Wires and Cables

Overhead Insulated Cable

2/0 Cyclops Aluminum Conductor Triplex Overhead Service Drop Cable

The 2/0 Cyclops Aluminum Conductor Triplex Overhead Service Drop Cable is engineered for reliable overhead electrical service from utility lines to residential and commercial buildings. This cable consists of two insulated phase conductors helically wrapped around a bare aluminum neutral messenger, ensuring mechanical strength and electrical stability. Manufactured using high-purity aluminum and weather-resistant insulation, the 2/0 Cyclops Aluminum Conductor Triplex Overhead Service Drop Cable delivers excellent conductivity, corrosion resistance, and long service life. Its lightweight construction simplifies installation while maintaining strong tensile performance for aerial applications. The cable is designed to meet utility standards and perform consistently under varying environmental conditions such as UV exposure, wind, and temperature fluctuations. Each production batch undergoes comprehensive testing to guarantee compliance, safety, and performance, making this cable a dependable solution for modern power distribution systems.

2/0 Dungeness Aluminum Conductor Triplex Overhead Service Drop Cable

The 2/0 Dungeness Aluminum Conductor Triplex Overhead Service Drop Cable is engineered to provide safe and efficient overhead power distribution. Featuring two insulated aluminum conductors and a bare aluminum neutral messenger, this cable delivers strong mechanical support and stable electrical transmission. The 2/0 Dungeness Aluminum Conductor Triplex Overhead Service Drop Cable is manufactured using premium aluminum materials and weather-resistant insulation to ensure long service life in outdoor environments. Its optimized design allows for easy installation while maintaining compliance with utility and industry standards. The cable performs reliably under mechanical stress, temperature changes, and prolonged UV exposure. Strict quality control and systematic testing procedures are applied throughout production to ensure consistent performance and dependable field operation.

2/0 Nassa Aluminum Conductor Triplex Overhead Service Drop Cable

The 2/0 Nassa Aluminum Conductor Triplex Overhead Service Drop Cable is designed for reliable overhead electrical service connections between utility distribution lines and end users. The cable structure includes two insulated aluminum phase conductors twisted around a bare aluminum neutral messenger, providing excellent electrical performance and mechanical strength. Manufactured with high-purity aluminum and durable, weather-resistant insulation, the 2/0 Nassa Aluminum Conductor Triplex Overhead Service Drop Cable offers low electrical resistance, corrosion resistance, and long-term stability in outdoor environments. Its lightweight design allows for efficient installation while maintaining the tensile strength required for aerial applications. The cable is engineered to perform under UV exposure, wind load, and temperature variations. Comprehensive quality control and systematic testing are applied throughout production to ensure compliance with industry standards and dependable service performance.

2/0 Runcina Aluminum Conductor Triplex Overhead Service Drop Cable

The 2/0 Runcina Aluminum Conductor Triplex Overhead Service Drop Cable is engineered to provide safe and efficient overhead electrical power distribution. It consists of two insulated aluminum phase conductors and a bare aluminum neutral messenger, delivering strong mechanical support and stable electrical transmission. Manufactured using premium aluminum materials and high-performance insulation compounds, the 2/0 Runcina Aluminum Conductor Triplex Overhead Service Drop Cable offers excellent resistance to corrosion, UV radiation, and environmental stress. Its optimized structure supports easy installation while meeting utility and industry standards. The cable performs reliably under mechanical load, temperature variation, and long-term outdoor exposure. Strict quality management systems and detailed testing procedures are implemented throughout production to ensure consistent performance and dependable service life.

2/0 Triton Aluminum Conductor Triplex Overhead Service Drop Cable

The 2/0 Triton Aluminum Conductor Triplex Overhead Service Drop Cable is engineered for reliable overhead electrical service from utility distribution lines to residential and commercial buildings. The cable consists of two insulated aluminum phase conductors twisted around a bare aluminum neutral messenger, providing balanced electrical performance and strong mechanical support. Manufactured from high-purity aluminum and weather-resistant insulation compounds, the 2/0 Triton Aluminum Conductor Triplex Overhead Service Drop Cable delivers low electrical resistance, excellent corrosion resistance, and long-term durability in outdoor environments. Its lightweight construction simplifies handling and installation while maintaining the tensile strength required for aerial service. The cable is designed to perform under UV exposure, wind loading, and temperature variation. Comprehensive quality control and systematic testing are applied throughout production to ensure compliance with utility standards and dependable field performance.

2/0 Trophon Aluminum Conductor Triplex Overhead Service Drop Cable

The 2/0 Trophon Aluminum Conductor Triplex Overhead Service Drop Cable delivers superior performance for overhead power distribution. Engineered with high-quality 1350-H19 aluminum conductors, black cross-linked polyethylene (XLPE) insulation, and a bare ACSR neutral messenger, this triplex cable ensures excellent conductivity, weather resistance, and mechanical strength. Rated for 600V phase-to-phase at up to 90°C conductor temperature (XLP), it offers approx. 230A ampacity, making it ideal for residential and light commercial service entrances. Compliant with ASTM B-230, B-231, B-232, and ICEA S-76-474 standards, the cable withstands harsh outdoor conditions while maintaining flexibility and reliability.

2 Clam Aluminum Conductor Triplex Overhead Service Drop Cable

2-2-2 Clam Aluminum Conductor Triplex Overhead Service Drop Cable provides high-performance overhead power transmission for utility-to-consumer connections. Constructed with compressed or concentric 1350-H19 aluminum phase conductors (#2 AWG), durable black XLPE insulation for enhanced thermal and environmental protection, and a bare neutral messenger (#2 AWG ACSR or AAC), it delivers efficient conductivity, corrosion resistance, and structural support. Suitable for 600V phase-to-phase applications with conductor temperatures up to 90°C, offering ≈150A ampacity. Meets or exceeds ASTM B-230/B-231/B-232/B-399 and ICEA S-76-474 requirements. Its lightweight design and flexibility make installation efficient, while rugged construction ensures long service life in demanding outdoor exposure to weather, abrasion, and mechanical stress.

2 Conch Aluminum Conductor Triplex Overhead Service Drop Cable

The 2-2-2 Conch Aluminum Conductor Triplex Overhead Service Drop Cable is a trusted solution for overhead power distribution from utility poles to residential or commercial weatherheads. Featuring concentric-lay-stranded 1350-H19 aluminum phase conductors (#2 AWG, 7-strand), durable black cross-linked polyethylene (XLPE) insulation, and a bare ACSR neutral messenger (#2 AWG, 6/1), it provides excellent electrical conductivity, superior weather/UV resistance, and mechanical support. Rated for 600 volts phase-to-phase with conductor temperatures up to 90°C (XLPE), it delivers an allowable ampacity of approximately 150 amps. Compliant with ASTM B-230, B-231, B-232, B-399, and ICEA S-76-474 standards, this lightweight, flexible cable ensures easy installation and long-term reliability in harsh outdoor environments, including wind, ice loading, and temperature fluctuations.

2 Shrimp Aluminum Conductor Triplex Overhead Service Drop Cable

2-2-2 Shrimp Aluminum Conductor Triplex Overhead Service Drop Cable delivers superior overhead power transmission for utility-to-consumer connections. Built with concentric or compressed 1350-H19 aluminum phase conductors (#2 AWG), black XLPE insulation offering enhanced thermal, abrasion, and environmental protection, plus a bare neutral messenger (#2 AWG ACSR/AAAC 6201), it ensures efficient conductivity, corrosion resistance, and structural strength. Rated 600V phase-to-phase up to 90°C (XLPE), with ≈150A ampacity, it complies with ASTM B-230/B-231/B-232/B-399 and ICEA S-76-474. Its balanced, lightweight construction simplifies installation while providing robust long-term performance against harsh outdoor factors like moisture, UV exposure, and mechanical stress.In-Depth Analysis

Comparative Analysis of Efficiency and Loss

Compared to the industry average, NPC Overhead Insulated Cable exhibit lower losses and higher efficiency across the entire load range.

Load Efficiency Comparison(%)

No-load Loss Comparison(W)

High Conductivity Design

High-purity oxygen-free copper or high-quality aluminum conductors are used with smooth surface and low resistance to ensure efficient power transmission and reduce energy loss.

Insulation Protection System

Use flame-retardant, wear-resistant and corrosion-resistant polymer insulation materials to meet the safe operation requirements in different environments.

Weather-Resistant & Durable Technology

The outer sheath is made of UV-resistant, heat-resistant, and oil-resistant materials, making it suitable for high and low temperatures, humidity, and long-term outdoor use.

Safe Flame Retardant System

The multi-layered flame-retardant structure effectively slows the spread of flames and releases low-smoke, halogen-free gases during combustion, reducing secondary hazards.

Easy Installation & Maintenance

The flexible core and flex-resistant outer sheath provide a small bend radius and high installation efficiency. Color coding and length markings reduce installation and maintenance costs.

Intelligent Monitoring

An optional remote monitoring system is available to monitor operating status, temperature, load and other parameters in real time, and supports fault warning and remote diagnosis.

Environmental Adaptability Analysis

NPC Overhead Insulated Cable have been rigorously tested and can operate stably under various harsh environmental conditions.

Temperature Range

-40℃ ~ +55℃

Can work normally in extreme high and low temperature environments

Humidity Adaptation

0 ~ 100% RH

Including condensation environment, no frost requirement

Weather Resistance Grade

UV/IEC 60811-501

The outer sheath has excellent UV resistance and aging resistance

Chemical Corrosion Resistance

Oil / Acid / Alkali

Resistant to oil, acid, alkali and some chemical corrosion environments

Why Choose Us

Overhead Insulated Cable Manufacturer

Overhead Insulated Cable Benefits

Overhead Insulated Cable Installation

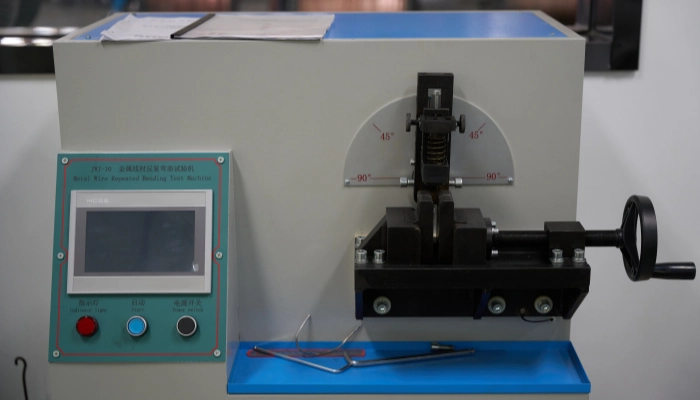

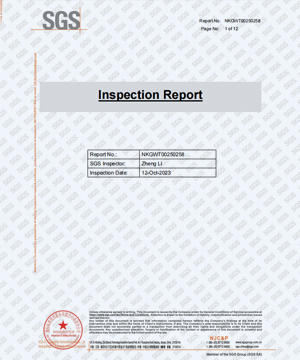

Testing and Certification

Product Show

Testing and Certification

Bare Cable Test Report

SGS Inspection Report

Certificate of Acceptance

ISO Quality Certificate

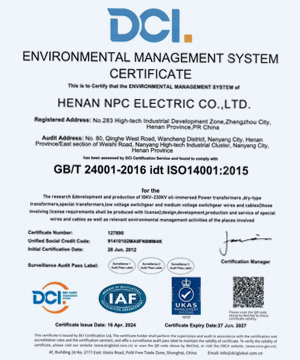

ISO Environmental Certificate

ISO Occupational Certificate

UL Laboratory Certificate

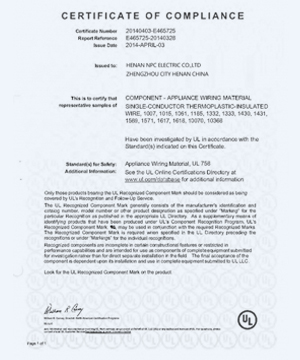

UL Product Certificate

Project Cases

Peru Solar PV Project

CompletedNPC Electric Delivers Medium-Voltage Cables for Peru Solar PV Project

Country:Peru

Model:HEPRZ1(AS) 1x630 mm² 19/33kV x 6km

Chile El Project

CompletedReliable 19/33kV MV cables ensuring safe, stable, and efficient power transmission for critical projects.

Country:Chile

Model:19/33kV MV Power Cables x 5km

Dominican Edenorte Project

CompletedProvide outdoor power solutions for urban main road reconstruction projects to adapt to complex environments.

Country:Dominican

Model:NPC AAAC Cable & Triplex Cable x 10km

Technical Advantages

FAQ From Customers

-

What is the structure of an overhead insulated cable?

Overhead insulated cables typically consist of a conductor, insulation layer, and an optional outer sheath. The conductor is usually made from aluminum or copper, providing excellent electrical conductivity. The insulation layer, made from materials like cross-linked polyethylene (XLPE) or PVC, protects the conductor and prevents accidental contact with live wires. An optional outer sheath is added for additional mechanical protection and durability, particularly in harsh environmental conditions. -

What materials are used for the insulation of overhead insulated cables?

The insulation of overhead insulated cables is typically made from cross-linked polyethylene (XLPE), which offers superior thermal stability, electrical insulation properties, and resistance to environmental factors. Alternatively, PVC (polyvinyl chloride) can be used for lower voltage applications. These materials help prevent electrical hazards by ensuring that the conductor remains safely insulated, especially in outdoor and exposed environments such as overhead power lines. -

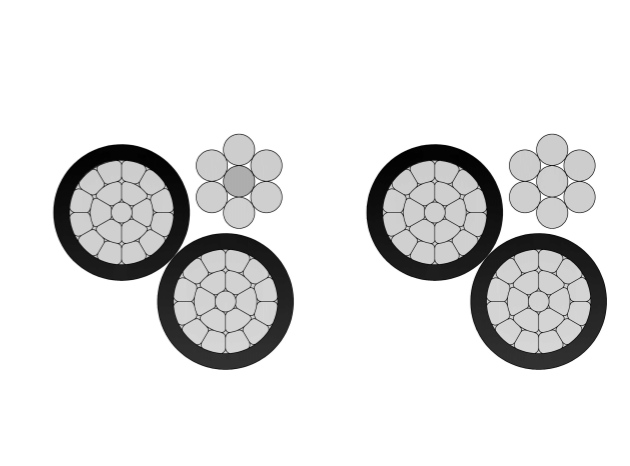

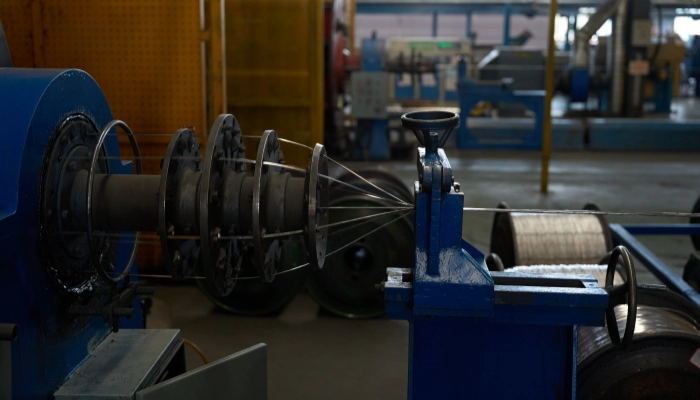

How are overhead insulated cables manufactured?

The manufacturing process of overhead insulated cables begins with the conductor preparation, which involves drawing aluminum or copper to the desired size. The insulation layer is then applied using extrusion technology, ensuring uniform thickness and durability. For high voltage cables, the insulation is cross-linked to improve performance at elevated temperatures and resist electrical stress. The outer sheath is then added, providing protection against physical damage and environmental conditions. The entire process follows stringent quality control and testing procedures to ensure reliability and compliance with international standards such as IEC and ANSI. -

What makes overhead insulated cables suitable for high voltage applications?

Overhead insulated cables are suitable for high voltage applications due to their specialized insulation materials such as cross-linked polyethylene (XLPE), which provides excellent electrical strength and thermal stability. These materials prevent the risk of electrical leakage and offer protection against high voltage surges. The cables' mechanical strength and weather-resistant outer sheath ensure long-term durability and performance, even in extreme environments. Additionally, the insulated layers prevent external damage from wind, moisture, and physical contact, making them ideal for high-voltage power transmission. -

How do overhead insulated cables protect against environmental factors?

Overhead insulated cables are designed to withstand environmental challenges such as moisture, extreme temperatures, UV radiation, and mechanical stress. The insulation material, typically XLPE or PVC, offers excellent resistance to corrosion and weathering, ensuring long-lasting performance even in harsh climates. The outer sheath further protects the cable from abrasion, chemical exposure, and physical damage, ensuring that the cables maintain their integrity and electrical safety during their service life.