used to measure the load current of the winding and ensure the accuracy of the test results.

Perform the test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20-30°C). Avoid high humidity or bad weather that may affect the test accuracy.

The voltage ratio between the windings

Deviation of the measured value from the rated ratio

0.5% < Turns ratio error ≤ 1% (caution)

Turns ratio error > 1% (further inspection or corrective action required)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.